Patents

Literature

91results about How to "Improves bond stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin bendable grinding wheel and preparation method and device

InactiveCN101804602AAvoid carbonizationIncrease contentFlexible-parts wheelsGrinding devicesFiberglass meshCarbide silicon

The invention discloses a resin bendable grinding wheel and a preparation method and a device thereof. The resin bendable grinding wheel consists of brown aluminium oxide, calcined alumina, white alundum, black silicon carbide, phenolic resin powder, phenolic resin liquid, cryolite, barium sulphate, pyretic, iron oxide red, Hunori gel, alkali-free high tensile glass fiber mesh and non-woven black cloth. Compared with the prior art, through the optimization configuration on the aspect of the material selection and working procedures, the strength, the flexibility and the aging resistance of the grinding wheel are greatly improved, and at the same time, the resource and the energy are saved; and the strength of the grinding wheel is more than 80m / s, the grinding ratio is more than or equal to 1:15, the maximum bendable angle can reach 40 degrees, the tensile strength is greatly improved, the service life is prolonged by two times, the energy consumption is reduced by 5 to 10 percent, and the yield of the finished product can reach more than 99 percent.

Owner:GUIZHOU FUSUN INDAL

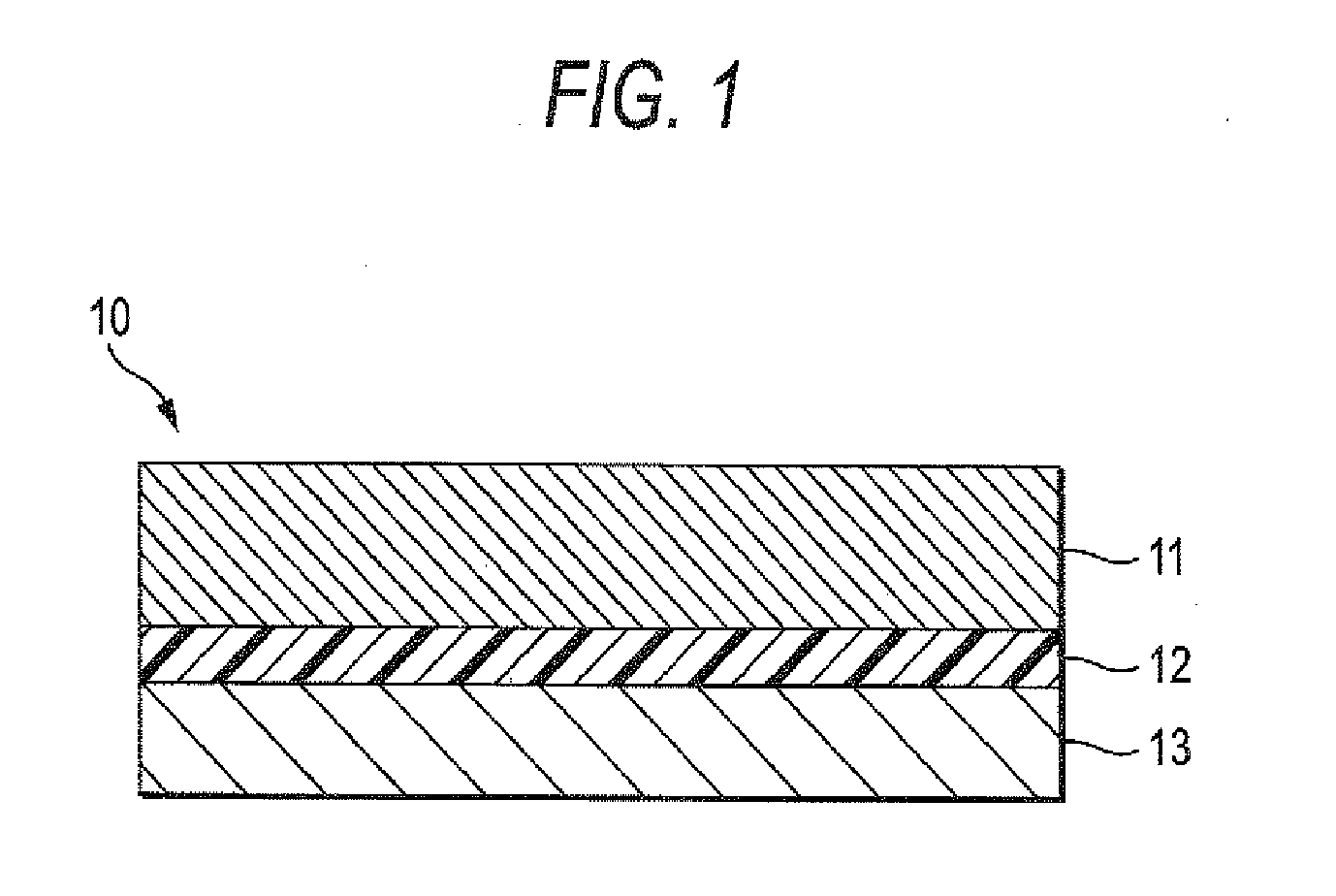

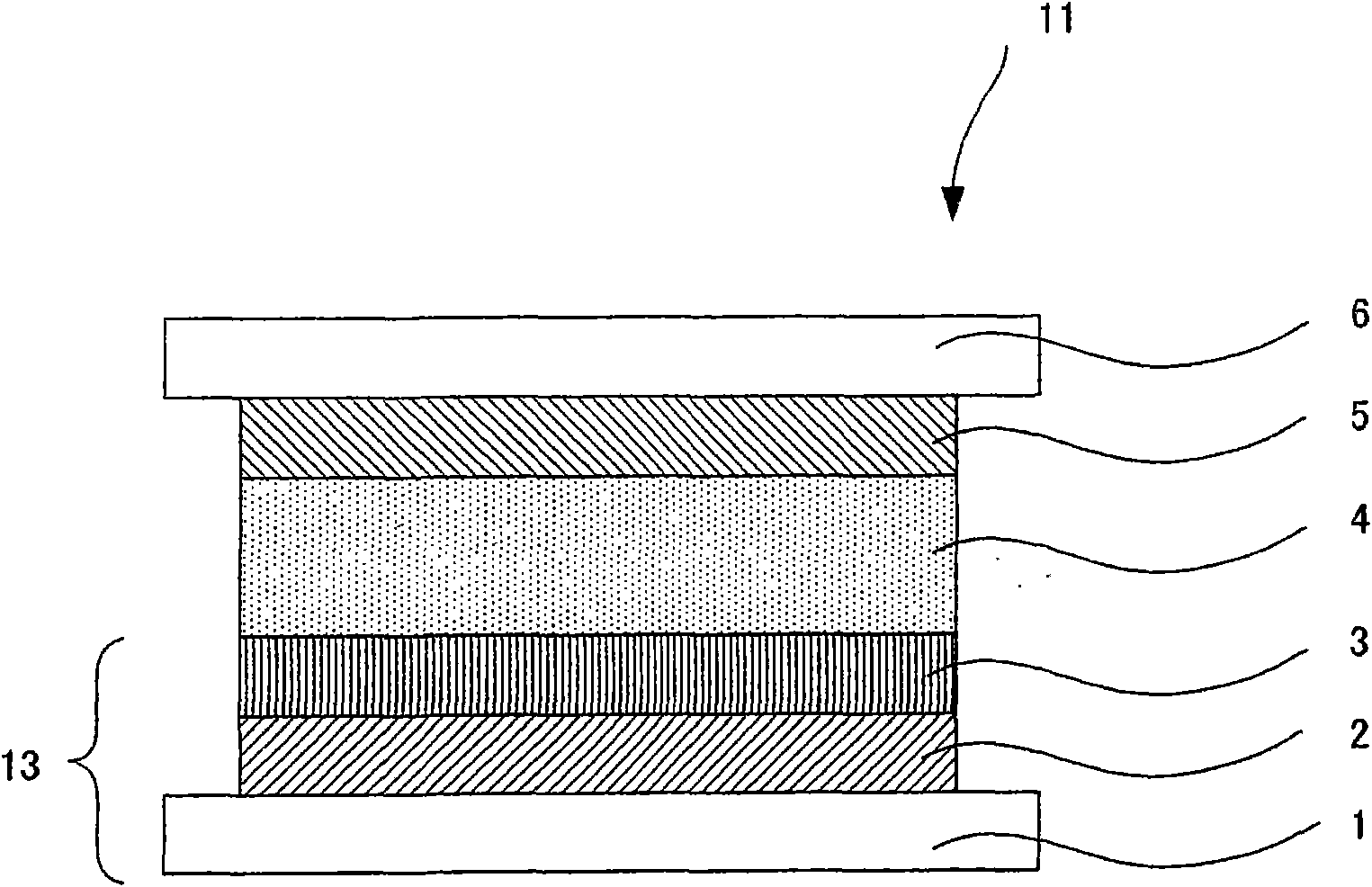

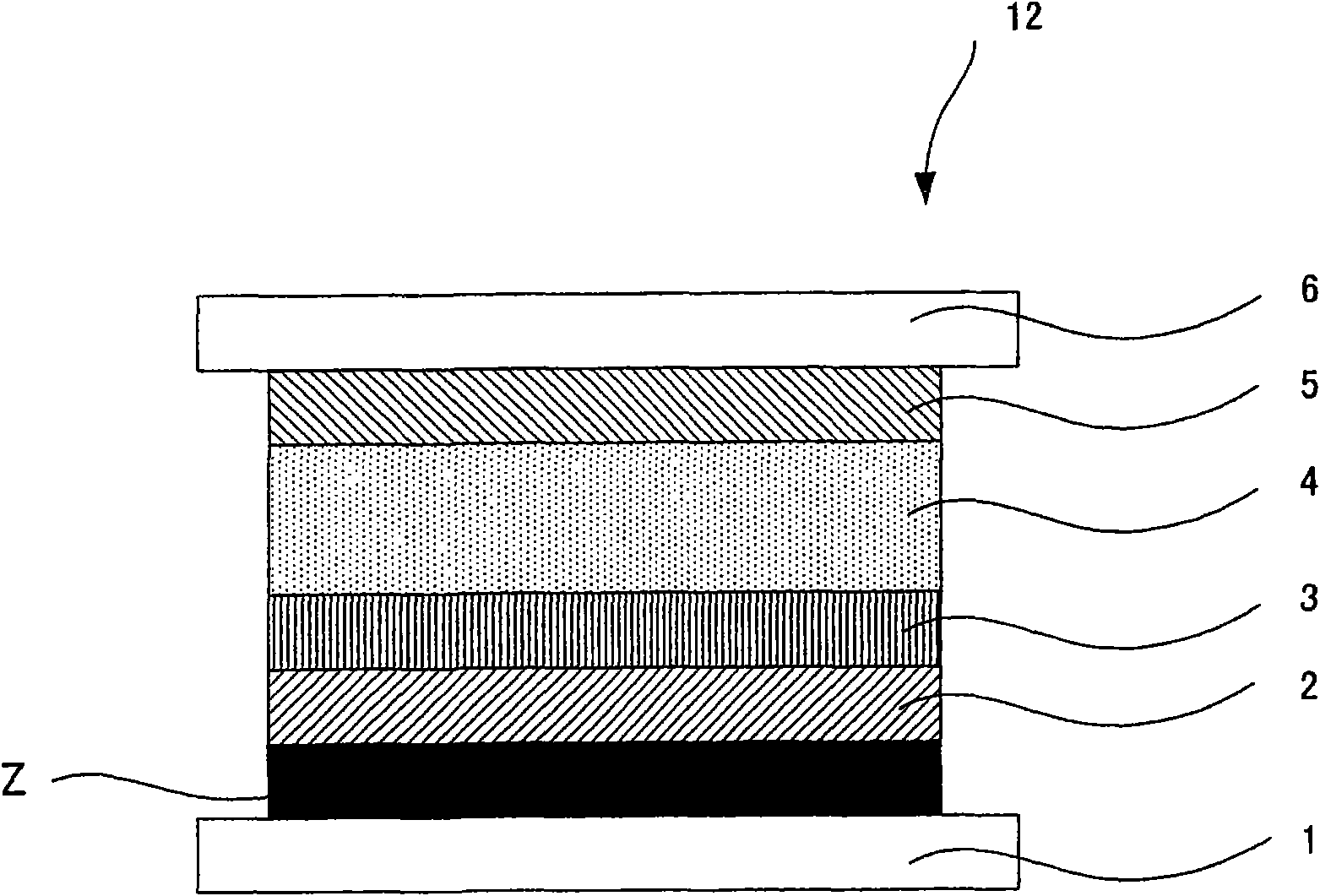

Laminate, printed wiring board and method for manufacturing them

InactiveCN1720136AImproves bond stabilityImprove bond reliabilityPrinted circuit manufactureMetal layered productsHigh densityEngineering

The invention provides a laminate which can be used for forming a high density circuit thereon, with good resistance to further processing such as decontamination and excellent adhesion, and excellent adhesion reliability in a high temperature atmosphere, as well as a print circuit wiring board, that is, the invention relates to a laminate and a print circuit wiring board, comprising a thermoplastic polyimide film layer and a metal layer which are formed on one side or two sides thereof or a non-thermoplastic polyimide film layer.

