Patents

Literature

326results about How to "Evenly wrapped" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

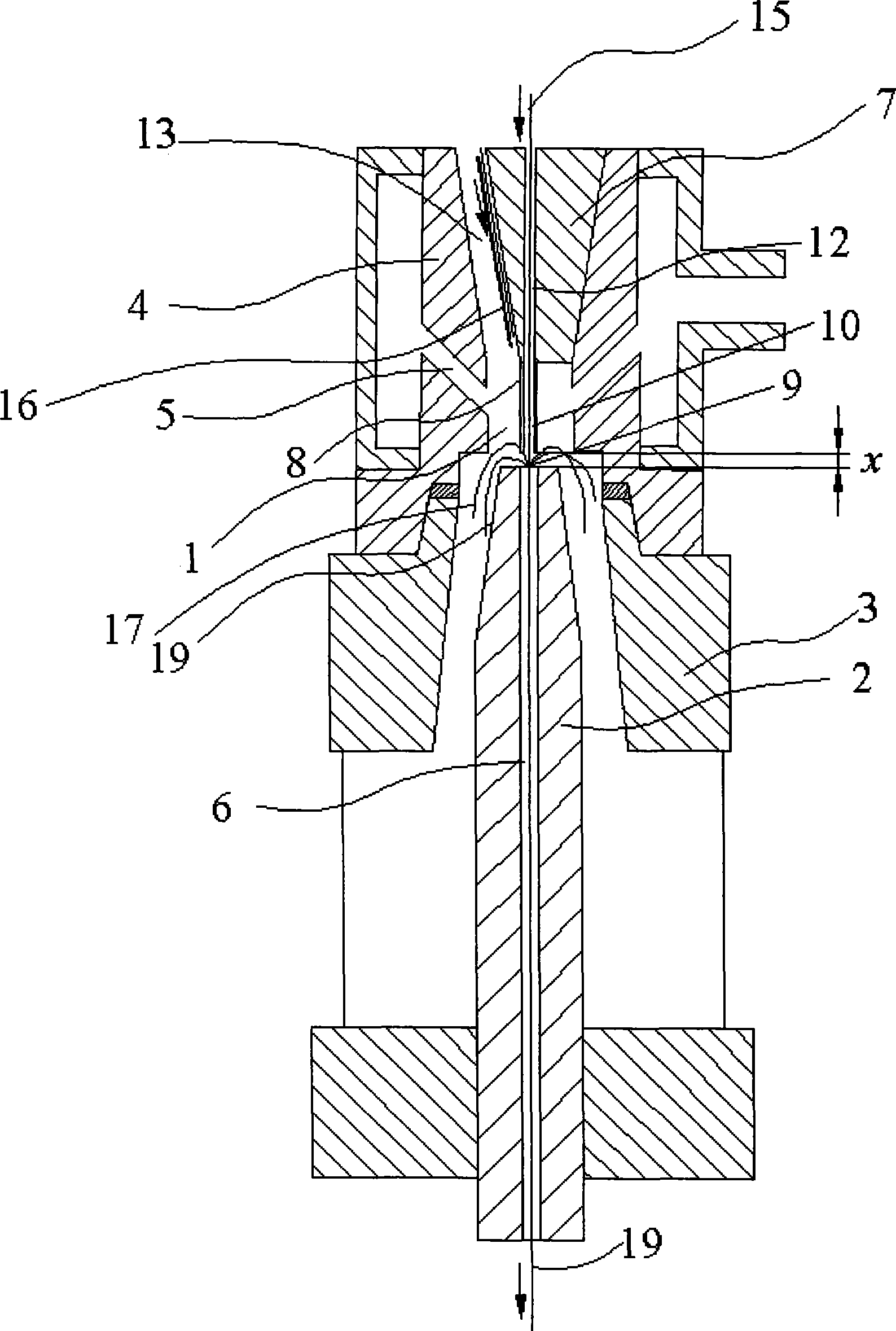

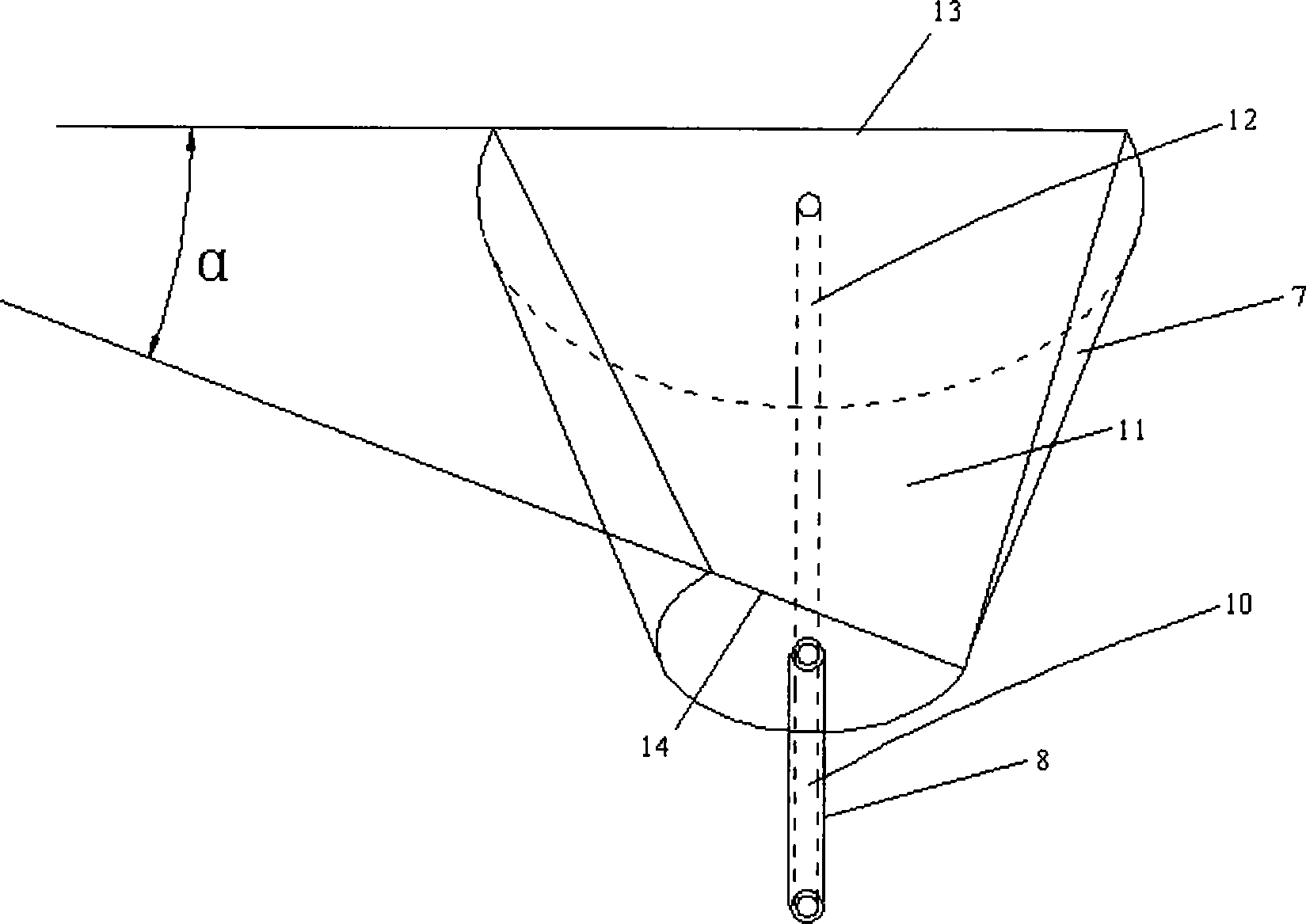

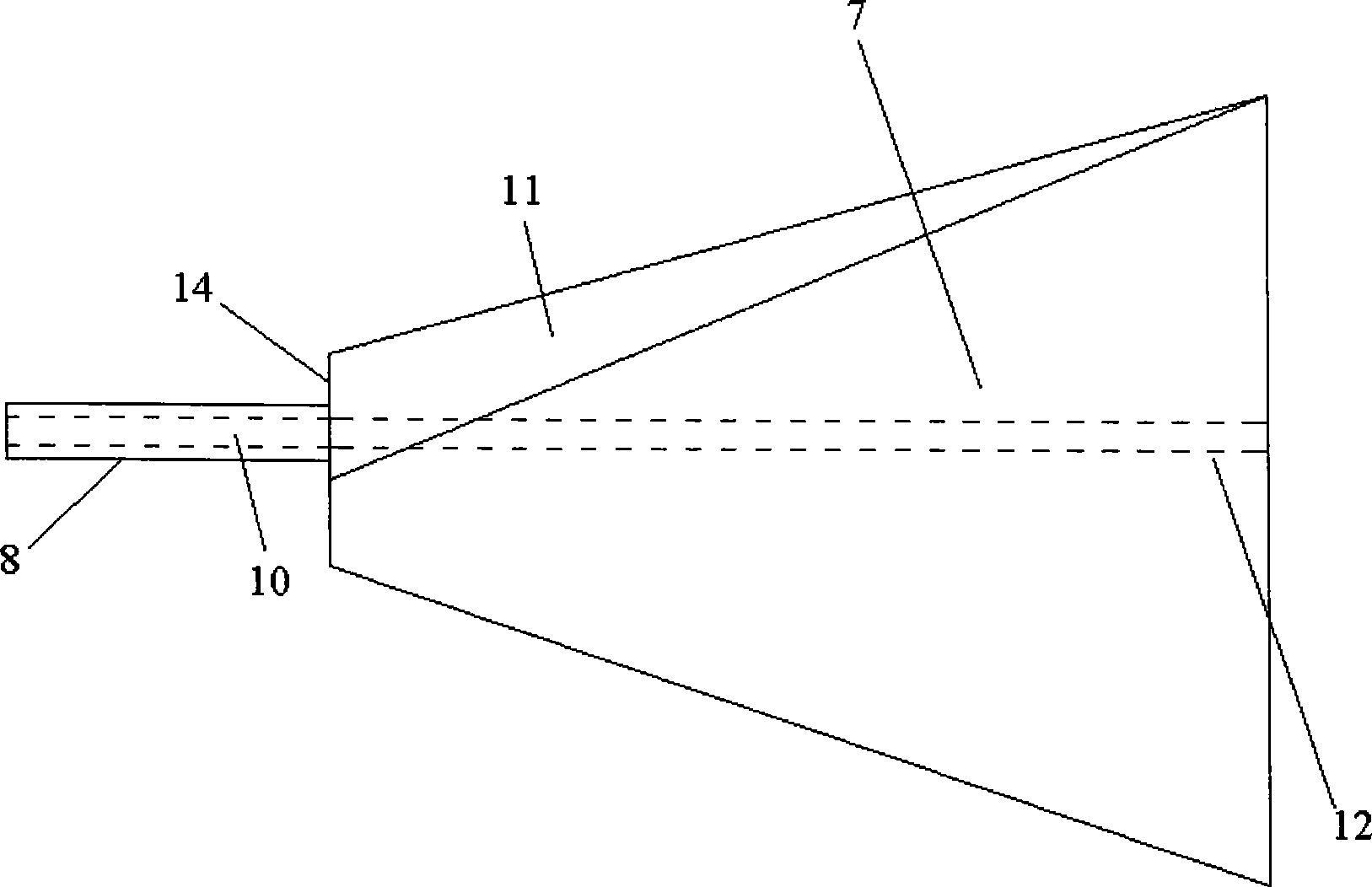

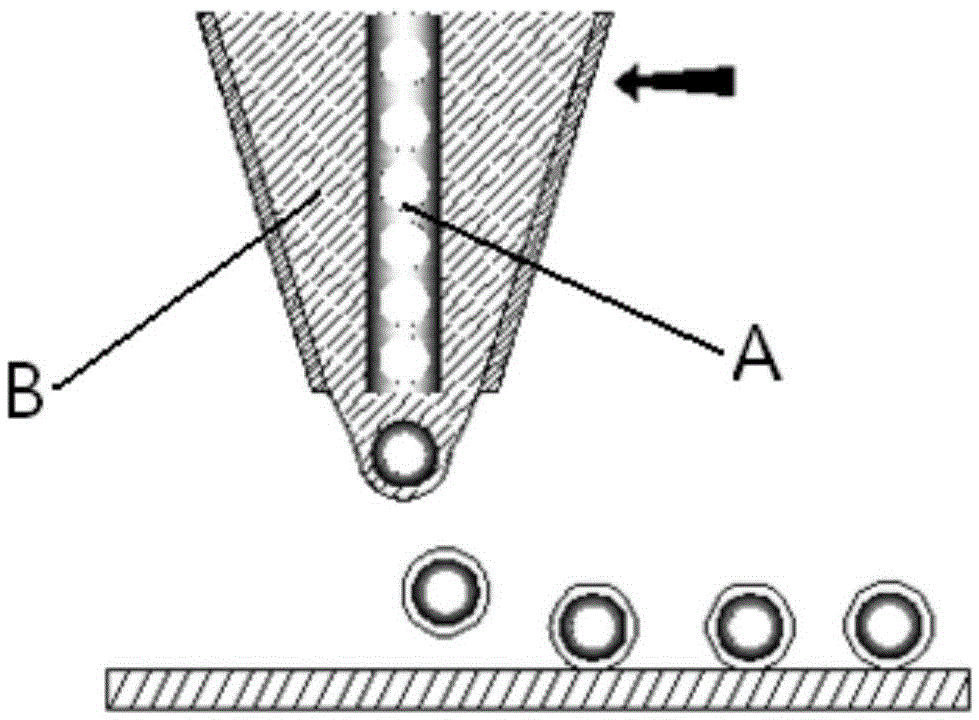

Air injection air vortex spinning apparatus capable of producing composite yarn

InactiveCN101368305AEvenly wrappedContinuous wound-up machinesOpen-end spinning machinesYarnFiber bundle

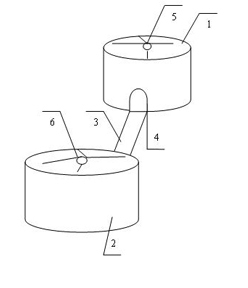

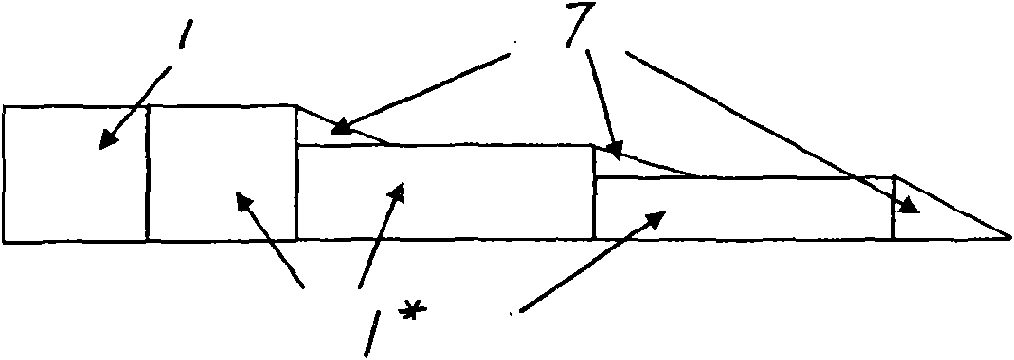

The invention provides an air-jet vortex spinning device which can be used to produce core-spun yarn. The air-jet vortex spinning device comprises a vortex chamber, a spindle-like doffing tube, a vortex tube connected with a fixing bracket, and an air jet orifice arranged inside the vortex tube. The air-jet vortex spinning device is characterized in that a truncated cone shaped or cylindrical fiber and core yarn guiding assembly is arranged at the entrance of the vortex tube. The air-jet vortex spinning device has the advantages that the air-jet vortex spinning device is capable of enabling the short fiber bundles to evenly wrap and twine the core yarn, and the core-spun yarn produced by the device is even in quality. The air-jet vortex spinning device ensures that the core yarn is totally wrapped by short fiber bundles, thus improving wear resistance of the core-spun yarn.

Owner:DONGHUA UNIV

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

Wind turbine blade structure, processing and forming method and applications thereof

InactiveCN101666290AEasy to placeEvenly wrappedFinal product manufactureMachines/enginesFiberTurbine blade

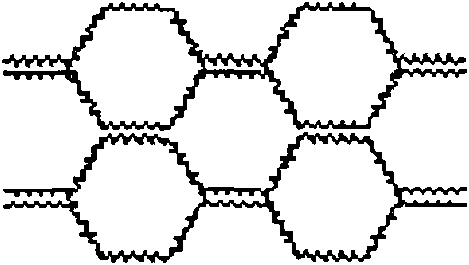

The invention relates to a wind turbine blade structure, a processing and forming method and applications thereof. The blade consists of a root segment, a main beam and a covering that wraps the rootsegment and the external side of the main beam; the blade is fixed with a wind wheel by a connecting piece that is arranged at the root segment, thus forming a spatial cantilever beam structure; at the main beam area and the root segment, one or more solid or hollow wedge-shaped columns are arranged between a top paving layer and a bottom paving layer; the wedge-shaped column at the internal-mostside of the root end is solid and is internally provided with the connecting piece, wherein the fiber cloth is arranged at least among the adjacent wedge-shaped columns at the internal-most side of the root segment and continuously intersects and enwinds the wedge-shaped columns in a horizontal S-shaped, thus forming an interlayer; and the top paving layer, the bottom paving layer and the fiber cloth interlayer are dipped and solidified to form a framework with a honeycomb-shaped section. The structure and the method have the advantages of: leading the once pouring of resin and once solidifying and forming for the large blade and the realizing of the pre-embedding of the connecting piece of the root part to be possible, dispersing the synergistic effect and solidifying shrinkage quantity of solidified heating of the bottom paving layer and the top paving layer by the wedge-shaped columns, and leading the unsaturated resin used as a substrate material to be possible.

