Preparation method of heteroatom doped porous molybdenum disulfide coated graphene

A technology of molybdenum disulfide and graphene, which is applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effect of facilitating the application of the method, wide application range, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Disperse 400mg of silica spheres in 200mL of ethanol, then reflux with 4mL of (3-aminopropyl)trimethoxysilane at 180°C for 5 hours, then add 0.8% graphene oxide water dispersion 3.7 g, stirred.

[0047] 2. Mix the sample obtained in (1) with 33 mg of ammonium molybdate, and dry at 80° C. for 5 hours.

[0048] 3. The sample obtained in (2) was transferred with 10 mL of carbon disulfide and sealed in a 60 mL autoclave in an argon atmosphere.

[0049] 4. React the autoclave in (3) at 400° C. for 9 hours.

[0050] 5. Treat the sample obtained in (4) with a 5% hydrofluoric acid solution by mass fraction for 8 hours, then wash with water, suction filter, and dry at 80° C. for 8 hours.

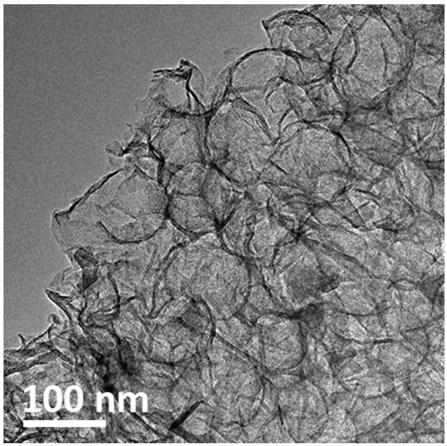

[0051] TEM (see figure 1 ) shows that the obtained sample has regular and uniform sponge-like three-dimensional channels, and the molybdenum disulfide single hole is evenly wrapped on the outer wall of the graphene single hole. X-ray diffraction spectrum (see Figure 4 Middle a) shows ...

Embodiment 2

[0053] 1. Disperse 400mg of silica spheres in 200mL of ethanol, then reflux with 4mL of (3-aminopropyl)trimethoxysilane at 180°C for 5 hours, then add 0.8% graphene oxide water dispersion 3.7 g, stirred.

[0054] 2. Mix the sample obtained in (1) with 33 mg of ammonium molybdate and 24 mg of cobalt nitrate, and dry at 80° C. for 5 hours.

[0055] 3. The sample obtained in (2) was transferred with 10 mL of carbon disulfide and sealed in a 60 mL autoclave in an argon atmosphere.

[0056] 4. React the autoclave in (3) at 400° C. for 9 hours.

[0057] 5. Treat the sample obtained in (4) with a 5% hydrofluoric acid solution by mass fraction for 8 hours, then wash with water, suction filter, and dry at 80° C. for 8 hours.

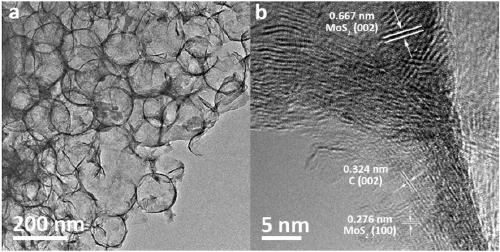

[0058] TEM (see figure 2 a) shows that the obtained sample has regular and uniform three-dimensional pores, and the high-resolution transmission electron microscope picture (see figure 2 b) It shows that the molybdenum disulfide single hole is evenly wrappe...

Embodiment 3

[0060] 1. Disperse 400mg of silica spheres in 200mL of ethanol, then reflux with 4mL of (3-aminopropyl)trimethoxysilane at 180°C for 5 hours, then add 0.8% graphene oxide water dispersion 3.7 g, stirred.

[0061] 2. Mix the sample obtained in (1) with 33 mg of ammonium molybdate and 12 mg of cobalt nitrate, and dry at 80° C. for 5 hours.

[0062] 3. The sample obtained in (2) was transferred with 10 mL of carbon disulfide and sealed in a 60 mL autoclave in an argon atmosphere.

[0063] 4. React the autoclave in (3) at 400° C. for 9 hours.

[0064] 5. Treat the sample obtained in (4) with a 5% hydrofluoric acid solution by mass fraction for 8 hours, then wash with water, suction filter, and dry at 80° C. for 8 hours.

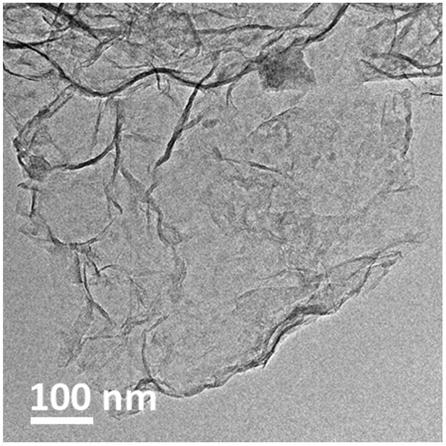

[0065] Transmission electron microscopy showed that the obtained sample had regular and uniform three-dimensional pores, and no metal particles were found. The X-ray diffraction spectrum shows that the obtained sample is composed of molybdenum disulfide and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com