Vertical combined sludge drying device

A sludge drying and drying technology, which is used in equipment for recycling waste resources, environmental protection innovation technology - sludge field, can solve the problems of slow drying time and insufficient drying degree of sludge, and achieve Reasonable production process, saving manpower and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

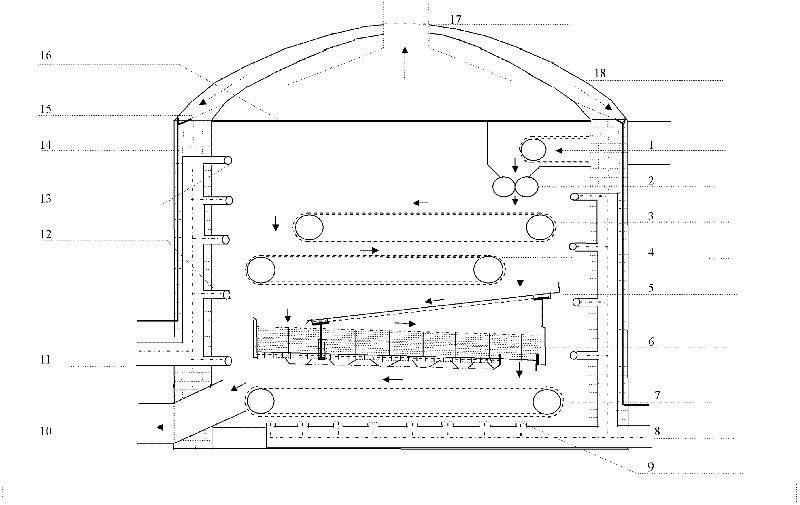

[0016] Such as figure 1 A vertical combined sludge drying device is shown, its core components are mainly composed of upper, middle and lower conveyor belts arranged in three layers, vibrating lower plates and vibrator screens arranged between the middle and lower layers. The conveyor belt is made of aluminum alloy crawler with large gap.

[0017] This vertical combined sludge drying device has a drying room. Above the steel structure beam on the top of the drying room is an interlayer arched roof of the drying room. There is a top hot steam recovery in the middle of the interlayer arched roof of the drying room. There is a water vapor return groove at the lower edge of the interlayer arched roof in the drying room, and there is a main hot air duct in the wall of the drying room. The entrance of the main hot air duct is outside the wall of the drying room. Inside the partition wall, there is also a main hot air duct on the ground of the drying room. The inlet of the main hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com