Owner:黄争鸣

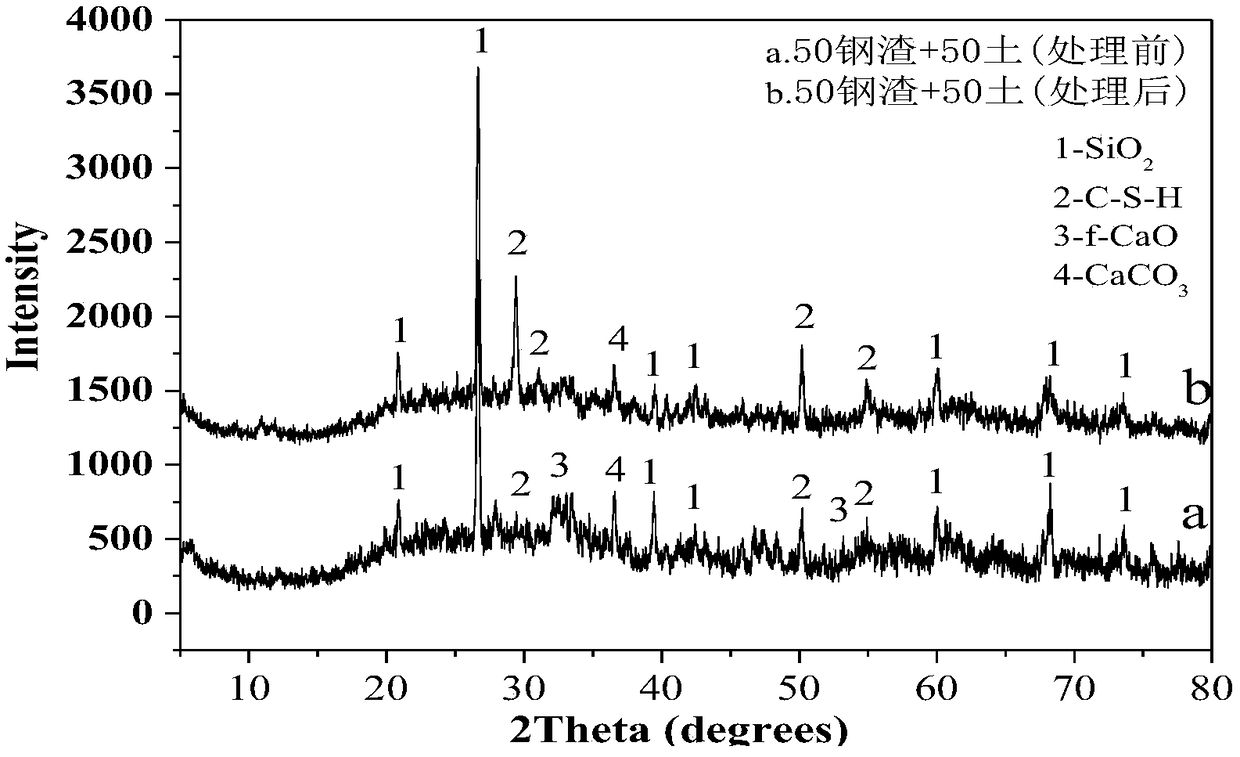

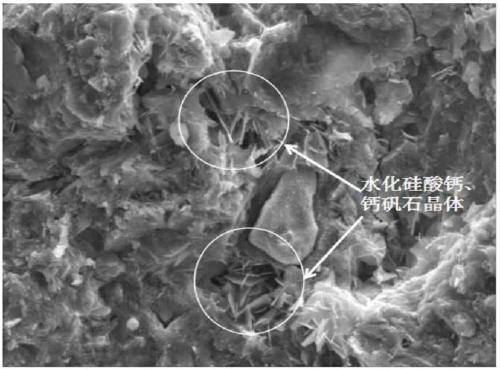

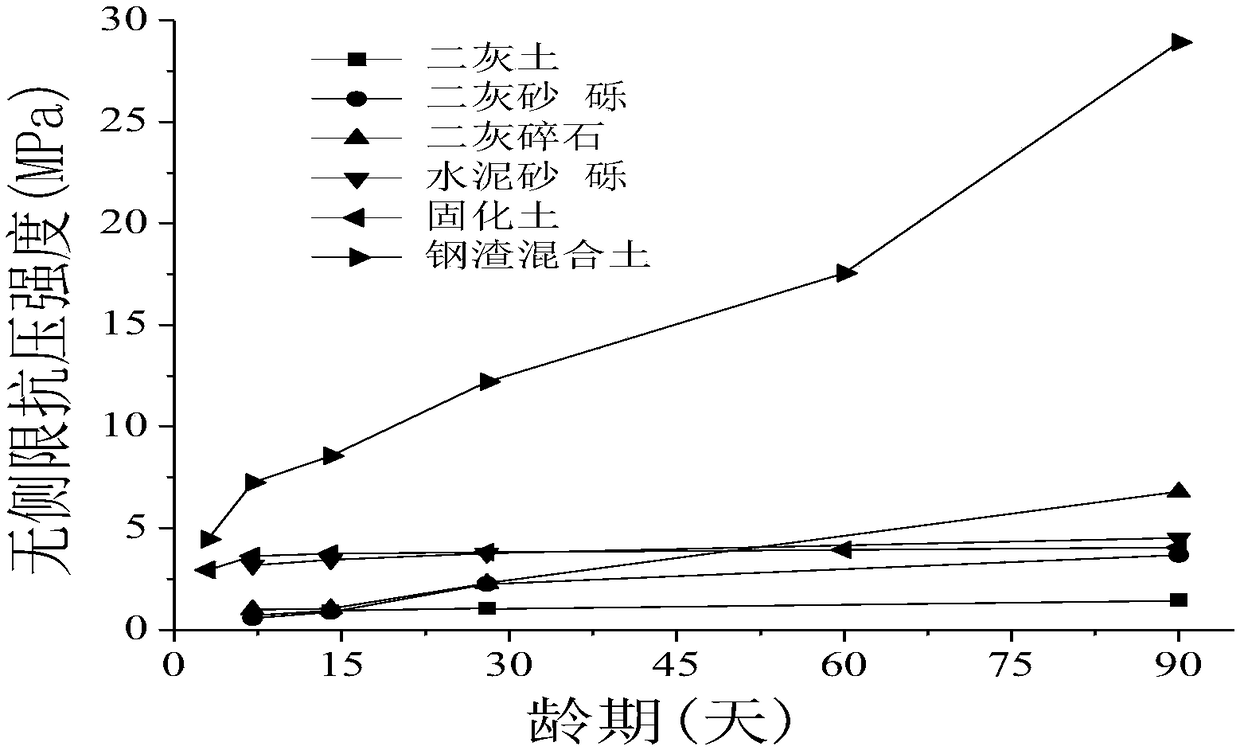

Novel steel slag composite soil road base material and preparation method thereof

The invention discloses a steel slag composite soil road base material and a preparation method thereof. The steel slag composite soil road base material contains the following materials in parts by weight: 0-15 parts of water, 40-80 parts of common soil, 20-60 parts of steel slag without ageing treatment, 5-25 parts of complexing agent, 1-5 parts of cement, and 0.01-0.05 part of modifying agent.The preparation method comprises the following steps: mixing the steel slag, the soil, the cement and the complexing agent and then performing a compaction test, and testing to obtain an optimal watercontent; smashing the steel slag; spraying tap water accounting for 50% of the total water amount, and sufficiently blending the steel slag with the complexing agent, to obtain a slag-powder mixture;spraying the modifying agent to the common soil and doping the redundant tap water, to obtain modified soil; blending and compacting the slag-powder mixture, the modified soil and Portland cement, toobtain a road base material. The steel slag composite soil road base material and the preparation method can sufficiently realize recycling of metallurgic solid water resource, and reduce pollution to the environment in the steel slag stacking and ageing process; also can effectively save the sandstone material, and avoid destruction of the ecological environment caused by sandstone material mining, and has remarkable economical and social benefits.

Owner:安徽马钢嘉华新型建材有限公司 +1

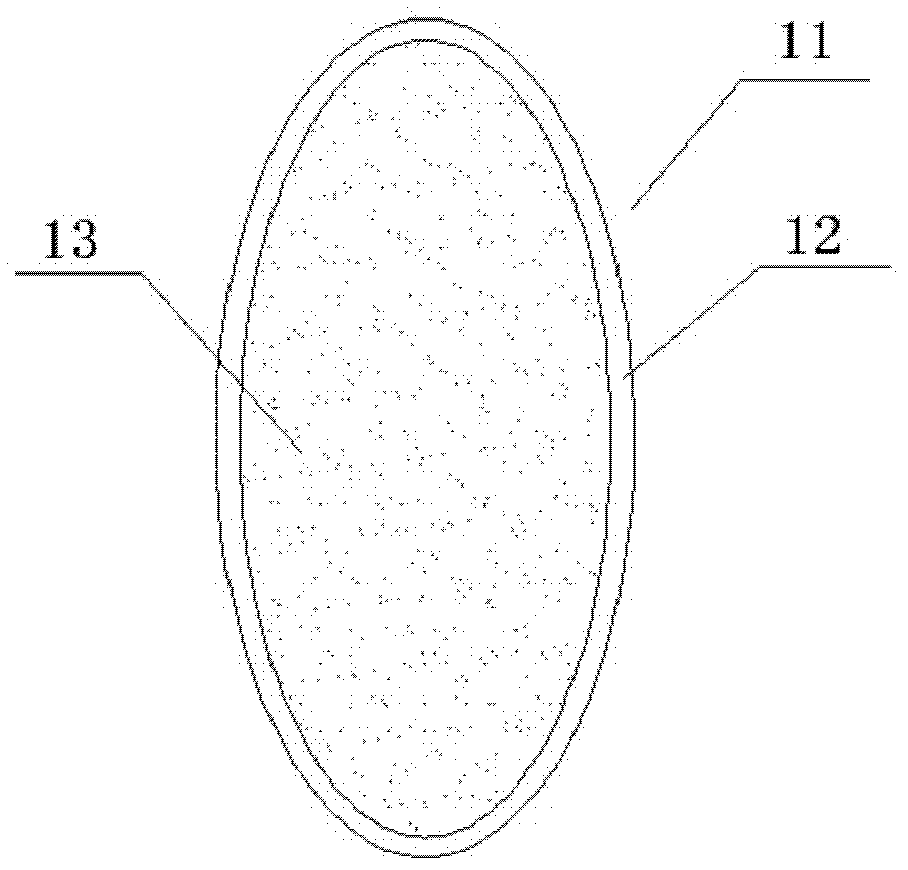

Synthetic rice capable of tonifying kidney and nourishing liver and preparation method thereof

InactiveCN103168996AEnhance physical vitalityImprove human immunityFood preparationBlack riceBiotechnology

The invention relates to the field of health-care food and in particular relates to synthetic rice. The synthetic rice capable of tonifying the kidney and nourishing the liver is characterized in that the raw materials of the synthetic rice include black rice, black beans, fleece-flower root, medlar, walnuts, black sesame and black ant powder. The synthetic rice is coated with a rice milk layer. The synthetic rice has mild efficacy, tonifies the kidney and nourishes the liver, blackens the hair and improves the eyesight, relieves fatigue, enhances the body vitality, has great effects for people with kidney deficiency, and can be eaten by the ordinary healthy people.

Owner:SHANGHAI YIYANGTANG FOOD TECH

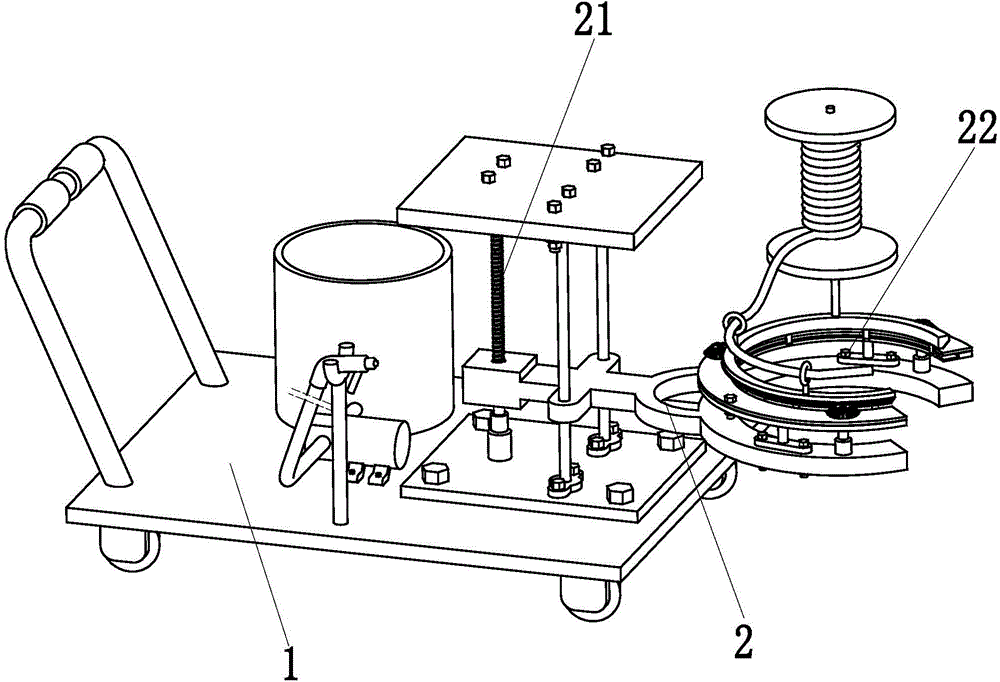

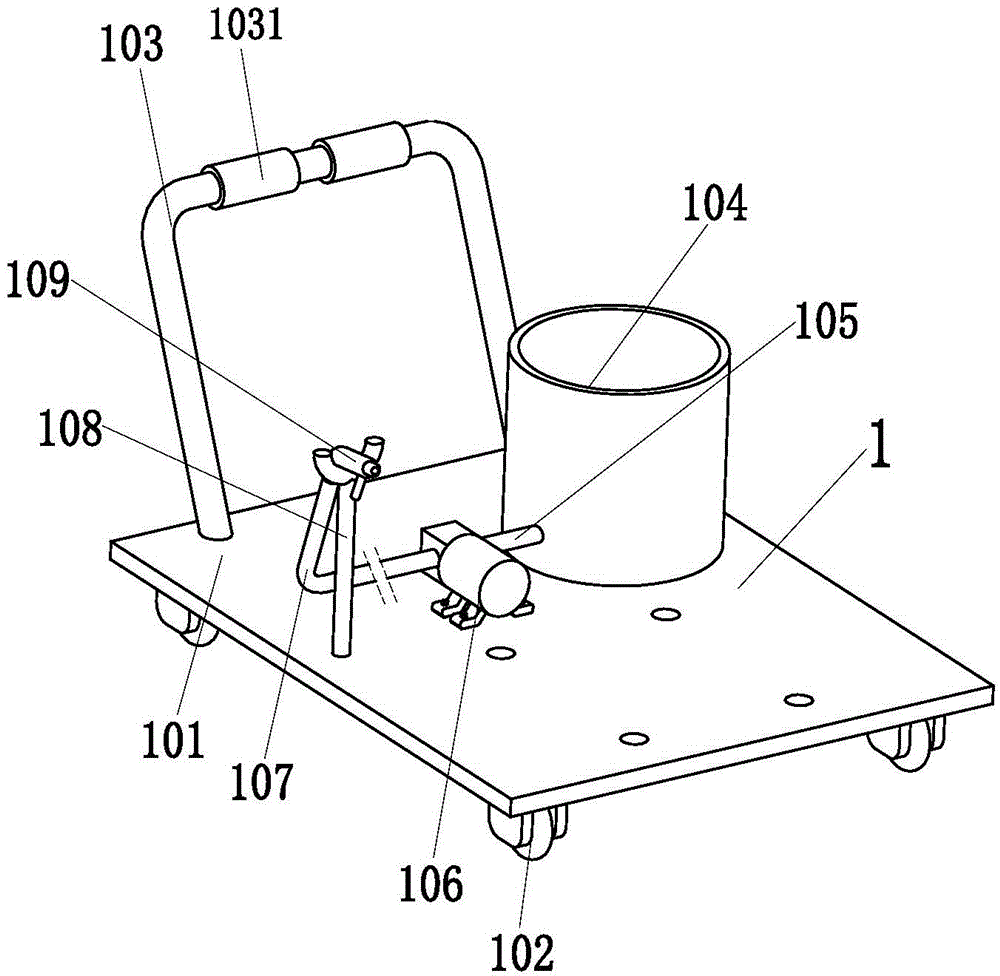

Spraying and binding machine

ActiveCN104429732AEvenly paintedWrap evenlySpraying apparatusPlant protective coveringsEngineeringUltimate tensile strength

The invention relates to a spraying and binding machine which comprises a spraying device and a binding system. The binding system and the spraying system are connected through bolts. The spraying device comprises an installation board, four universal wheels, a handrail, a liquid storage barrel, a first liquid conveying pipe, a liquid pump, a second liquid conveying pipe, a support and a spraying gun. The four universal wheels are symmetrically installed on the lower end face of the installation board. The handrail is welded to the left side of the upper end face of the installation board. The liquid storage barrel is placed on the installation board and connected with an inlet of the liquid pump through the first liquid conveying pipe. The liquid pump is installed on the installation board through bolts. An outlet of the liquid pump is connected with the second liquid conveying pipe. The support is welded to the installation board and provided with the spraying gun. The spraying gun is connected with the second liquid conveying pipe. The spraying and binding machine has the advantages that the structure is simple, manufacturing cost is low, operation is easy and convenient, labor intensity is low, work efficiency is high, trees are sprayed evenly, straw ropes are twisted evenly, and trunks can be rapidly and evenly sprayed or coated with the straw ropes in a twisted mode.

Owner:平湖市盛泰五金制品有限公司

Whole grain compound rice containing embryo and fabrication technique

InactiveCN103168997AHigh nutritional valueAvoid chippingFood preparationHorticultureArtificial foods

The invention relates to the field of artificial food, and particularly relates to compound rice, namely whole grain compound rice containing embryo. The whole grain compound rice comprises the raw materials of rice and wheat with embryo, wherein the raw material is extruded into granules after being crushed, and prepared into the whole grain compound rice; and a rice milk layer is coated at an outer layer of the whole grain compound rice. The broken rice which is neglected and abandoned by people in the past and other side grain ingredients are taken as raw materials and processed into healthy and delicious whole grain compound rice by a high-tech craft technique. The whole grain compound rice is green and environment-friendly, and the production cost can be reduced; nutritional ingredients of the whole grain compound rice are more abundant and balanced than those of common rice; and the requirements of human health are met.

