Patents

Literature

46results about How to "High evaporation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

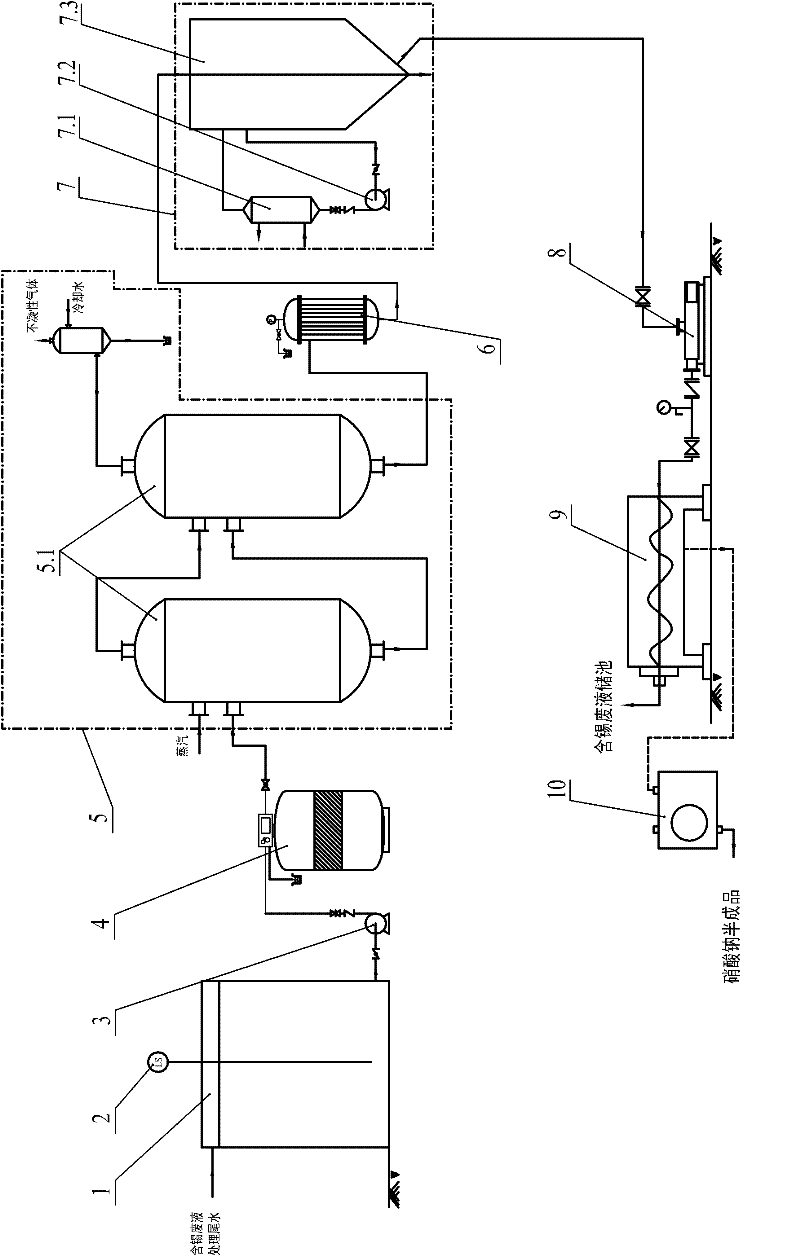

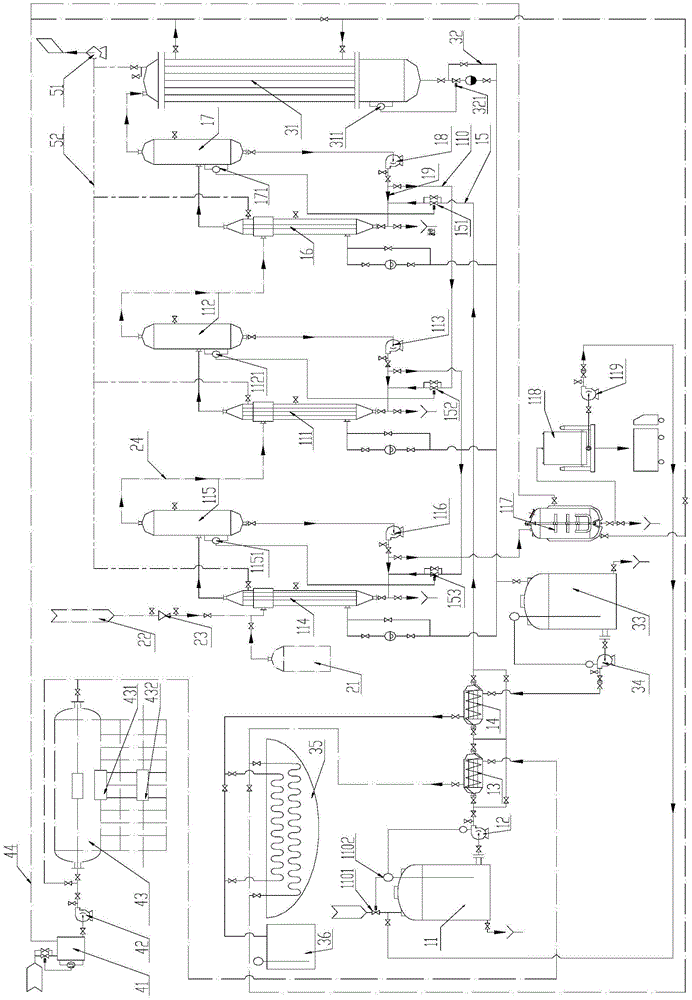

System and technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water

ActiveCN102351220AEasy to operate and manageGuaranteed operating efficiencyAlkali metal nitratesMultistage water/sewage treatmentFiltrationSlag

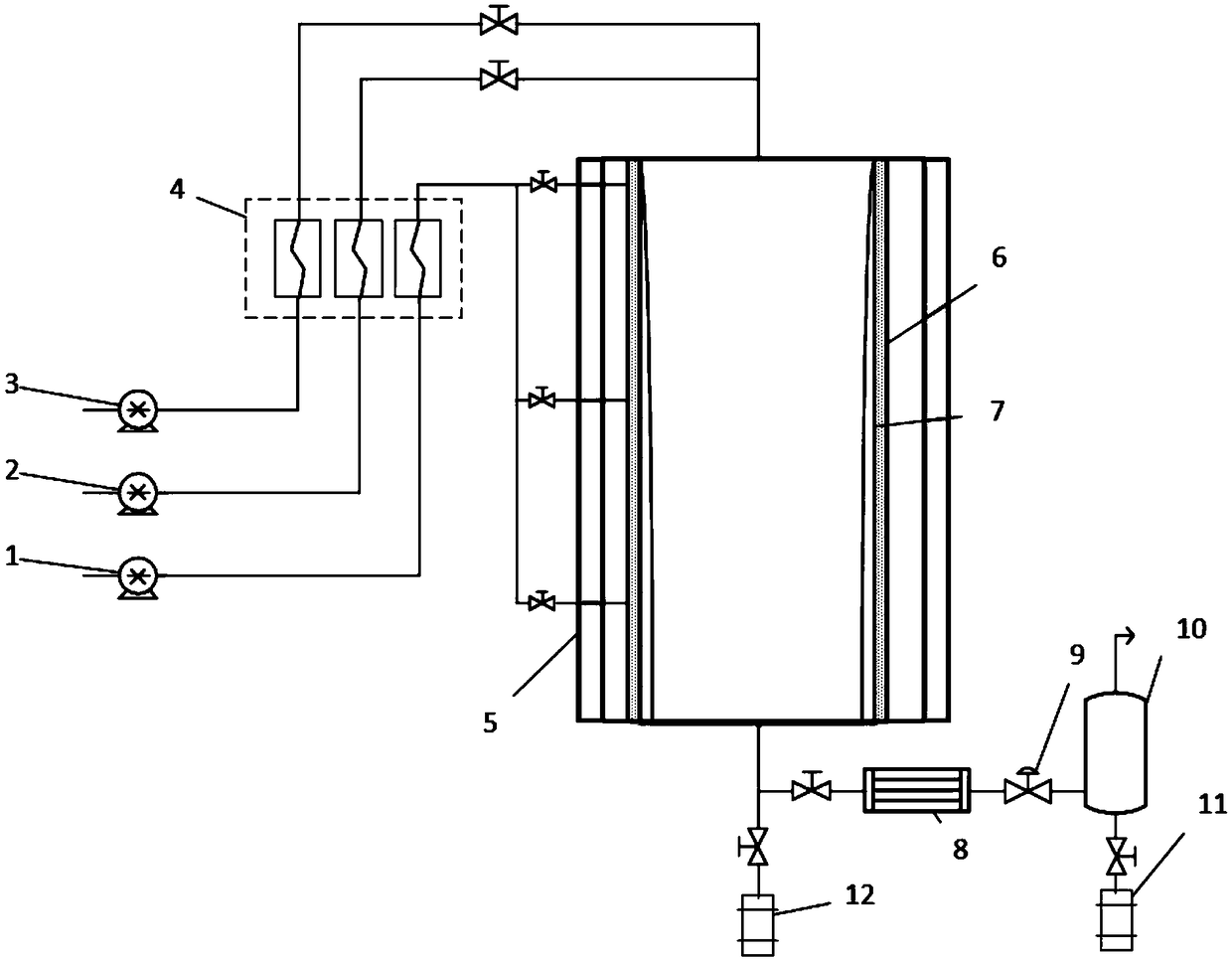

The invention relates to a system and a technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises a waste water storage pool, a purification refining device, a multi-effect evaporator, a filter, a crystallization device, a centrifugal machine and a drying machine. The technology for recovering sodium nitrate from tin-containing waste liquid treatment tail water comprises the following steps of collecting tin-containing waste liquid treatment tail water, storing the collected tin-containing waste liquid treatment tail water in the waste water storage pool, feeding the tin-containing waste liquid treatment tail water in the waste water storage pool into the purification refining device to carry out purification refining, feeding the tin-containing waste liquid treatment tail water subjected to purification refining into the multi-effect evaporator, feeding steam into the multi-effect evaporator to carry out circulation evaporation, feeding the steam obtained by the previous step into the filter to carry out heat filtration, feeding the filtrate into the crystallization device to carry out crystallization to obtain crystals, carrying out centrifugation of the obtained crystals by the centrifugal machine to obtain solid slag and a mother solution, transferring the solid slag to the drying machine to carry out drying to obtain a sodium nitrate finished product, and feeding the mother solution back to the waste water storage pool for recycle. The system for recovering sodium nitrate from tin-containing waste liquid treatment tail water has the advantages of relatively low recovery cost, simple and convenient operation management, long-term and stable operation and no discharge of pollutants.

Owner:无锡金品环境技术有限公司

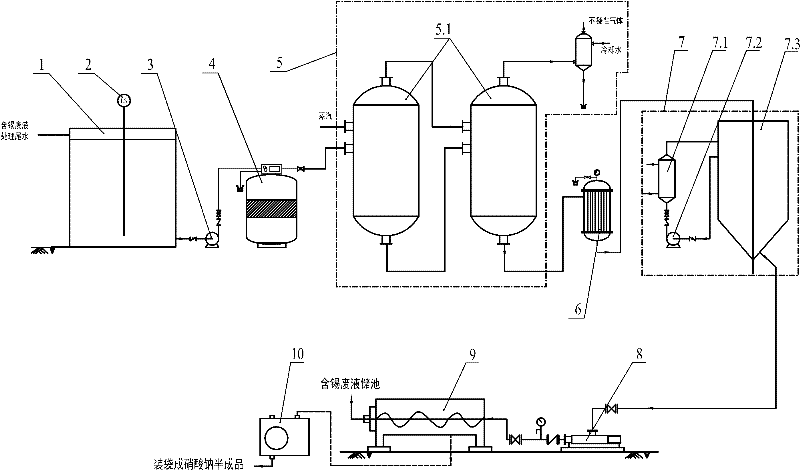

Low temperature high-efficient energy-saving evaporation process

InactiveCN101444673AIncrease vacuumHigh evaporation strengthGeneral water supply conservationEvaporationEngineeringCooling capacity

The invention relates to a low temperature high-efficient energy-saving evaporation process, comprising the following process steps successively: heat pump compression, condensing evaporation, water jet condensation and evaporative cooling. The evaporation process utilizes low heat energy which is compressed and improved by a heat pump as a heat source for decompression vacuum evaporation; the heat energy is improved by 5 times. Simultaneously, the cooling capacity of the heat pump is used for lowering the temperature of cooling water of a water jet condenser, improving the vacuum degree of the vacuum evaporation, increasing the evaporation strength, improving the evaporation efficiency and reducing the used amount of the cooling water. Meanwhile, matching equipment investment of a heating system is reduced, and the investment is saved by one fourth. Therefore, the low temperature high-efficient energy-saving evaporation process can achieve the advanced techniques of energy saving and high efficiency, low cost, little investment, pollution-free, and the like. The process is applied to salt industry, sugar industry, seawater desalination, chemical and food industries, etc.

Owner:林晓山

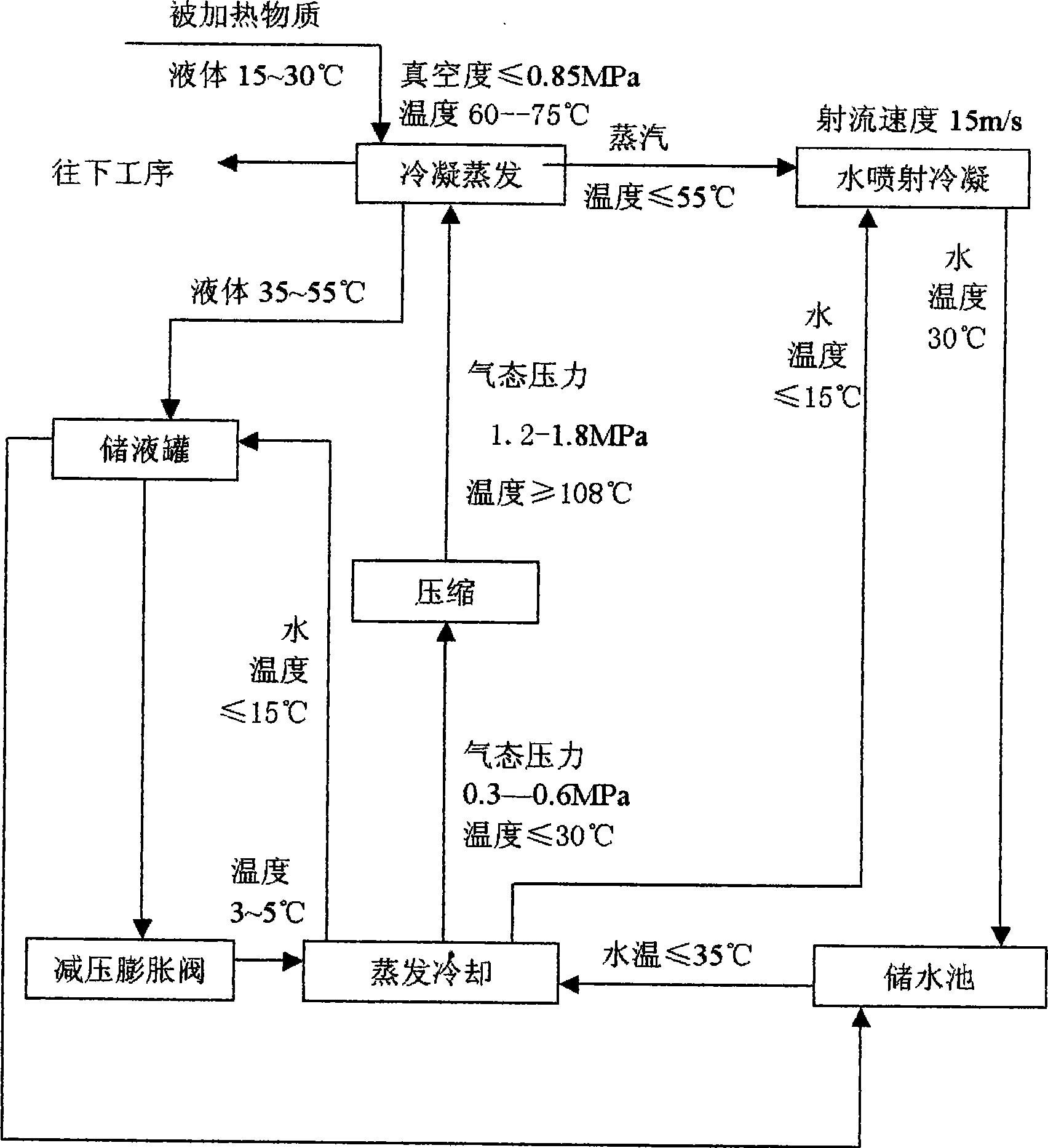

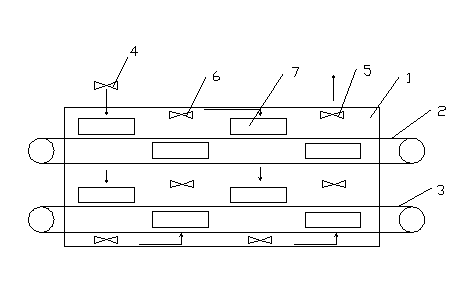

Belt dryer

The invention relates to a belt dryer which comprises a drying case. A conveying belt for conveying materials is penetratingly arranged in the drying case, a feeding port and a discharging port are arranged at two ends of the conveying belt respectively, a hopper is connected onto the feeding port, and heating devices are arranged above and below the conveying belt at intervals. The belt dryer has the advantages that by means of the heating devices arranged above and below the conveying belt at intervals, both the upper sides and the lower sides of to-be-dried materials can be dried, drying effects are quite remarkable, and evaporation intensity is high, so that product quality is guaranteed.