Owner:KANEKA CORP

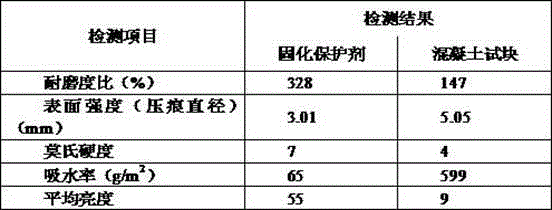

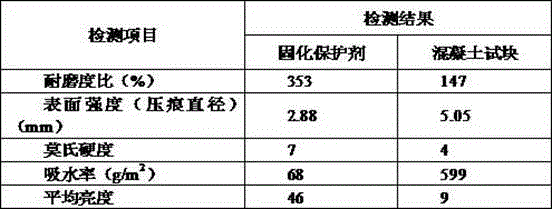

Concrete curing protective agent

The invention relates to a concrete curing protective agent, which is prepared from the following components by weight percent: 20-30wt.% of nano-silica, 10-20wt.% of silicate, 20-35wt.% of acrylic ester, 8-15wt.% of a water repellent, 1-5wt.% of a film-forming assistant, and the balance water. The curing protective agent can improve the hardness and wear resistance of concrete ground, effectively solves the problems of concrete ground sugaring, dusting and the like, also can endow concrete with excellent waterproof and oil resistant properties, and can greatly improve the brightness of concrete ground without polishing.

Owner:湖南交泰建材有限公司

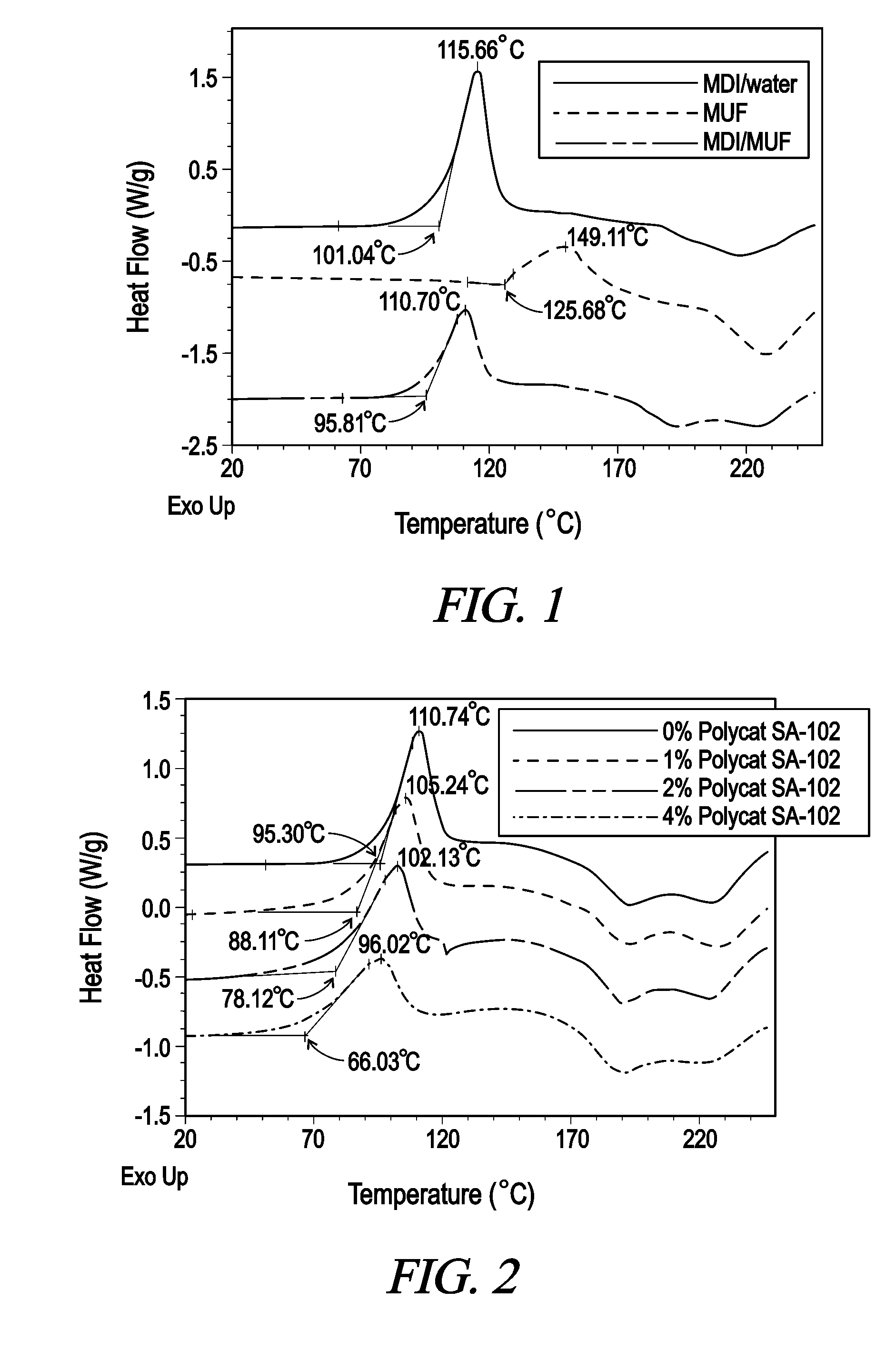

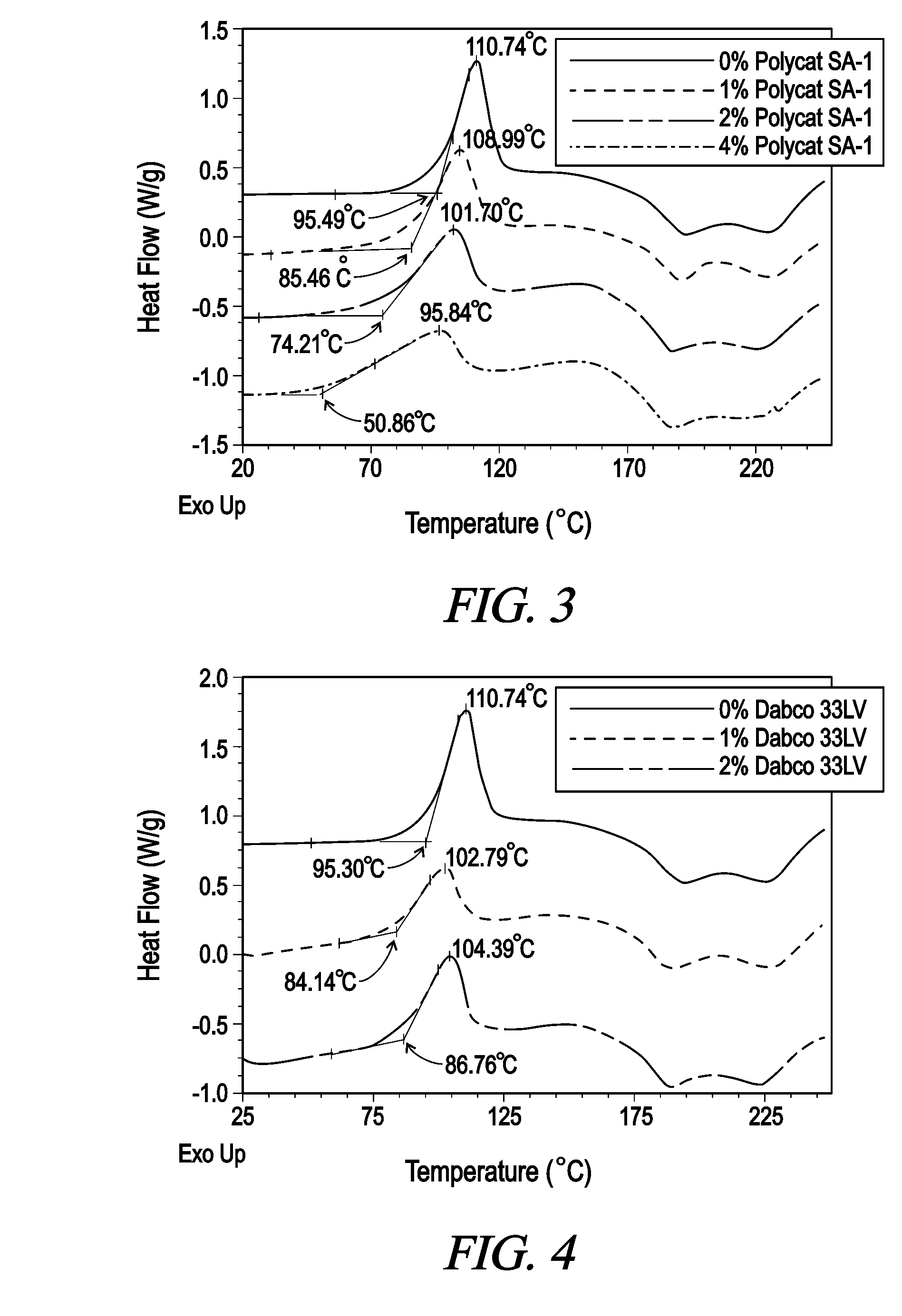

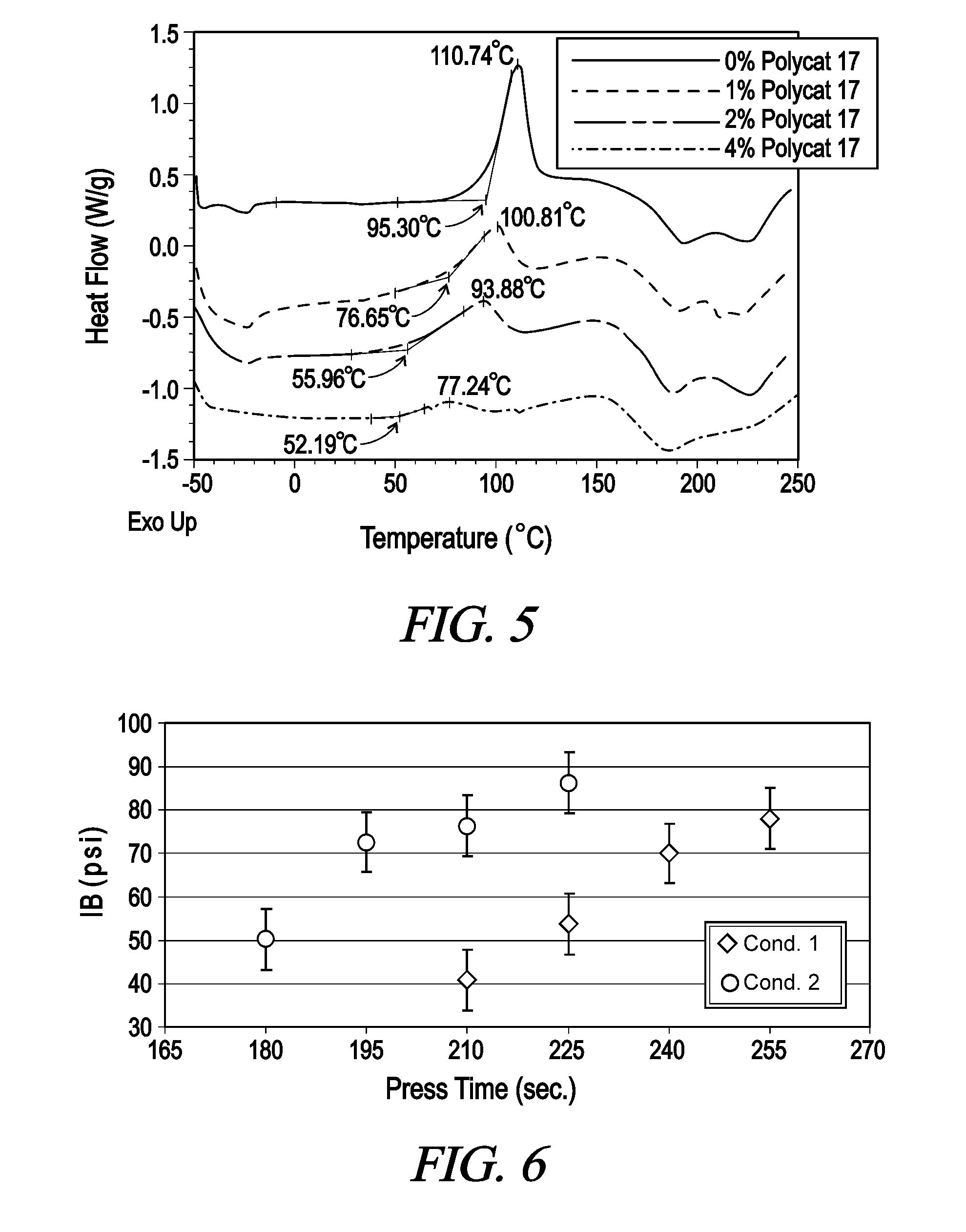

Catalyzed Isocyanate Adhesive System For Wood Composites

InactiveUS20100075153A1Speed up the processFast curingAdhesive articlesSynthetic resin layered productsPolymerChemistry

An adhesive system for, inter alia, the manufacturing of wood composites, which includes a two part adhesive system with an isocyanate polymer and an isocyanate catalyst in an thermosetting resin.