Owner:SHANGHAI YIYANGTANG FOOD TECH

C / C-SiC composite material and preparation method and application thereof

ActiveCN107266075AConsistent performanceHigh hardnessFriction liningActuatorsCompression moldingFiber

The present invention discloses a C / C-SiC composite material and a preparation method and application thereof. The C / C-SiC composite is a multilayer symmetrical gradient structure, the symmetrical multilayer gradient structure comprises from the inner layer to the outer layer in turn a middle layer, a longitudinally-symmetrical second layer short-cut carbon fiber reinforced silicon carbide layer and a longitudinally-symmetrical first layer short-cut carbon fiber reinforced silicon carbide layer, the carbon fiber content of the first layer short-cut carbon fiber reinforced silicon carbide layer is lower than that of the second layer short-cut carbon fiber reinforced silicon carbide layer, and the middle layer is a 90 DEG and 45 DEG plain carbon fiber cloth interlaced superposed reinforced toughened interlayer. The C / C-SiC composite is prepared from short-cut carbon fiber, plain carbon fiber cloth, phenolic resin and industrial silica fume as raw materials by compression molding, curing, carbonization and infiltration. Products prepared by the C / C-SiC composite material have high density, excellent mechanical property, oxidation resistance, friction and wear resistance and fatigue resistance, and are suitable for the fields of high end industries such as high speed and high energy transportation vehicles.

Owner:HUNAN UNIV OF TECH

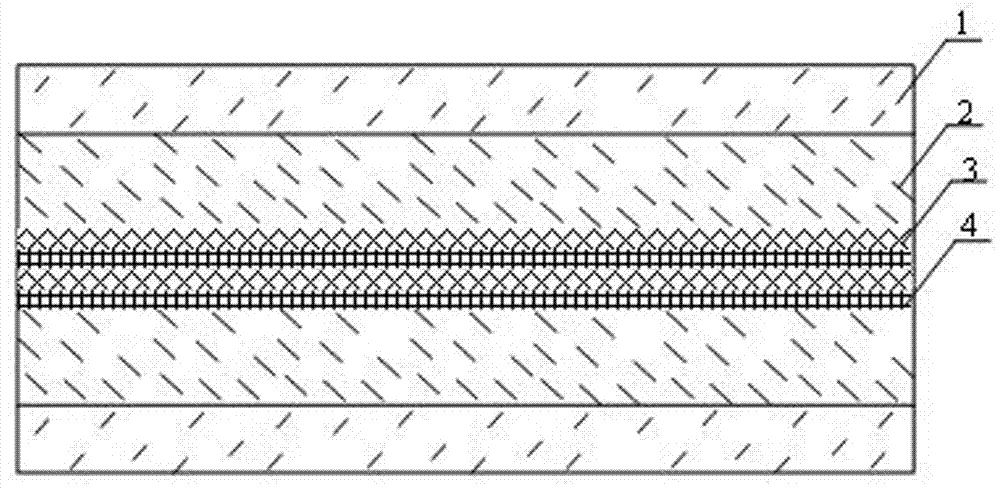

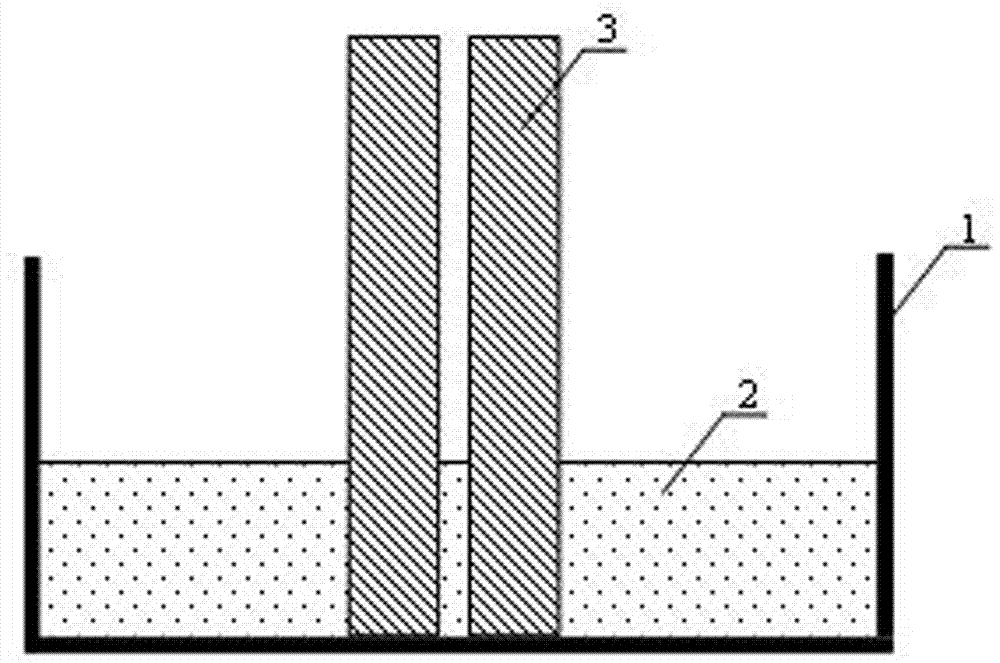

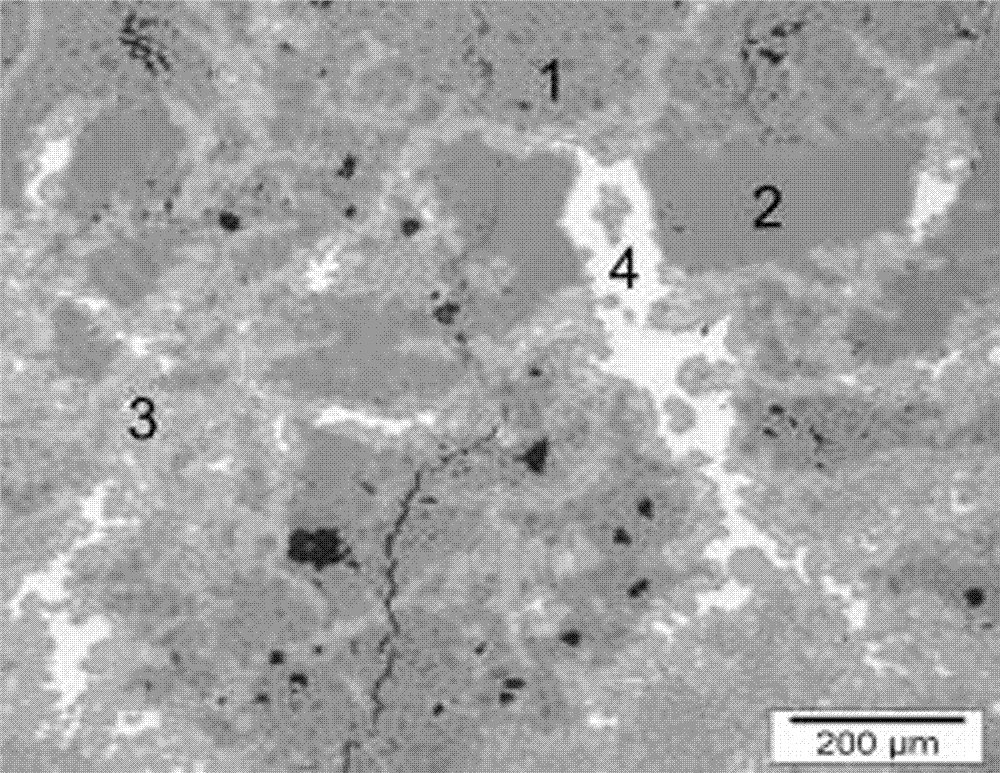

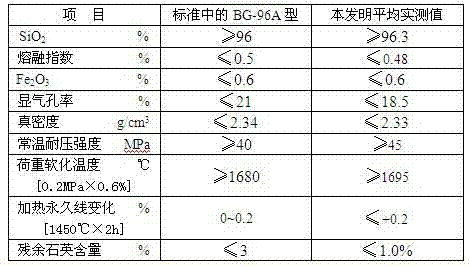

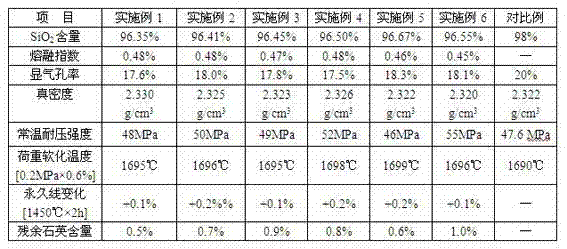

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

Synthetic rice with effects of blackening and caring hair and preparation process thereof

The invention relates to the field of health-care food and in particular relates to synthetic rice. The synthetic rice with the effects of blackening and caring hair is characterized in that the raw materials of the synthetic rice include black food and traditional Chinese food materials; the black food includes black sesame, black beans and black rice; and the traditional Chinese food materials include walnuts, fleece-flower root and medlar. The synthetic rice has the beneficial effects that due to adoption of pure natural plant ingredients, the synthetic rice can be taken for a long time and can be even eaten as staple food, is capable of improving satiety, and has the health-care effects of blackening and caring hair.

Owner:SHANGHAI YIYANGTANG FOOD TECH

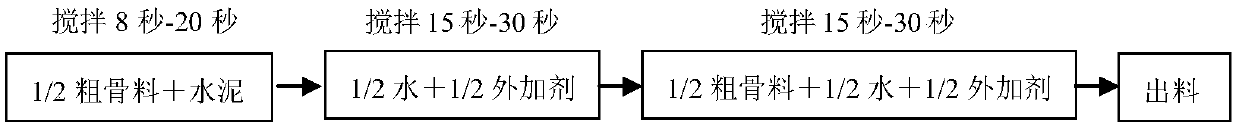

Preparation method for coal gangue aggregate no-sand porous plant-growing concrete

InactiveCN107857528ARealize comprehensive utilizationWide range of raw materialsPorosityPlant growth

The invention discloses a preparation method for coal gangue aggregate no-sand porous plant-growing concrete. The method comprises the following steps: taking coal gangue coarse aggregate as a skeleton structure, taking cement and fly ash as cementing materials, adding an admixture which is a water reducing agent, performing stirring step by step, performing vibration molding to obtain porous concrete, covering the concrete with a transparent plastic film, performing wet curing for 28 days, spraying an acetic acid aqueous solution at the surface of the porous concrete for alkali reducing treatment, detecting the pH value of the surface of the porous concrete, when the pH value is less than or equal to 9, stopping to spray the acetic acid aqueous solution, and performing natural drying to obtain the coal gangue aggregate no-sand porous plant-growing concrete. The concrete provided by the invention has the advantages of higher compressive strength, a large communicating porosity, good water permeability, and good air permeability; and the alkaline environment in gaps of the coal gangue aggregate no-sand porous plant-growing concrete after the pH value alkali reducing treatment is performed in a later period can be better improved to meet the environmental requirements of plant growth.

Owner:LIAONING TECHNICAL UNIVERSITY

Synthetic rice suitable for patients with diabetes mellitus and preparation method thereof

InactiveCN103169090AEnhance physical fitnessCan be eaten for a long timeFood preparationThirstBitter gourd

The invention relates to the field of health-care food and in particular relates to synthetic rice. The synthetic rice suitable for patients with diabetes mellitus is characterized in that the raw materials of the synthetic rice include coarse food materials and traditional Chinese medicine food materials; the coarse food materials include black beans, black sesame and oat; and the traditional Chinese medicine food materials include Chinese yam, kudzuvine root, Indian buead and bitter gourd powder. The raw materials are ground and then extruded into rice grains, thus preparing the synthetic rice; and the synthetic rice is coated with a rice milk layer. The synthetic rice has mild efficacy, tonifies the spleen and benefits qi, nourishes yin and activates collaterals, lowers blood sugar and quenches thirst, is suitable for people with diabetes mellitus, relieves the physical pains caused by diabetes mellitus to the patients while enabling the patients with diabetes mellitus to have satiety, and moreover enhances the immunities of the patients with diabetes mellitus.

Owner:SHANGHAI YIYANGTANG FOOD TECH

Inkjet head assembly of biological printer and biological printer

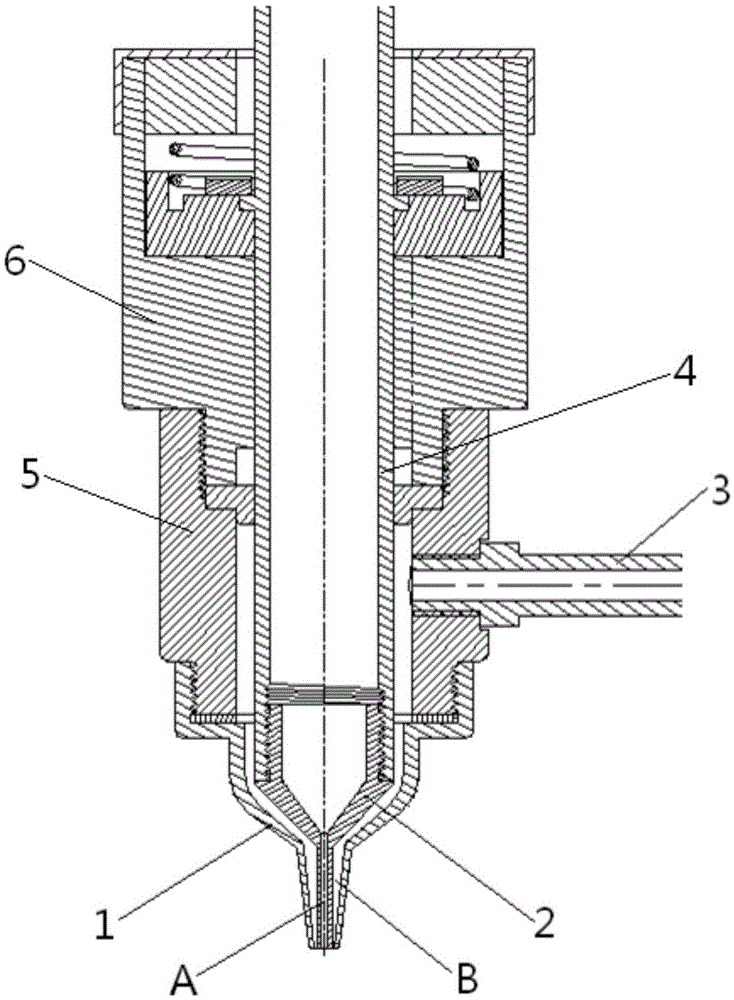

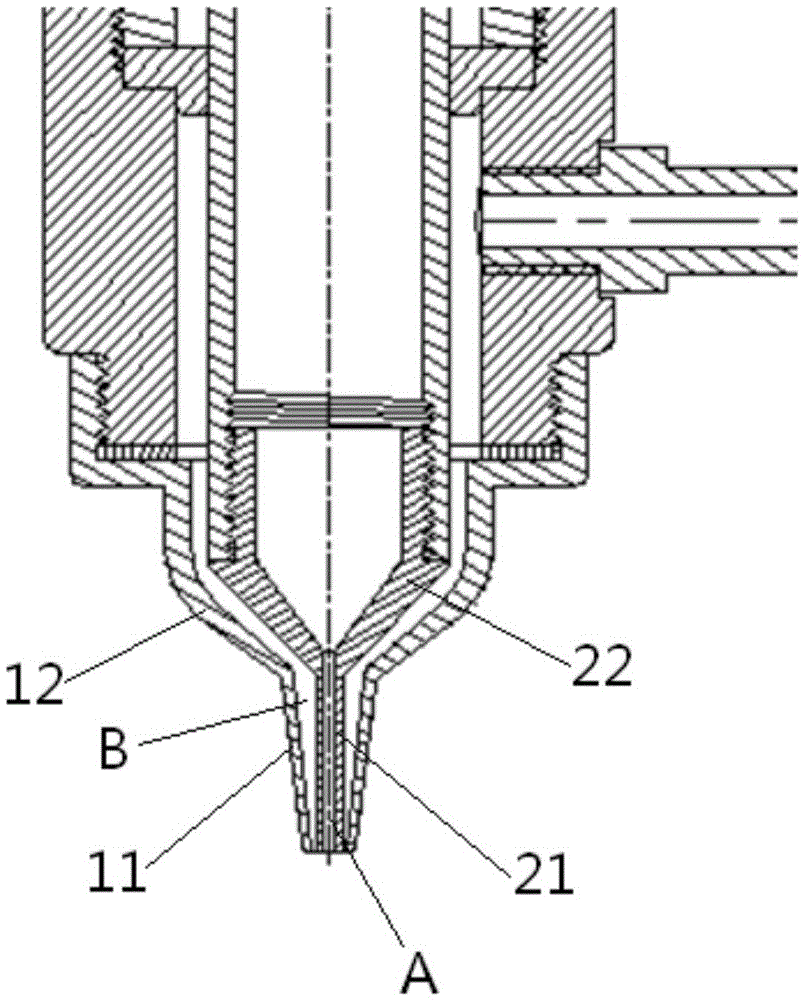

ActiveCN105647801AQuality improvementAvoid damageAdditive manufacturing apparatusTissue/virus culture apparatusEngineeringNozzle

The invention relates to an inkjet head assembly of a biological printer and the biological printer. The inkjet head assembly of the biological printer comprises an outer inkjet nozzle with a second channel and an inner inkjet nozzle with a first channel; the inner inkjet nozzle is coaxially arranged in the second channel; a first material channel is formed by the first channel; a second material channel is formed by an annular space between the outer inkjet nozzle and the inner inkjet nozzle; the second material channel surrounds the first material channel at an outlet of the first material channel and is used for enabling second materials ejected from an outlet of the second material channel to gather towards first materials ejected from the outlet of the first material channel so as to form a fluid printing unit. According to the inkjet head assembly, the second materials are uniformly coated with the first materials at the outlet of the inkjet head assembly, so that the fluid printing unit with higher quality is formed for protecting the cells, further cell damage caused by an extrusion pressure and a frictional force in the printing process is reduced, and the survival rate of the cells is improved.

