Method for preparing compressible cane sugar from cane sugar syrup

A sucrose and syrup technology, applied in the production of sucrose, sugar production and application, can solve the problems of inability to recycle, easily infected with bacteria, long operation time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

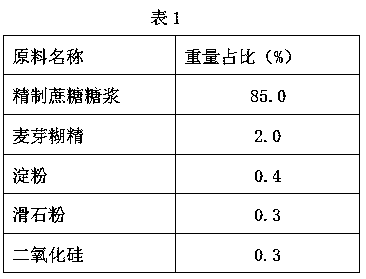

[0036] A kind of method that adopts sucrose syrup to prepare compressible sucrose, used raw material component and weight percentage composition are as shown in table 1 below:

[0037]

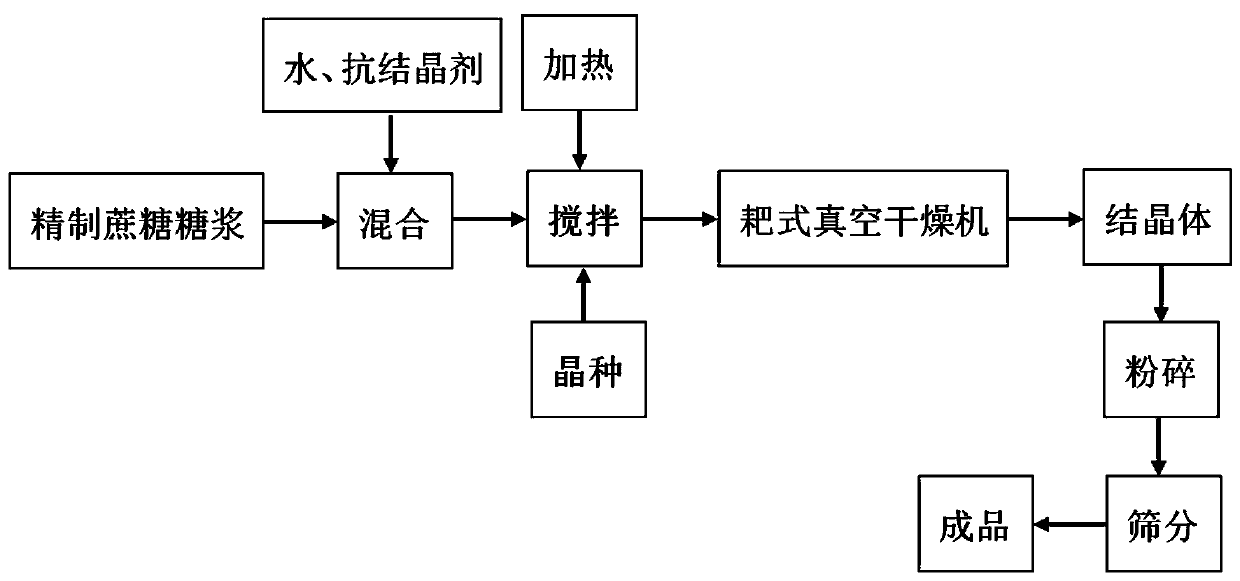

[0038] The specific preparation method of the method for preparing compressible sucrose by using sucrose syrup comprises the following steps:

[0039] (1) According to the weight percentage ratio of each raw material in Table 1, use refined sucrose syrup as raw material, add pre-dissolved maltodextrin, starch, talcum powder, and silicon dioxide, and make up the remaining part to 100% with pure water , stirring, heating, and dissolving; adding compressible sugar seed crystals to the obtained liquid and mixing uniformly; the compressible sucrose seed crystals are compressible sucrose with unqualified particle size remaining after sieving; compressible The addition of sugar crystal seed is 1% of refined sucrose syrup weight;