Owner:金伟均

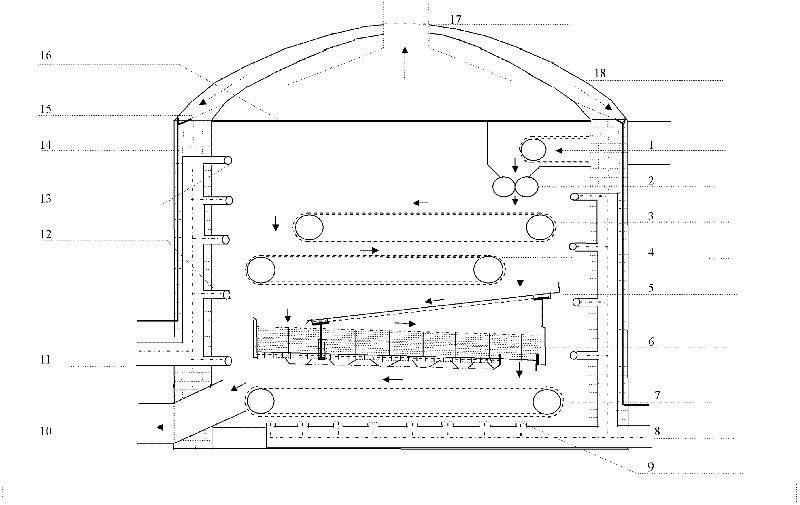

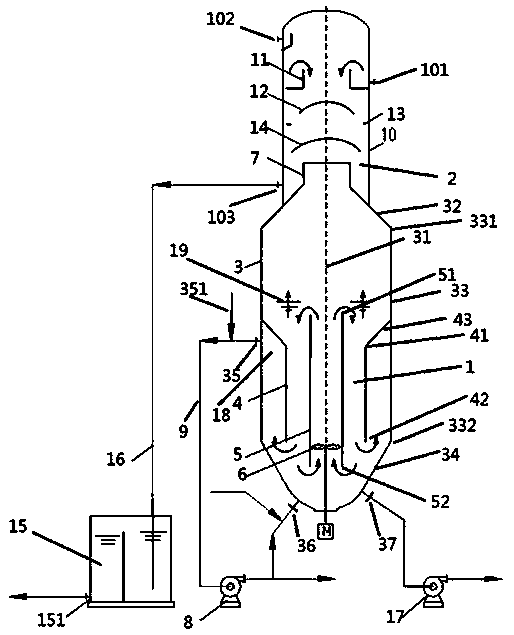

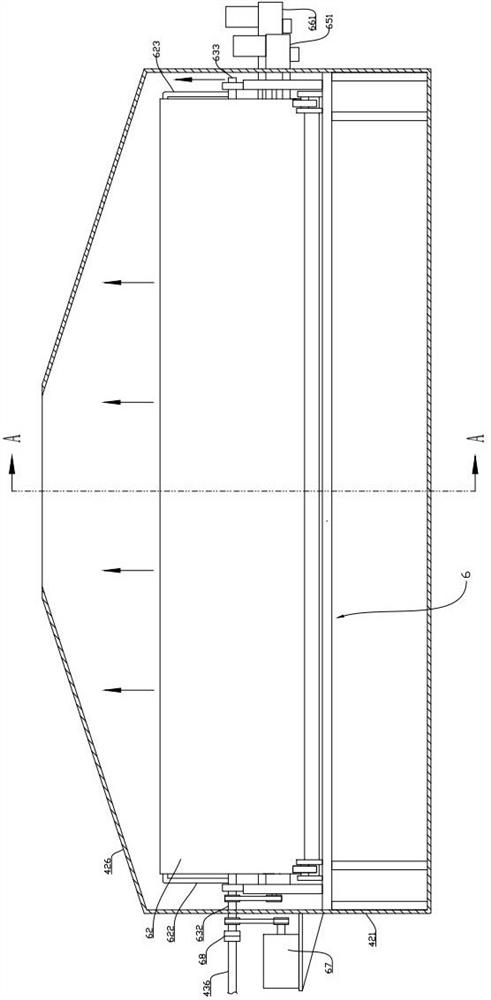

Vertical combined sludge drying device

InactiveCN102295400AThe production process is reasonableSave human effortSludge treatment by de-watering/drying/thickeningClimate change adaptationWater vaporSludge

A vertical combined sludge drying device. Above the steel structure beam on the top of the drying room is an interlayer arched roof. There is a top hot steam recovery port in the middle of the roof. There is a water vapor return groove on the lower edge of the roof. There are hot air main pipes inside and on the ground, and the outlets of multiple hot air main pipes are in the wall of the drying room and on the ground. There is a sludge conveying inlet above the wall of the drying room. There are multiple layers of metal mesh conveyor belts arranged. Below the discharge side of the bottom metal mesh conveyor belt is a metal vibrating lower slide. Below the discharge edge of the lower slide is a metal oscillator screen. The discharge side of the net conveyor belt is facing the dry mud granulation outlet. The sludge drying device makes full use of the space, the three-dimensional combined structure is reasonable, and the comprehensive performance is strong. It has fast drying speed, high evaporation intensity and good consistency of material drying. Easy to install, operate and maintain. Safe and efficient, energy saving and environmental protection.

Owner:TIANJIN KIWI TECH DEV

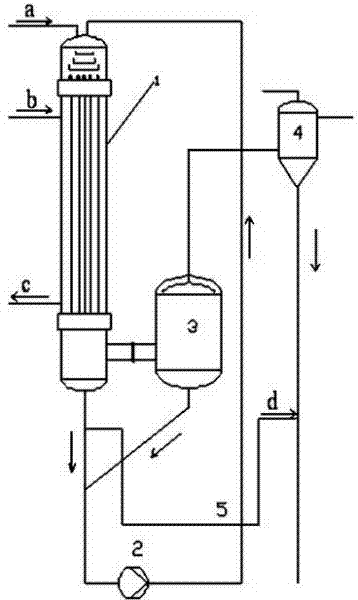

Phosphoric acid evaporation process and device thereof

InactiveCN102249203ALow investment costLow running costChemical industryPhosphorus compoundsPhosphoric acidEvaporation

The invention relates to a phosphoric acid evaporation process, and a device which is mainly used in the phosphoric acid evaporation process; the process comprises the following steps: allowing dilute phosphoric acid to enter the top of a graphite falling film evaporation heater, and to flow downwards in a membrane mode along the inner wall of a heat exchange tube, introducing steam from the side wall of the heater, heating the outer wall of the heat exchange tube, transferring heat to the dilute phosphoric acid in the tube through the tube wall, heating the dilute phosphoric acid during flowing, and evaporating the water. Compared with traditional circulating pump external-circulation single-effect evaporation processes, the process of the invention has high evaporation intensity, requires less heat exchangers and circulating pumps to be allocated under equal production capacity than the circulating pump external-circulation single-effect evaporation processes, and can greatly reduce investment cost, operation cost, and maintenance cost of a phosphoric acid concentration device.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