Owner:GANG NAIL SYST

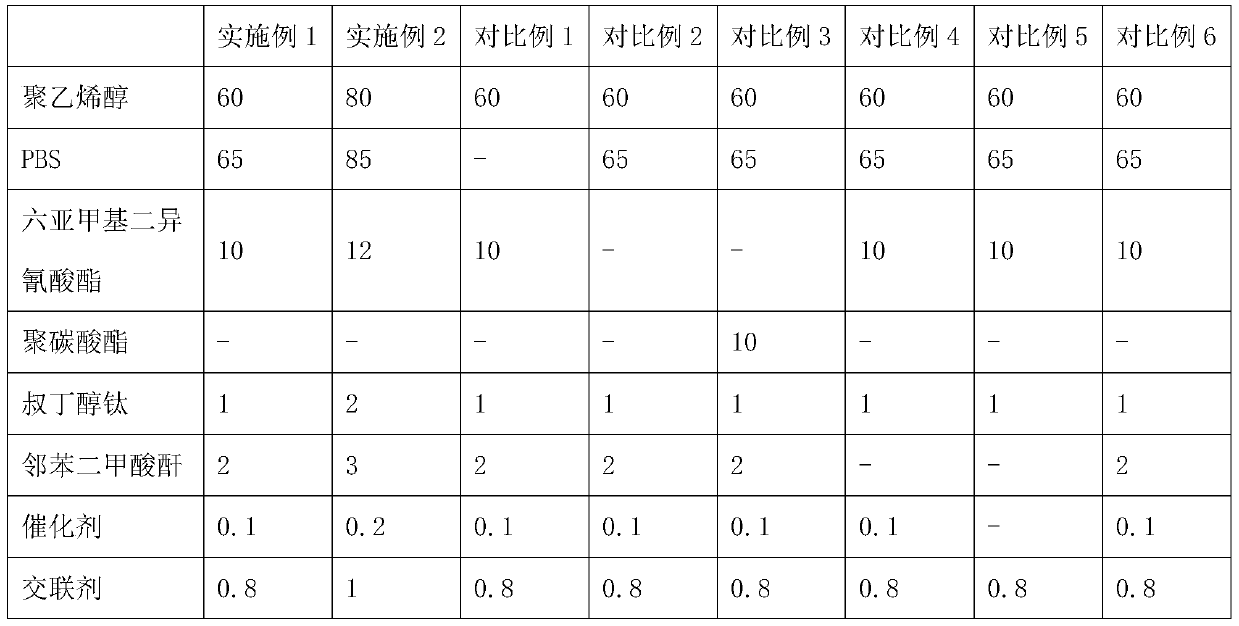

Production process of degradable paper bag

ActiveCN110735360AImprove waterproof performanceImprove toughnessNon-fibrous pulp additionPaper/cardboardPolymer scienceEngineering

The invention relates to the technical field of packaging, and discloses a production process of a degradable paper bag. The degradable paper bag comprises a paper bag main body; and the paper bag main body comprises packaging paper and a waterproof film. The production process of the paper bag main body comprises the following steps: S1, a film spraying machine is adopted for conducting hot melting on the waterproof film, then spraying the waterproof film on the surface of the packaging paper for coating to form a waterproof layer, and carrying out hot melting on the waterproof layer for primary bonding with the packaging paper; and S2, blowing out hot air by using a hot air bag making machine, so that the waterproof film is further bonded with the packaging paper to prepare the water-proof paper bag. Compared with the prior art, the advantages are as following: the packaging paper is coated with the water-proof film using the film spraying machine, so that the water resistance of thepackaging paper is improved, and in addition, a toughening film is compounded, so that the toughness of the paper bag is improved.

Owner:浙江超凡科技股份有限公司

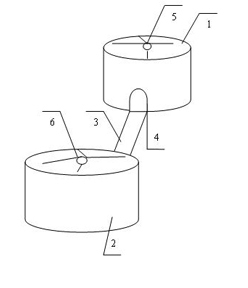

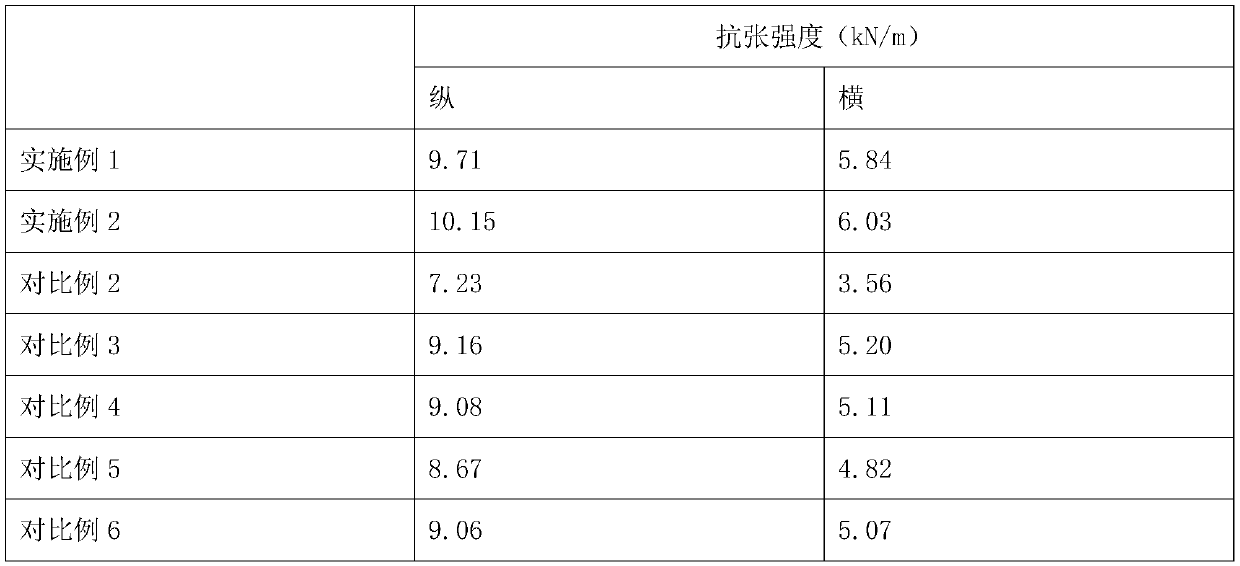

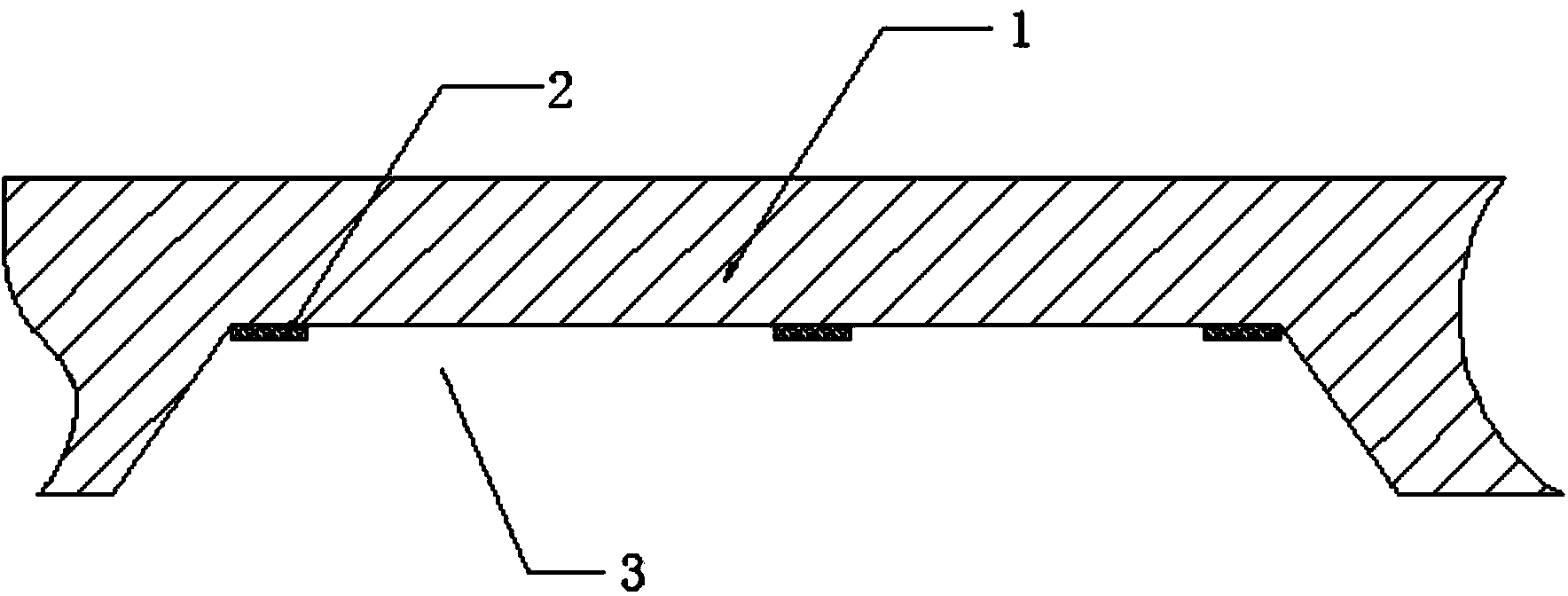

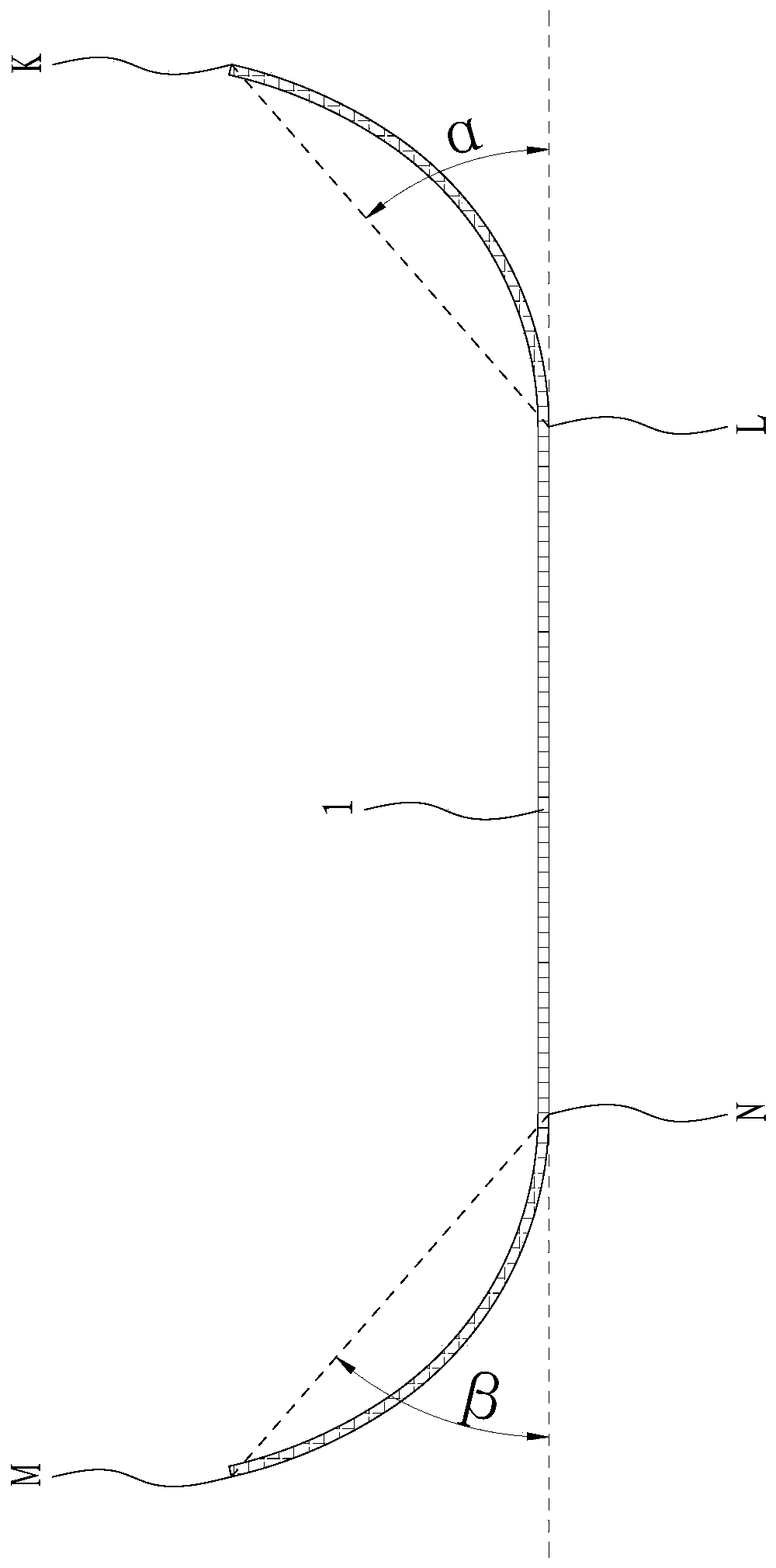

Joint coating repairing anticorrosion layer structure for in-service pipeline

ActiveCN104110556AAdhesiveImproves bond stabilityCorrosion preventionPipe protection against corrosion/incrustationLap jointCompound structure

The invention discloses a joint coating repairing anticorrosion layer structure for an in-service pipeline, and belongs to the field of oil and gas pipeline transportation technologies. The in-service pipeline comprises steel pipes (1), anticorrosion layers (2) and joint coating metal ring seams (3). The steel pipes (1) are buried in the ground, a viscoelastic rubber band (4) is arranged on the outer surface of each joint coating metal ring seam (3), a pressure-sensitive adhesive type thermal contraction band (5) covers the outer periphery of each viscoelastic rubber band (4), each viscoelastic rubber band (4) completely covers the corresponding joint coating metal ring seam (3), two ends of each viscoelastic rubber band (4) are in lap joint with the corresponding anticorrosion layers (2), each pressure-sensitive adhesive type thermal contraction band (5) completely covers the corresponding viscoelastic rubber band (4), and two ends of each pressure-sensitive adhesive type thermal contraction band (5) are in lap joint with the corresponding anticorrosion layers (2). The joint coating repairing anticorrosion layer structure has the advantages that compound structures with the viscoelastic rubber bands and the pressure-sensitive adhesive type thermal contraction bands which are combined with one another are arranged at joint coating positions of the pipeline, so that the joint coating repairing anticorrosion layer structure is excellent in anticorrosion performance and has low surface treatment requirements, and a construction process can be carried out conveniently and quickly.