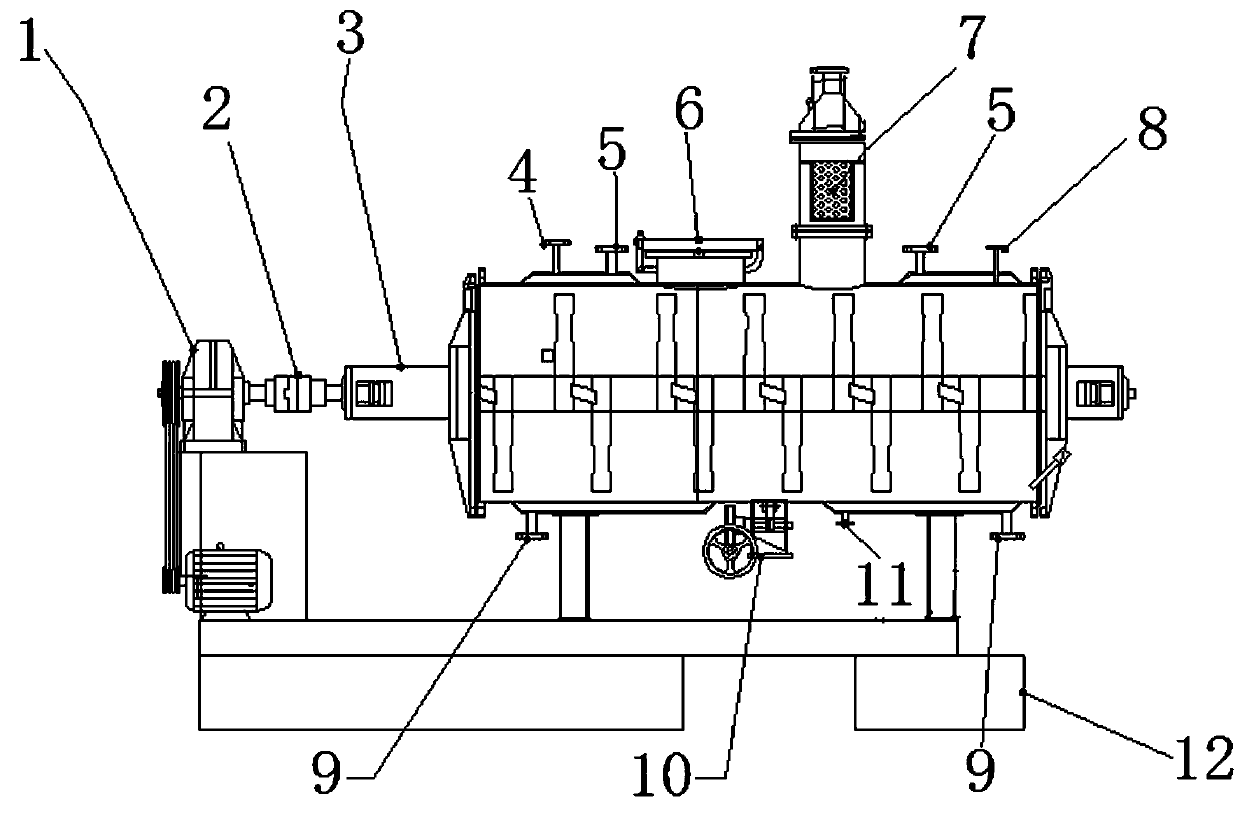

[0040] (2) Pump the mixed liquid obtained in step (1) into a rake ...

Embodiment 2

[0042] A kind of method that adopts sucrose syrup to prepare compressible sucrose, used raw material component and weight percentage composition are as shown in table 2 below:

[0043]

[0044] The specific preparation method of the method for preparing compressible sucrose by using sucrose syrup comprises the following steps:

[0045] (1) According to the weight percentage ratio of each raw material in Table 2, use refined sucrose syrup as raw material, add pre-dissolved maltodextrin, starch, talcum powder, and silicon dioxide, and make up the remaining part to 100% with pure water , stirring, heating, and dissolving; adding compressible sugar seed crystals to the obtained liquid and mixing uniformly; the compressible sucrose seed crystals are compressible sucrose with unqualified particle size remaining after sieving; compressible The add-on of sugar crystal seed is 3% of refined sucrose syrup weight;

[0046] (2) Pump the mixed liquid obtained in step (1) into a rake vacu...

Embodiment 3

[0048] A kind of method that adopts sucrose syrup to prepare compressible sucrose, used raw material component and weight percentage composition are as shown in following table 3:

[0049]

[0050] The specific preparation method of the method for preparing compressible sucrose by using sucrose syrup comprises the following steps:

[0051] (1) According to the weight percentage of each raw material in Table 3, use refined sucrose syrup as raw material, add pre-dissolved maltodextrin, starch, talcum powder, and silicon dioxide, and use pure water to make up 100% of the rest , stirring, heating, and dissolving; adding compressible sugar seed crystals to the obtained liquid and mixing uniformly; the compressible sucrose seed crystals are compressible sucrose with unqualified particle size remaining after sieving; compressible The addition of sugar crystal seed is 5% of refined sucrose syrup weight;

[0052] (2) Pump the mixed liquid obtained in step (1) into a rake vacuum dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com