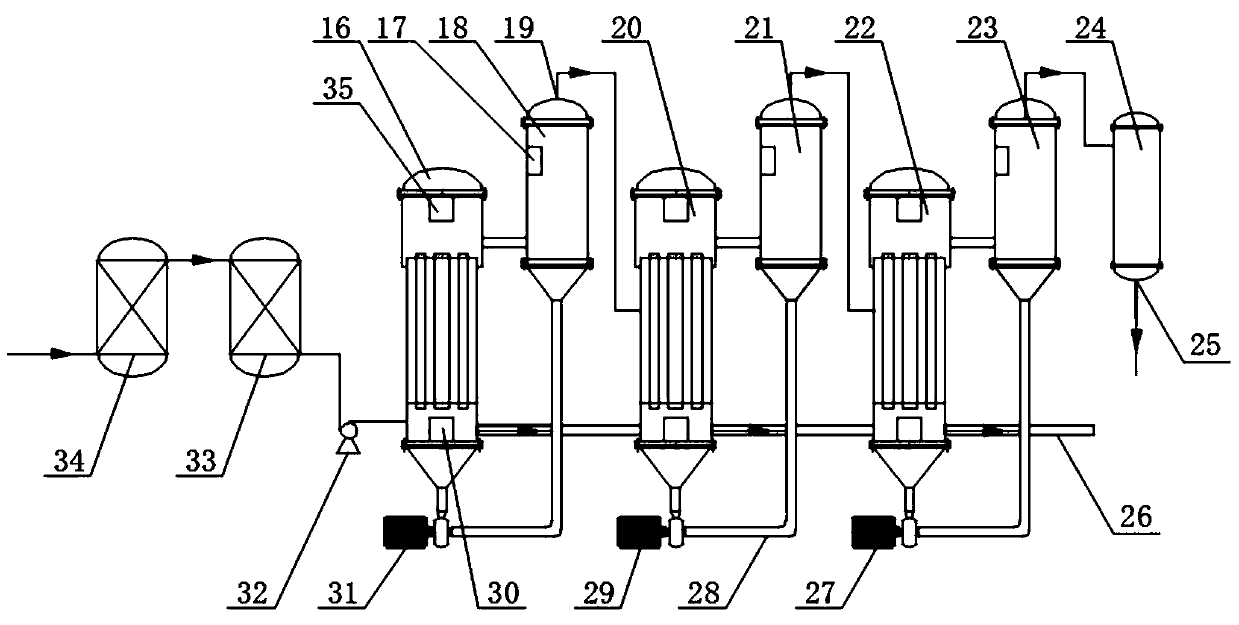

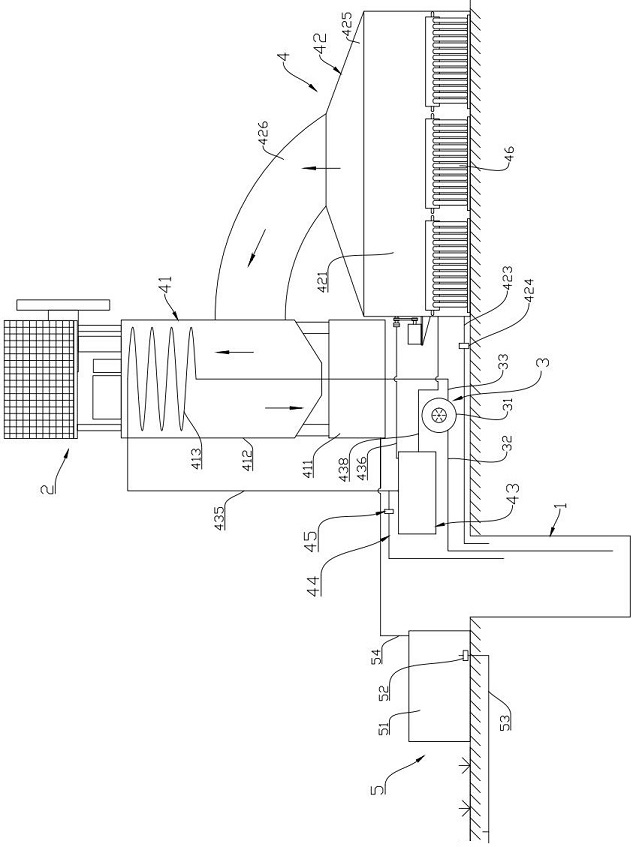

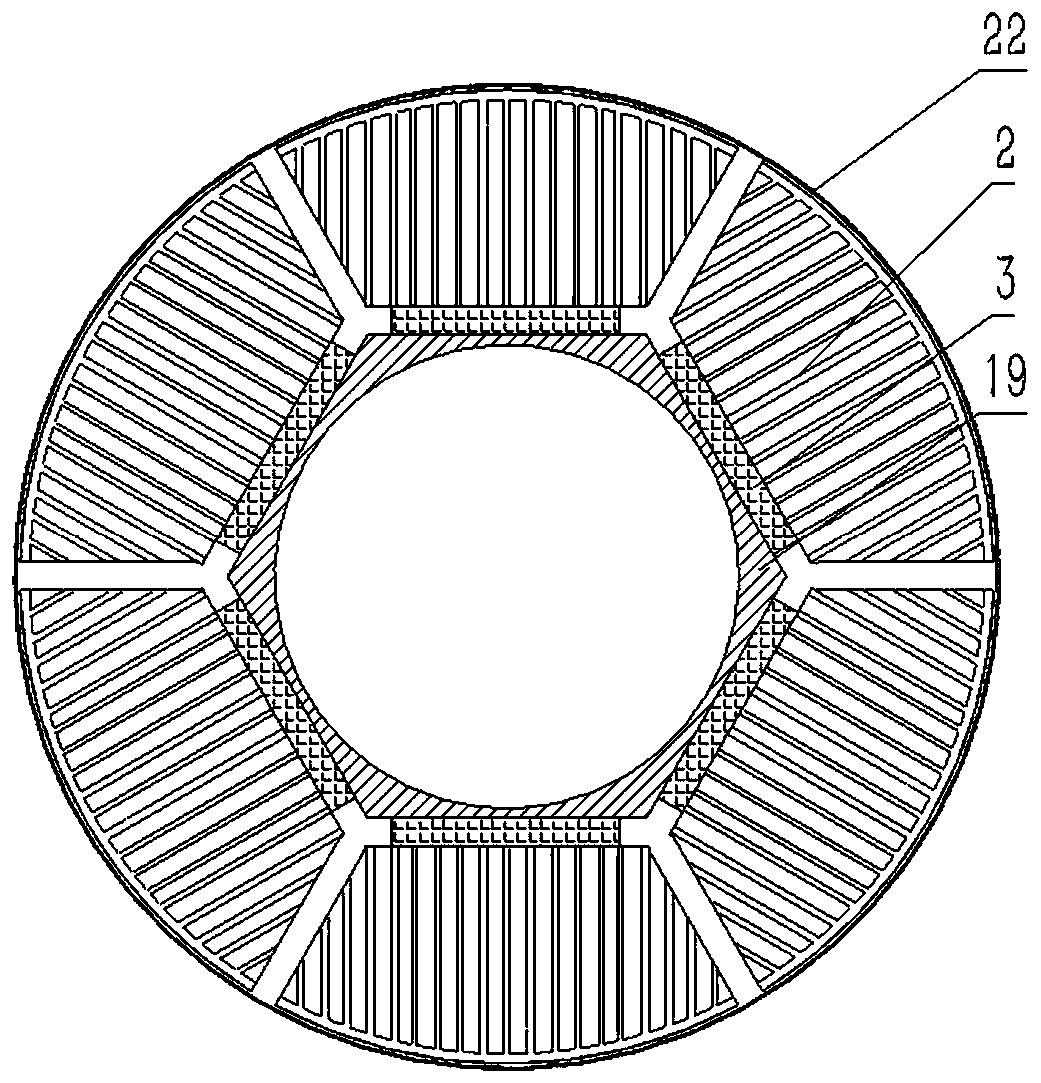

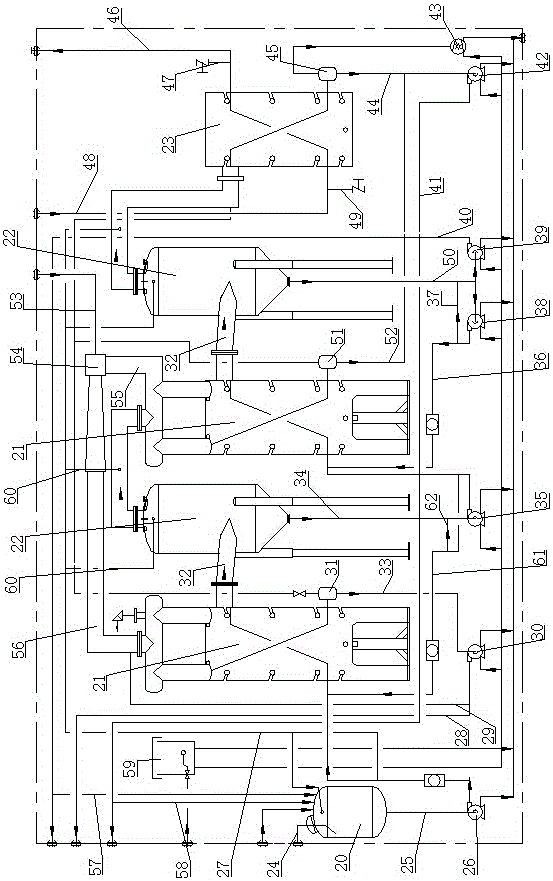

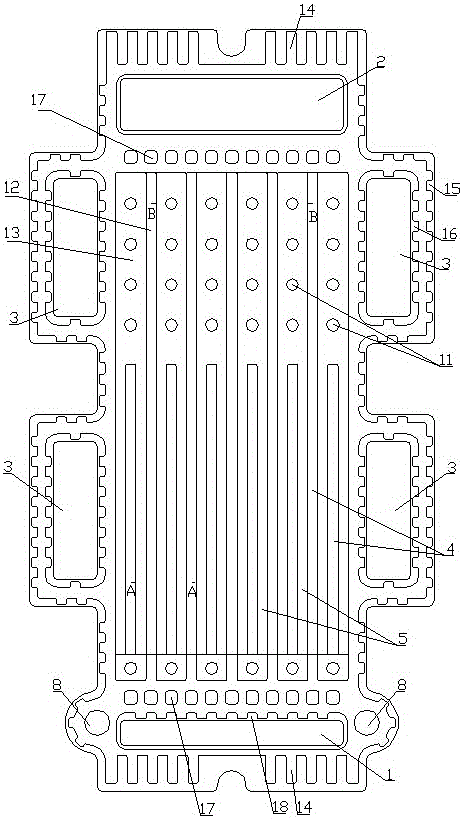

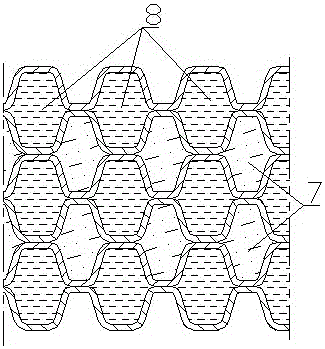

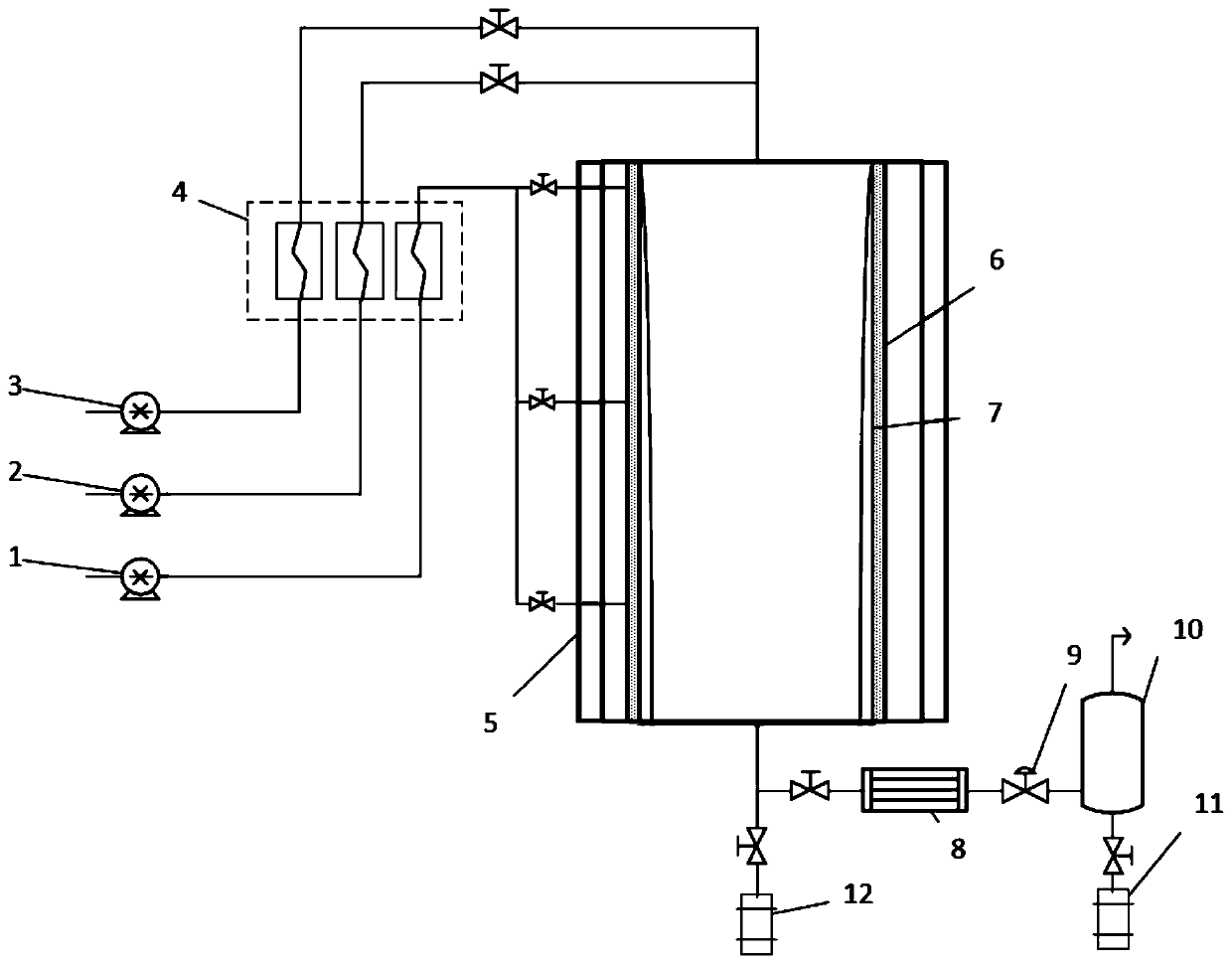

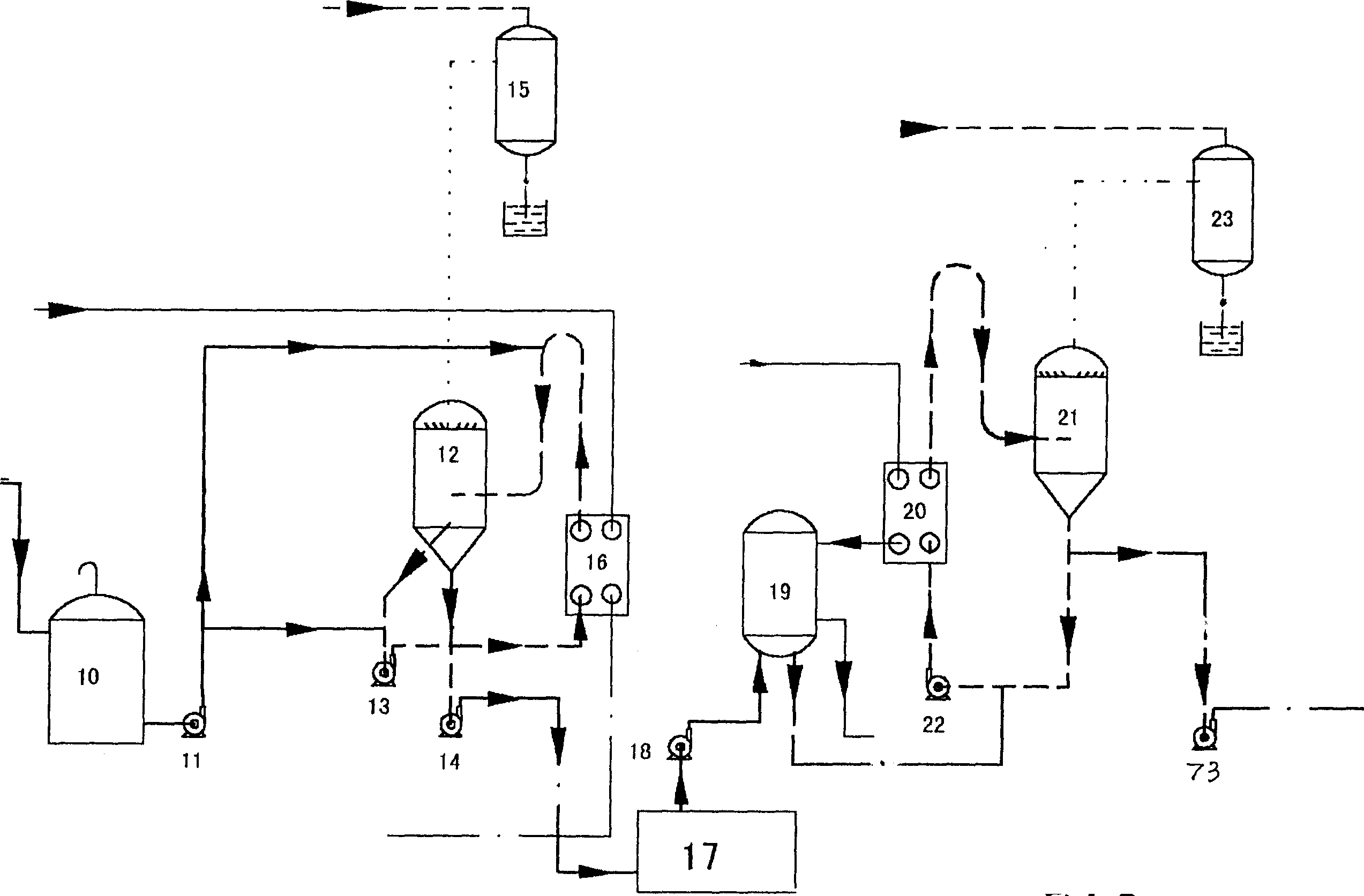

Multifunctional energy-saving type continuous wastewater evaporative crystallization process and device

ActiveCN105461141AHigh evaporation strengthPerfect energy saving measuresWater/sewage treatment by centrifugal separationEnergy based wastewater treatmentBoiling pointWastewater

The invention discloses a multifunctional energy-saving type continuous wastewater evaporative crystallization process. The process includes the step A of first-stage preheating of wastewater, the step B of second-stage preheating of wastewater, the step C of triple-effect heating of wastewater, the step D of triple-effect separation of wastewater, the step E of vapor condensation, the step F of forced circulation and two-effect heating of wastewater, the step G of two-effect separation of wastewater, the step H of cyclic utilization of two-effect vapor, the step I of forced circulation and one-effect heating of wastewater, the step J of one-effect separation of wastewater, the step K of cyclic utilization of one-effect vapor, the step L of recovery of vapor condensate, the step M of discharged of non-condensable gas, the step N of forced circulation and crystallization of wastewater, the step O of centrifugal separation and the step P of sewage discharge and secondary circulation of wastewater. Corresponding adjustment can be conduced according to the properties and boiling points of wastewater, conditions required by users, concentration changes of material crystallization and the like, and therefore optimization of the effective number and the minimization of the heat exchange area are achieved, and the evaporation intensity is improved to the maximum.

Owner:ZHEJIANG HAIYAN POWER SYST RESOURCES ENVIRONMENTAL TECH

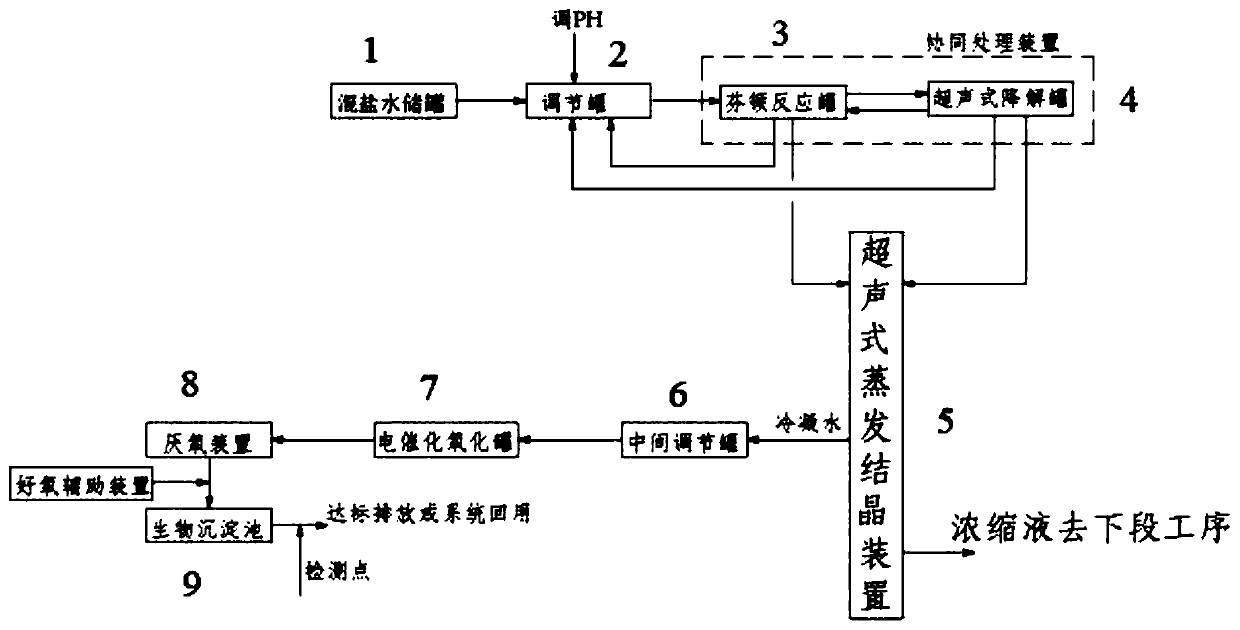

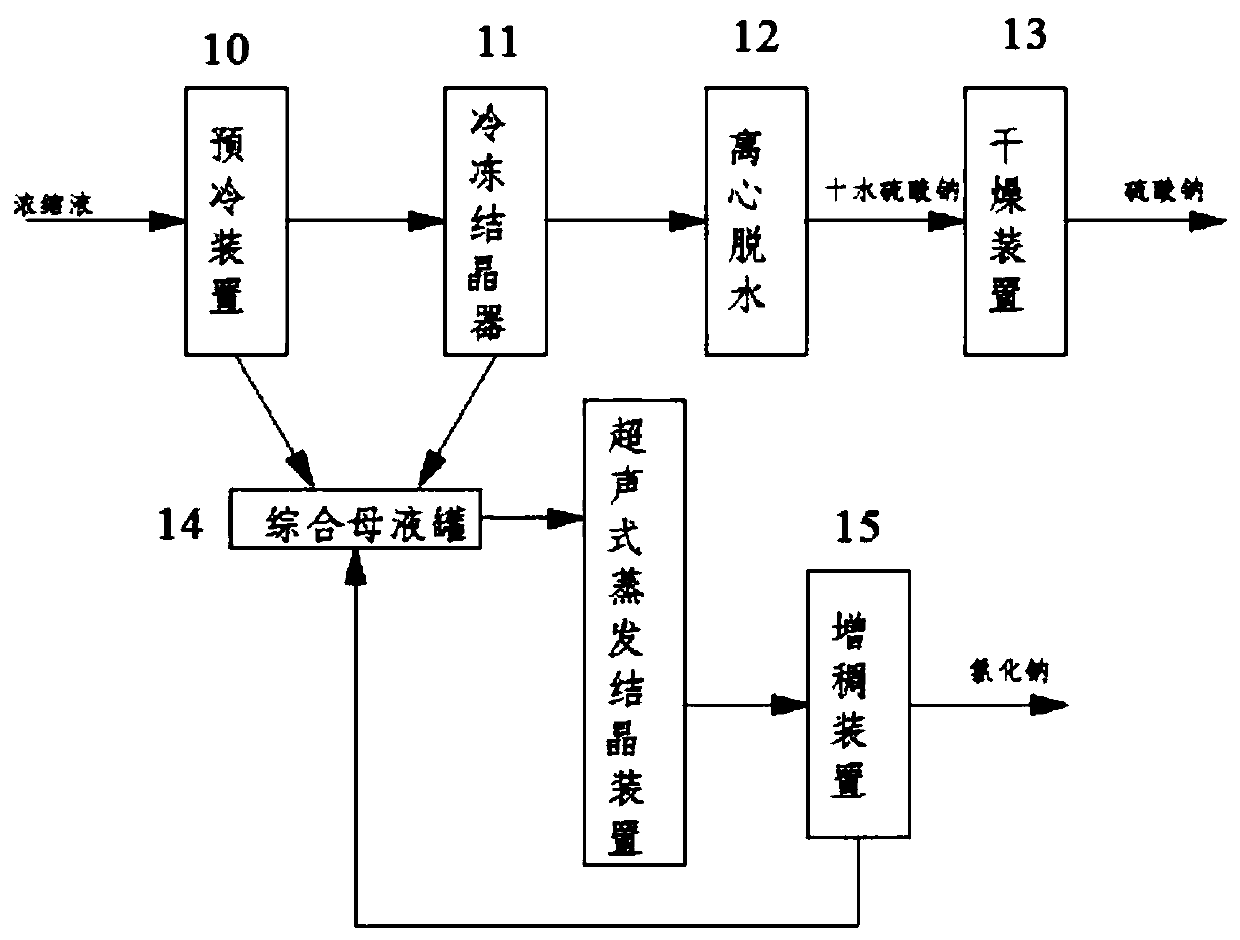

Sodium chloride and sodium sulfate ultrasonic type evaporative-crystallization salt separating system and method

PendingCN110040908ARealize recycling of resourcesGood for maintaining purityWater treatment compoundsWater contaminantsResource recoveryEvaporation

The invention relates to a sodium chloride and sodium sulfate ultrasonic type evaporating, crystallizing and salt separating system. The system is characterized by comprising a mixed salt wastewater storage tank, a regulating tank, a pretreating device, an ultrasonic type evaporative-crystallization device, a condensing treatment device and a salt separating device. The invention further relates to a sodium chloride and sodium sulfate ultrasonic type evaporating-crystallizing and salt separating method which comprises the steps: 1) pretreating high-salt wastewater; 2) performing ultrasonic type evaporative crystallization; 3) treating evaporation condensate water; 4) performing salt separating treatment. The system and method disclosed by the invention have the advantages of scientific andreasonable design and novel technology; by means of the system and the method, the high-salt wastewater can be recycled; meanwhile, salt resources can be recycled.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