Owner:PETROCHINA CO LTD

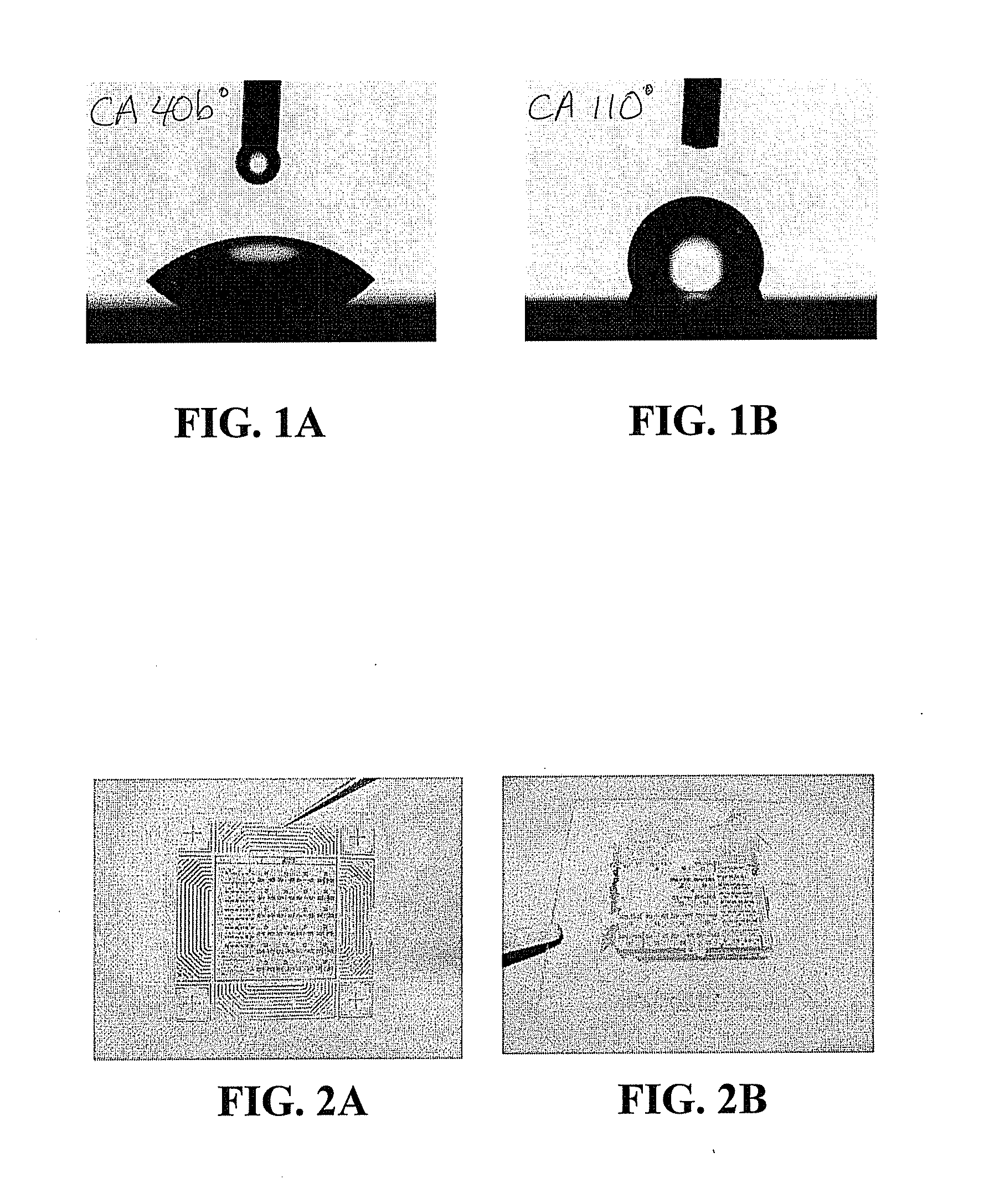

Surface treatment of an organic or inorganic substrate for enhancing stability of a lithographically defined deposited metal layer

InactiveUS20110006032A1General applicabilityImprove mechanical propertiesConductive material chemical/electrolytical removalCable/conductor manufactureHydrophobic surfacesMetal deposition

A method of metal deposition may include chemically modifying a surface of a substrate to make the surface hydrophobic. The method may further include depositing a layer of metal over the hydrophobic surface and masking at least a portion of the deposited metal layer to define a conductive metal structure. The method may also include using an etching agent to etch unmasked portions of the deposited metal layer.

Owner:STMICROELECTRONICS SRL

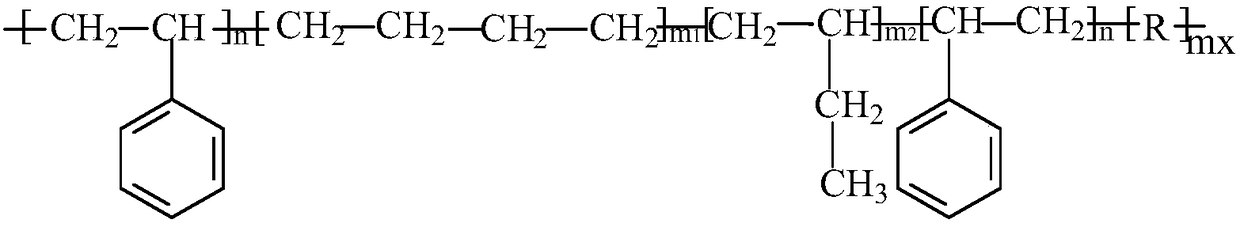

Hydrogenated styrene-conjugated diene copolymer as well as preparation method and application thereof in self-adhesive films

InactiveCN108219090AGood mechanical properties and processing propertiesEasy to prepareFilm/foil adhesives without carriersConjugated dieneSelf adhesive

The invention discloses a hydrogenated styrene-conjugated diene copolymer as well as a preparation method and application thereof in self-adhesive films. The hydrogenated styrene-conjugated diene copolymer has the following expression: S1-EB1-S2-EB2, wherein S1 and S2 are styrene blocks; EB1 is a hydrogenated butadiene block; and EB2 is a hydrogenated conjugated diene block. The hydrogenated styrene-conjugated diene copolymer has good processing properties and can be used for preparing the self-adhesive films together with other poly stylene polymers; and the prepared self-adhesive films are less affected by temperature, humidity and other external conditions, have good stability, have adhesive strength capable of being controlled within a wide range, and are suitable for application requirements of various materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water-based inorganic environment-friendly coating and preparation method thereof

InactiveCN108047839AGood optical performanceGood compatibilityFireproof paintsAnti-corrosive paintsWater basedEnvironmental resistance

The invention proposes a water-based inorganic environment-friendly coating and a preparation method thereof, which solve the problem that water-based coating in the prior art cannot resist acid and alkali and is low in corrosion resistance. The technical solution of the invention is implemented in the following way: the water-based inorganic environment-friendly coating is prepared from the following materials in parts by weight: 10 to 40 parts of silicasol, 20 to 40 parts of polymer emulsion, 4 to 10 parts of nano silicon dioxide powder, 3 to 6 parts of thickener, 0.1 to 0.5 part of mould inhibitor, 0.1 to 0.3 part of defoaming agent, 1 to 3 parts of film coalescing aid, 1 to 10 parts of dispersant, 10 to 30 parts of calcined kaolin, 10 to 50 parts of heavy calcium carbonate, 10 to 30 parts of pigment and 20 to 40 parts of deionized water. The compatibility between the additives chosen by the invention is better, the coating is odorless and smellless, the protection of ecological environments is benefited, the coating has the nature of inorganic matter, and does not contain any organic chemical material or solvent, and during production and application, the coating has the characteristics of no odor and no allergy, which are good for environment and ecology.

Owner:环秀(青岛)建材科技有限公司

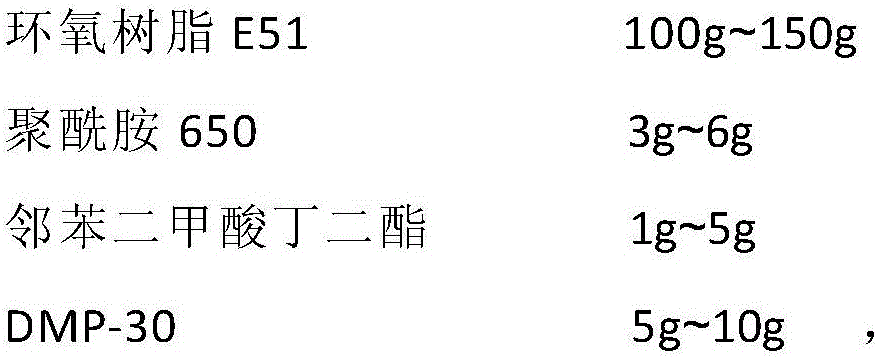

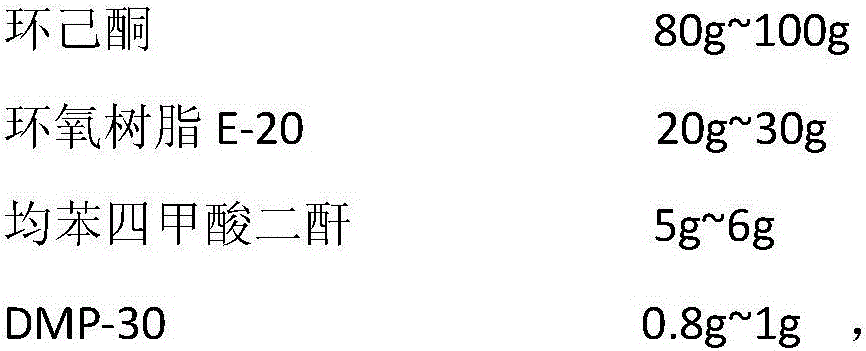

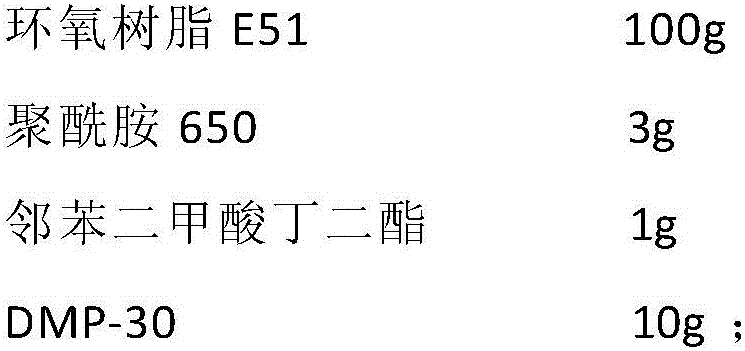

Preparation method of bondable polyfluortetraethylene plate anti-corrosion lining

InactiveCN105885752AStrong bond tensile strengthShorten drying timeNon-macromolecular adhesive additivesLamination ancillary operationsEpoxyBiological activation

The invention discloses a preparation method of a bondable polyfluortetraethylene plate anti-corrosion lining. The preparation method comprises the specific steps that a polyfluortetraethylene plate is grinded with abrasive paper, is cleaned with acetone and is put into a mixed solution of sodium, naphthalene and tetrahydrofuran for surface activation treatment; the surface of the treated polyfluortetraethylene plate is coated with an epoxy resin pre-coated adhesive to obtain the treated polyfluortetraethylene plate instant to adhere; then, a steel plate and the polyfluortetraethylene plate are superposed and bonded together through an epoxy hot-melt adhesive, and the anti-corrosion lining is obtained after curing is performed for 24 hours. Due to the fact that a preparation process is simple, the construction is easy, the labor costs for construction is low, the raw materials are easy to obtain, the price is relatively cheap, and the obtained polyfluortetraethylene plate anti-corrosion lining has the advantages of high bonding tensile strength, short drying time, high in bonding stability, excellent physical and chemical properties and the like, and is expected to replace a most often used glass fiber reinforced plastic lining.

