C / C-SiC composite material and preparation method and application thereof

A composite material and mixing technology, applied in mechanical equipment, friction linings, gear transmission mechanisms, etc., can solve the problem of large-scale industrialization and meet high-end industrial applications, low material density and mechanical properties, long production cycle, etc. problem, to achieve the effect of superior performance, excellent mechanical properties, and consistent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

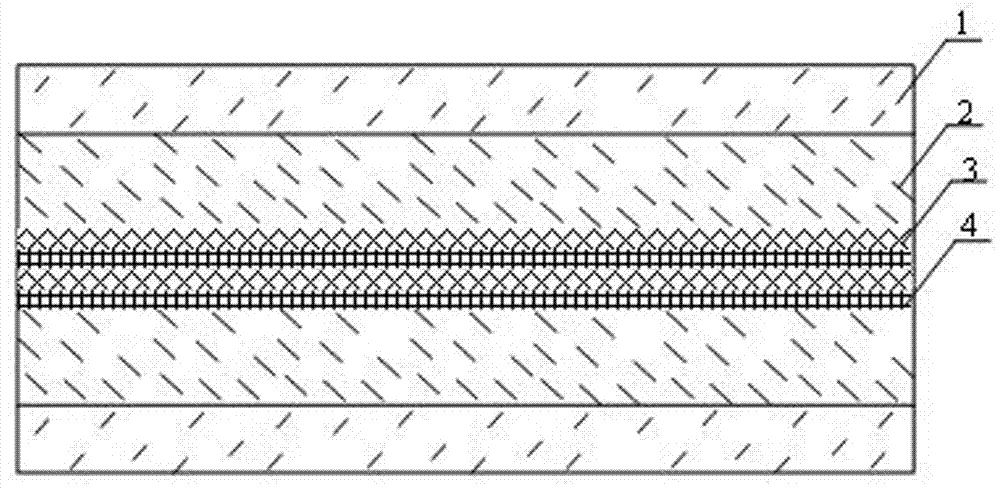

[0046] This embodiment provides a method for preparing a C / C-SiC composite material. The C / C-SiC composite material is a multilayer symmetrical gradient structure, such as figure 1 The multi-layer symmetrical gradient structure shown from the inner layer to the outer layer is the middle layer, the upper and lower symmetrical 6mm chopped carbon fiber reinforced silicon carbide matrix layer 2 and the upper and lower symmetrical 3mm chopped carbon fiber reinforced silicon carbide matrix layer 1, and the middle layer is 90° Plain carbon fiber The toughening layer 4 and the 45° plain carbon fiber toughening layer 3 are interlaced to form a reinforced and toughened interlayer, the carbon fiber content of the 3mm chopped carbon fiber reinforced silicon carbide matrix layer 1 is 20vol%, and the 6mm chopped carbon fiber reinforced silicon carbide matrix layer 2 The carbon fiber content is 50vol%;

[0047] Include the following steps:

[0048] S1. Preparation of carbon fiber reinforced...

Embodiment 2

[0058] This embodiment provides a method for preparing a C / C-SiC composite material. The C / C-SiC composite material is a multilayer symmetrical gradient structure, such as figure 1 The multi-layer symmetrical gradient structure shown from the inner layer to the outer layer is the middle layer, the upper and lower symmetrical 10mm chopped carbon fiber reinforced silicon carbide matrix layer 2 and the upper and lower symmetrical 6mm chopped carbon fiber reinforced silicon carbide matrix layer 1, and the middle layer is 90° Plain carbon fiber The toughening layer 4 and the 45° plain carbon fiber toughening layer 3 are interlaced to form a reinforced and toughened interlayer, the carbon fiber content of the 6mm chopped carbon fiber reinforced silicon carbide matrix layer 1 is 30vol%, and the 12mm chopped carbon fiber reinforced silicon carbide matrix layer 2 Carbon fiber content is 60vol%;

[0059] Include the following steps:

[0060] S1. Preparation of carbon fiber reinforced p...

Embodiment 3

[0070] This embodiment provides a method for preparing a C / C-SiC composite material. The C / C-SiC composite material is a multilayer symmetrical gradient structure, such as figure 1 The multi-layer symmetrical gradient structure shown from the inner layer to the outer layer is the middle layer, the upper and lower symmetrical 8mm chopped carbon fiber reinforced silicon carbide matrix layer 2 and the upper and lower symmetrical 4mm chopped carbon fiber reinforced silicon carbide matrix layer 1, and the middle layer is 90° Plain carbon fiber The toughening layer 4 and the 45° plain carbon fiber toughening layer 3 are interlaced to form a reinforced and toughened interlayer. The carbon fiber content of the 4mm chopped carbon fiber reinforced silicon carbide matrix layer 1 is 30vol%, and the 15mm chopped carbon fiber reinforced silicon carbide matrix layer 2. Carbon fiber content is 60vol%;

[0071] Include the following steps:

[0072]S1. Preparation of carbon fiber reinforced pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com