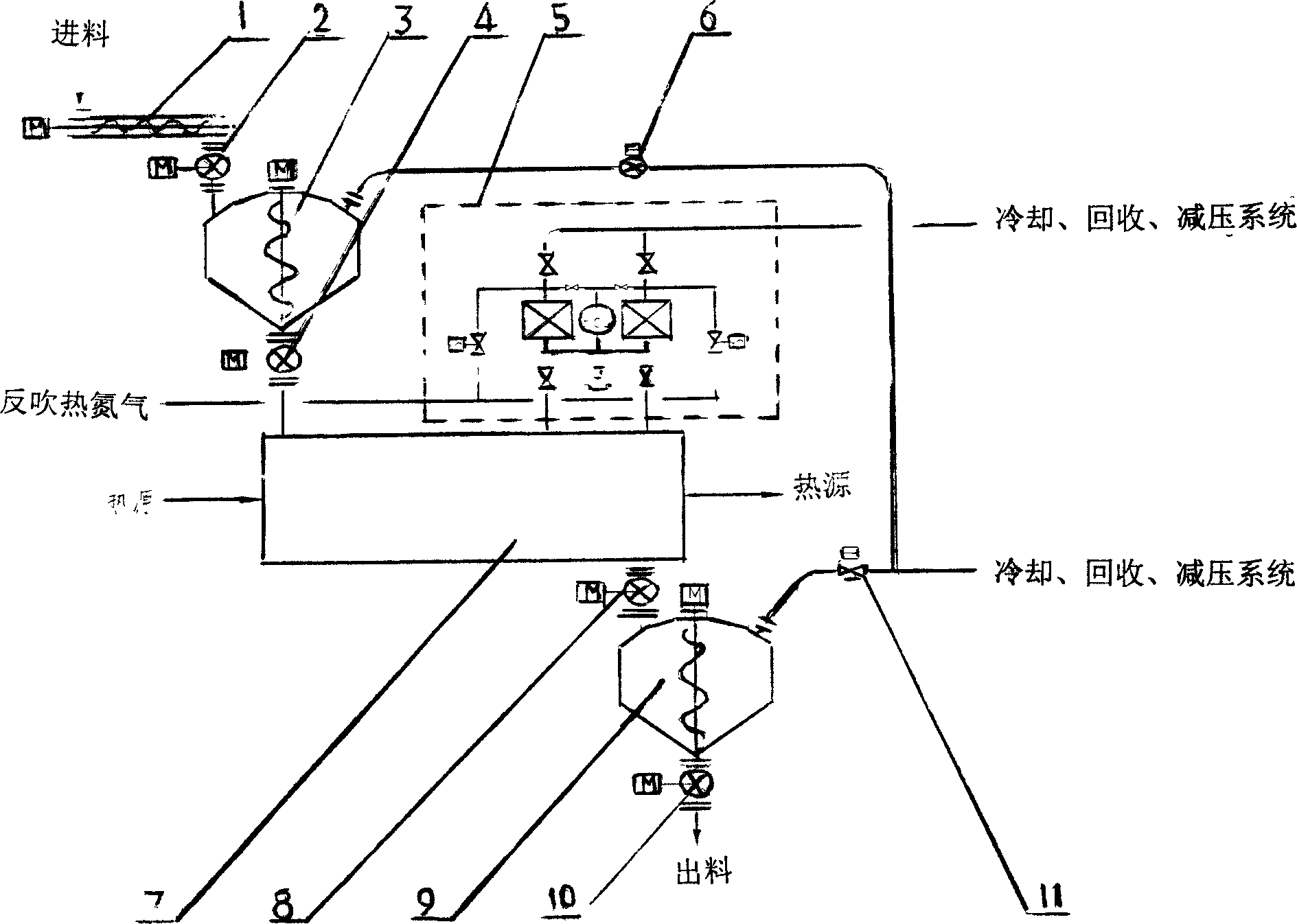

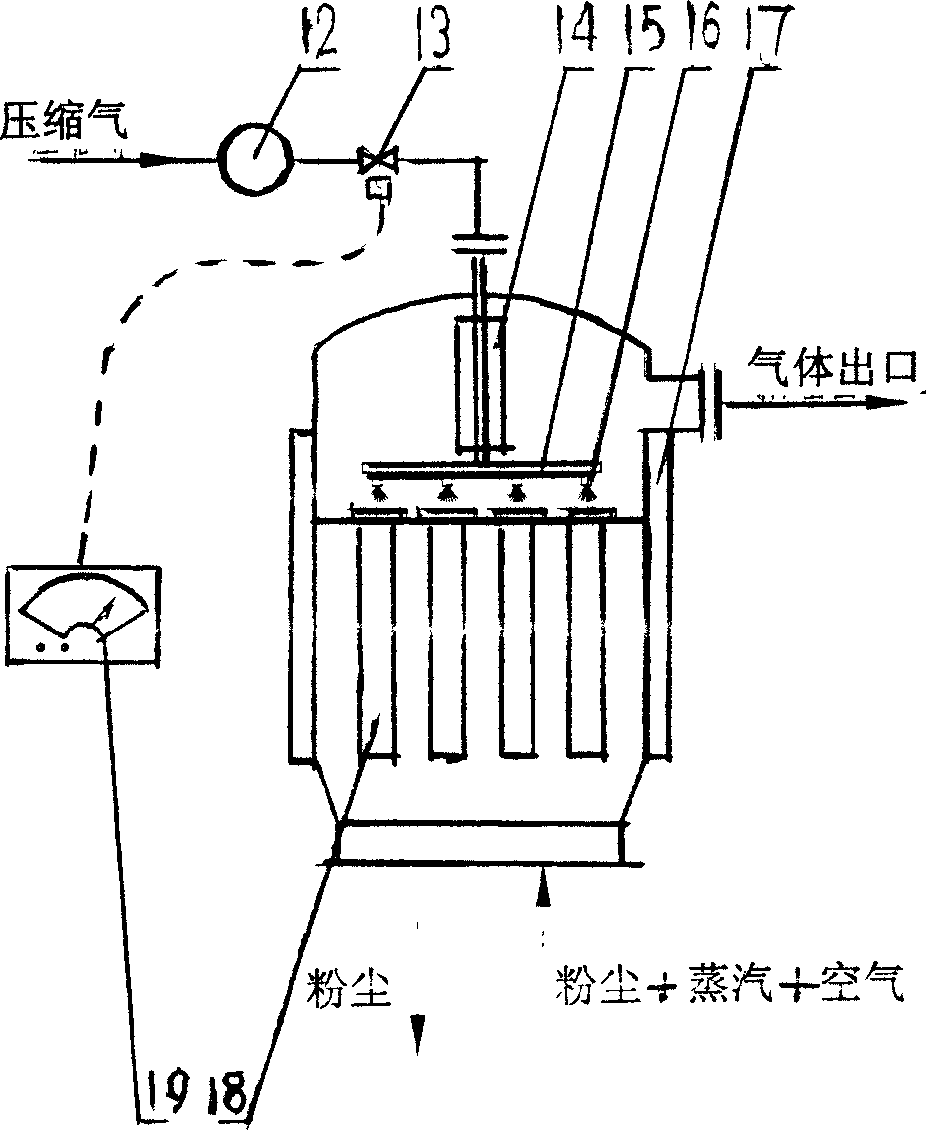

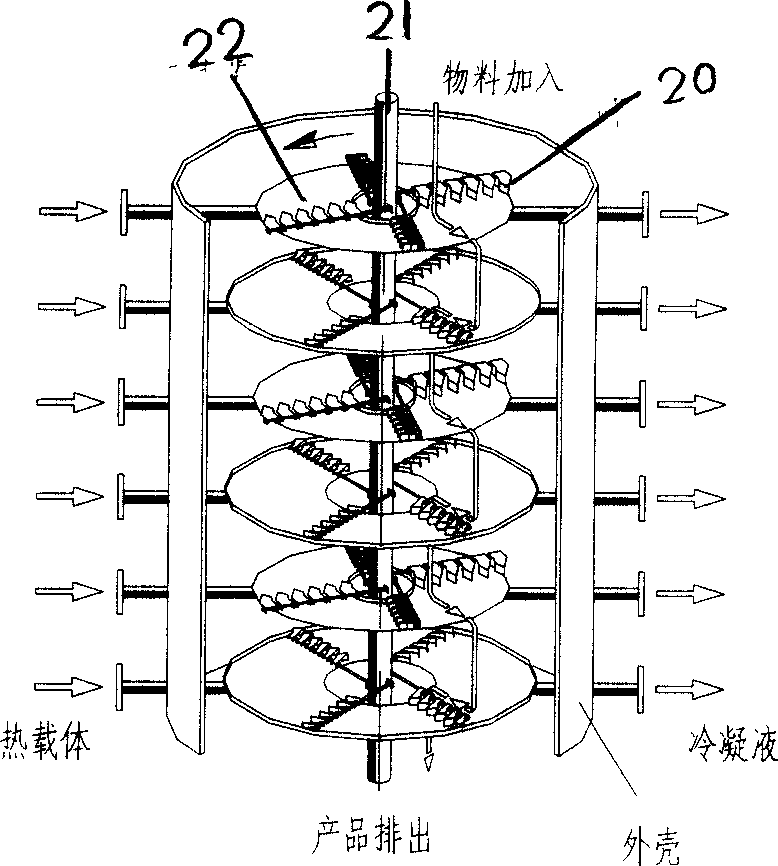

Vacuum drying method of carbon dioxide full base degradation plastic-polypropylidene carbonate and its device

The present invention discloses a carbon-dioxide all-base degradable plastics-polypropylidene carbonate vacuum drying method and its equipment. Said equipment includes the following several portions: spiral conveyer, transfer rotary valve, decompression transfer tank, decompression system, rotary valves with high-blocking performance, heat source and drying machine and drying unit. Said invention also provides their connection mode and the concrete operation method and steps of said vacuum drying equipment.

Owner:LANZHOU RUIDE DRYING TECH +2

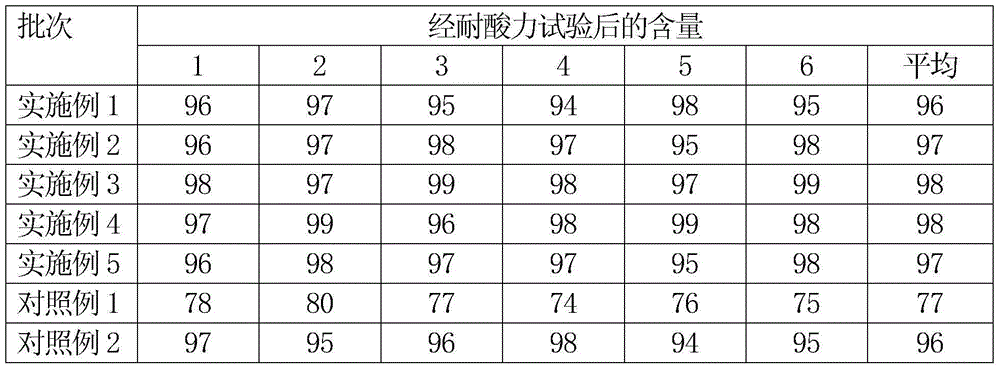

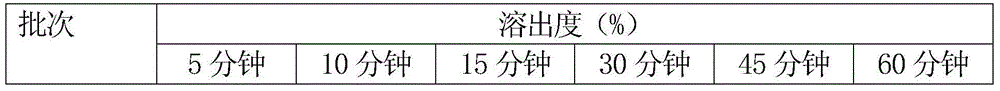

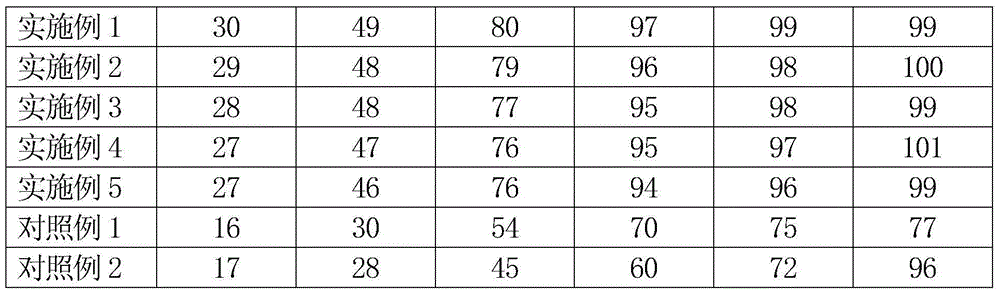

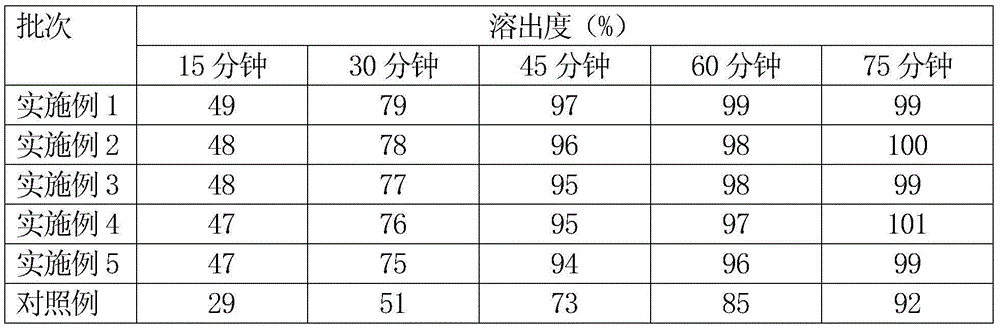

Pellet type pantoprazole sodium enteric capsule and preparation method thereof

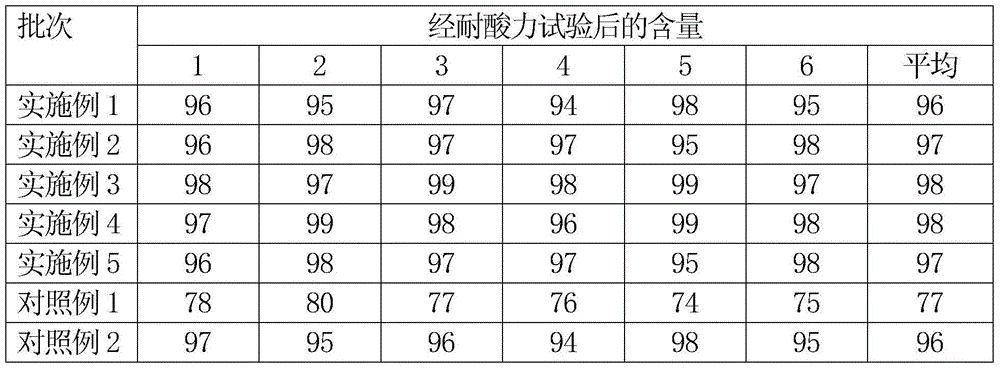

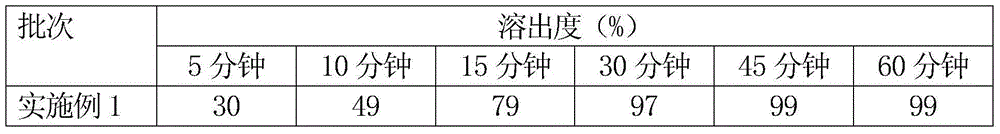

InactiveCN104644616AImprove stabilityAvoid photolysisOrganic active ingredientsDigestive systemGranularityIsolation layer

The invention discloses a pellet type pantoprazole sodium enteric capsule and a preparation method thereof. The pellet type pantoprazole sodium enteric capsule is a sustained-release preparation composed of a capsule shell and uniformly mixed pantoprazole sodium pellets held in the capsule shell; the pantoprazole sodium pellet from inside to outside in turn comprises a blank pellet core, a main drug layer, an isolation layer and an enteric layer, wherein the weight of the main drug layer is 14-55% of that of the blank pellet core, the weight of the isolation layer is 9-10% of that of the total weight of the blank pellet core and the main drug layer, the weight of the enteric layer is 28-32% of that of the total weight of the blank pellet core, the main drug layer and the isolation layer; 40-60% of that of the pantoprazole sodium pellet is coated with a pigmented layer on the outside of the enteric layer; the weight of the pigmented layer is 0.5-1% of that of the total weight of the blank pellet core, the main drug layer, the isolation layer and the enteric layer; the diameter of the blank pellet core is 0.8-1.0 mm; the granularity of the pantoprazole sodium pellet is 14-20 mesh; each capsule contains 20-40 mg of the pantoprazole sodium. The pellet type pantoprazole sodium enteric capsule has the advantages of acidproof, rapid release and stable.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

Mini-pill type nicergoline capsule and preparation method thereof

InactiveCN104622850AImprove solubilityWidely distributedSenses disorderNervous disorderSide effectBiomedical engineering

The invention discloses a mini-pill type nicergoline capsule and a preparation method thereof. The mini-pill type nicergoline capsule is a sustained-release preparation and is prepared from a capsule shell and a nicergoline mini-pill accommodated in the capsule shell, wherein the nicergoline mini-pill sequentially comprises an empty pill core, a main drug layer and a pigmented layer from inside to outside; the main drug layer accounts for 15-60 percent of the empty pill core, and the pigmented layer accounts for 0.5-1 percent of the total weight of the empty pill core and the main drug layer. The mini-pill type nicergoline capsule has the advantages of small stimulation to intestines and stomach, high utilization rate, high stability, less toxic or side effects and capability of fully releasing effective components in time.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

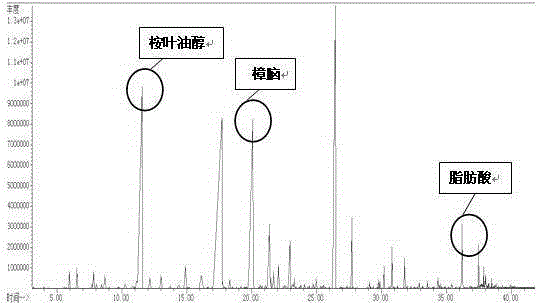

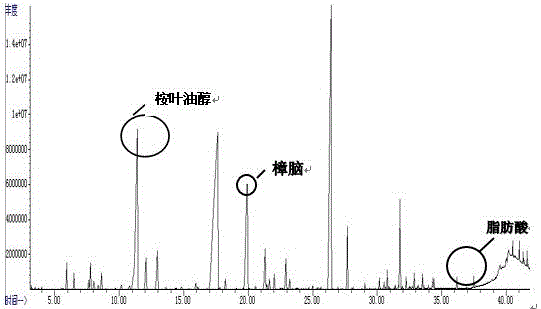

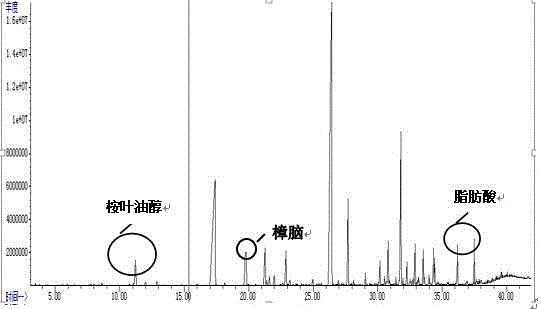

Disordered flowers lavender essential oil and refining method thereof

InactiveCN105296158AImprove qualityLow heating temperatureEssential-oils/perfumesBiotechnologyLavandula

The invention relates to disordered flowers lavender essential oil and a refining method thereof. The method comprises the steps that the disordered flowers lavender essential oil obtained by steam distillation is subjected to low temperature pre-freezing and low temperature freezing centrifugation to remove part of fatty acid, eudesmol and camphor; primary molecular distillation and secondary molecular distillation are performed to remove the most part of the eudesmol and the camphor. In the disordered flowers lavender essential oil, the content of the fatty acid after refining is lowered to 2.61 percent to 2.88 percent from 4.23 percent before the refining; the content of the eudesmol is lowered to 0.67 percent to 0.98 percent from 18.31 percent before the refining; the content of the camphor is lowered to 1.40 percent to 1.48 percent from 14.57 percent, and accords with the requirements of the content of the camphor in the national standard (GB / T12653-2008). The yield is 65.22 percent to 74.28 percent in the whole refining process. The disordered flowers lavender essential oil and the refining method thereof, provided by the invention, are simple in process and high in yield, a technology that refrigerated centrifugation is combined with the molecular distillation is adopted, the content of the fatty acid, the eudesmol and the camphor in the disordered flowers lavender essential oil are lowered, the content of the camphor is enabled to reach the national standard, and the quality and the market competitiveness of disordered flowers lavender are improved.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

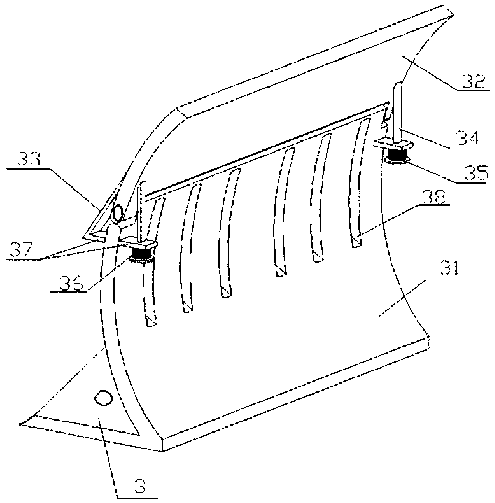

Method for optimally regulating thickness of water film of supercritical water oxidation and evaporation wall type reactor

ActiveCN109133317AAdjustable thicknessPromote formationWater contaminantsWater/sewage treatment by oxidationBarrel ShapedEvaporation

The invention discloses a method for optimally regulating the thickness of a water film of a supercritical water oxidation and evaporation wall type reactor. The method is based on a system for adjusting the coverage rate of the water film of the supercritical water oxidation and evaporation wall type reactor. The system comprises an outer pressure bearing wall. A barrel-shaped porous evaporationwall is arranged in the outer pressure bearing wall. An outlet of an evaporation wall water pump is connected with a water inlet of the porous evaporation wall through a pipeline. Outlets of a gas booster pump and a material pump are connected with an inlet of the supercritical water oxidation and evaporation wall type reactor through pipelines. The porous evaporation wall is of a conical structure. The thickness of the porous evaporation wall is gradually increased from top to bottom. The section of the porous evaporation wall is a right trapezoid. The method includes the steps that the thickness of the water film is adjusted by adjusting the evaporation intensity, the concentration of organic raw materials, the preheating temperature of the organic raw materials, the evaporation water inlet temperature and branch evaporation wall water flow proportions. The method can be applied to optimally adjusting performance parameters of the water film of the supercritical water oxidation and evaporation wall type reactor.