Owner:王兆华

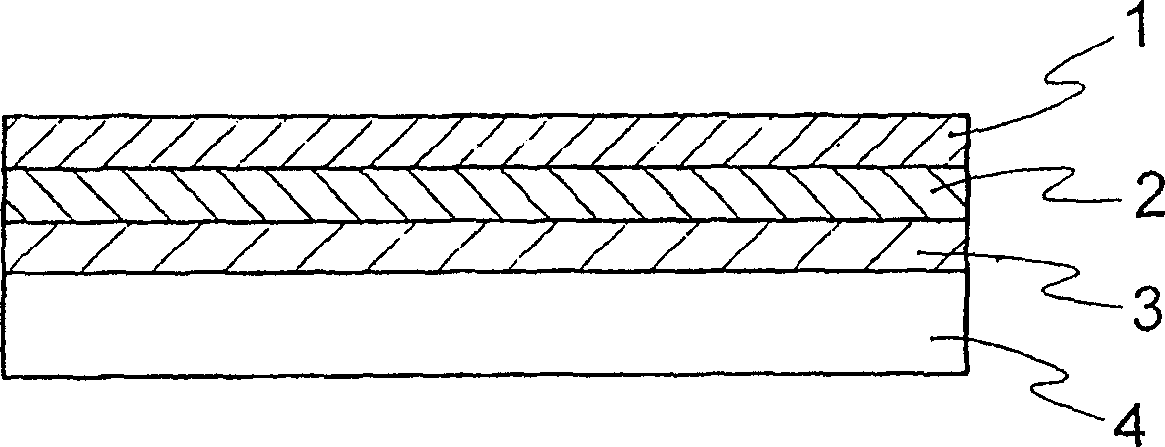

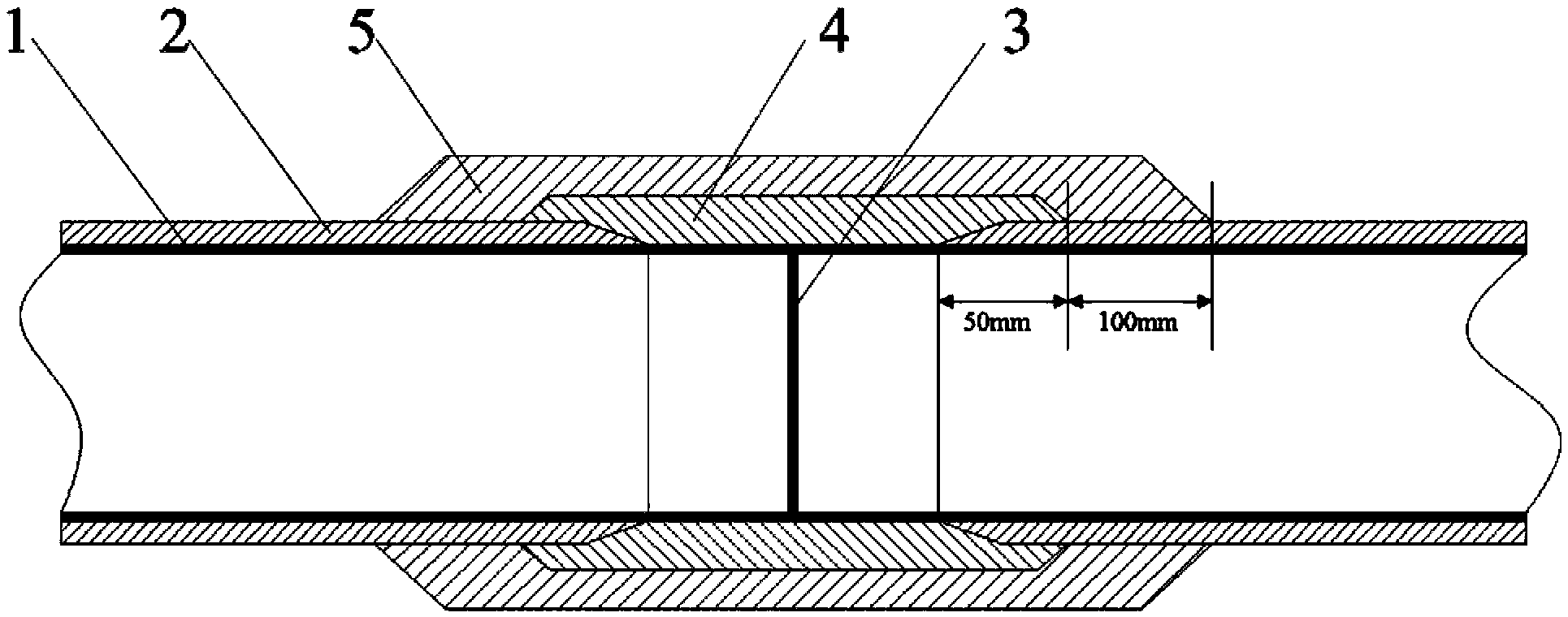

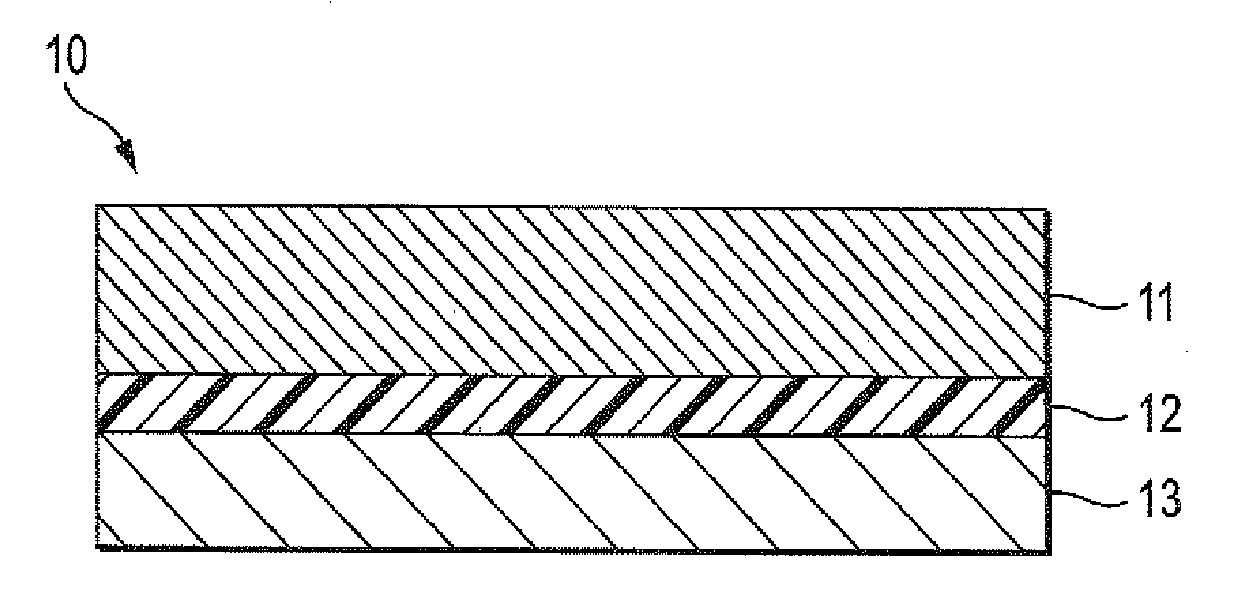

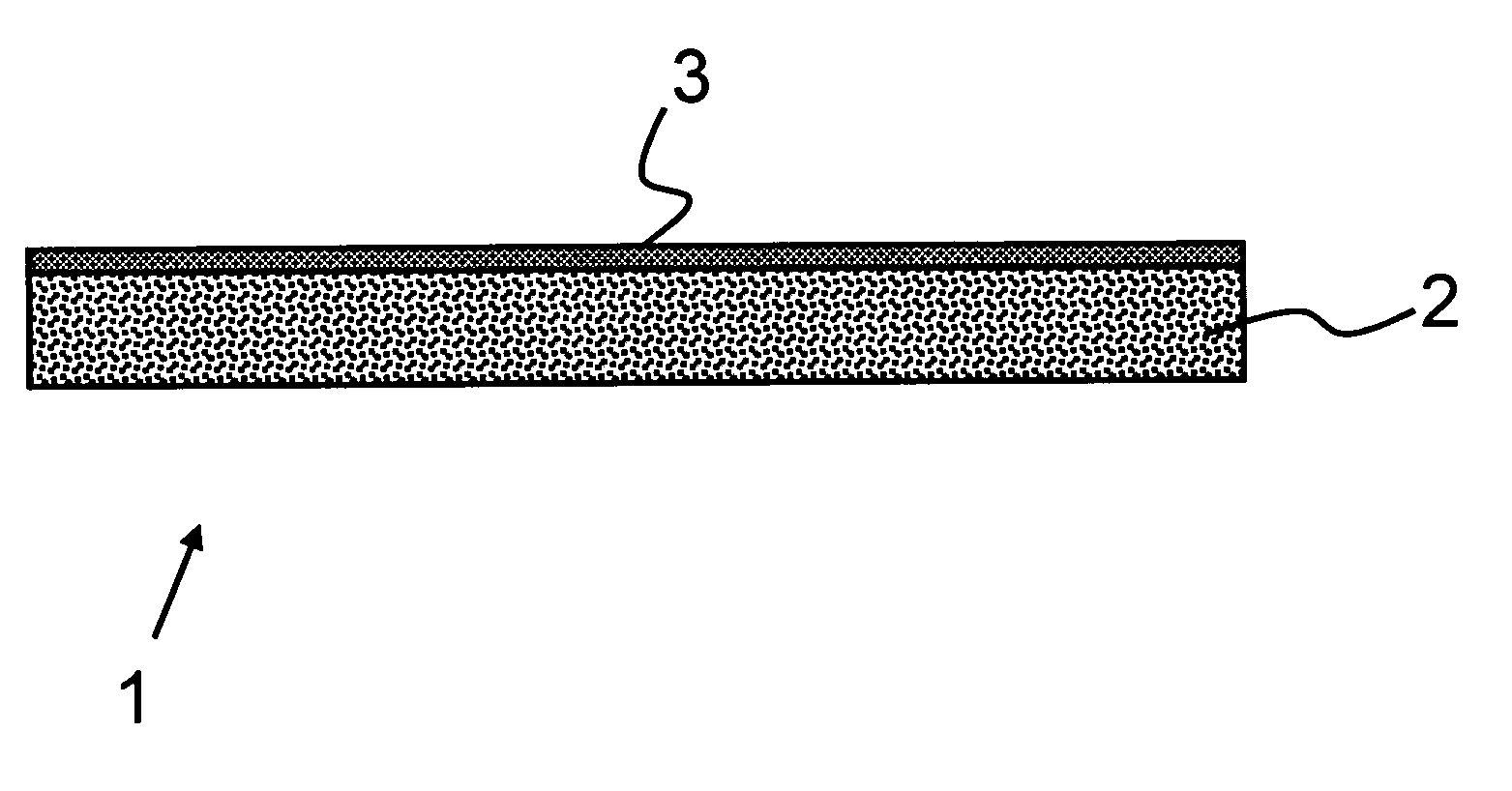

Pressure sensitive adhesive sheet for dicing

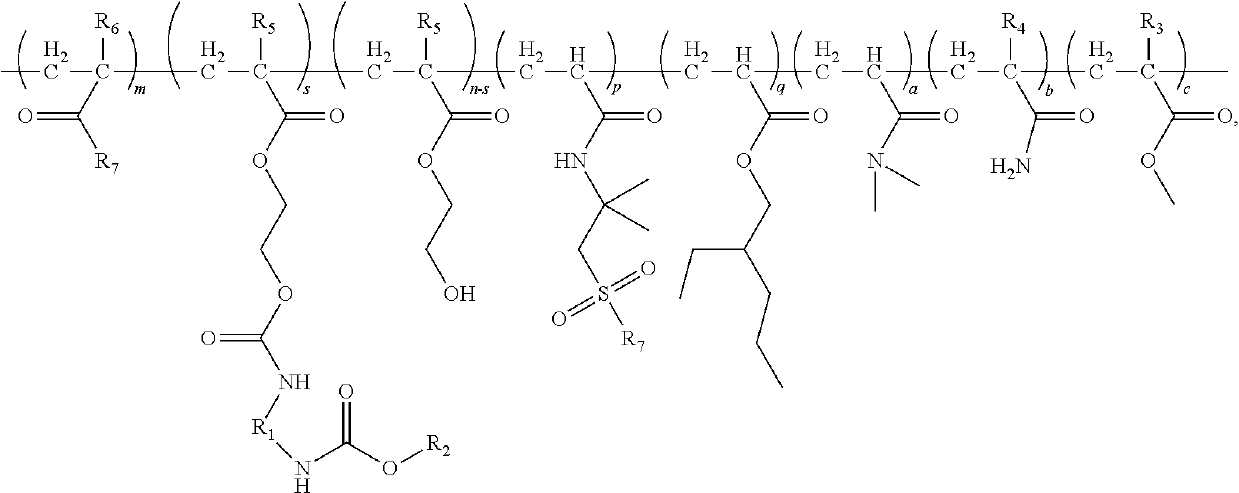

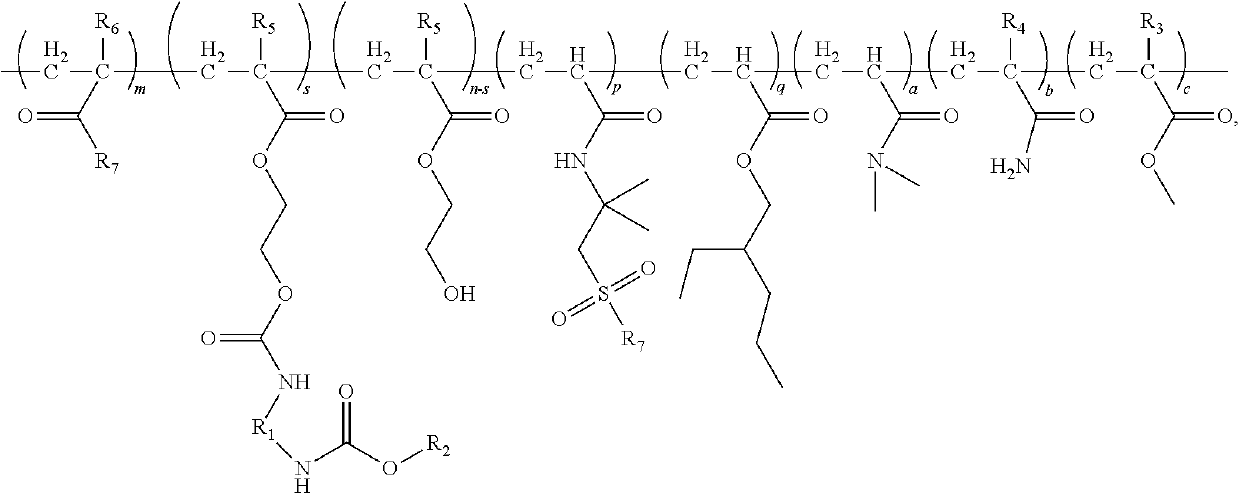

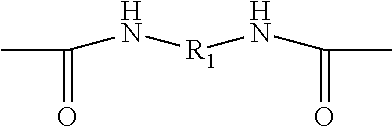

InactiveUS20070281153A1Improves bond stabilityGood flexibilityLamination ancillary operationsPaper/cardboard articlesMeth-Polyvinyl chloride

The present invention relates to a pressure-sensitive adhesive sheet for dicing, which comprises a substrate and at least one pressure-sensitive adhesive layer disposed on at least one surface of the substrate, the substrate containing polyvinyl chloride as a primary component and a trialkyl phosphite as a thermal stabilizer of the polyvinyl chloride, and the pressure-sensitive adhesive layer containing poly(meth)acrylic acid ester as a primary component, in which the trialkyl phosphite transited from the substrate into the pressure-sensitive adhesive layer is not unevenly distributed on a surface of the pressure-sensitive adhesive layer; a method of processing a processed material using the same, and a piece of a processed material obtainable by the method.