Owner:SICHUAN REVOTEK CO LTD

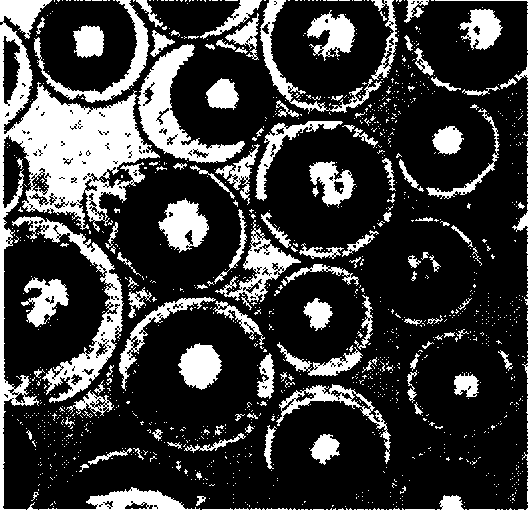

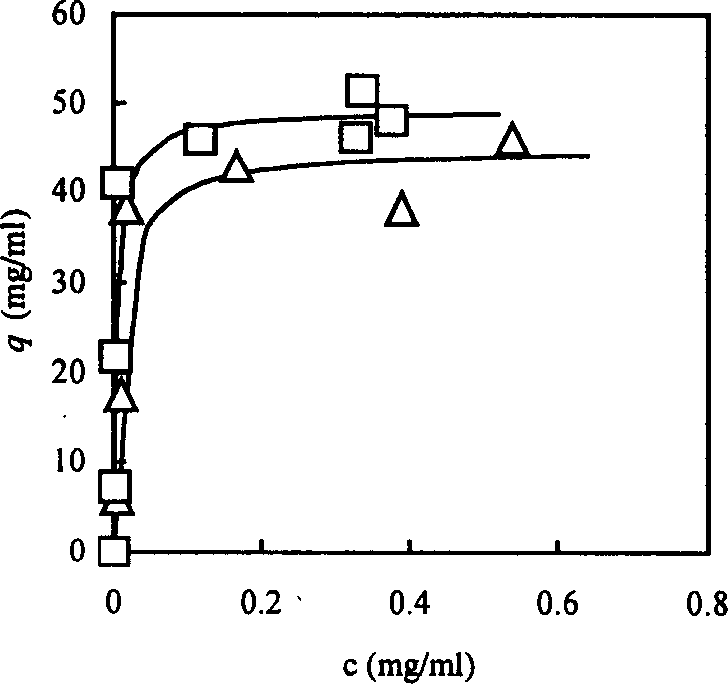

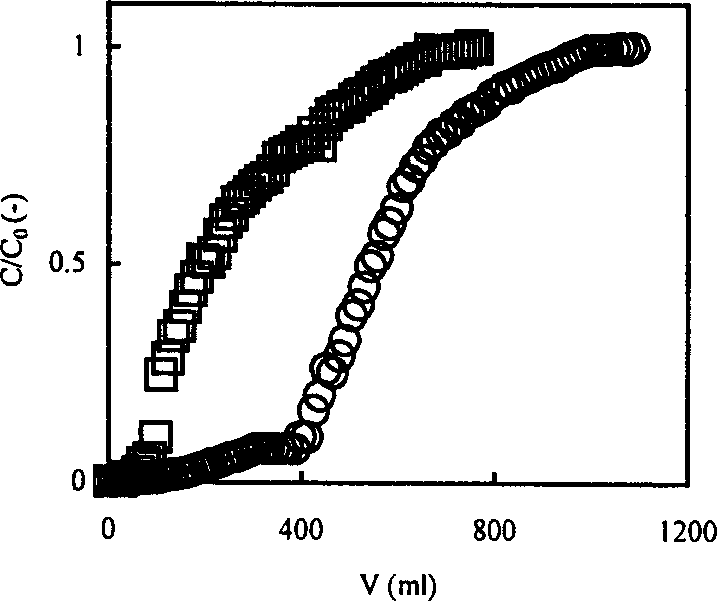

Method for preparing high density core material coated with thin shell medium of agarose gel

InactiveCN1457919AUniform densityDensity regulationIon-exchange process apparatusOther chemical processesEpoxyThin shells

The present invention discloses the technology of preparing gel carrier microballoon with loaded inert grain. The preparation process includes preparing suspension, emulsifying and coating reaction, and curing and crosslinking process. The preparation process features that the glass bead is dispersed inside the water solution of agarose to prepare suspension; the suspension is then added into salad oil while adding emulsifier Span-80 and stirring for emulsification and coating reaction to lower temperature fast to form microballoon; and epoxy chloropropane is then added for crosslinking at alkaline condition and sodium borohydride is added for reduction to prepare dispersed medium with particle size 40-500 mincrons and agerose content 20-70 wt%. The dispersed medium exhibits certain density and particle size distribution and has high density in expanding bed, column efficiency, adsorption capacity and thus wide application.