Owner:XI AN JIAOTONG UNIV +1

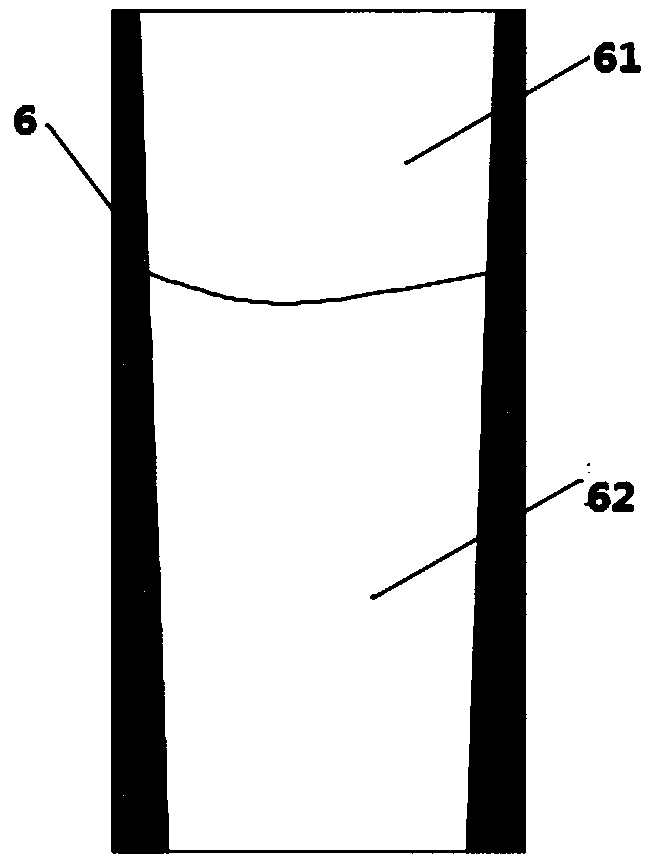

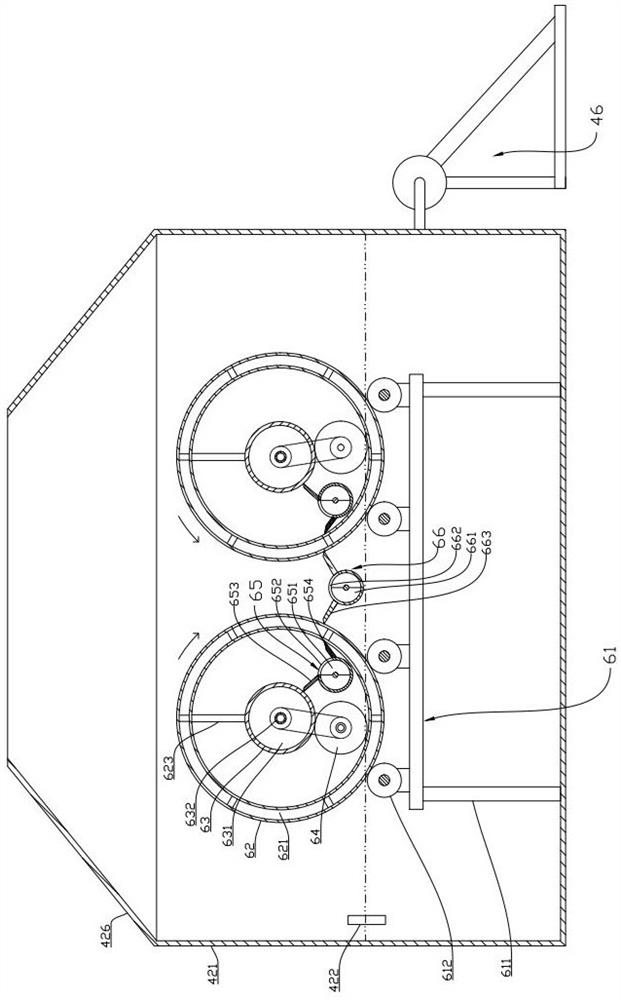

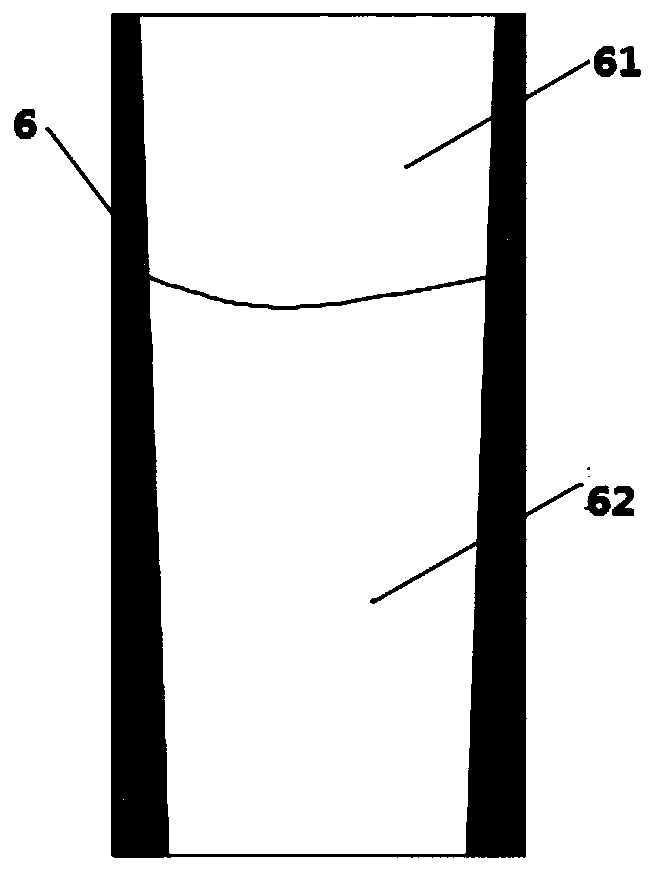

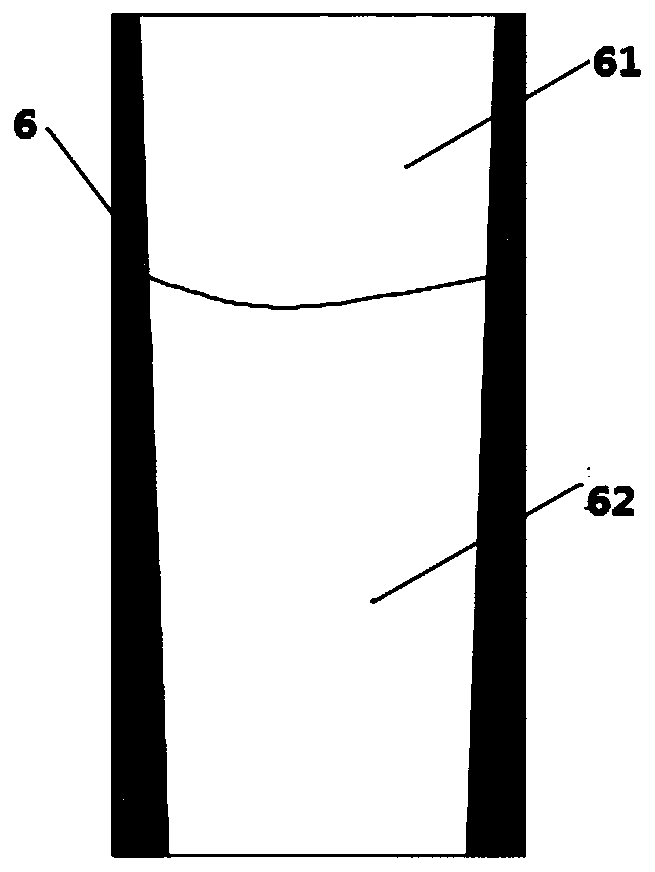

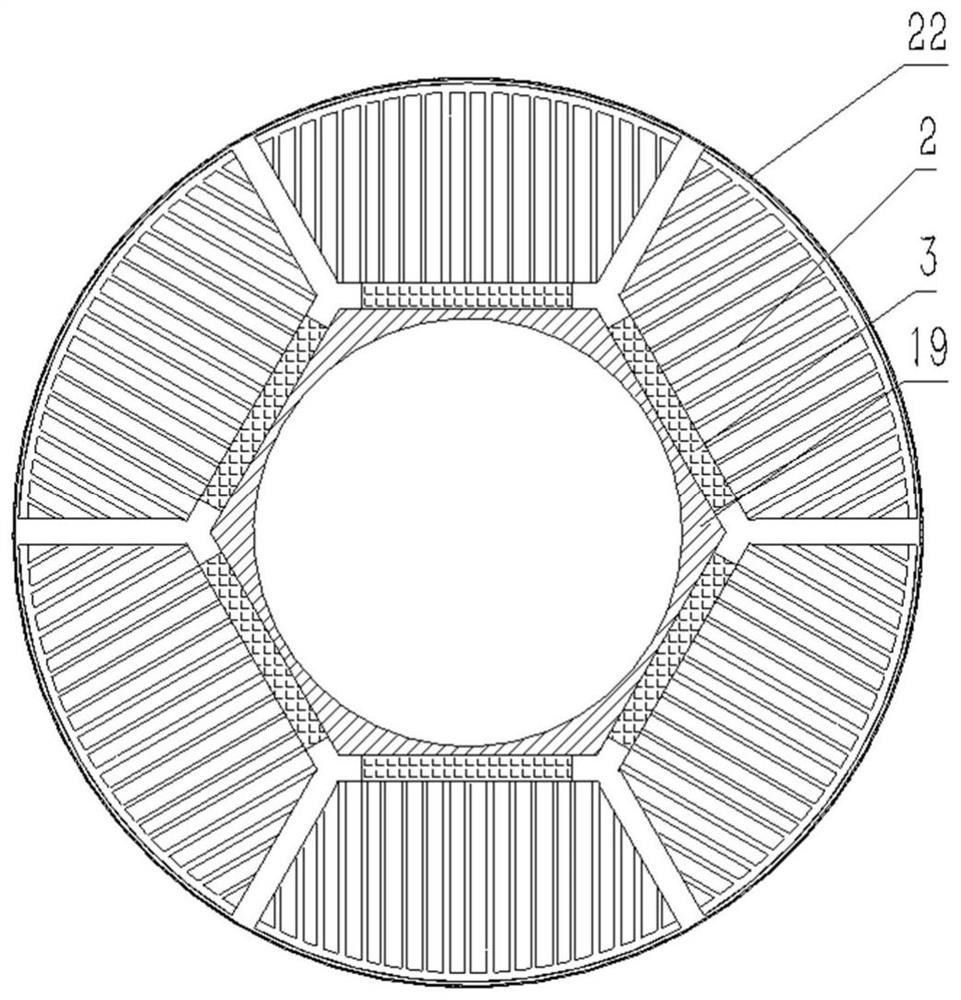

Vertical vacuum crystallization device

PendingCN108714311AAccelerate evaporationEliminate overheatingSolution crystallizationCrystallization by component evaporationCirculator pumpEngineering

The invention provides a vertical vacuum crystallization device. The vertical vacuum crystallization device comprises a crystallization part and a condensing part, wherein the crystallization part islocated below the condensing part and comprises a crystallization section cylinder, an outer flow guiding cylinder, a central flow guiding cylinder, a bottom stirrer, a secondary stream rising cylinder, a circulating cylinder, an inner circulating channel and an outer circulating channel; and the condensing part comprises a condensing section cylinder as well as an overflow weir, a first water baffling cap, a liquid baffling ring and a second water baffling cap which are sequentially arranged in the condensing section cylinder from top to bottom. The vertical vacuum crystallization device hasthe advantages that a heat exchanger does not need to be replaced, and the problems that the inner surface is seriously scaled, and the scale is difficult to clean are prevented; an vacuum processingpressure is similar to a solution steam partial pressure, and the operation is relatively stable; the crystallization part and the condensing part form equipment, so that a secondary steam flow path is shortened, and the leakage of leaking points caused due to the connection of pipelines is eliminated; by utilizing the inner circulating channel, the high-saturability region in the crystallizationpart is eliminated, and the saturability at each site is relatively uniform and low; and by utilizing the outer circulating channel, the excess crystallization is eliminated; and meanwhile, products with relatively narrow particle size distribution can be elutriated.

Owner:JIANGSU XINHONGDA GROUP

Dual-layer belt dryer

InactiveCN102840747AReduce lossHigh evaporation strengthDrying machines with progressive movementsPulp and paper industry

The invention discloses a dual-layer belt dryer which comprises a drying tank body, wherein an upper-layer conveyer belt and a lower-layer conveyer belt are arranged in the drying tank body, an air inlet fan and an air outlet fan are sequentially arranged on the upper-layer conveyer belt along the delivery direction, a plurality of circulating fans are arranged in the drying tank body which is arranged between the air inlet fan and the air outlet fan and circulate in the drying tank body, and a plurality of heaters are arranged above and below the upper-layer conveyer belt and the lower-layer conveyer belt in a staggering manner. Due to the structure, the dual-layer belt dryer has the advantages of being capable of realizing continuous drying in batch, reducing loss of circulating heat in the tank body, saving energy and being efficient, and being high in drying speed and high in evaporating strength.

Owner:李严光

Pellet type omeprazole enteric capsule and preparation method thereof

InactiveCN104546737AWidely distributedIncrease local concentrationOrganic active ingredientsDigestive systemGranularityIsolation layer

The invention discloses a pellet type omeprazole enteric capsule and a preparation method thereof. The pellet type omeprazole enteric capsule is a sustained-release preparation, and is composed of a capsule shell and evenly mixed omeprazole pellets received in the capsule shell; each omeprazole pellet is composed of a blank pill core, a main drug layer, an isolation layer and an enteric layer in order from inside to outside, wherein the weight of the main drug layer accounts for 15-60% of that of the blank pill core, the weight of the isolation layer accounts for 10% of the total weight of the blank pill core and the main drug layer, the weight of the enteric layer accounts for 28-32% of the total weight of the blank pill core, the main drug layer and the isolation layer; besides, the enteric layers of 40-60% of omeprazole pellets are further coated with pigment layers; the weight of the pigment layer accounts for 0.5-1% of the total weight of the blank pill core, the main drug layer, the isolation layer and the enteric layer; the diameters of the blank pill cores are 0.8-1.0mm; the granularity of the omeprazole pellets is 14-20 meshes; each capsule contains 15-30mg of omeprazole. The pellet type omeprazole enteric capsule has the advantages of good acid resistance, sufficient active ingredient release without delay, good stability and the like.

Owner:ZHEJIANG CHANGDIAN PHARMA +1

Para toluene sulfonate continuous drying method

PendingCN108489238AEvenly distributedEasy to evaporateDrying solid materials without heatDrying machines with progressive movementsAlcoholBoiling point

The invention discloses a para toluene sulfonate continuous drying method which adopts a crawler type continuous drying method. A baffling type channel formed by an upper heating slab and a lower heating slab which are on a crawler and middle solid square steel allows materials to be distributed uniformly, the surface is heated uniformly, a fluid medium flows without a dead angle, and water, alcohol and low boiling impurities are evaporated more easily; with the combination of vacuumizing, a feeding bin and a discharge bin are designed like a space capsule, so that the impurities such as waterand alcohol are removed more easily; and the para toluene sulfonate continuous drying method has the advantages of high drying rate, high evaporation intensity, short time and stable product quality.

Owner:浙江嘉化新材料有限公司 +1

Saline water desalination and supplementary irrigation device for saline-alkali soil

ActiveCN114303507AMake up for the shortage of fresh waterImprove utilization efficiencySoil lifting machinesGeneral water supply conservationAlkali soilWater source

The invention discloses a saline-alkali soil salt water desalination and supplementary irrigation device which comprises a salt water source, a wind-solar complementary power generation system, a water lifting device, a desalination distillation device and a field supplementary irrigation system. The desalination distillation device distills saline water to obtain fresh water and conveys the fresh water to the field supplementary irrigation system, the field supplementary irrigation system conveys the fresh water to the field, the problem of fresh water shortage of the saline-alkali soil is solved, the wind-solar complementary power generation system supplies energy to the water lifting device, the desalination distillation device and the field supplementary irrigation system, and independent laying of power transmission equipment and the like is reduced. The method can be applied to barren areas lacking electric power facilities; the desalination distillation device is high in evaporation intensity and desalination water collection efficiency, salt in salt water can be separated and extracted, the total salt content of the saline-alkali soil is reduced, the saline-alkali soil is treated, the crop growth environment is improved, and crop harvest is improved.

Owner:HEBEI UNIV OF ENG

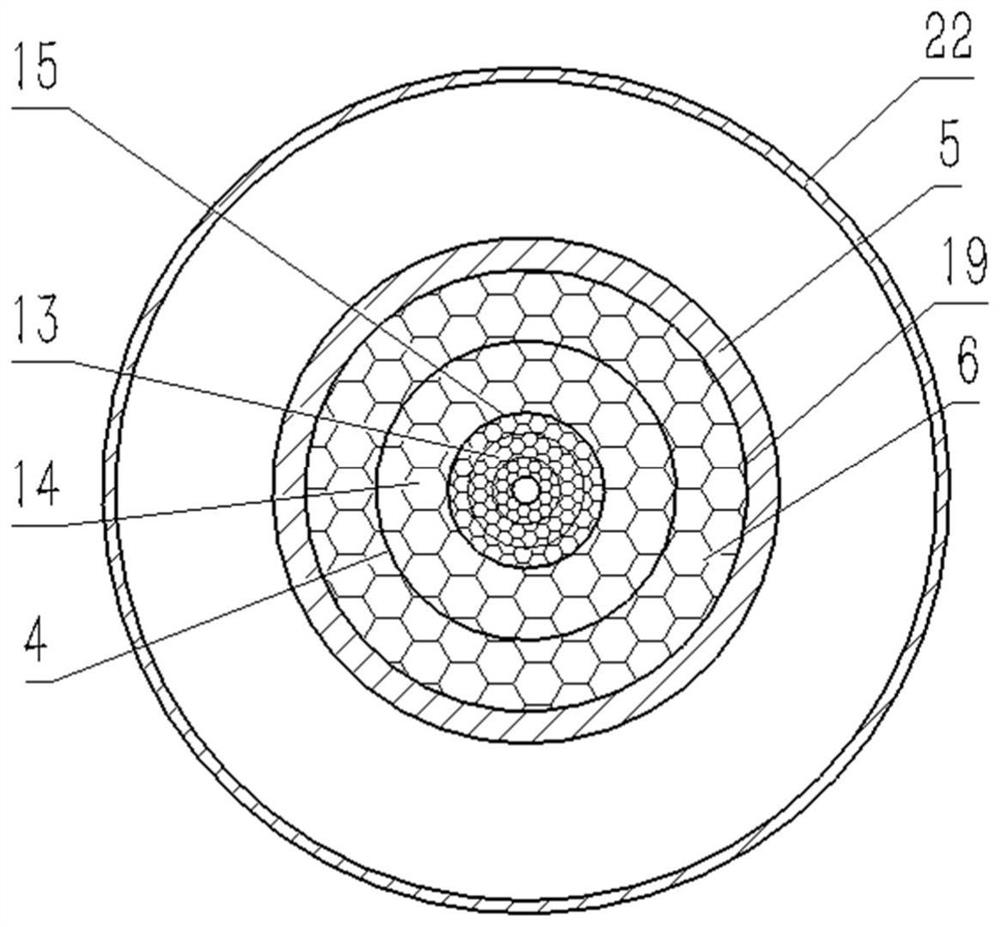

Thermoelectric conversion device based on liquid fuel combustion

ActiveCN110594730AIncrease temperatureHigh evaporation strengthBurnersIndirect carbon-dioxide mitigationThermal energyPorous medium

The invention discloses a thermoelectric conversion device based on liquid fuel combustion. The thermoelectric conversion device based on liquid fuel combustion comprises a combustion cylinder. A combustor is arranged inside the combustion cylinder. An ignition mechanism is arranged on the top of the combustor. A fuel evaporation tube is arranged inside the combustor. The lower part of the interior of the fuel evaporation tube is filled with oil absorption porous media. Fuel vapor holes are formed in the upper part of the fuel evaporation tube. An oil pump is arranged at the lower end of the fuel evaporation tube, and is connected with the lower end of the fuel evaporation tube. A mixing chamber is formed between the upper part of the fuel evaporation tube and the inner wall of the combustor. An air delivery channel is formed between the lower part of the fuel evaporation tube and the inner wall of the combustor and communicates with the mixing chamber. A flue gas channel is formed between the outer wall of the combustor and the inner wall of the combustion cylinder. A thermoelectric power generation module is arranged on the outer wall of the combustion cylinder. According to thethermoelectric conversion device based on liquid fuel combustion, liquid fuel can be burned sufficiently, thermal energy is converted into electric energy, the environmental pollution caused by usingbatteries is reduced, the burden caused to a user during outdoor movement is reduced, and then it is avoided that electric equipment is cut off from a power source for a long time.