Owner:NITTO DENKO CORP

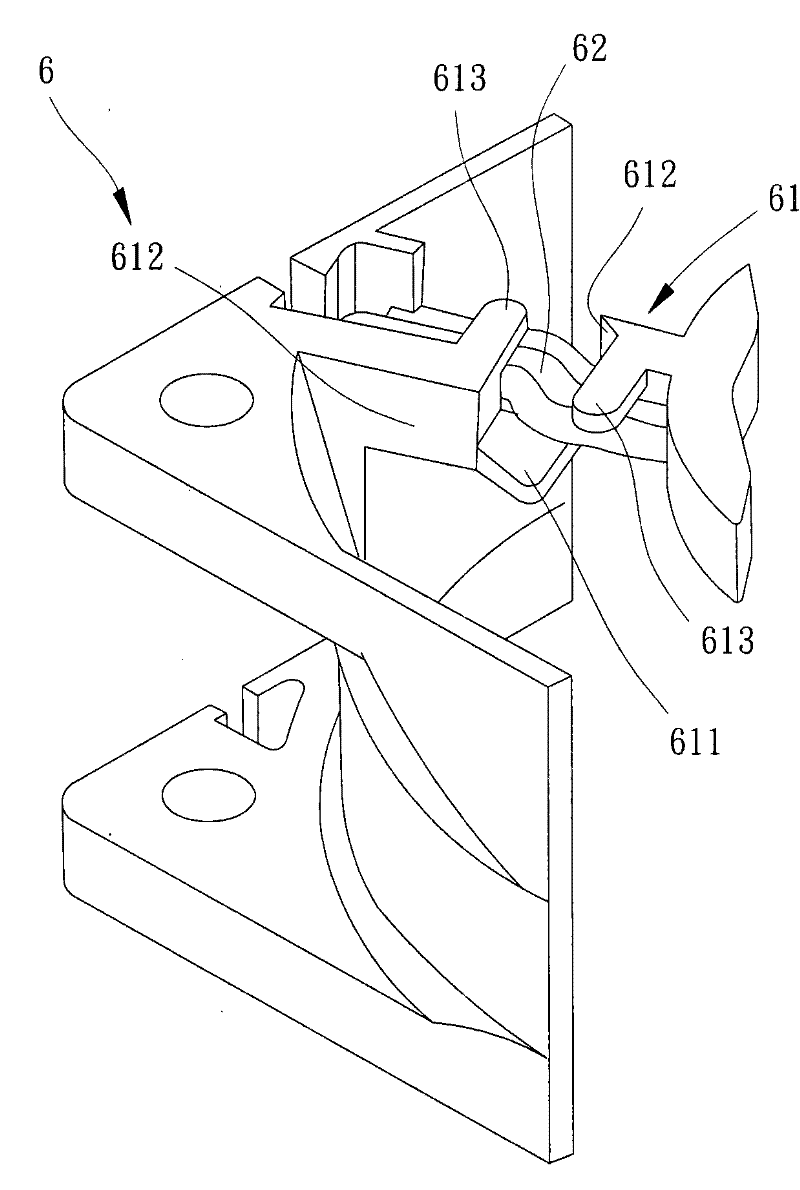

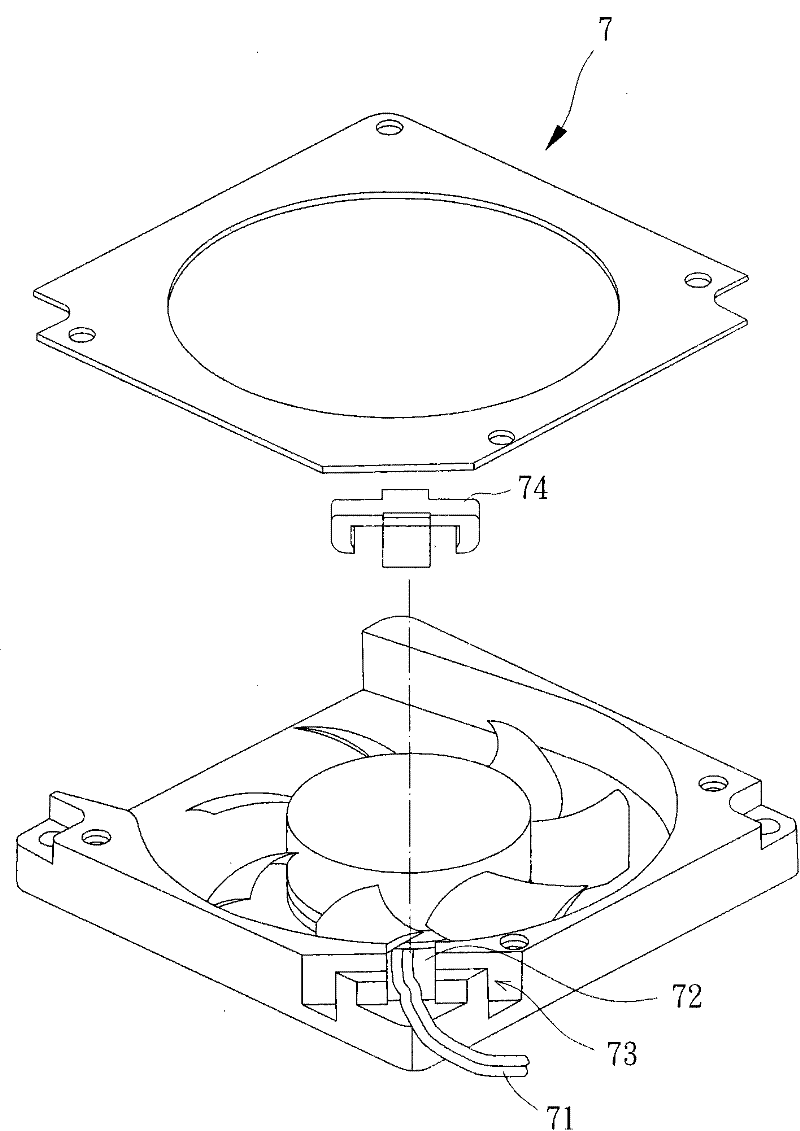

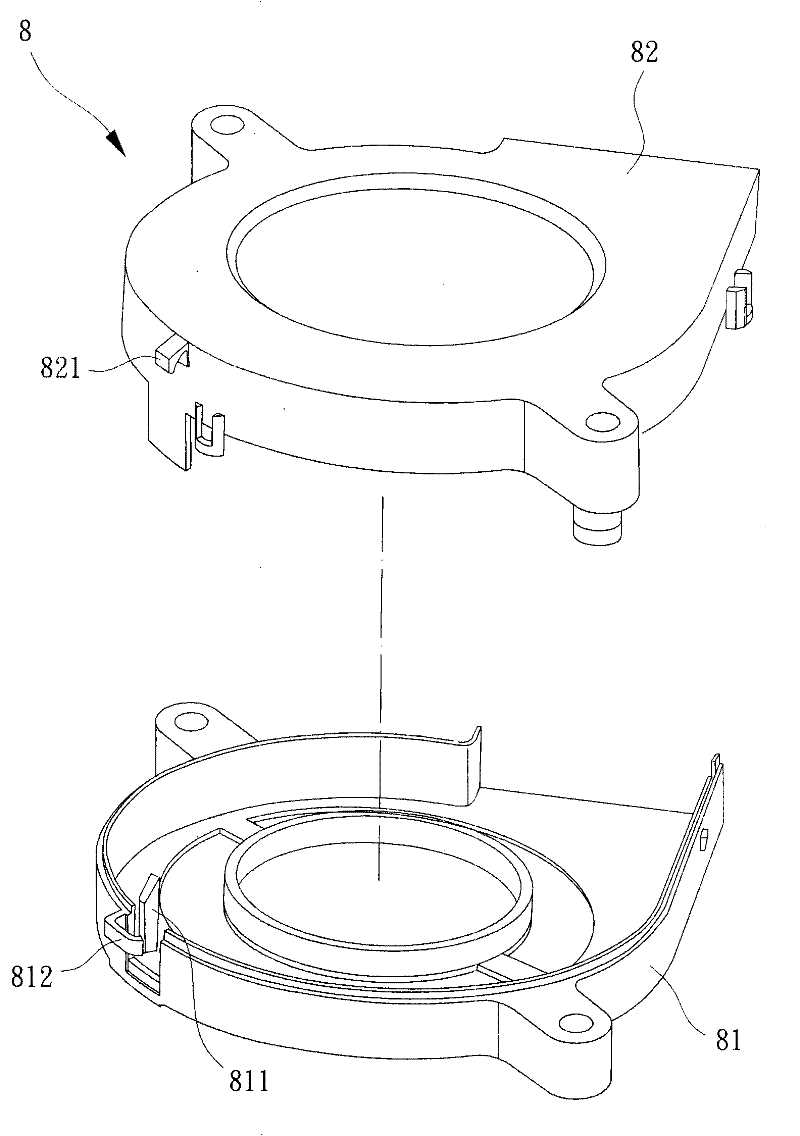

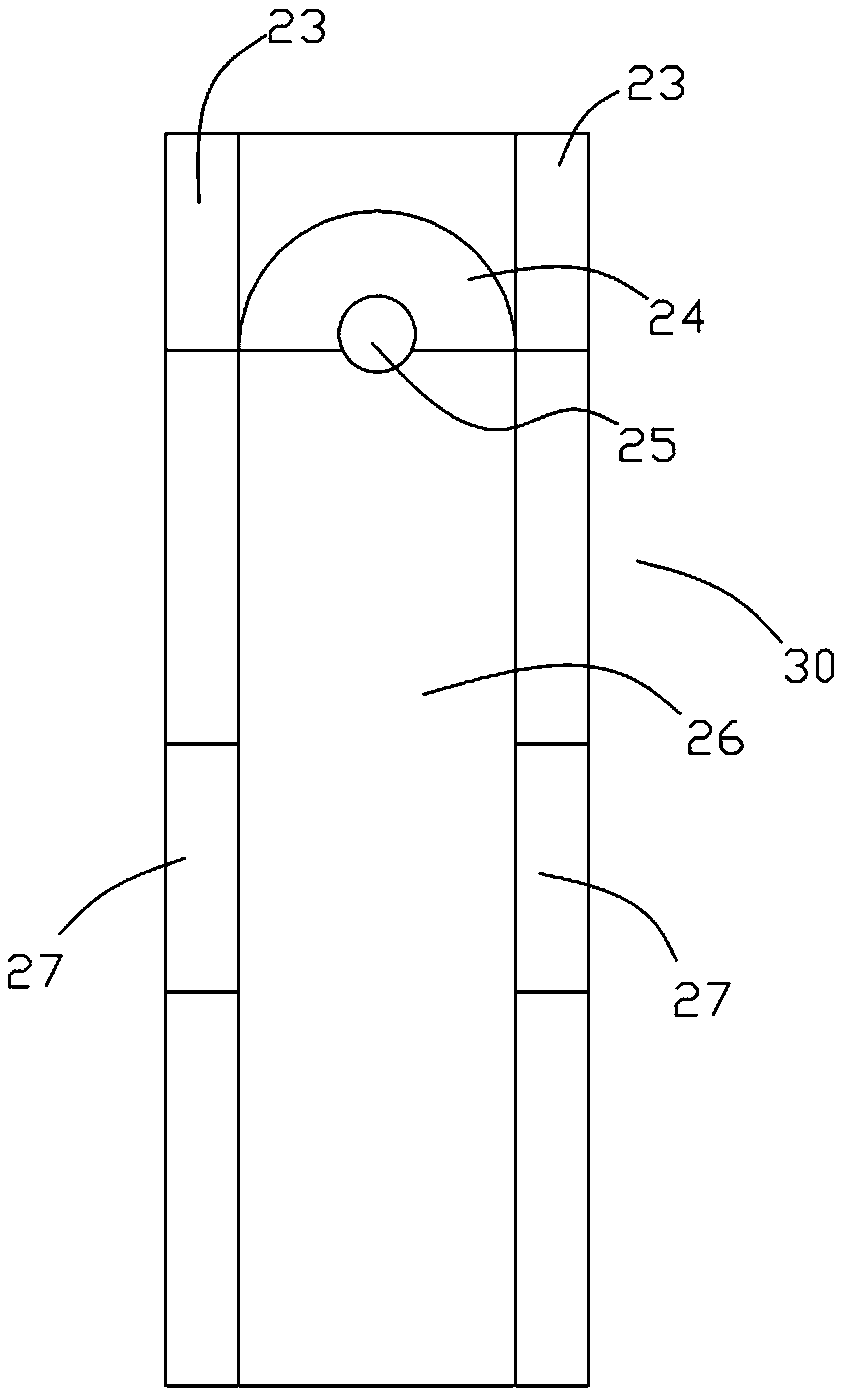

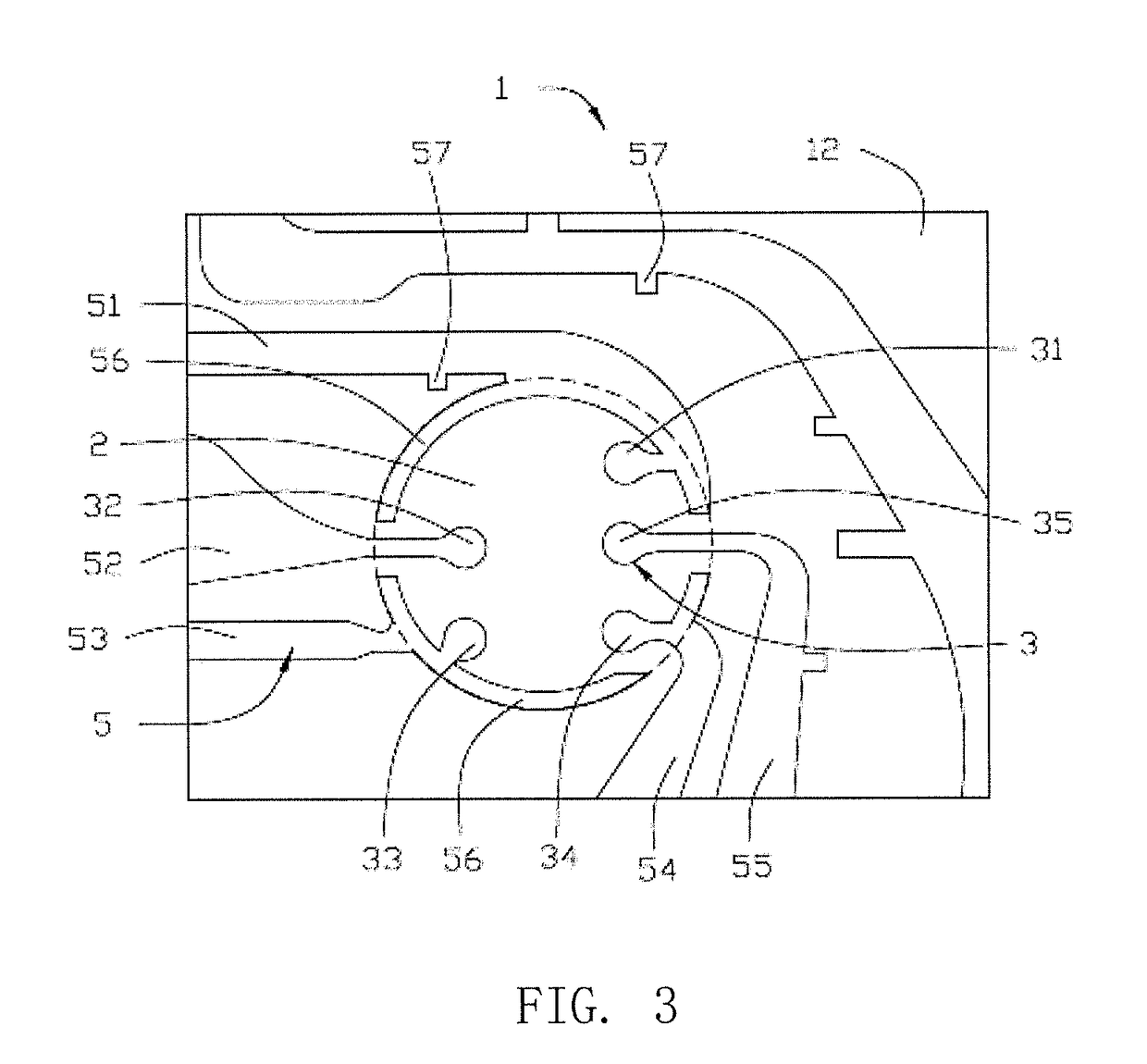

fan frame

ActiveCN102297162AReally fixedImproves bond stabilityPump componentsPumpsEngineeringMechanical engineering

Owner:SUNONWEALTH ELECTRIC MACHINE IND

An aqueous antifogging resin, aqueous antifogging coating composition and preparation method thereof

ActiveUS20210071031A1Improve hydrophilicityGood hygroscopicityPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

The present invention discloses an aqueous antifogging resin, introducing a molecular segment and a functional group with good hydrophilicity and hygroscopicity, which impart excellent antifogging performance, coating strength and transparent flow appearance to the aqueous antifogging resin and the cured coating has a water contact angle of up to 1˜10°. The present invention further discloses a coating composition including the aqueous antifogging resin, and the cured coating of the coating composition has good antifogging, wear-resistant, water-resistant, chemical resistant, stain-resistant and UV-resistant performance, and excellent adhesion to a substrate; and the coating is firm at the same time, and has excellent film-forming strength and flexual endurance. The coating composition can be used for antifogging surface treatment of the window of mobile phone, PC or PMMA transparent materials, automotive glass and bathroom mirrors and has good long-term stability.