Owner:TIANJIN UNIV

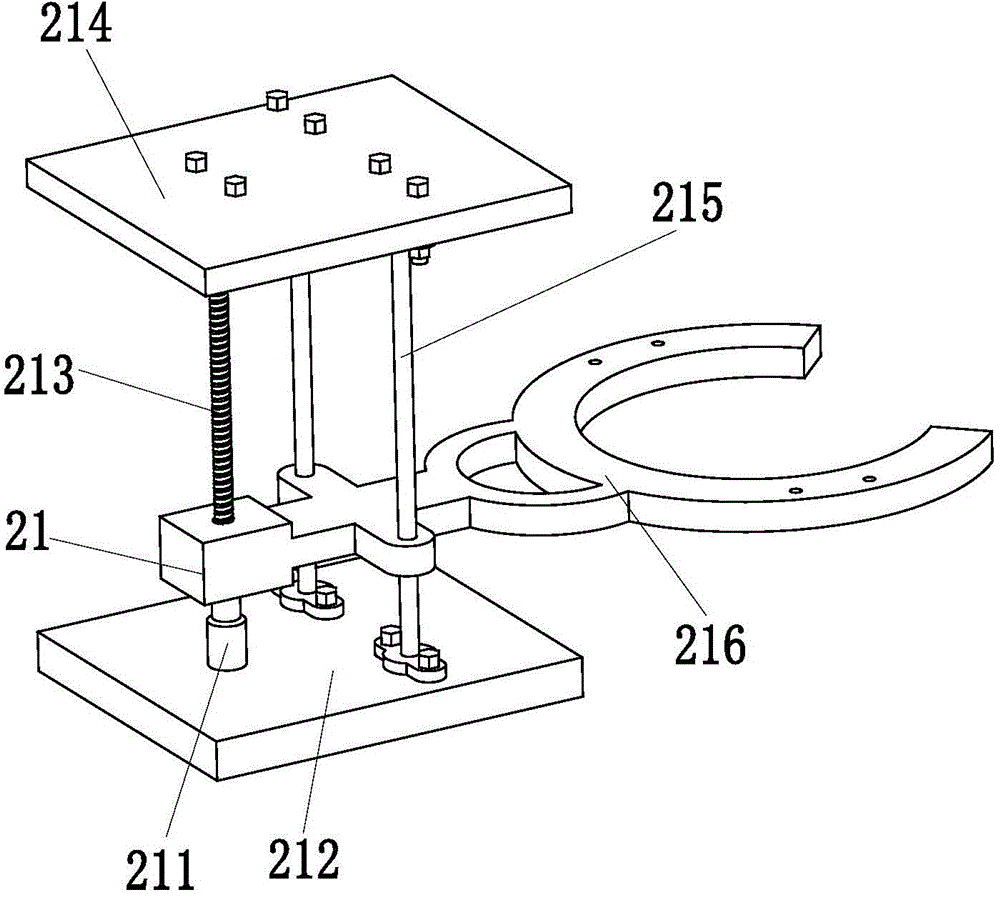

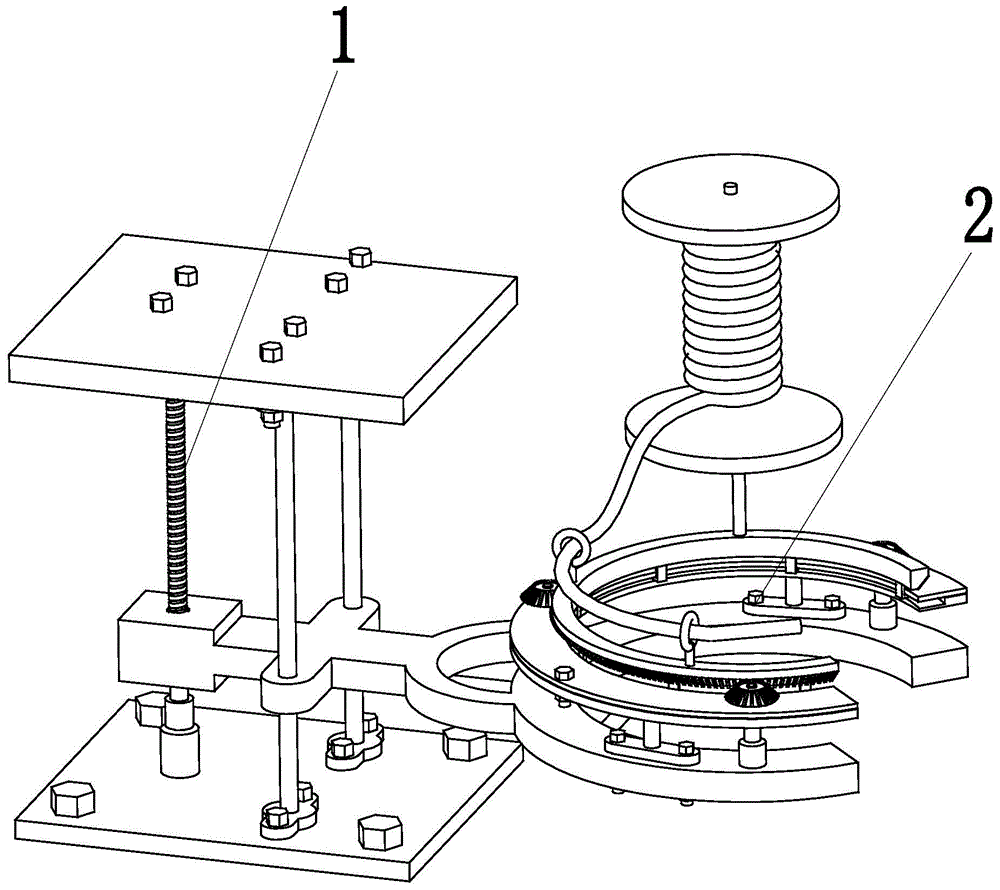

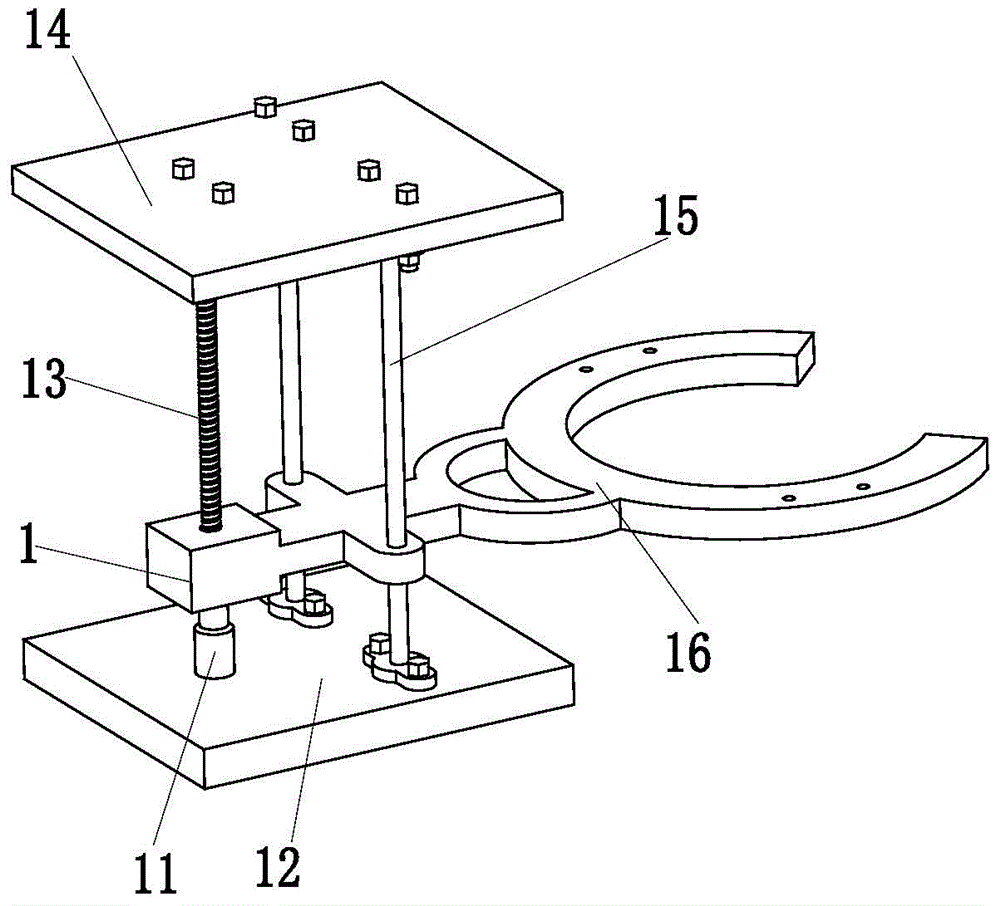

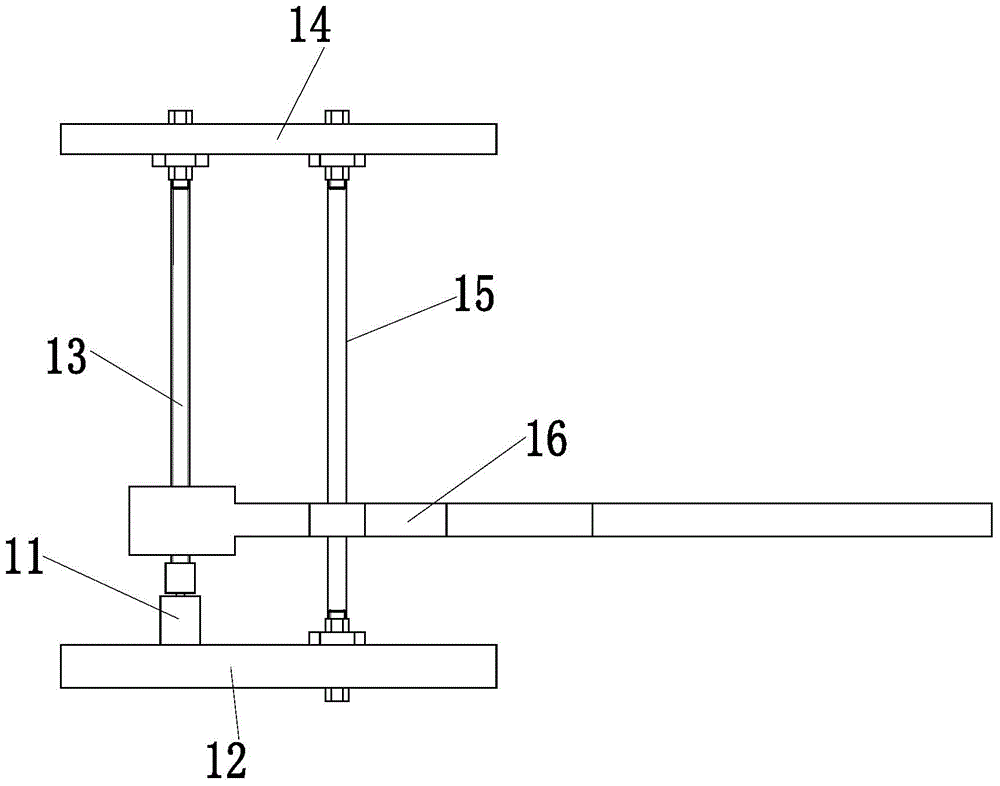

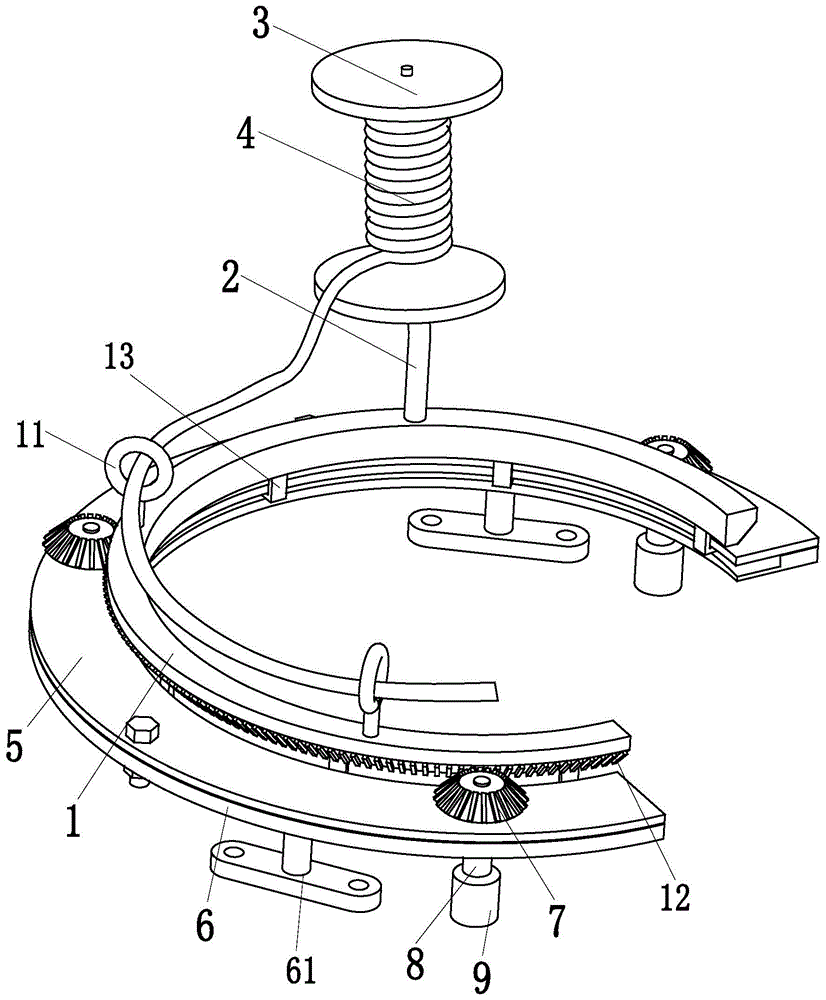

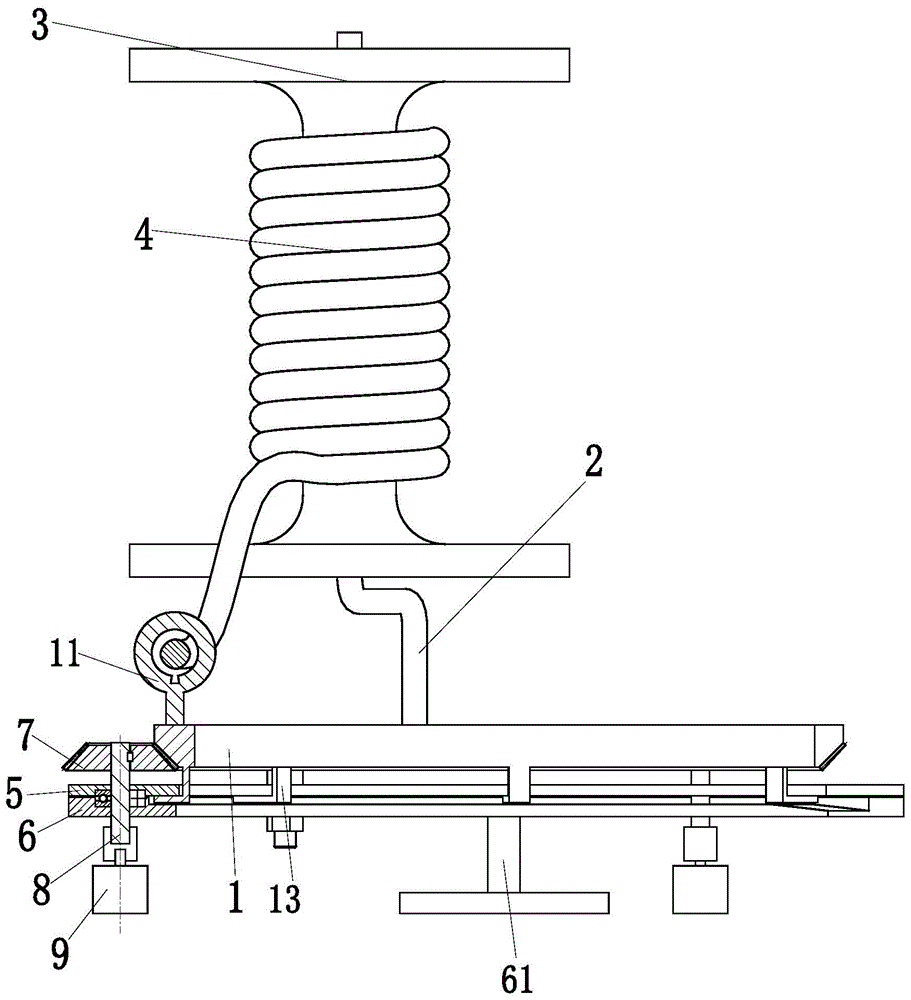

Binding system of spraying and binding machine

The invention relates to a binding system of a spraying and binding machine. The binding system comprises a lifting device and a rotating device. The rotating device is installed on the right side of the lifting device. The lifting device comprises a drive motor, a lower bottom board, a lead screw, an upper bottom board, two polish shafts and a lifting platform. The drive motor is installed on the lower bottom board through a motor seat. An output shaft of the drive motor is connected with the lower end of the lead screw through a coupler. The upper end of the lead screw is connected with the upper bottom board through a bearing with a seat. The lower ends of the polish shafts are installed on the lower bottom board through bearings with seats. The upper ends of the polish shafts are installed on the upper bottom board through bearings with seats. The lifting platform is connected with the lead screw through threads and connected with the two polish shafts in a clearance fit mode. The binding system has the advantages that the structure is simple, manufacturing cost is low, operation is easy and convenient, labor intensity is low, work efficiency is high, straw ropes are twisted evenly, and the straw ropes can be rapidly and evenly twisted.

Owner:平湖市盛泰五金制品有限公司

Method of preparing functional ceramic part of complex structure by powder injection molding

ActiveCN110480016AImprove product performanceShort degreasing cycleTransportation and packagingMetal-working apparatusAir atmosphereAdhesive

The invention relates to a method of preparing a functional ceramic part of complex structure by powder injection molding. The method is characterized by comprising the following steps: S1, feed preparation: uniformly mixing functional ceramic powder with an adhesive to form a feed; S2, injection moulding: putting the feed prepared in the S1 in a powder injection moulding machine, and injecting the feed into a mold cavity under conditions of an injection pressure of 80-200 MPa and an injection temperature of 160-200 DEG C to form an injection blank; S3, degreasing: catalytically degreasing theinjection blank prepared in the S2 to form a catalytically degreased blank; S4, thermal degreasing: thermally degreasing the catalytically degreased blank prepared in the S3 to obtain a thermally degreased blank; and S5, sintering: putting the thermally degreased blank prepared in the S4 in a sintering furnace, and sintering the thermally degreased blank in an air atmosphere to obtain a sinteredblank. By setting a volume ratio range of the functional ceramic powder and the adhesive, the functional ceramic powder can be totally coated by the adhesive, so that the flawless injection blank is more easily obtained.

Owner:CHANGZHOU GIAN TECH

Method for improving neodymium, cerium, iron and boron sintered magnet coercivity by adding neodymium hydride

InactiveCN106710768AImprove utilizationLow costInductances/transformers/magnets manufactureMagnetic materialsCeriumSintered magnets

The invention discloses a method for improving neodymium, cerium, iron and boron sintered magnet coercivity by adding neodymium hydride. The method comprises the steps that on the basis of the dual-main-phase alloy technology and the crystal boundary technology, two-main-phase alloy and crystal boundary auxiliary alloy are separately designed, prepared and powdered, magnetic field compression, sintering and thermal sintering are performed after powder is mixed proportionally to obtain a magnet. The coercivity of the obtained neodymium, cerium, iron and boron sintered magnet is high, preparation is easy and convenient, operation is easy, and the raw material cost of the magnet is effectively lowered.

Owner:ZHEJIANG UNIV

Method for preparing aluminum oxide for catalyst

InactiveCN102658114AWell mixedFully packagedMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateManufacturing technology

A method for preparing aluminum oxide for catalysts relates to the improvement of the preparation method of activated aluminum oxide used in catalysis field such as petrochemical engineering, industrial catalysis, automobile exhaust purification and the like. The method is characterized in that one or any two of lanthanum nitrate, zirconium nitrate and cerium nitrate is / are added in a reaction tank preparing pseudoboehmite and is / are used as modifying agents, and action is performed; slurry is processed through suction filtration, washing and drying after reaction and then modified pseudoboehmite powders are obtained; and the powders that are dried are roasted and then the aluminum oxide for the catalysts is obtained. The method is adopted to process the pseudoboehmite slurry through doping modification, is closely combined with the manufacturing process of the pseudoboehmite, effectively simplifies the manufacturing technology, lowers the manufacturing cost, achieves good surface modification effect, improves the heat stability of activated aluminum oxide powders, and improves the service performance of the activated aluminum oxide powders.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

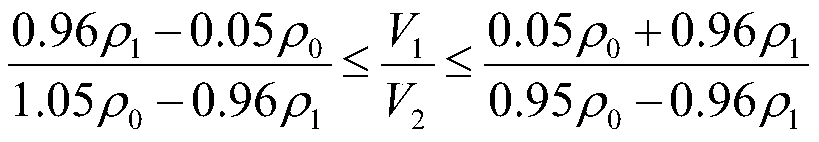

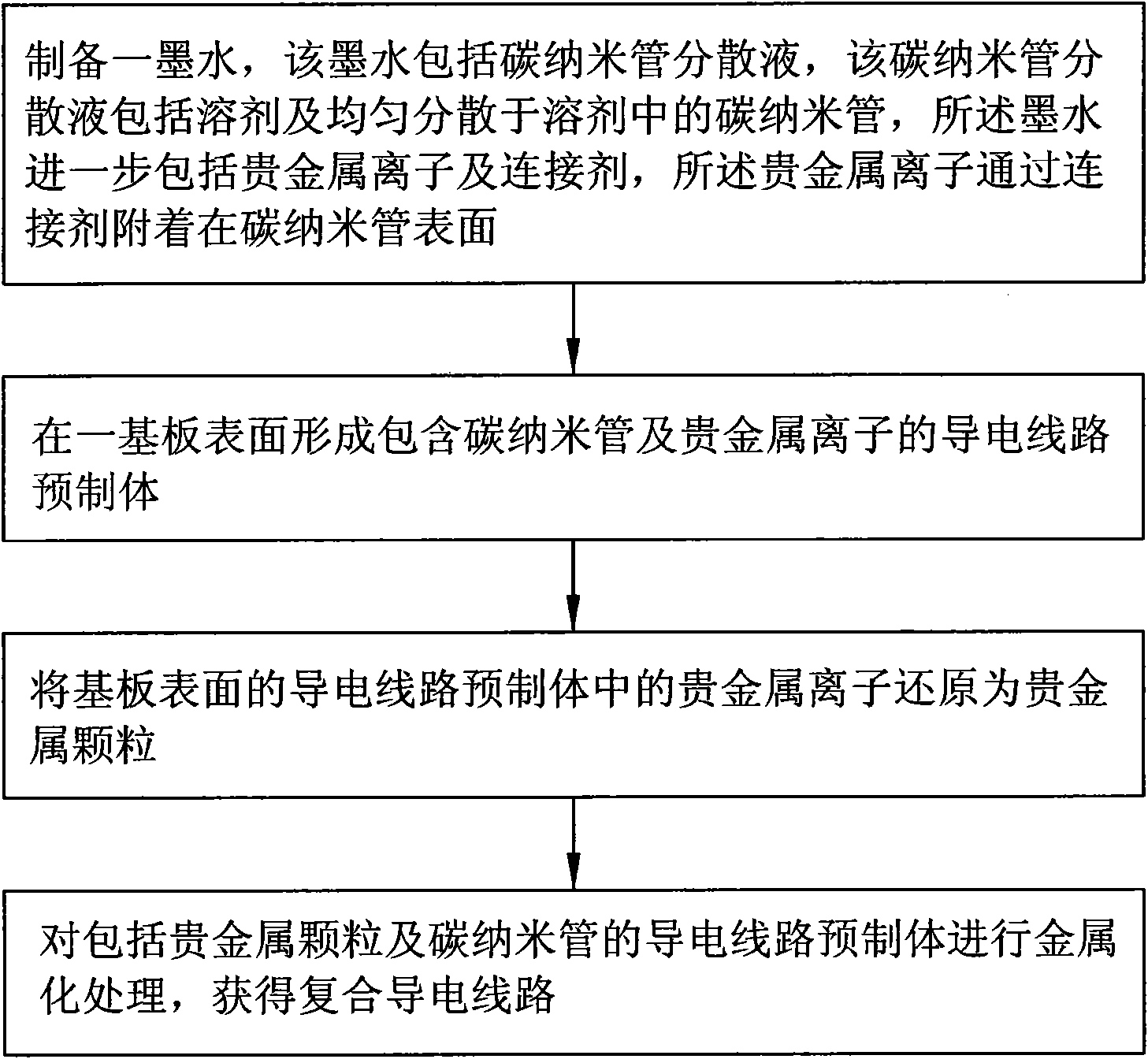

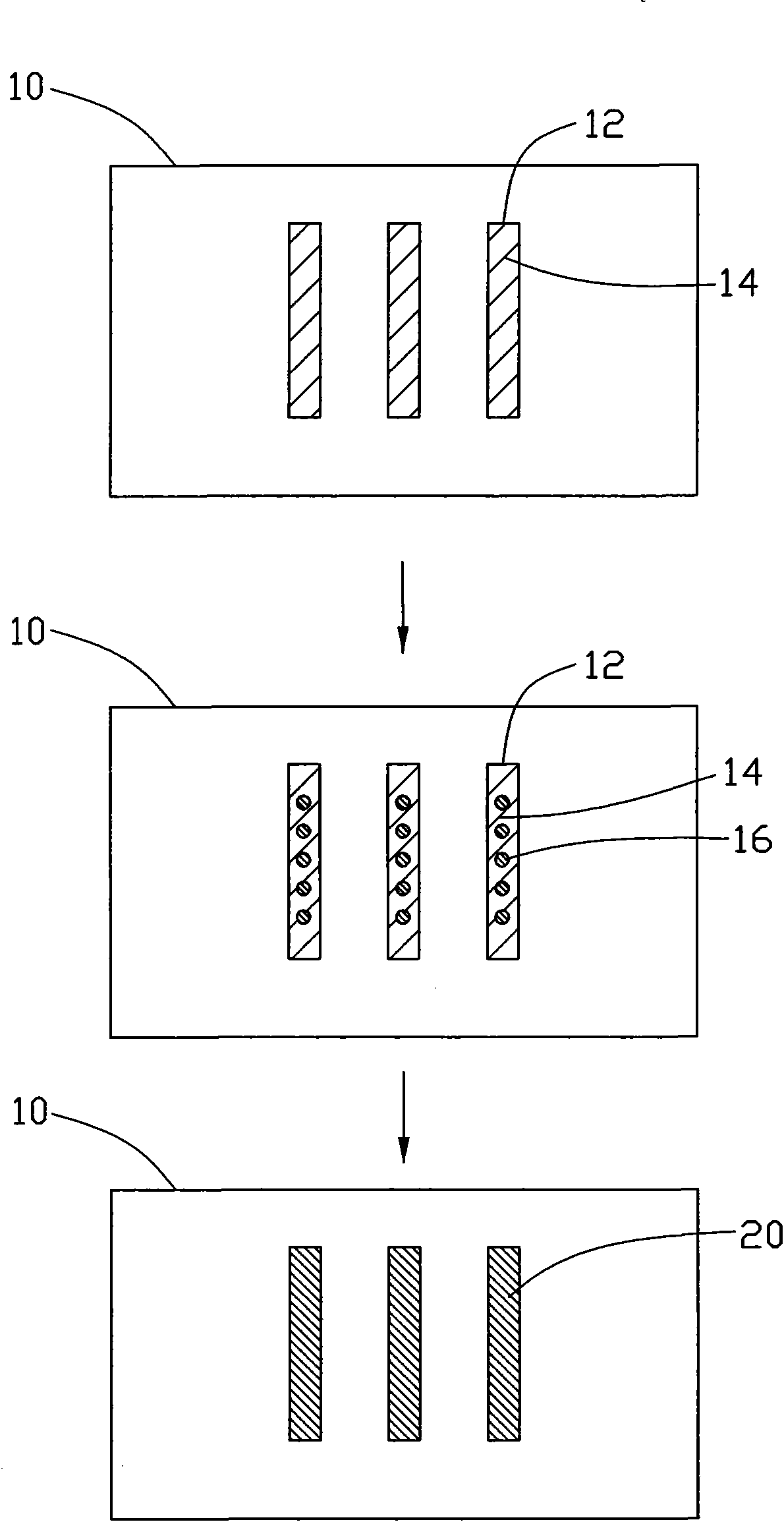

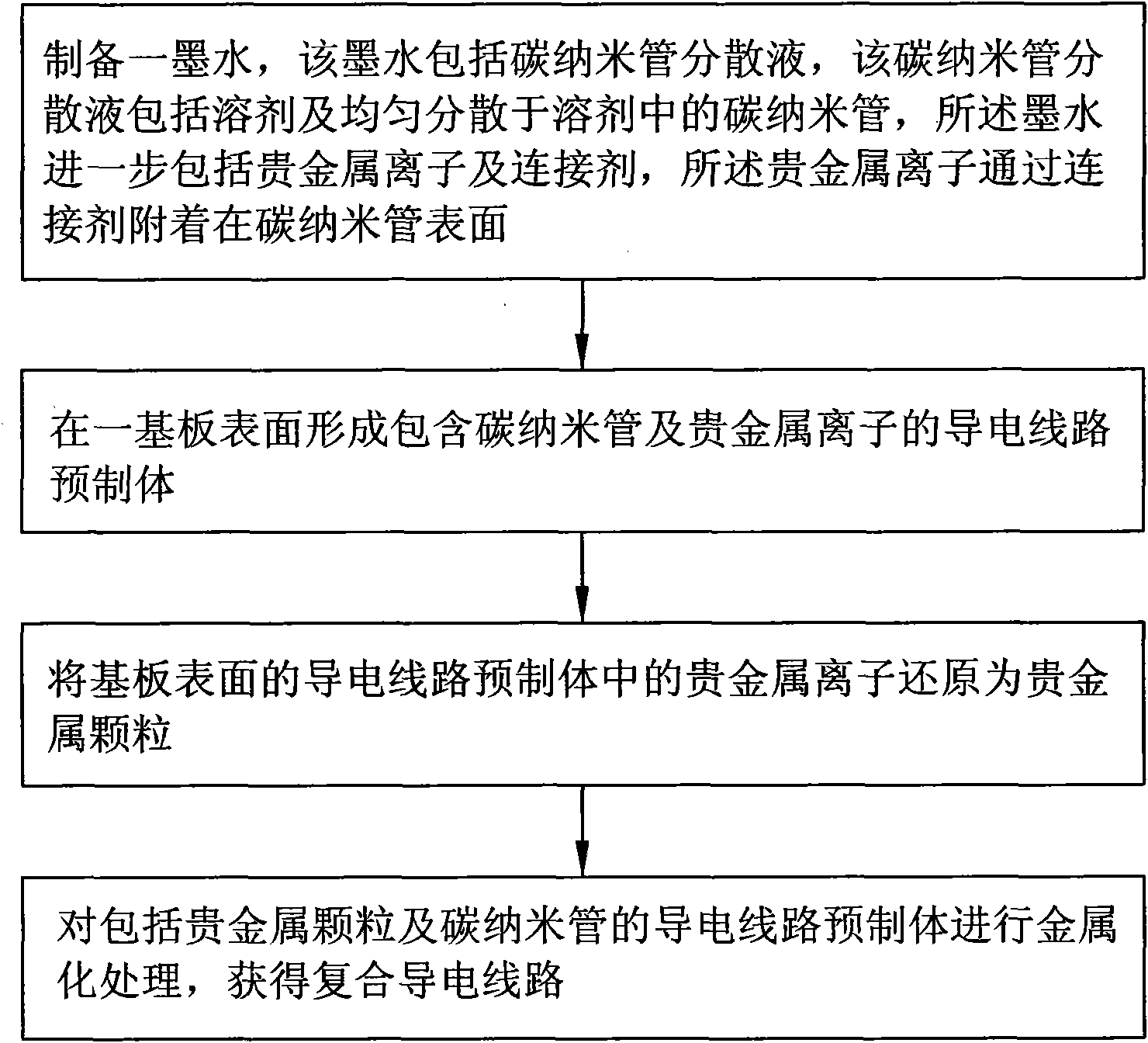

Ink and method adopting ink to prepare conductive line

ActiveCN101768386AImprove conductivityEvenly wrappedNanoinformaticsPrinted circuit aspectsBasementCoupling

The invention discloses an ink, which comprises CNT dispersion. The CNT dispersion comprises solvent and CNTs dispersed in the solvent wherein the ink further comprises precious metal ions and a coupling agent. The precious metal ions adhere to the surface of the CNTs through the coupling agent. The invention also relates to a method preparing the conductive line. The method comprises the following steps: the ink is provided, the ink comprises the solvent, the CNTs dispersed in the solvent evenly, the precious metal ions and the coupling agent, the precious metal ions adhere to the surface of the CNTs through the coupling agent, a conductive line prefabricated body comprising the CNTs and the precious metal ions is formed on a basement surface, the precious metal ions in the conductive line prefabricated body are restored to precious meta particles and the conductive line prefabricated body comprising the precious meta particles and the CNTs is metalized.

