Low-carbon magnesia carbon brick with magnesia impregnated by tar and asphalt as aggregate and preparation method thereof

A carbon-magnesium-carbon brick and tar-impregnated technology, applied in the field of low-carbon magnesia-carbon bricks, can solve the problems of reducing resin viscosity and cohesiveness, reducing resin viscosity and cohesiveness, and difficult to uniformly disperse nano carbon sources, and reducing porosity. , reduce thermal stress concentration, improve the effect of thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The low-carbon magnesia-carbon brick disclosed in this embodiment is made of the following raw materials in percentage by weight: 45% magnesia aggregate impregnated with tar and asphalt, 44% unimpregnated Magnesia, 4% flake graphite, 1.5% high temperature pitch, 2.5% antioxidant, 3% binder.

[0020] The magnesia aggregate is obtained by impregnating anhydrous tar and medium-temperature asphalt with magnesia for impregnation, and the ratio by weight is tar: medium-temperature asphalt=4:1. The particle size of the impregnated magnesia is divided into two grades: ≤6mm and >3mm, ≤3mm and >1mm, and the weight percentages are 43% and 57% respectively; the porosity of the impregnated magnesia aggregate is ≤1%. The reason why magnesia aggregates use larger particles is because if impregnated with small particles or fine powder, they will form agglomerates after impregnation and cannot be dispersed, resulting in inconvenient operation. The choice of medium temperature asphalt f...

Embodiment 2~5

[0034] The raw material components of Examples 2-5 are detailed in Table 1 below, and the remaining raw material indicators are the same as in Example 1.

[0035] Each embodiment raw material composition table of table 1

[0036]

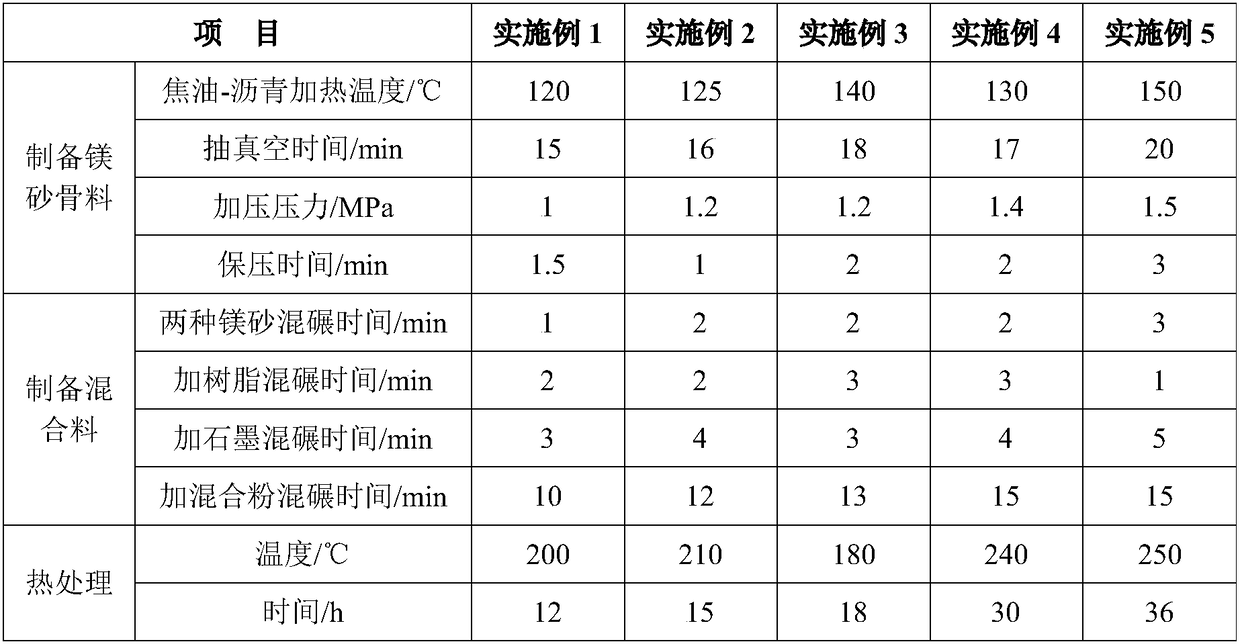

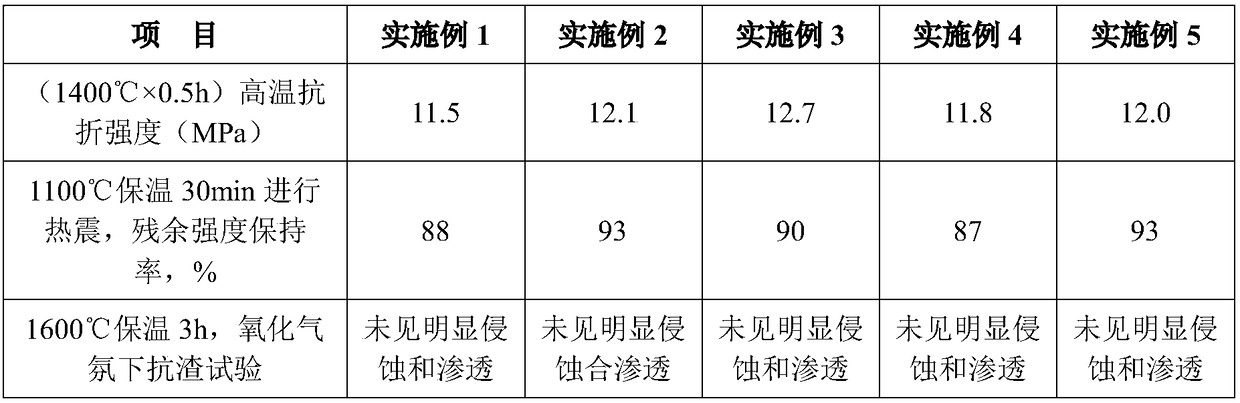

[0037] The difference between the preparation methods of Examples 2-5 and Example 1 lies in some process parameters, which are listed in Table 2 below.

[0038] Table 2 each embodiment process parameter table

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com