Owner:XIAN UNIV OF SCI & TECH

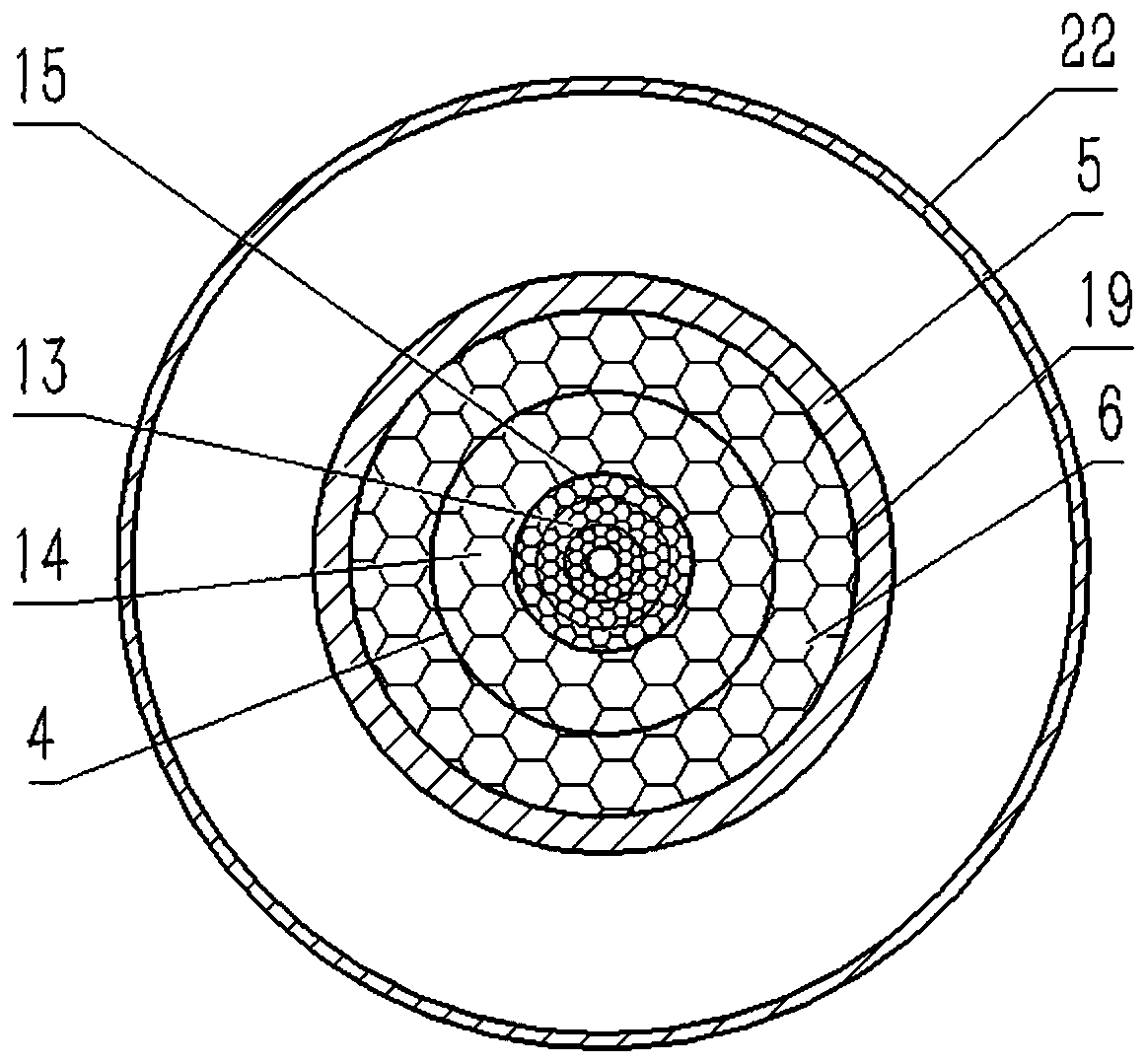

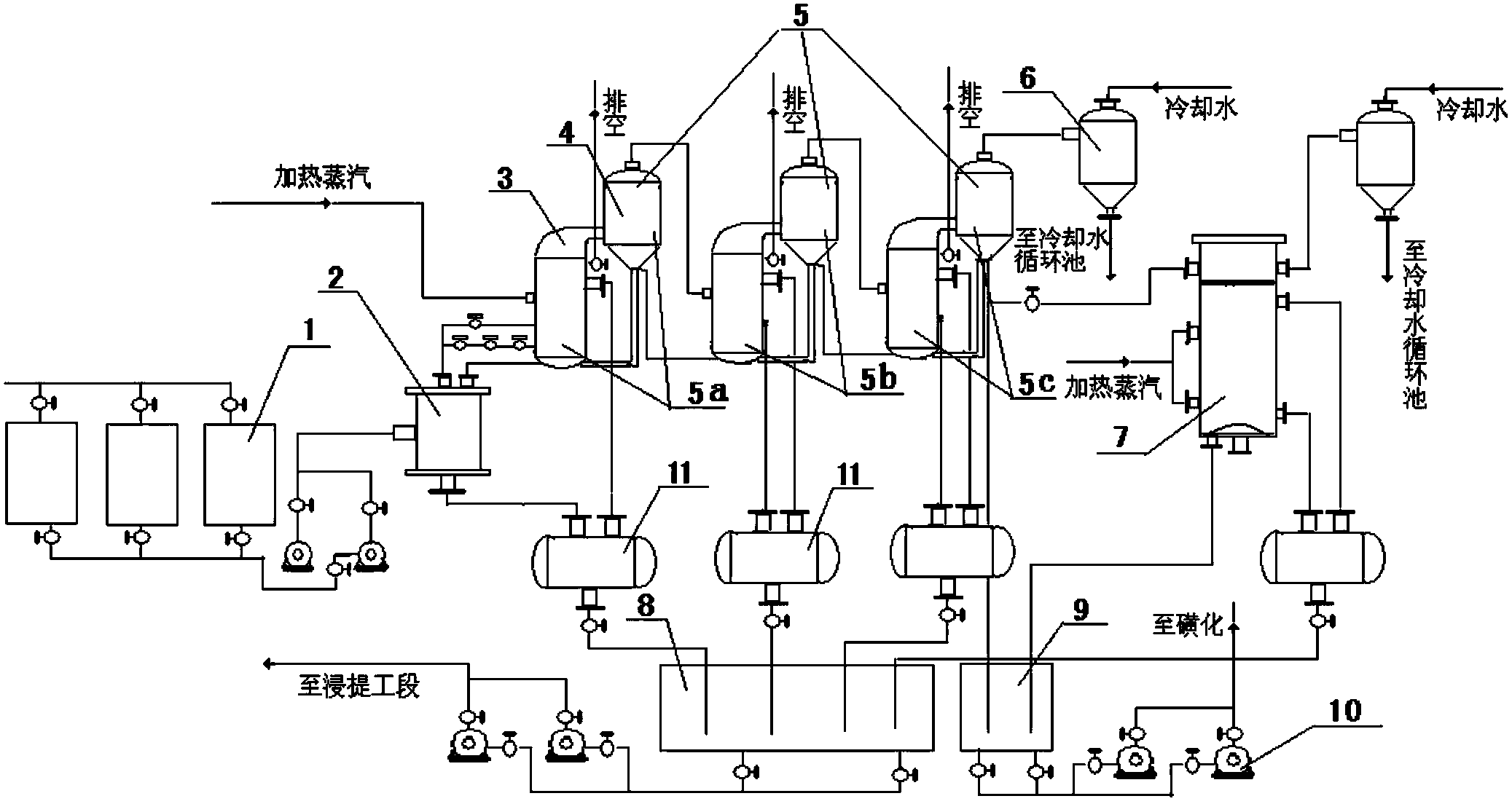

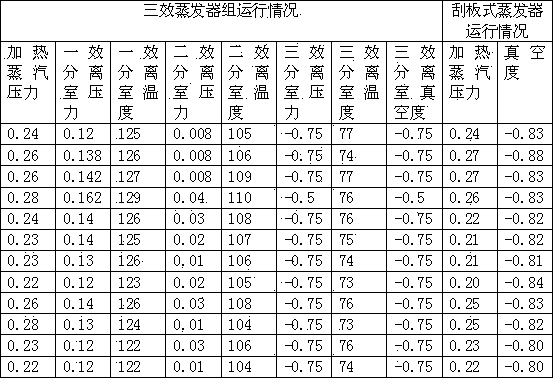

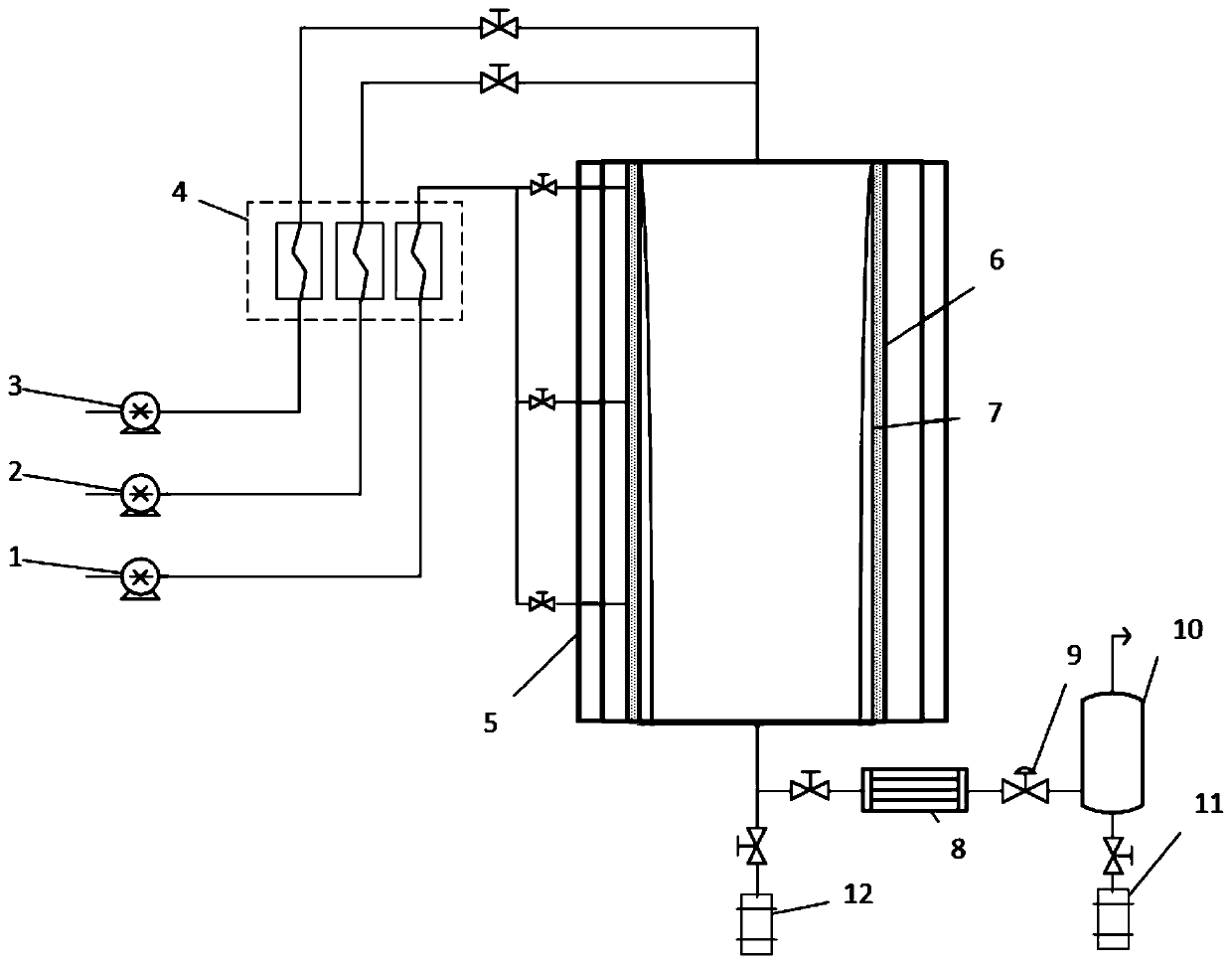

Unpowered automatic liquid-transferring method in production and evaporation procedures of tanning extracts

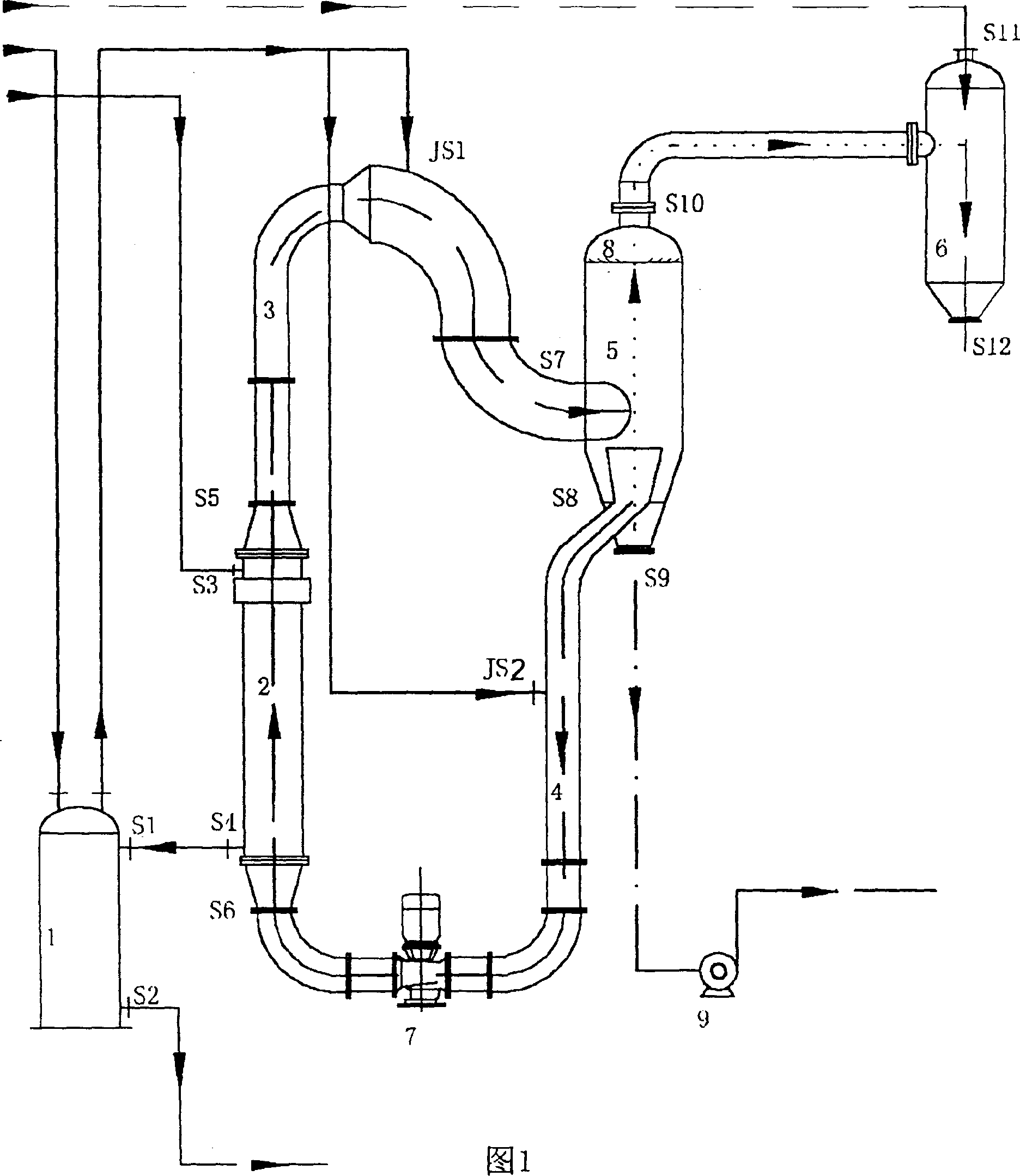

InactiveCN103908790AStable vacuum pressureReduce energy consumptionMultiple-effect evaporationVacuum pressurePulp and paper industry

The invention relates to the field of tanning extracts and particularly relates to an unpowered automatic liquid-transferring method in the production and evaporation procedures of the tanning extracts. A triple-effect evaporator is connected with a scratching-plate type evaporator to form a quadruple-effect down-flow evaporation system. The unpowered automatic liquid-transferring method is characterized in that liquid-level difference exists between the triple-effect evaporator (5) and the scratching-plate type evaporator (7), and simultaneously the boiling circulation speed of glue solution in the triple-effect evaporator is accelerated, so that the vacuum degree of the triple-effect evaporator is less than that of the scratching plate type evaporator, a water column between the triple-effect evaporator and the scratching plate type evaporator and with the vacuum-degree pressure difference being more than or equal to 100mm forms differential pressure; and glue solution in the triple-effect evaporator is automatically transferred into the scratching type evaporator under the action of pressure difference power. The unpowered automatic liquid-transferring method has the advantages that concentrated glue is suctioned to the scratching type evaporator for further evaporation and concentration from the triple-effect evaporator by utilizing the power formed by vacuum pressure difference, and automatic liquid transferring between the triple-effect evaporator and the scratching-plate type evaporator in the evaporation procedure without mechanical power is realized, so that the energy consumption in the production process of the tanning extracts is reduced and the production efficiency is improved.

Owner:陈晓程

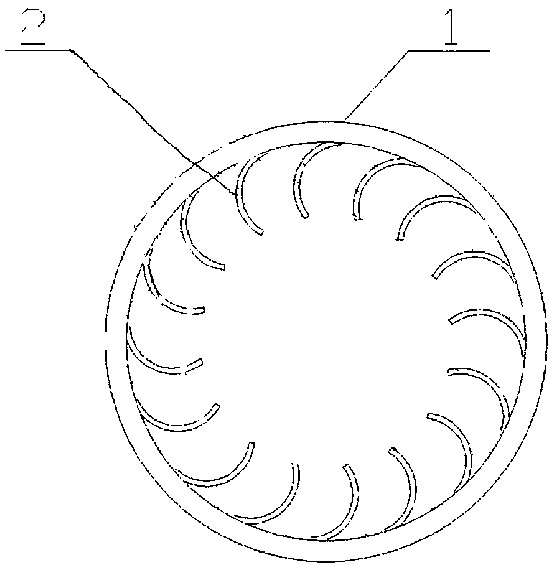

Dryer material lifting mechanism

InactiveCN108826956ALarge scattering areaEvenly distributedDrying solid materialsEngineeringMechanical engineering

The invention relates to a dryer material lifting mechanism. Aiming at the design of a material lifting plate in the prior art, the structure and the position distribution are improved; based on no influence on the material lifting operation, lifted material blocks are effectively prevented from falling and rupturing; and meanwhile, the drying efficiency is improved.