Owner:TSINGHUA UNIV +1

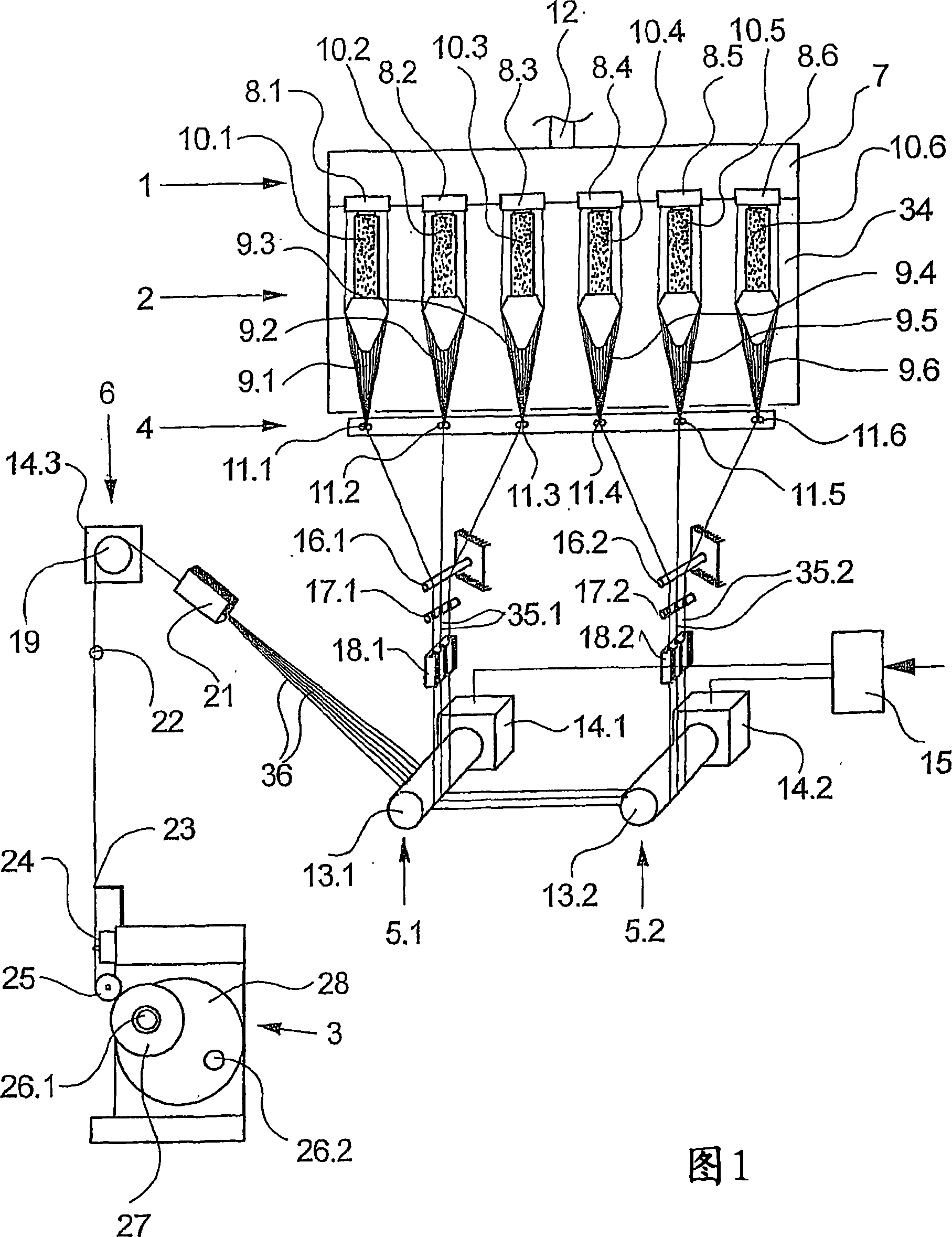

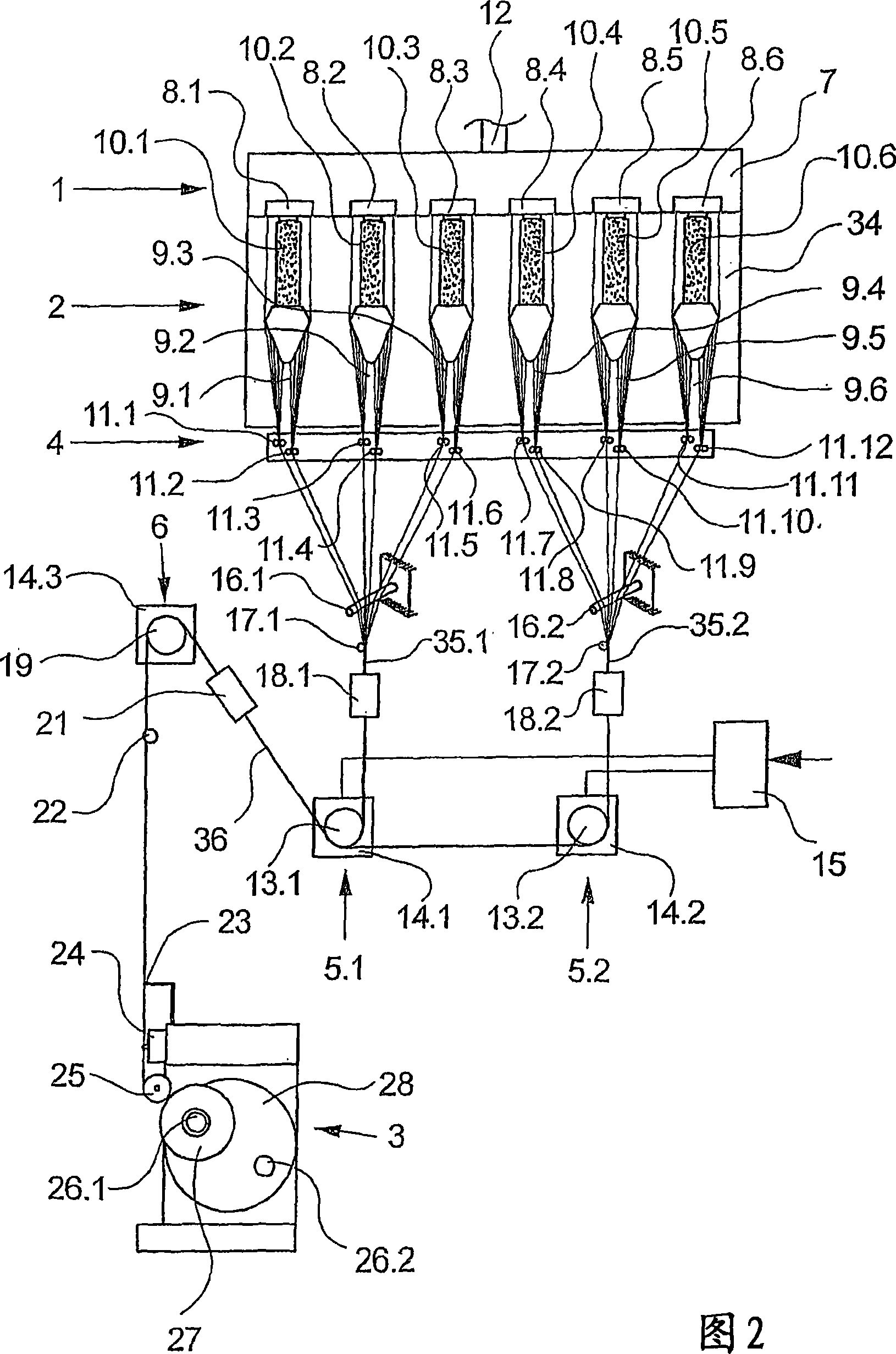

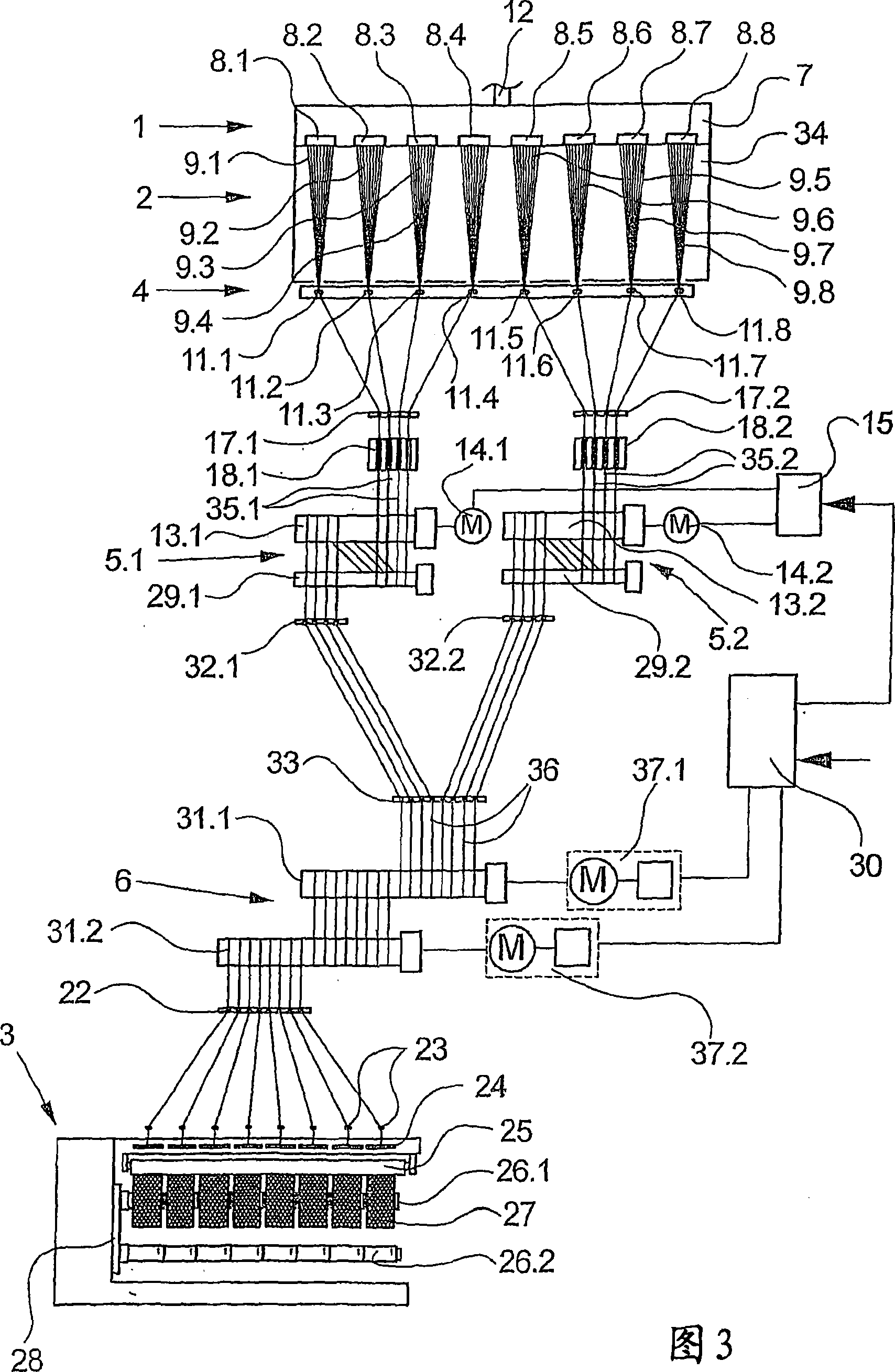

Device and method for melt-spinning, drawing off, processing, and winding up several synthetic threads

InactiveCN101006209AEvenly wrappedImprove uniformityArtificial thread manufacturing machinesBobbinEngineering

The invention relates to a device and a method for melt-spinning, drawing off, processing, and winding up several synthetic threads. For this purpose, several filament bundles are extruded from several spinning nozzles that are located next to each other, are cooled, and are combined into one thread, respectively. The threads are wound to bobbins in parallel next to each other after being drawn off and processed. In order to allow the threads to be combined into a thread bundle at the smallest possible deflection angles from a plurality of spinning nozzles, several drawing-off elements are provided which are assigned to a group of spinning nozzles and thus draw off a group of threads. Said drawing-off elements cooperate with at least one processing element that is mounted downstream thereof in such a way that the threads can be directed through the processing element as a thread bundle.

Owner:SAURER GMBH & CO KG

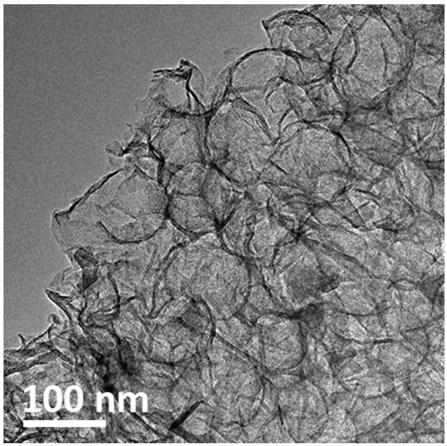

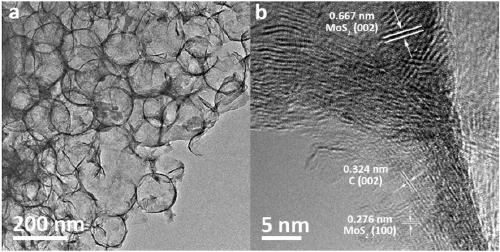

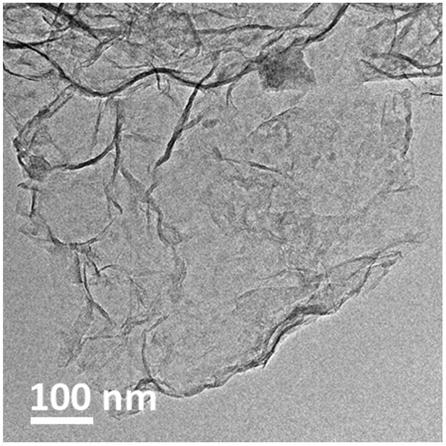

Preparation method of heteroatom doped porous molybdenum disulfide coated graphene

InactiveCN110479311AHigh activityImprove cycle stabilityPhysical/chemical process catalystsElectrodesHydrogenHeteroatom

The invention discloses a preparation method of heteroatom doped porous molybdenum disulfide coated graphene. Specifically, the method comprises the following steps: wrapping a template agent with graphene oxide, with the mass ratio of the template agent to the graphene oxide being 20:1 to 1:10; then dispersing a metal ion salt on the abovementioned sample; carrying out a reaction with a sulfur-containing compound at a certain temperature; and finally removing the template agent to obtain the target product. The material prepared by the method has a regular spongy three-dimensional pore channel structure, and the outer walls of the graphene single pores are uniformly covered with heteroatom-doped molybdenum disulfide single pores. The material has high activity and good cycling stability when being used for an electrocatalytic hydrogen evolution reaction. The method is simple and easy to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

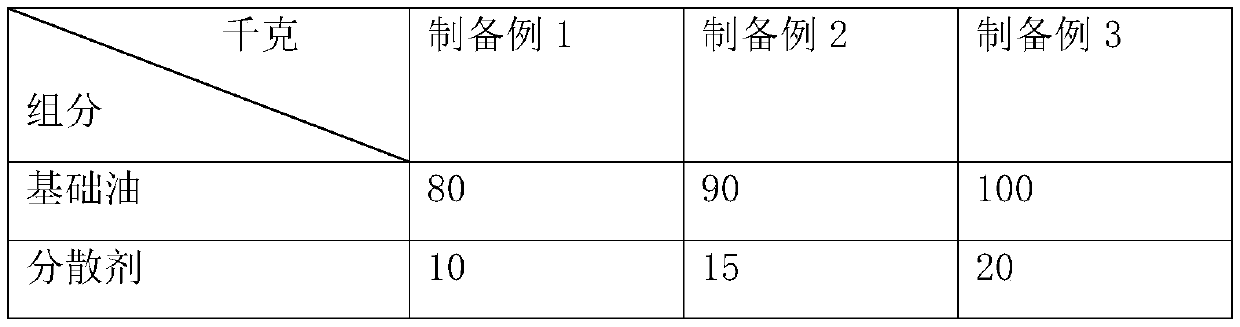

Heat-resistant recycled asphalt concrete and preparation method thereof

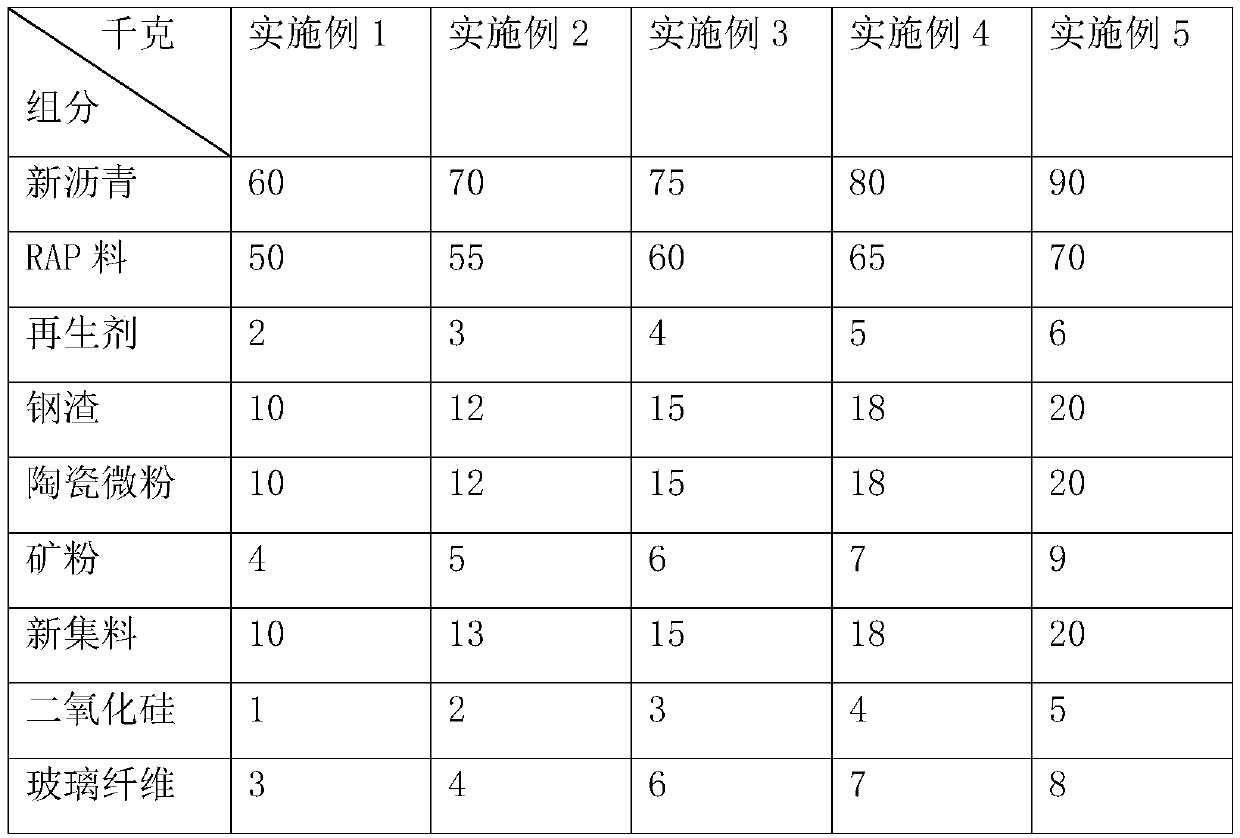

The invention discloses heat-resistant reclaimed asphalt concrete and a preparation method thereof. The heat-resistant reclaimed asphalt concrete comprises the following components: new asphalt, a RAPmaterial, a regenerant, steel slag, ceramic micropowder, mineral powder, a new aggregate, silica and glass fiber; the regenerant includes the following components: base oil, a dispersant, an alkylated diphenylamine antioxidant, dichloromethane, an ultraviolet absorber, dicumyl peroxide, a surfactant, a SBS modifier, anhydrous ethanol, styrene butadiene rubber powder and hollow glass microspheres;and the preparation thereof is as follows: S1, collecting the RAP material; S2, preparing a first mixture; S3, preparing a second mixture; S4, preparing a third mixture; and S5, preparing the finished product. The heat-resistant reclaimed asphalt concrete of the present invention is excellent in crack resistance, durability, and high-temperature and rutting deformation resistance; in addition, the preparation method of the present invention has the advantage of making asphalt distribution uniform.