Owner:HUNAN SOKAN NEW MATERIAL

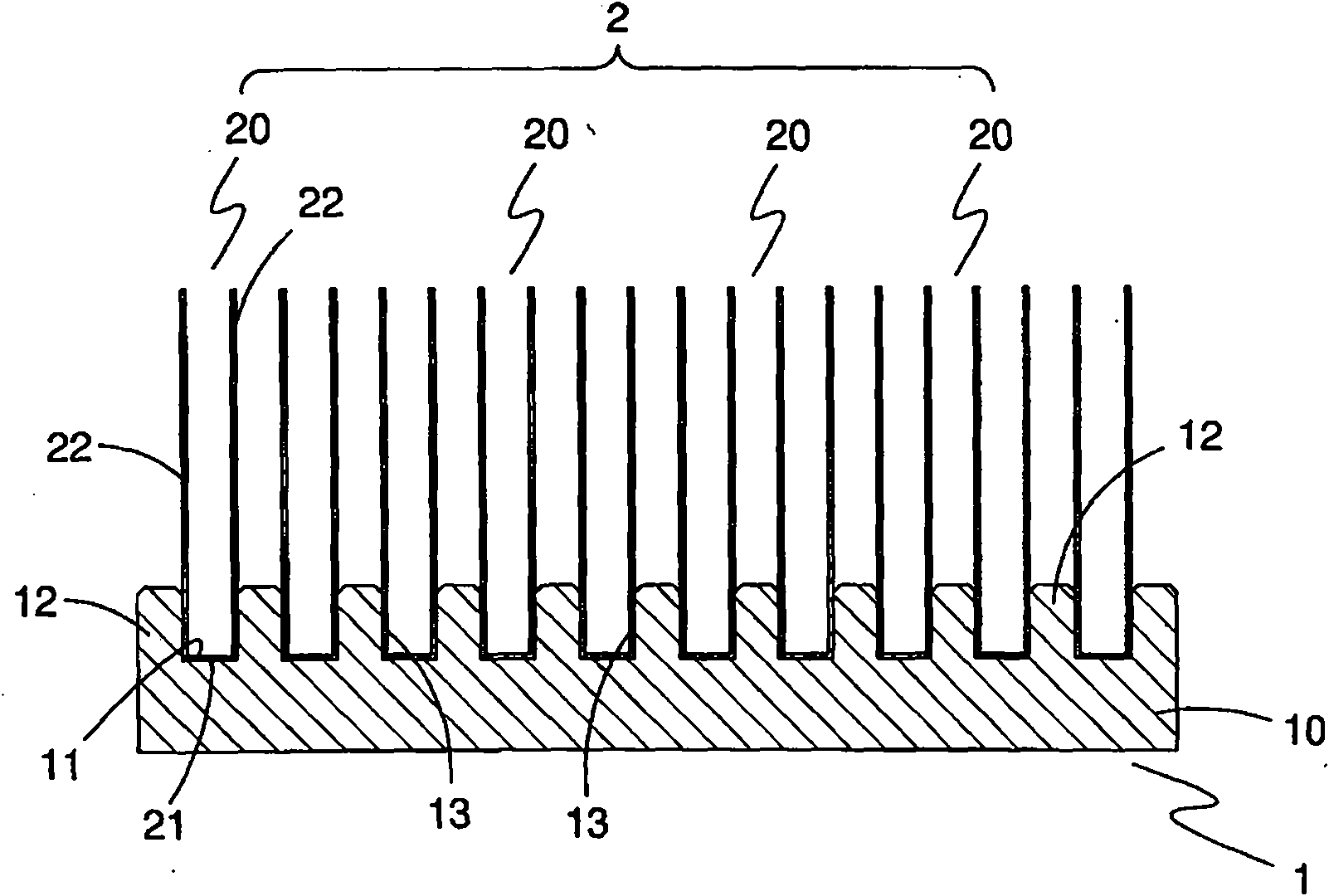

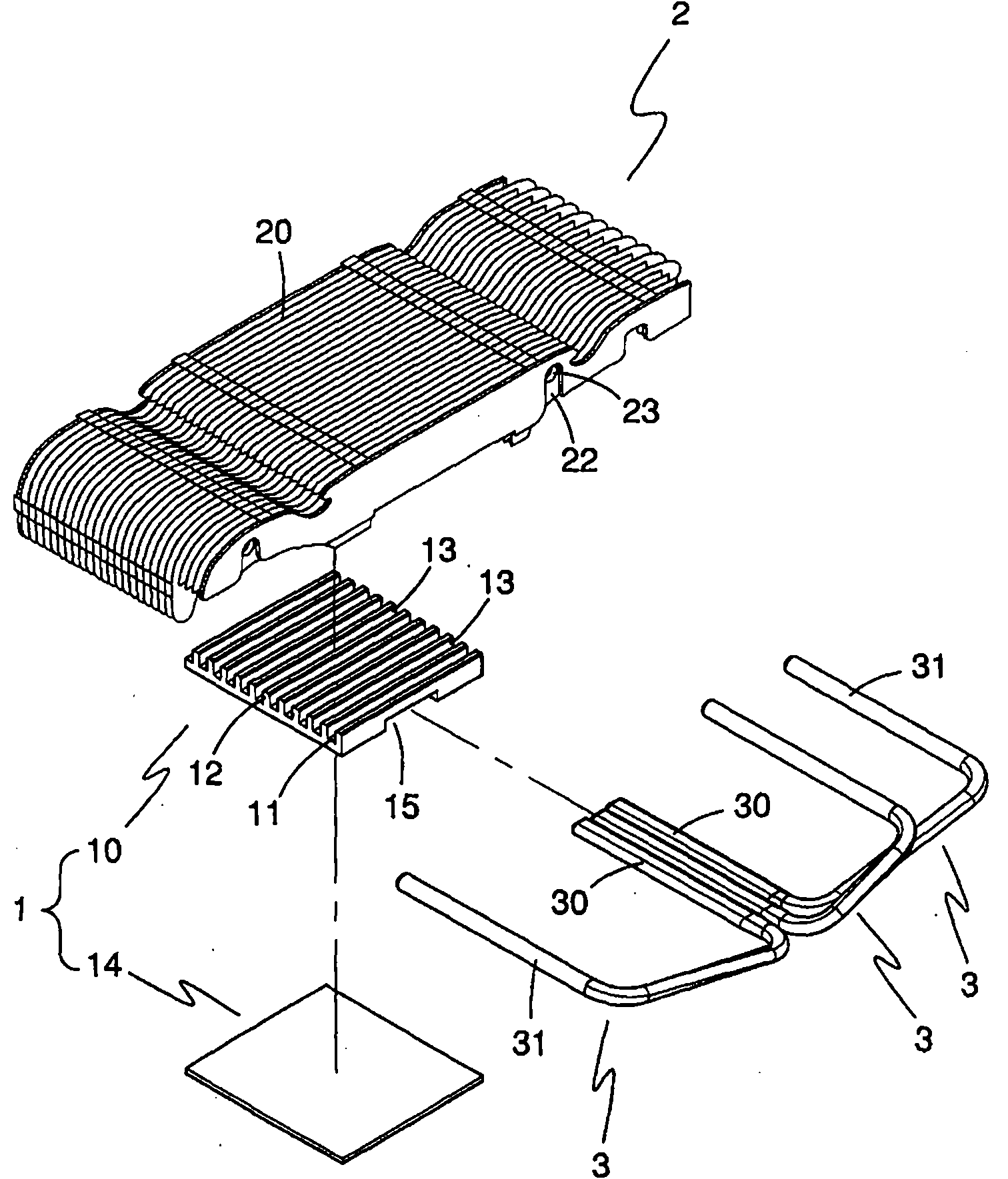

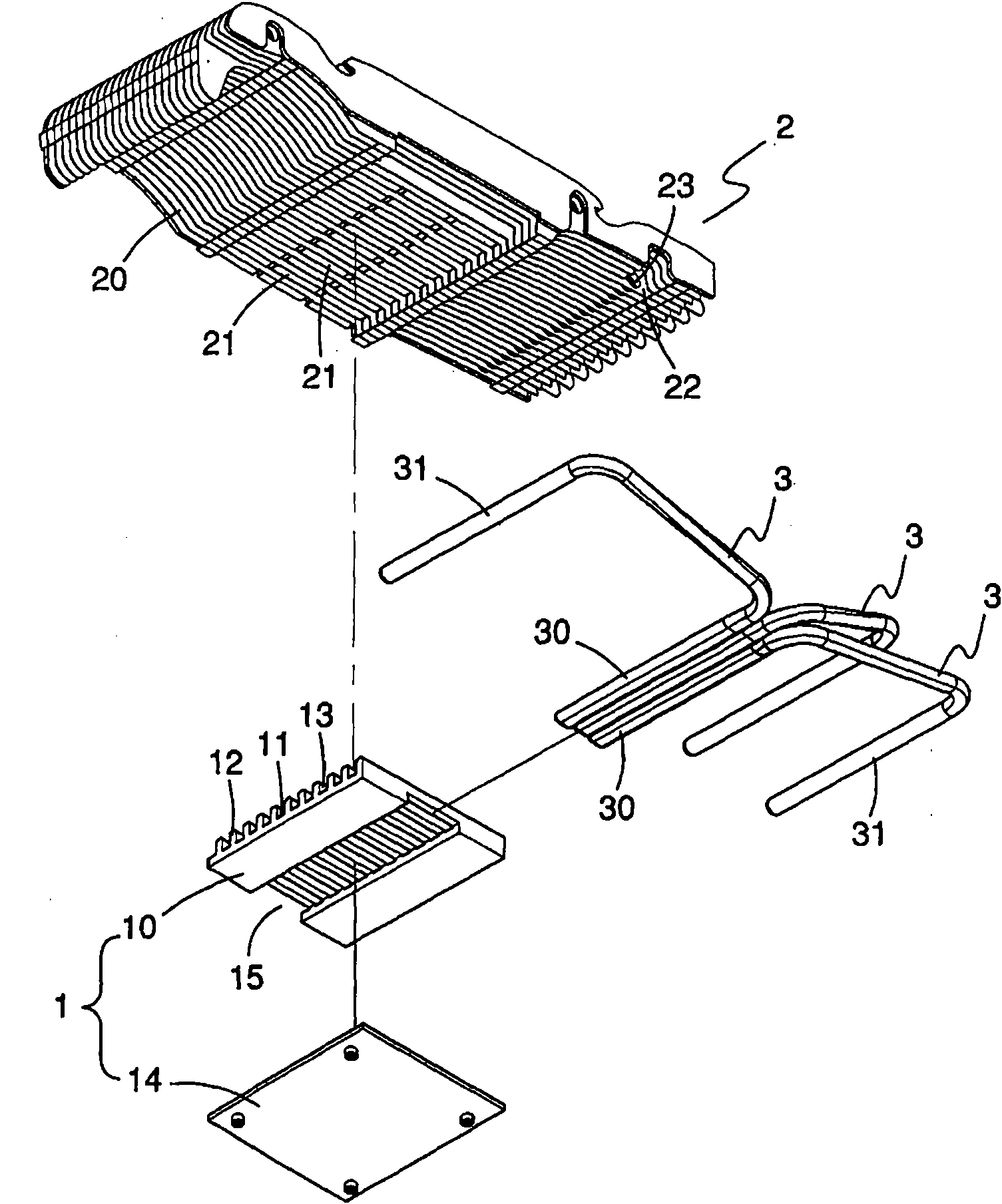

Heat radiator and manufacturing method thereof

ActiveCN102012183AEasy to manufactureEasy to assembleSoldering apparatusIndirect heat exchangersHeat conductingEngineering

The invention relates to a heat radiator, which comprises a heat conducting plate and a heat radiating fin group. The heat conducting plate comprises a first plate, and the top surface of the first plate is provided with a plurality of lugs arranged side by side at intervals. The heat radiating fin group comprises a plurality of heat radiating units, each heat radiating unit is provided with a bottom sheet and two side sheets, the bottom sheets are appressed to the top surface of the first plate, and the two side sheets are partially appressed onto the adjacent lugs. In the invention, the bottom surface of the first plate can be provided with a transverse trench penetrating to the top surface so as to ensure that the bottom sheets of the heat radiating units are exposed in the transverse trench, the heat radiator comprises a plurality of heat pipes arranged in the transverse trench and appressed to the bottom sheets of the heat radiating units, and the heat conducting plate comprises a second plate combined onto the bottom surface of the first plate. A preferable manufacturing method of the heat radiator comprises the steps of: embedding each heat radiating unit between every two adjacent lugs correspondingly; coating solder paste in the transverse trench; assembling the heat pipes in the transverse trench; coating the solder paste on the top surface of the second plate and covering the top surface of the second plate at the bottom surface of the first plate; and heating the solder paste to weld the structural members into a whole.

Owner:GIGA BYTE TECH CO LTD

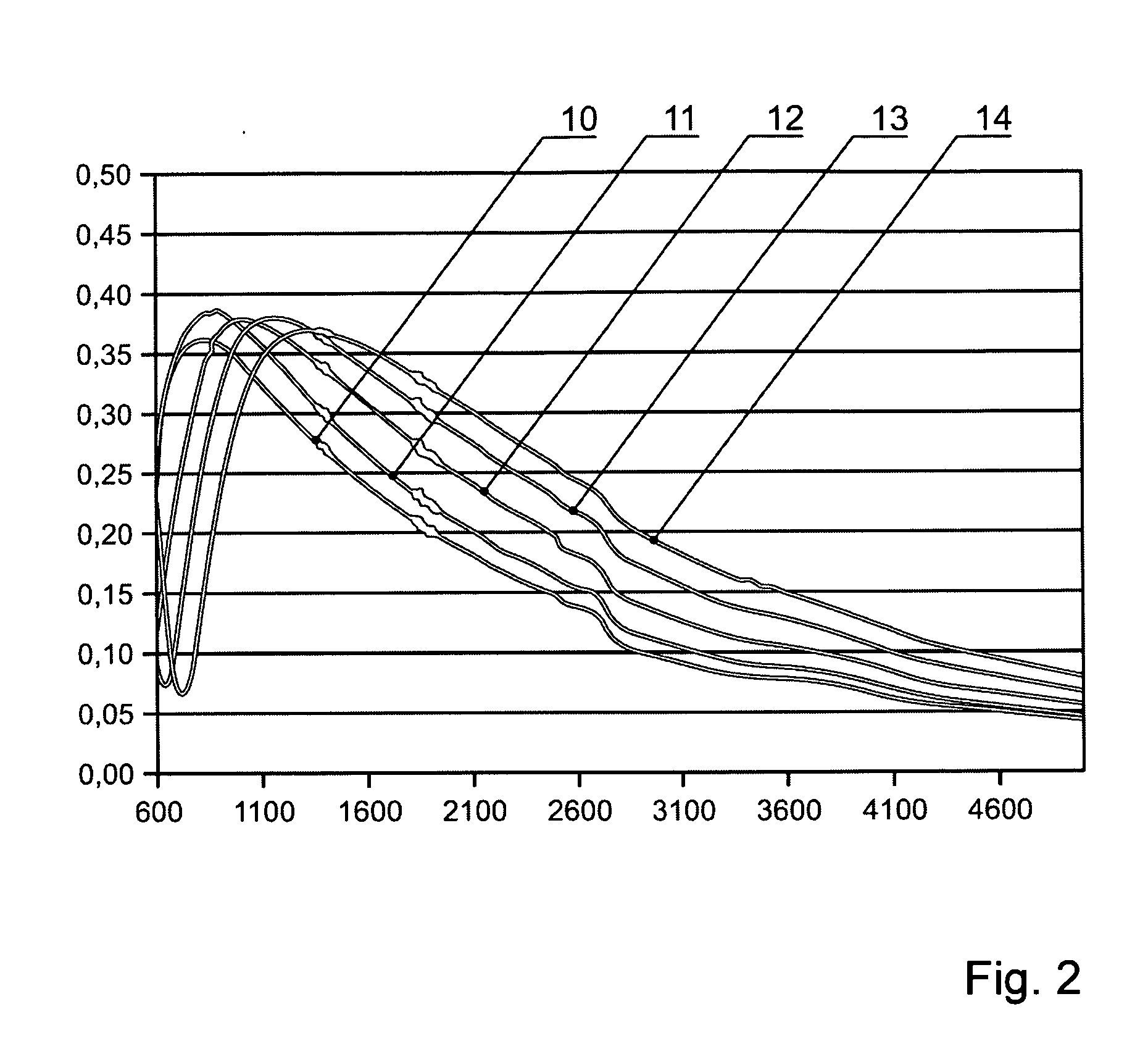

Transparent glass or glass ceramic pane with a layer that reflects infrared radiation