Owner:李晓

Efficient concentrator

ActiveCN106110694AReduce the temperatureRelieve pressureEvaporator accessoriesMultiple-effect evaporationGas phaseAgricultural engineering

The invention discloses an efficient concentrator. A discharging hole of a balance tank is connected with a discharging pipe; a separation device comprises a plate type evaporator and a separation tank; two or more than two groups of separation devices are arranged; the discharging pipe is connected with a raw material inlet of the first-grade plate type evaporator; a liquid-phase outlet of the former grade of separation tank is communicated with the raw material inlet of the plate type evaporator of the next grade of separation device; the liquid-phase outlet of the final grade of separation tank is connected with a liquid outlet pipe; a gas-phase outlet of the former grade of separation tank is communicated with a steam inlet of the next grade of plate type evaporator; the gas-phase outlet formed in the top of the separation tank of the final grade of separation device is communicated with a solvent inlet of a plate type condenser; a steam inlet pipe of the first-grade plate type evaporator is connected with an outlet of a spraying pump; an inlet of the spraying pump is connected with a fresh steam general pipe; an air suction hole of the spraying pump is communicated with a steam channel of each plate type evaporator; a steam condensed water outlet of the first-grade plate type evaporator is connected with a water discharging pipe and the water discharging pipe is communicated with the steam inlet pipe of the first-grade plate type evaporator through a pipeline.

Owner:山东精鹰机械制造有限公司

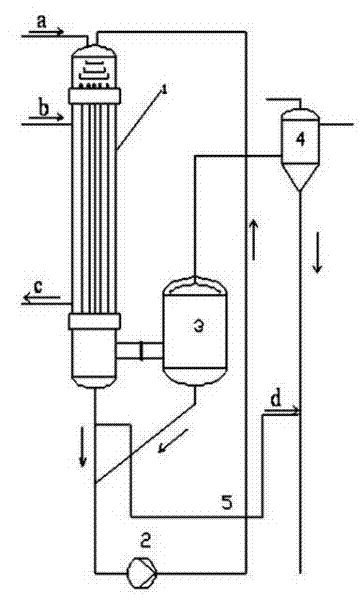

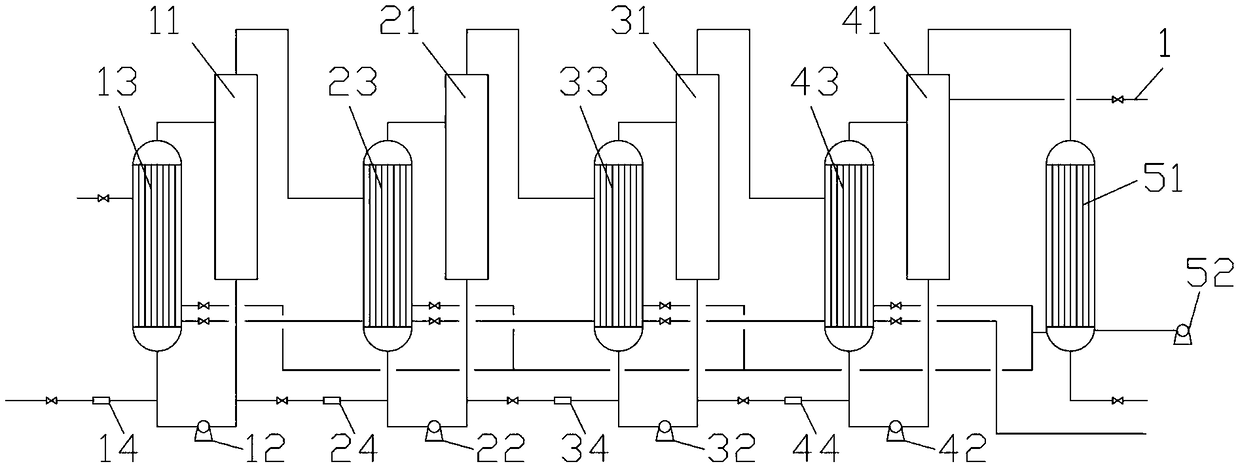

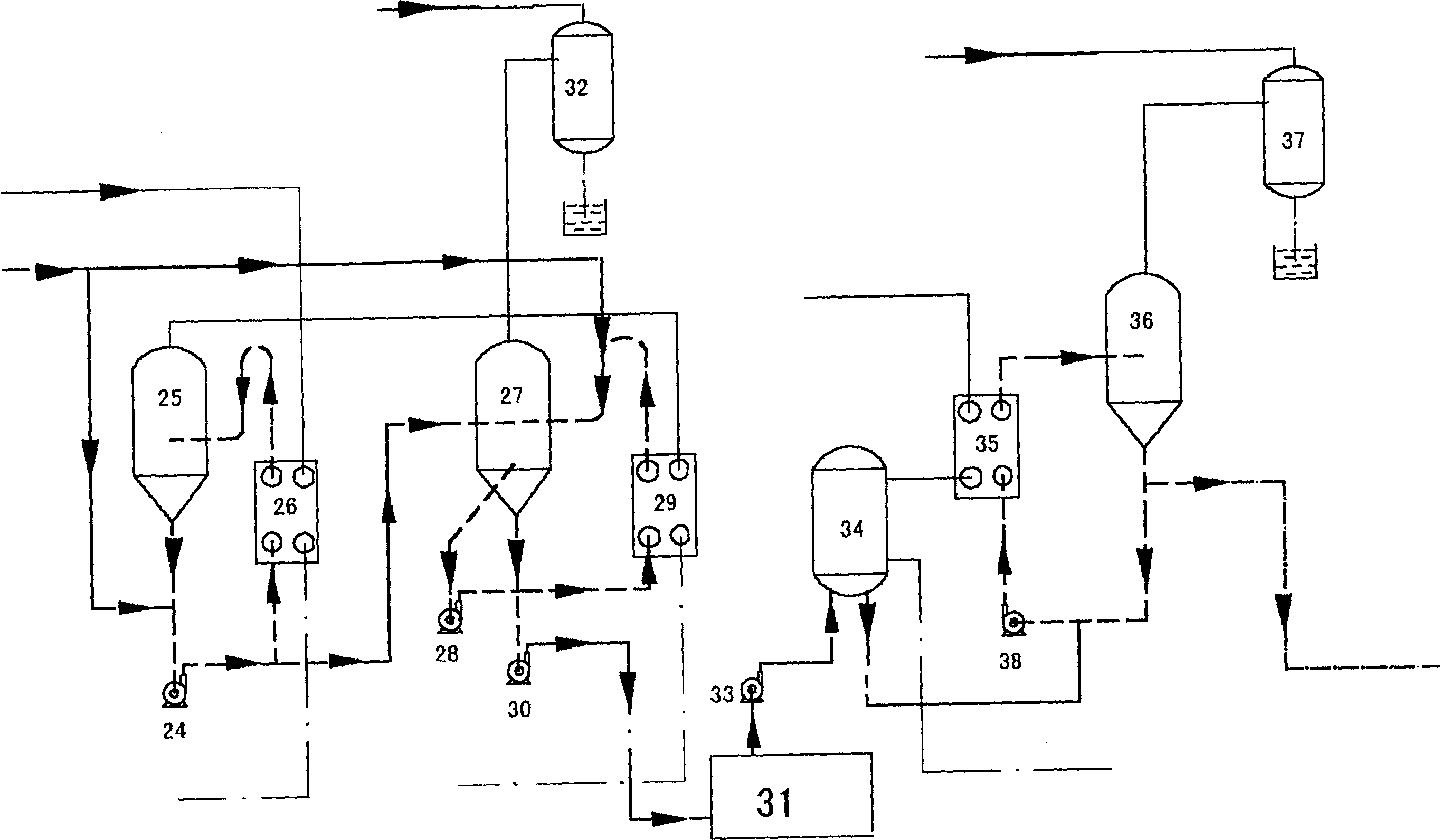

High-efficiency energy-saving nmmo solution concentration system and method

ActiveCN108823684AEfficient use ofReduce consumptionArtificial filament recoveryTextile/flexible product manufactureHigh concentrationEvaporation

The invention relates to a high-efficiency energy-saving nmmo solution concentration system and method. The concentration system comprises at least two stages of concentration units arranged in sequence. The each stage concentration unit comprises a separator and a heater communicated through a connecting pipe and mutually circulating materials. The separator is provided with a secondary steam outlet. A steam outlet of the last stage of the concentration unit is used for discharging excess secondary steam. A steam outlet of the separator of each one of other concentration units is communicatedwith the heater in the next stage of the concentration unit through a gas outlet pipe. The heaters are provided with solution outlets. A solution outlet of the heater of the first stage of the concentration unit discharges a concentrated high-concentration nmmo solution through a liquid outlet pipe. A solution outlet of the heater of each one of other concentration units is communicated with theseparator of the previous stage of the concentration unit through a liquid outlet pipe. Through the countercurrent decompression evaporation system and method, low-concentration low-temperature evaporation and high-concentration high-temperature evaporation are realized and the secondary steam is effectively utilized as a heating heat source.

Owner:唐山三友集团兴达化纤有限公司 +1

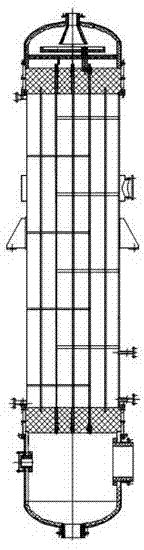

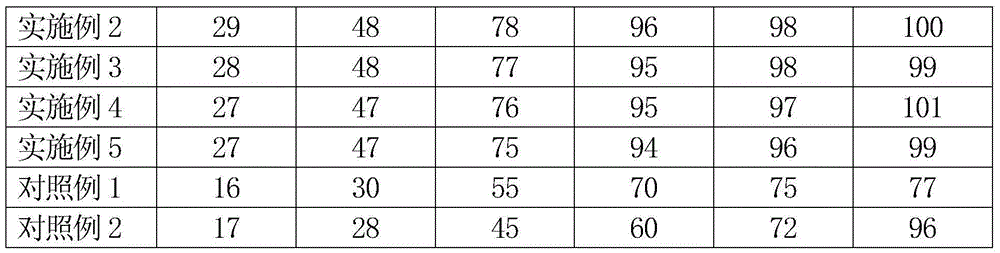

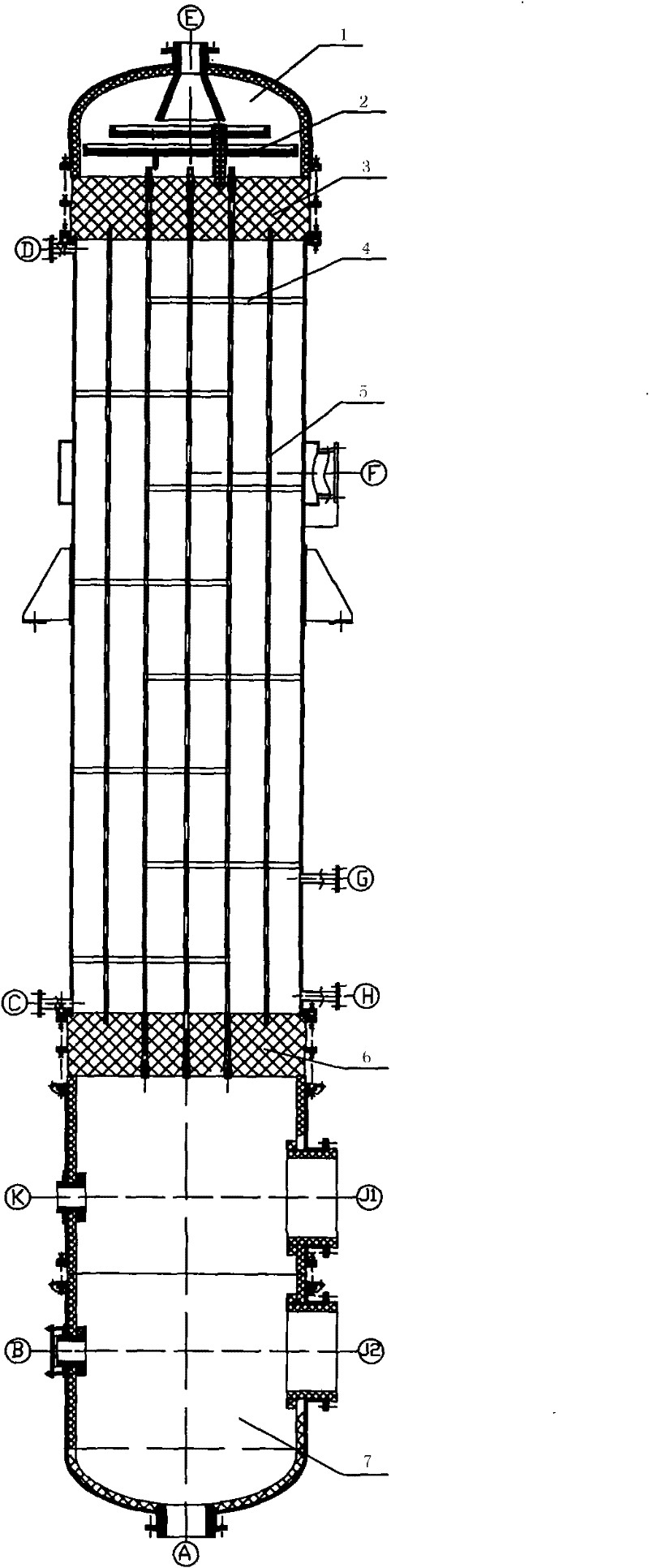

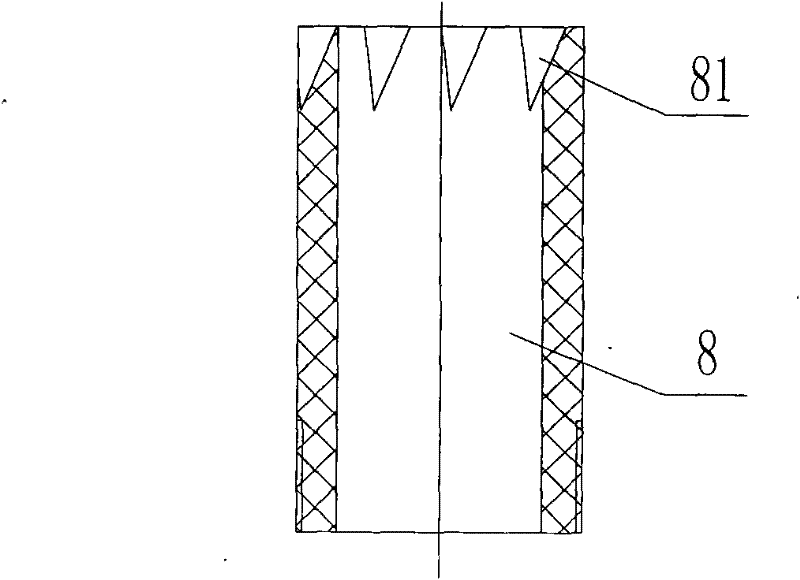

Shell and tube graphite falling film evaporation heater

The invention discloses a shell and tube graphite falling film evaporation heater, which comprises an upper tube box, a graphite liquid distribution device, an upper sealing element, a graphite heat exchange assembly, a lower sealing element and a lower tube box, wherein the upper tube box, the upper sealing element, the graphite heat exchange assembly, the lower sealing element and the lower tube box are sequentially overlapped from top to bottom. The graphite heat exchange assembly comprises more than two graphite heat exchange tubes, a sealing assembly and a tube plate, the sealing assembly is arranged between the graphite heat exchange tubes and the pipe plate in a sealed way, and in addition, the graphite heat exchange tubes are modified phenolic resin profiling graphite tubes. Therefore, the modified phenolic resin profiling graphite tubes are adopted as the graphite heat exchange tubes, the shell and tube graphite heat exchange tubes can be used for the falling film evaporation heater, the defects of the traditional shell and tube graphite heat exchanger are overcome, the use range of the shell and tube graphite heat exchanger is enlarged, the evaporation intensity is high, the heat exchange area is small, and the material circulation quantity is small.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

Continuous preparation technology of m-methyl benzoyl chloride

InactiveCN105348085AImprove heat transfer coefficientHigh evaporation strengthOrganic compound preparationCarboxylic compound separation/purificationBenzoic acidDistillation

The invention relates to a continuous preparation technology of m-methyl benzoyl chloride, and belongs to the technical field of fine chemical engineering. The continuous preparation technology comprises the steps of adding m-methyl benzoic acid, thionyl chloride and an organic solvent in a reaction kettle for reaction under a condition that a phase transfer catalyst exists, and obtaining reaction liquid; then adding the reaction liquid in a rectifying tower for carrying out normal-pressure rectifying so as to recycle the thionyl chloride and the organic solvent in the reaction liquid, and obtaining a m-methyl benzoyl chloride crude product; adding the m-methyl benzoyl chloride crude product in a film evaporator to carry out pressure-reduction distillation, and obtaining the m-methyl benzoyl chloride. According to the continuous preparation technology disclosed by the invention, the problems existing in a batch method / technology that the product quality is unstable, the automation degree of a device is low, and the labor intensity is large are solved; the continuous preparation technology has the characteristics that the technological route is concise, the production period is short, and the product yield is high; a side reaction can be prevented from being generated while the production capacity is increased.