Owner:江苏盛达飞建筑材料有限公司

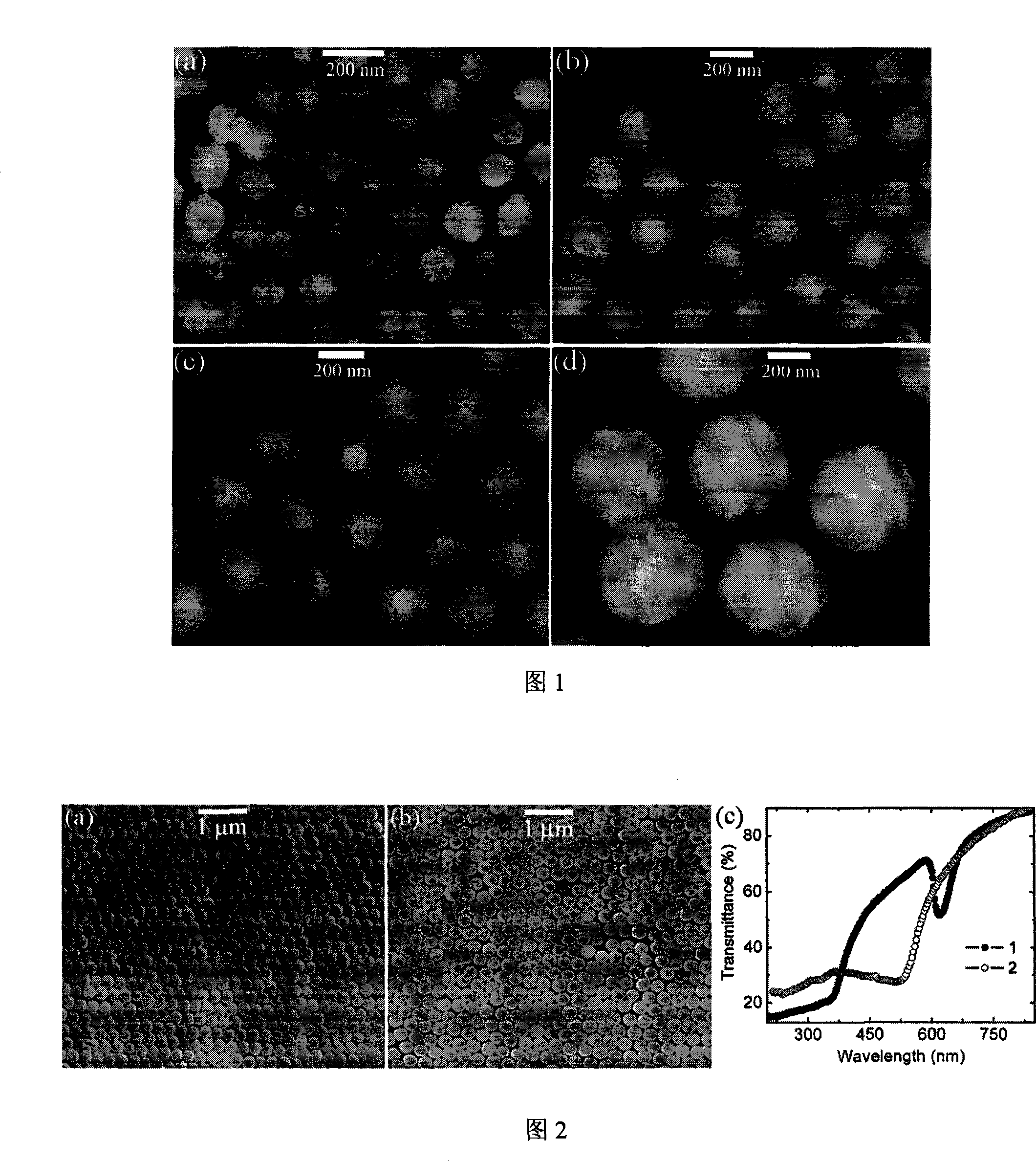

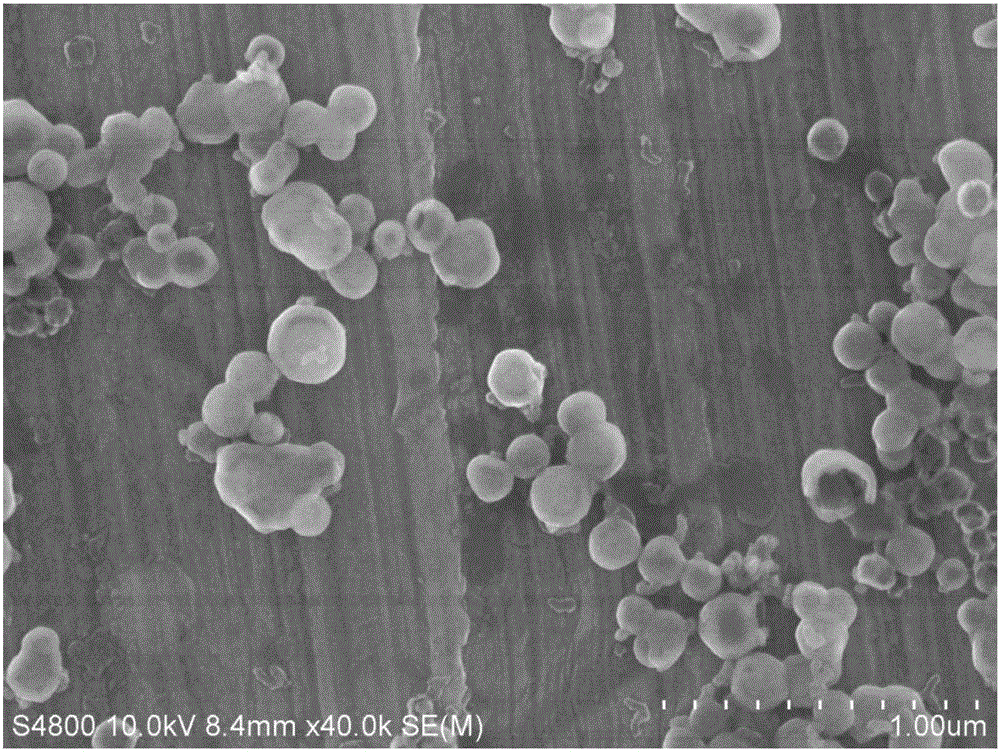

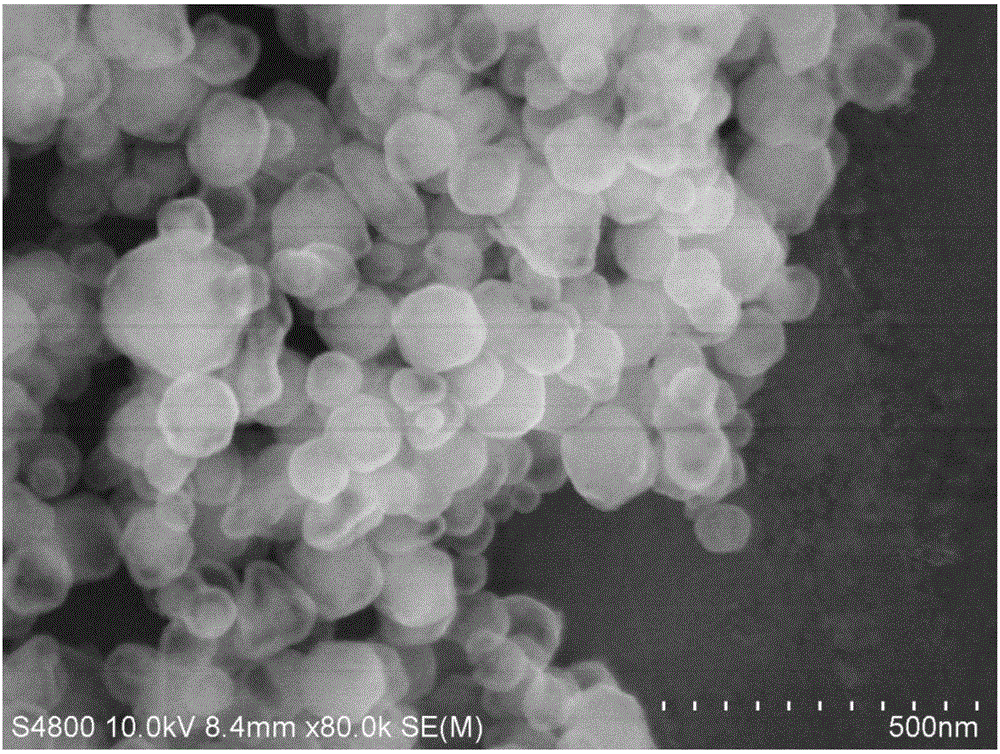

Method for enwrapping ferric oxide by silicon dioxide

InactiveCN101186762AEvenly wrappedGood dispersionInorganic pigment treatmentAlcoholPhysical chemistry

The invention discloses a process for coating ferric oxide with silicon dioxide, which comprises the procedures that ferric oxide particles are homogeneously dispersed into mixed solution of ethanol and ammonia, then the mixture is added into n-pentanol solution of polyvinylpyrrolidone in the condition of stirring, the mixture is continuously stirred for 6-24hours, after the reaction liquid is centrifugated, the fluid portion is removed, thereby ferric oxide particles coated by silicon dioxide are achieved. The invention employs restriction of polyvinylpyrrolidone to water and perfect adsorption effect of polyvinylpyrrolidone to ferric oxide, successfully locates hydrolysis reaction of ethyl orthosilicate on the surface of the ferric oxide, thereby the ferric oxide is coated homogeneously. Thickness of layer of the silicon dioxide can be constantly increased by simply increasing mass ratio of ethyl orthosilicate and ferric oxide particles. The invention has the advantages of low costs and simple operation, which needs no complex equipment and is capable of rapid volume-production, and the like.

Owner:NANJING UNIV

Synthetic rice with functions of nourishing heart and tranquilizing mind and preparation method thereof

The invention relates to the field of health-care food and in particular relates to rice. The synthetic rice with the functions of nourishing the heart and tranquilizing the mind is characterized in that the raw materials of the synthetic rice include lotus seeds, gordon euryale seed, Indian buead, red dates and black sesame. The raw materials are ground and then extruded into rice grains, thus preparing the spleen-tonifying and stomach-nourishing rice; and the synthetic rice is coated with a rice milk layer. The synthetic rice can nourish the heart, tranquilize the mind and promote sleep, fundamentally reconciles the functions of human bodies, improves the constitutions of the human bodies, has better effects for people with insomnia and dreaminess and poor sleep quality, has the effect of nourishing the stomach as the efficacy is mild and can be eaten by the ordinary healthy people.

Owner:SHANGHAI YIYANGTANG FOOD TECH

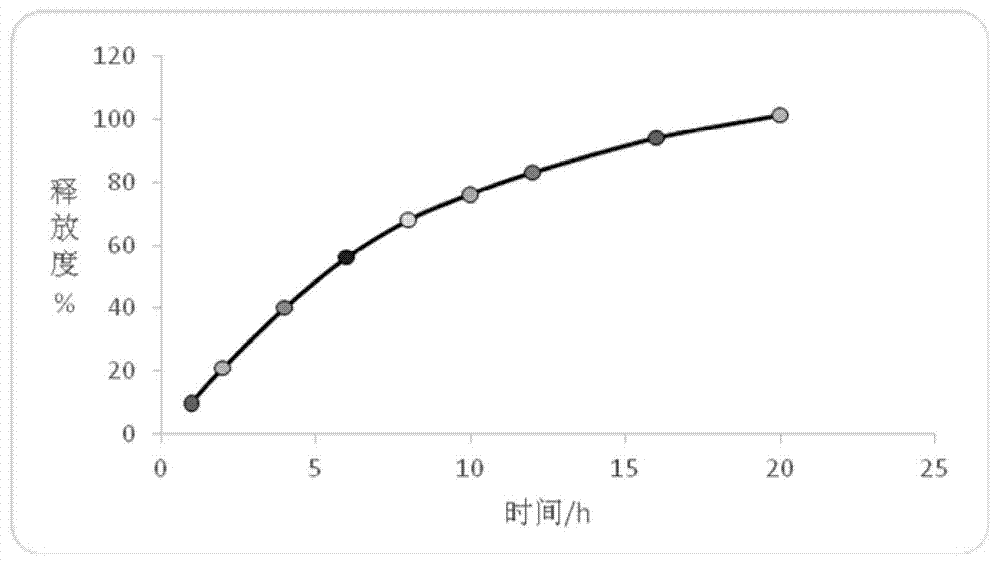

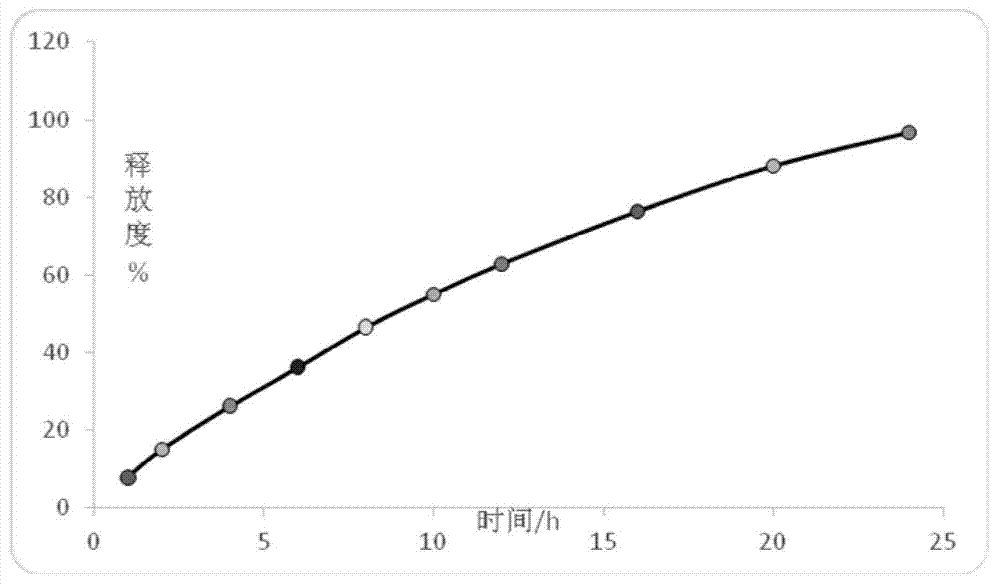

Long-acting sustained-release pellet and preparation method thereof

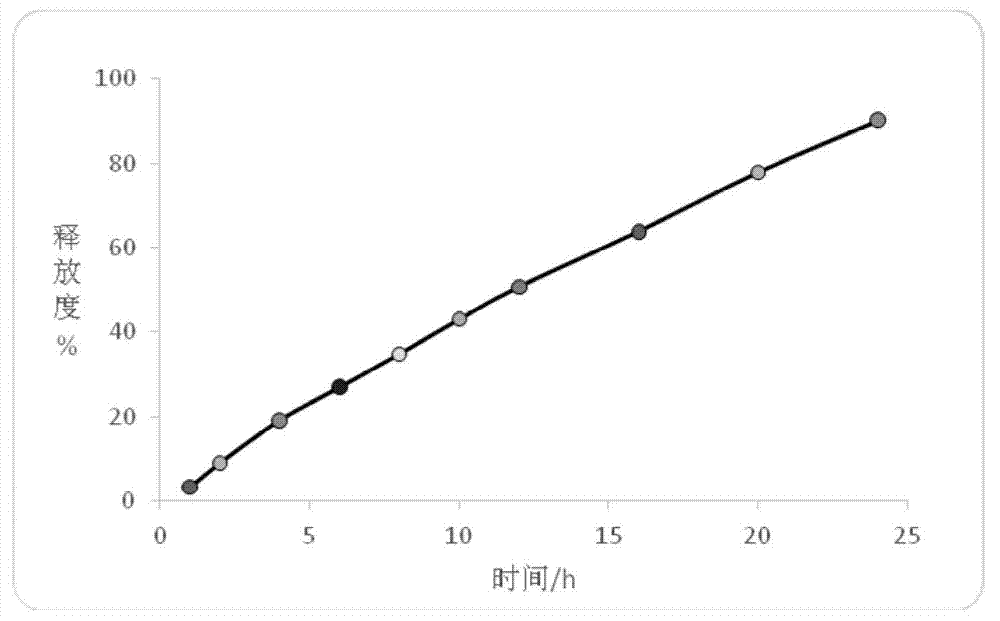

InactiveCN103565751AEvenly wrappedReduced release rateOrganic active ingredientsGranular deliverySustained release pelletsBlood concentration

The invention discloses a long-acting sustained-release pellet and a preparation method thereof. The long-acting trimetazidine hydrochloride sustained-release pellet comprises a drug-containing core and a sustained-release coating layer from inside to outside sequentially, wherein an optional isolation coating layer is arranged between the drug-containing core and the sustained-release coating layer; the isolation coating layer accounts for 0-15 percent of the mass of the drug-containing core, and the sustained-release coating layer accounts for 5-30 percent of the mass of the drug-containing core; a gastrointestinal adhesive is contained in the sustained-release coating layer. According to the trimetazidine hydrochloride sustained-release pellet, the prescription is meticulously designed, the drug-containing core is uniformly coated by utilizing the sustained-release coating material, so that slow and uniform drug release of the drug-containing core can be maintained, the active component releasing speed can be reduced, the time for reaching the peak can be postponed, the pellet can be constantly and stably released in 24 hours, the blood concentration stability can be maintained, and the phenomenon of insufficient blood concentration in morning ischemia can be avoided. The administration frequency can be reduced to once a day, and the compliance of patients can be improved.

Owner:AC PHARMA CO LTD

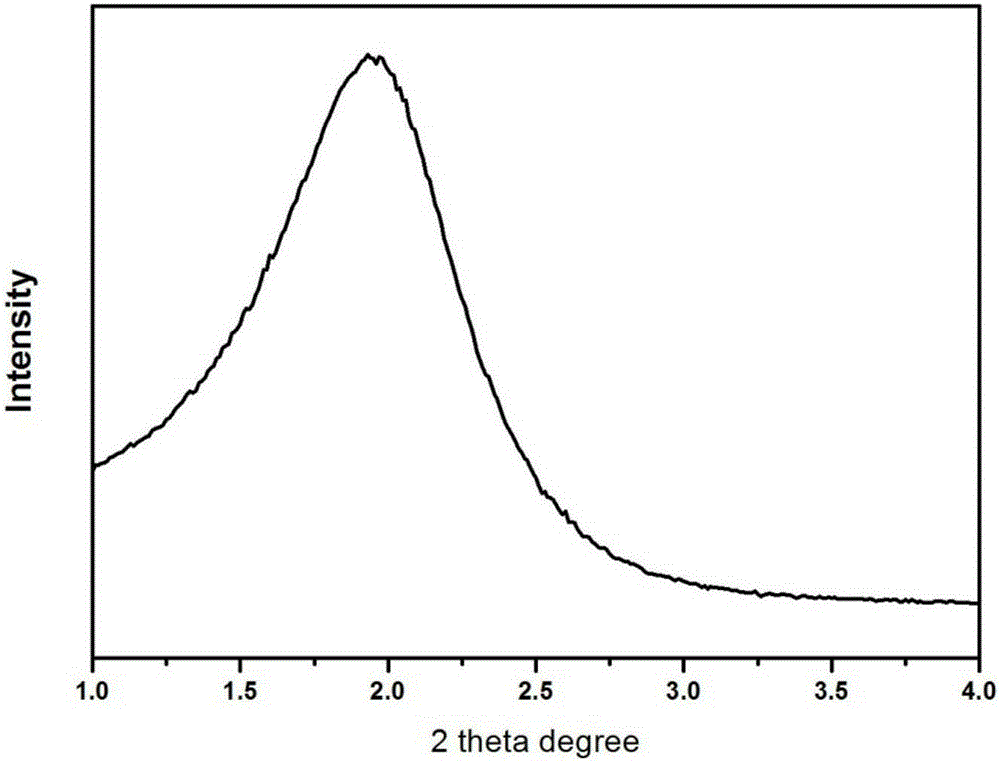

ZIF-8@MCM-41 molecular sieve and preparation method thereof

ActiveCN105170185ACoated evenlyGood chemical stabilityOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsPorosityAfter treatment

The invention relates to a ZIF-8@MCM-41 molecular sieve and a preparation method thereof. The ZIF-8@MCM-41 molecular sieve is of a core-shell structure and is prepared with ZIF-8 particles as a core-phase material and a MCM-41 molecular sieve as a shell-phase material, wherein the MCM-41 molecular sieve is coated outside of the ZIF-8 particles. The preparation method comprises the following steps: 1) preparation of the ZIF8 particles; and 2) preparation of the ZIF-8@MCM-41 molecular sieve: dispersing the ZIF-8 particles in water, then adding a surfactant and alkali liquid, then heating the obtained dispersion liquid, slowly adding tetraethylortho silicate and continuously carrying out reaction, carrying out after-treatment so as to obtain white powder, then adding the white powder into an ethanol solution and carrying out heating reflux so as to remove the surfactant, and carrying out after-treatment so as to obtain the ZIF-8@MCM-41 molecular sieve. The ZIF-8@MCM-41 molecular sieve prepared by using the method provided by the invention has the advantages of large specific surface area, high porosity and excellent catalytic reaction activity.

Owner:WUHAN UNIV OF TECH

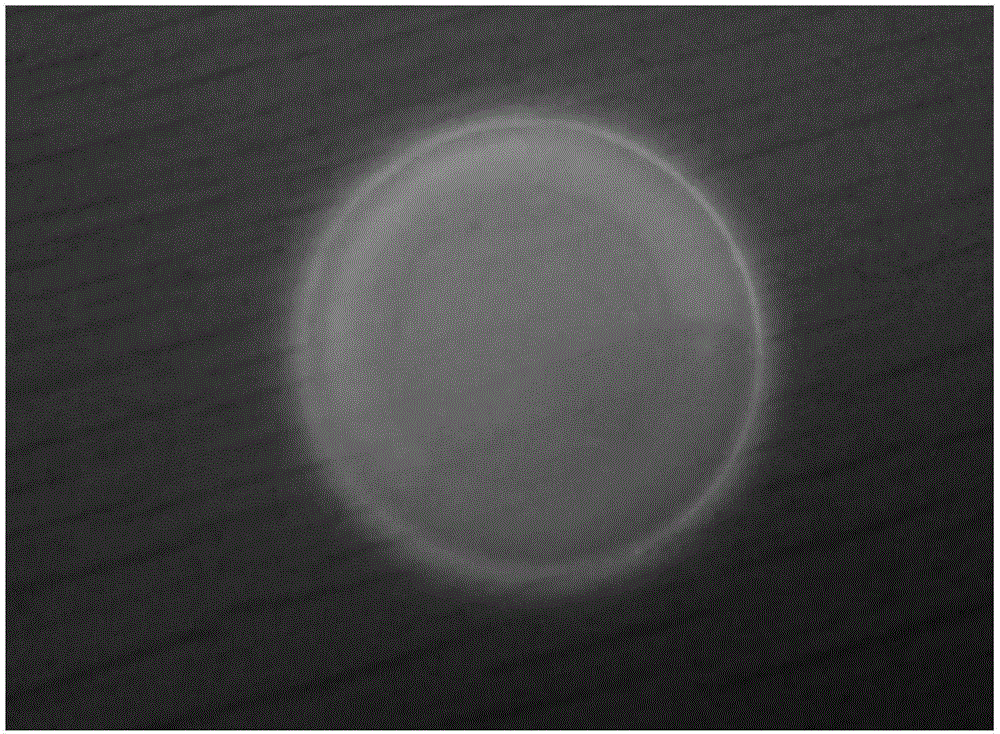

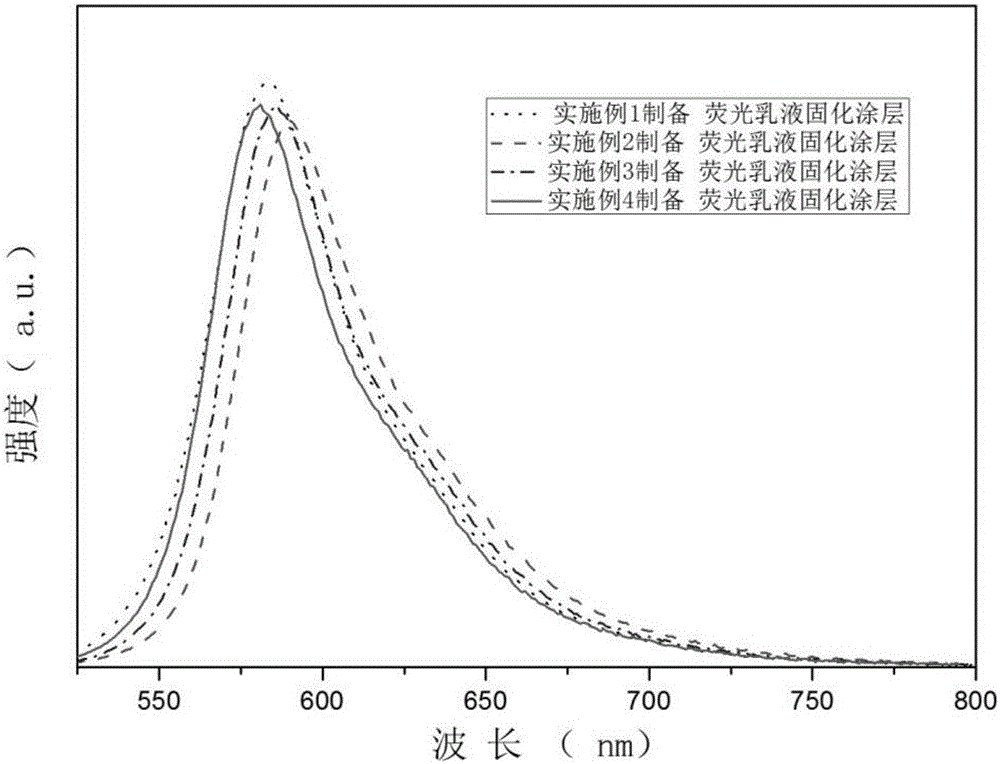

Fluorescent latex containing rhodamine B and preparing method thereof

InactiveCN105820283AEvenly wrappedExcellent fluorescence performanceLuminescent paintsLuminescent compositionsWater basedFluorescence

The invention discloses fluorescent latex containing rhodamine B and a preparing method thereof. The fluorescent latex is prepared from, 0.1-1wt% of rhodamine B, 5-25wt% of methyl methacrylate, 45-65wt% of styrene, 25-45wt% of butyl acrylate, cationic emulsifier and thermal initiator, the cationic emulsifier is one of cetyl trimethyl ammonium bromide, dodecyl ammonium chloride and dodecyl pyridine ammonium chloride, and the thermal initiator is azobis(2-methylpropionamidine) amidine hydrochloride or azobisisobutryamide imidazoline chloride. The relative amount of added water is controlled, and the solid content range of the prepared water-based fluorescent latex polymer is 10-40wt%. According to the prepared fluorescent latex containing rhodamine B, rhodamine B is evenly adsorbed on the surfaces of latex particles through charge attraction so as to be uniformly dispersed during solidification, and the aggregation-induced quenching effect is inhibited.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

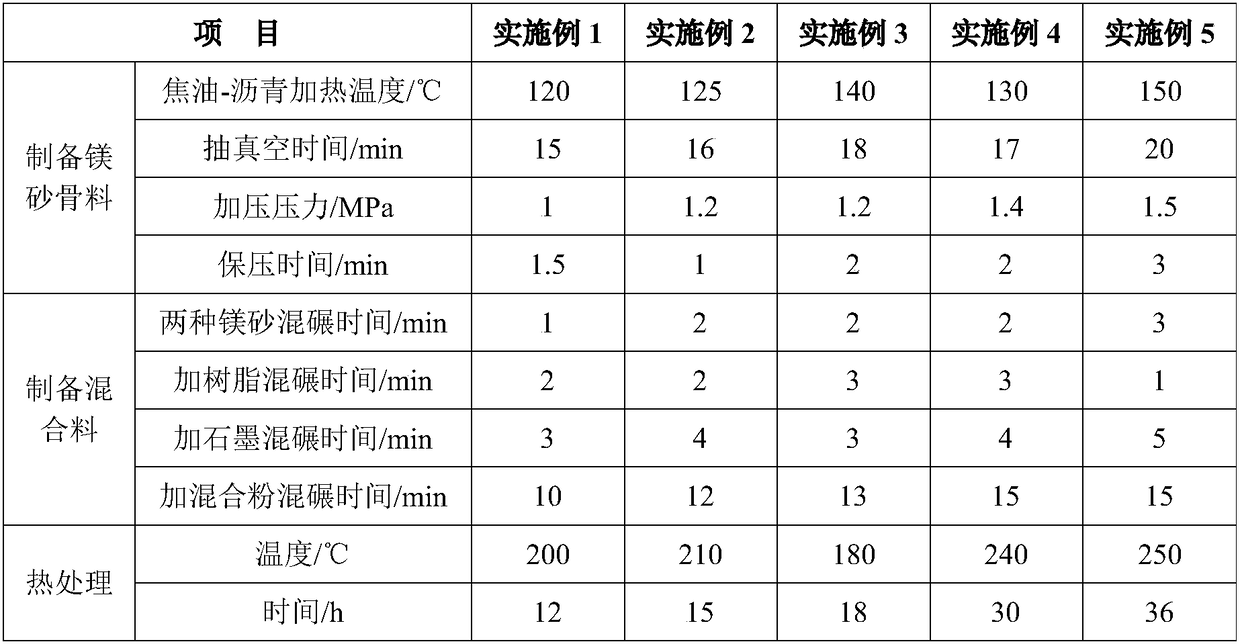

Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as aggregate and preparation method thereof

The invention discloses a Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as an aggregate and a preparation method thereof. The low-carbon magnesia carbon brick comprisesthe following components by weight: 45 to 55% of a magnesia aggregate impregnated by tar and asphalt, 35 to 45% of unimpregnated magnesia, 3 to 5% of graphite, 0.5 to 1.5% of high-temperature asphalt, 2 to 3% of an antioxidant and 2.5 to 3.5% of a binder. The preparation method comprises the following steps: 1) carrying out impregnating so as to obtain the magnesia aggregate impregnated by tar and asphalt; 2) weighing the components with the desired weight; 3) premixing unimpregnated magnesia powder, high-temperature asphalt and the antioxidant to obtain mixed powder; 4) subjecting the magnesia aggregate and the unimpregnated magnesia powder to dry mixing in a mixing and grinding machine, then successively adding the binder, graphite and the mixed powder, and carrying out mixing and grinding to form a mixture; and 5) carrying out briquetting, molding and heat treatment so as to obtain the low-carbon magnesia carbon brick with the magnesia impregnated by tar and asphalt as the aggregate. The low-carbon magnesia carbon brick has the advantages of good thermal shock resistance, good resistance to slag erosion and great high-temperature strength, and is significantly prolonged in service life.

Owner:WUGANG REFRACTORY CO LTD

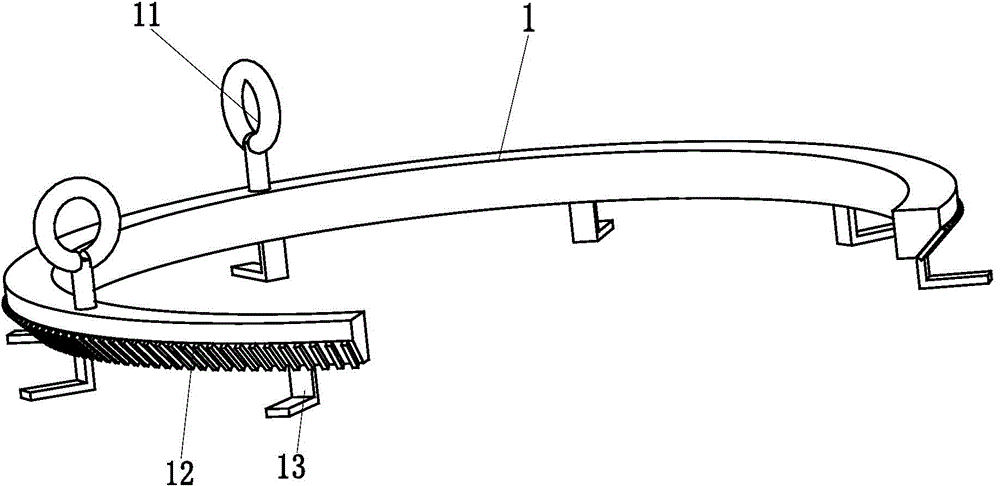

Rotating device for binding system

InactiveCN104429745AAddress operational complexitySolve the labor intensity of operationPlant protective coveringsDrive shaftEngineering

The invention relates to a rotating device for a binding system. The rotating device for the binding system comprises a rotating ring, a mounting rod, a pulley, a straw rope, an upper fixing ring, a lower fixing ring, three drive bevel gears, three drive shafts and three drive motors. Two rope through rings are arranged on the rear side of the upper end face of the rotating ring, an outer bevel gear is arranged at the lower end of the outer wall of the rotating ring, and six L-shaped positioning rods are symmetrically arranged at the lower end of the rotating ring. The mounting rod is welded to the front side of the upper end face of the rotating ring. The pulley and the mounting rod are connected through a bearing. The straw rope is arranged on the pulley in a sleeving mode, and the straw rope sequentially penetrates through the two rope through rings on the rotating ring. The six L-shaped positioning rods of the rotating ring are placed between the stepped face of the lower fixing ring and the lower end face of the upper fixing ring. The rotating device for the binding system has the advantages of being simple in structure, low in construction cost, easy and convenient to operate, low in labor intensity, high in working efficiency, even in straw rope wrapping and the like, and the straw rope wrapping function can be quickly and evenly achieved.

Owner:芜湖赛德交通设备有限公司

Natural plant hair dye

ActiveCN102048670AIncrease contact areaImprove uniformityCosmetic preparationsHair cosmeticsHair ColorantsPolyol

The invention discloses a natural plant hair dye which is prepared by mixing a polyalcohol phase and an aqueous phase, wherein, the mass percent concentration of the polyalcohol phase is 20-50, and the balance is the aqueous phase; the polyalcohol phase comprises the following components in parts by mass: 20-50 parts of polyalcohol, 0.5-3 parts of nanometer package carrier and 1-3 parts of hematoxylin; and the aqueous phase comprises the following components: 1-3% of water-solubility ferrite, 0.3-2% of thickening agent, and the balance of water. In the natural plant hair dye of the invention, a natural plant extract is adopted as a main ingredient, and toxic chemicals such as dye intermediates and the like, toxic mineral substances and bleacher are not contained; and the natural plant hair dye is natural and non-toxic, has no toxic and side effect after being used, greatly improves the safety than that of the conventional coloring agent, is a single component agent, and is convenient to store and use.

Owner:ZHUHAI EASYCARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com