Owner:SHANDONG KAISHENG NEW MATERIALS

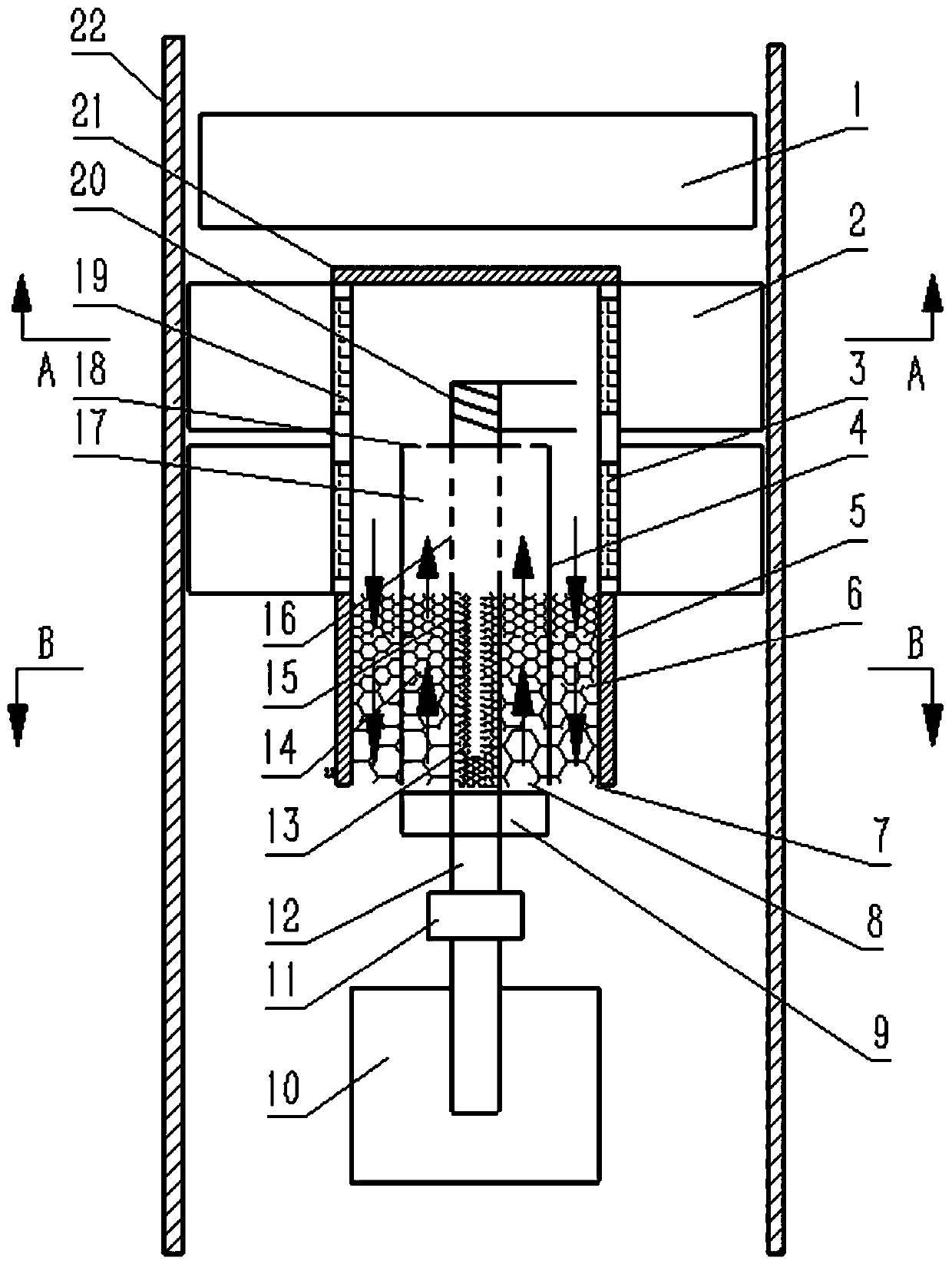

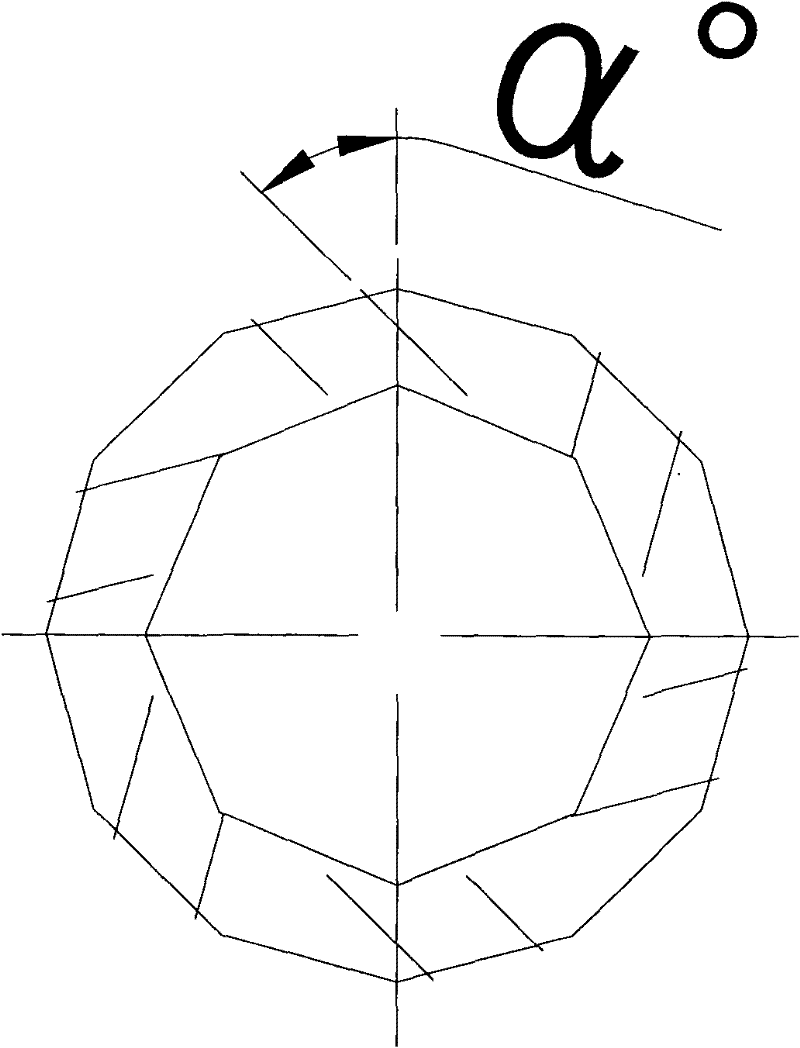

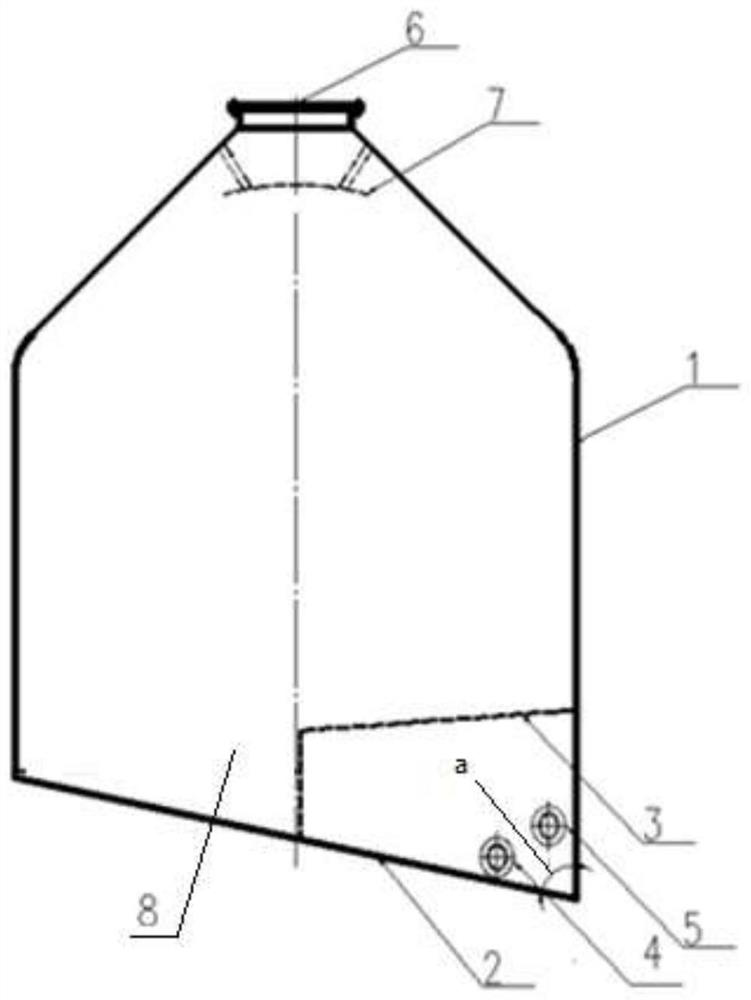

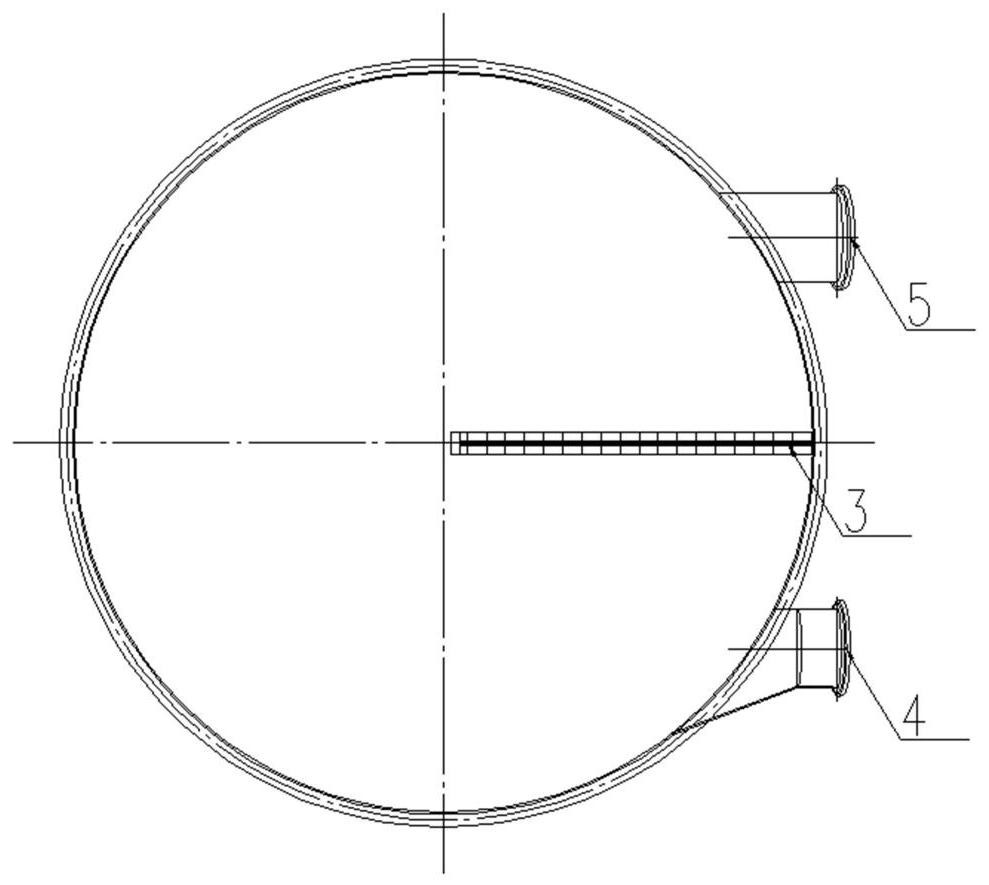

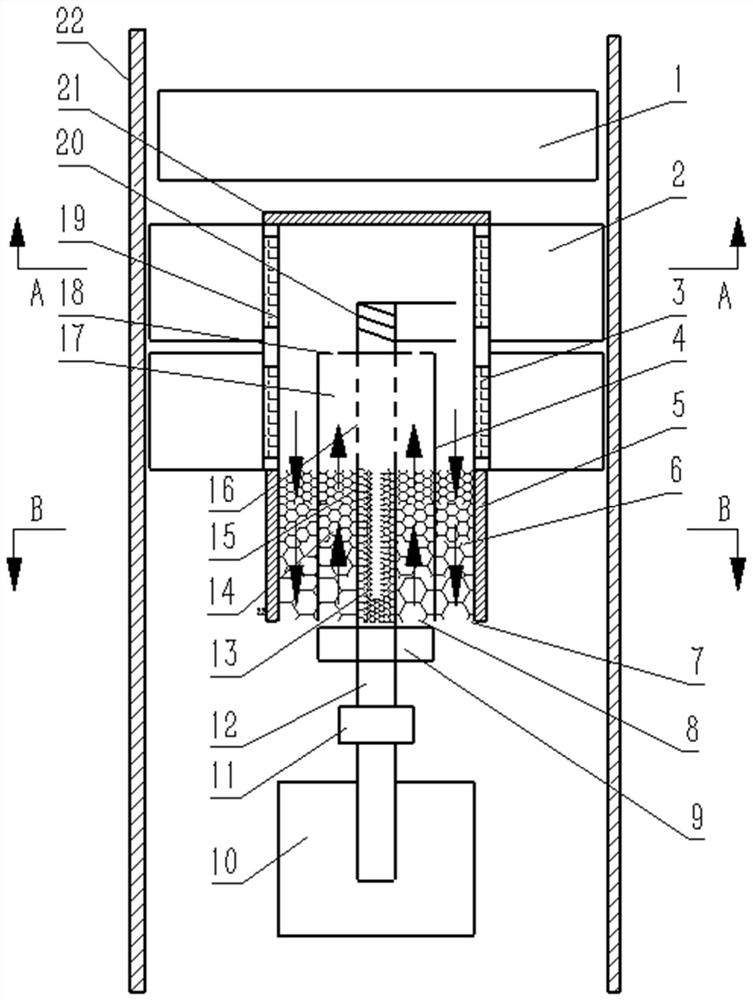

A system and method for adjusting water film coverage of supercritical water oxidation evaporation wall reactor

ActiveCN109052614BRegulate coveragePromote formationWater contaminantsWater/sewage treatment by oxidationPhysical chemistryEnvironmental engineering

The invention discloses a system and a method for adjusting a water film coverage rate of a supercritical water-oxidation transpiring wall reactor. The system comprises a transpiring wall water pump,a gas supercharging pump, a material pump and a supercritical water-oxidation transpiring wall reactor; the supercritical water-oxidation transpiring wall reactor is a cylindrical shape and comprisesan outer pressure-bearing wall, and a cylindrical porous transpiring wall is arranged in the outer pressure-bearing wall; an annular space formed in the porous transpiring wall is a supercritical water-oxidation reaction area; an outlet of the transpiring wall water pump is connected with a water inlet of the porous transpiring wall by virtue of a pipeline; outlets of the gas supercharging pump and the material pump are connected with an inlet of the supercritical water-oxidation transpiring wall reactor by virtue of a pipeline; the porous transpiring wall adopts a conical structure; the wallthickness of the porous transpiring wall is gradually increased from top to bottom; and the cross section of a single side wall of the porous transpiring wall is a right-angle trapezoidal shape. By improving the transpiring wall structure and controlling the parameters, the formation of a water film can be optimized, and the system and the method can be used for optimizing and adjusting the performance parameters of the water film of the supercritical water-oxidation transpiring wall reactor.

Owner:XI AN JIAOTONG UNIV +1

A method for optimally adjusting water film thickness in supercritical water oxidation evaporation wall reactor

ActiveCN109133317BAdjustable thicknessPromote formationWater contaminantsWater/sewage treatment by oxidationChemical physicsPhysical chemistry

The invention discloses a method for optimally regulating the thickness of a water film of a supercritical water oxidation and evaporation wall type reactor. The method is based on a system for adjusting the coverage rate of the water film of the supercritical water oxidation and evaporation wall type reactor. The system comprises an outer pressure bearing wall. A barrel-shaped porous evaporationwall is arranged in the outer pressure bearing wall. An outlet of an evaporation wall water pump is connected with a water inlet of the porous evaporation wall through a pipeline. Outlets of a gas booster pump and a material pump are connected with an inlet of the supercritical water oxidation and evaporation wall type reactor through pipelines. The porous evaporation wall is of a conical structure. The thickness of the porous evaporation wall is gradually increased from top to bottom. The section of the porous evaporation wall is a right trapezoid. The method includes the steps that the thickness of the water film is adjusted by adjusting the evaporation intensity, the concentration of organic raw materials, the preheating temperature of the organic raw materials, the evaporation water inlet temperature and branch evaporation wall water flow proportions. The method can be applied to optimally adjusting performance parameters of the water film of the supercritical water oxidation and evaporation wall type reactor.

Owner:XI AN JIAOTONG UNIV +1

High Level Flash Cooler for Wet Process Phosphoric Acid

ActiveCN112973163BReduce intensityGuaranteed StrengthVacuum distillation separationFlash distillationO-Phosphoric AcidCooling effect

The invention discloses a high-level flash cooler for wet-process phosphoric acid, which solves the problems of the existing high-level flash cooler that materials are easy to boil, easy to accumulate, difficult to clean and high investment cost. The technical solution includes a casing provided with a feed pipe, a discharge pipe and a gas outlet, the bottom surface of the casing is a slope, the feed pipe and the discharge pipe are located on the side wall of the casing at the lower end of the slope, the A partition is arranged between the feed pipe and the discharge pipe at the bottom of the housing, the rear end of the partition is fixed on the housing side wall at the lower end of the slope, and there is a gap between the front end and the housing side wall at the high end of the slope. The invention has extremely simple structure, easy operation, low production cost and investment cost, effectively reduces the occurrence of accumulation and blockage problems, high safety and reliability, and good flash cooling effect.

Owner:WUHUAN ENG

Regenerative drying method for titanium silicalite molecular sieve catalyst

InactiveCN102716765ADry evenlyPrevent oxidationMolecular sieve catalystsCatalyst regeneration/reactivationMolecular sieveWater vapor

The invention relates to a regenerative drying method for a titanium silicalite molecular sieve catalyst. When the titanium silicalite molecular sieve catalyst is regenerated, titanium silicalite molecular sieve catalyst solution is added into a vacuum rake dryer, and vapor is used as a heating medium for indirectly heating to obtain the dried titanium silicalite molecular sieve catalyst. In the regenerative drying method, the evaporation intensity is high, materials are uniformly dried, oxidization and overheating are avoided, and products with the moisture content lower than 5% can be obtained and can be packaged without crushing operation. As the water vapor is used as the heating medium, the materials are sufficiently mixed and sufficiently exchange heat in a cylinder when stirred, energy consumption is reduced, and the materials are conveniently recycled.

Owner:FUJIAN JINJIANG PETROCHEM

Evaporator and process for continuously producing 38-58% liquid calcium chloride

InactiveCN1121252CImprove heat transfer efficiencyIncrease evaporation rateEvaporationChemical industryPhysical chemistry

An evaporator and its continuous production process of 38-58% calcium chloride liquid, the process flow is the use of forced circulation of steam with low enthalpy value and multi-effect evaporation in a special liquid feeding mode. The heating chamber is made of titanium or stainless steel. The U-shaped pipe of the upper circulation pipe is a variable diameter pipe. The outlet of the circulating liquid is drawn from the center of the separation chamber. In the upper part of the descending section, the liquid inlet of the separation chamber is 1.8-6.5m away from the demister, the volume below the liquid inlet is 55-95% of the system volume, and the finished liquid outlet is at the bottom of the separation chamber. The invention has the advantages of less investment, short process, simple operation and good energy-saving effect. Applicable to ammonia and alkali plants, salt chemical industry, paper making, etc. 4 In the scarring process.

Owner:岳中洲

A thermoelectric conversion device based on liquid fuel combustion

ActiveCN110594730BIncrease temperatureHigh evaporation strengthBurnersIndirect carbon-dioxide mitigationCombustorElectrical battery

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com