InactiveUS20100261009A1Easy to produceUniform appearanceSynthetic resin layered productsVacuum evaporation coatingRefractive indexThermal expansion

A transparent glass or glass ceramic pane is provided that includes a glass or glass ceramic substrate having a thermal expansion coefficient a of less than 4.2 and an infrared radiation-reflecting layer, formed as a single-layer reflection layer and having a refractive index greater than 2.2.

Owner:SCHOTT AG

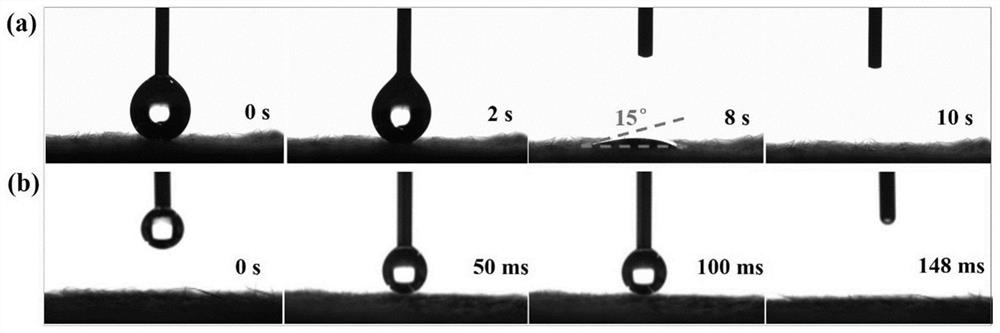

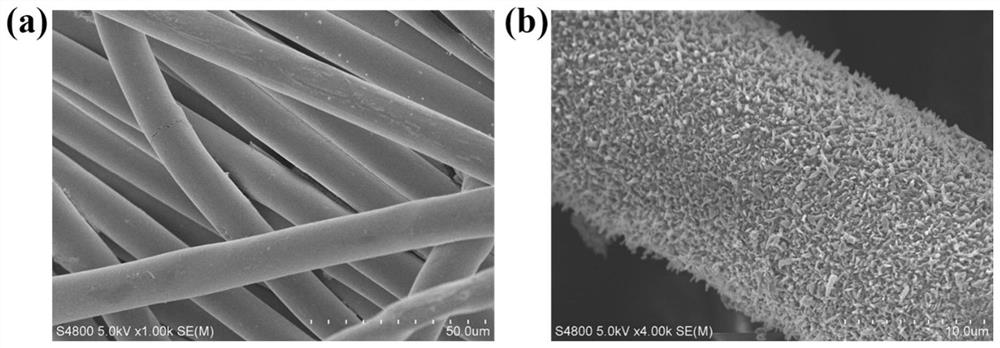

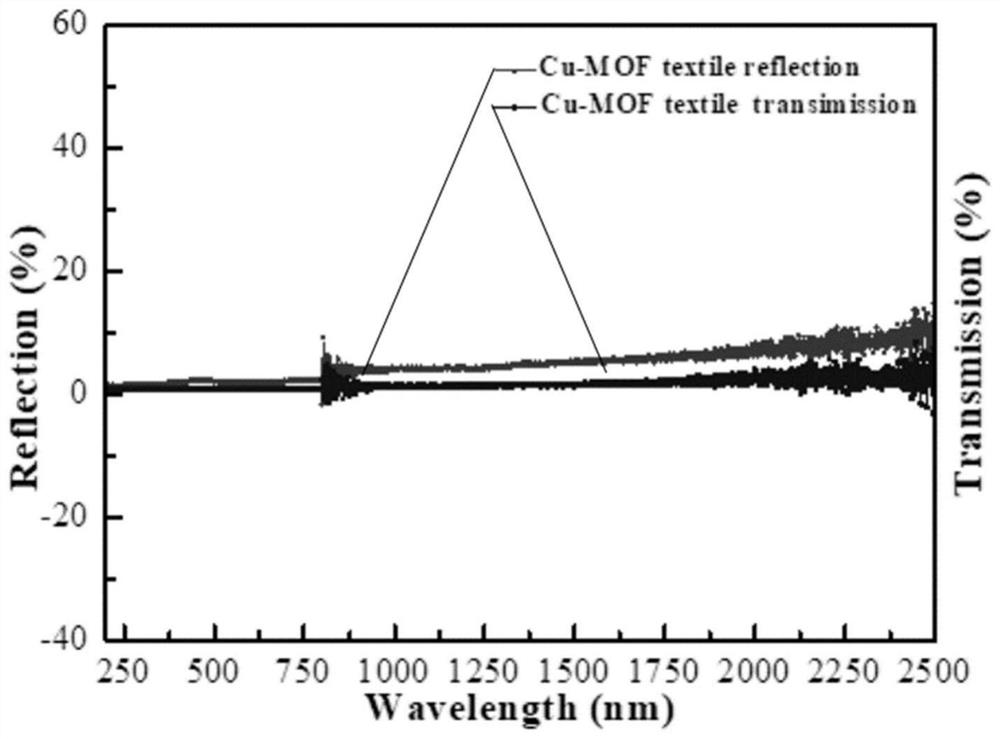

Super-hydrophilic copper-based MOF photo-thermal material, preparation method and application thereof

InactiveCN112980399AStrong absorbanceImprove breathabilityGeneral water supply conservationSeawater treatmentEvaporation (deposition)Nanowire

The invention discloses a super-hydrophilic copper-based MOF photo-thermal fabric, a preparation method and application thereof, and belongs to the technical field of photo-thermal material preparation. The preparation method comprises the following steps: carrying out plasma etching treatment and deposition treatment by taking a polymer fabric film as a substrate to prepare a copper-coated polymer fabric film; and carrying out Cu(OH)2 nanowire growth treatment on the obtained copper-coated polymer fabric film, and then carrying out hydrothermal treatment to prepare the super-hydrophilic copper-based MOF photo-thermal material. According to the invention, the super-hydrophilic copper-based MOF photo-thermal material has excellent super-hydrophilicity and ultrahigh evaporation efficiency due to a unique metal organic porous carbon skeleton structure, so that a brand new photo-thermal conversion material is provided for a solar-driven interface seawater desalination technology; and the preparation process is simple, large-scale production can be achieved, and the preparation method can be well applied to the field of preparation and application of portable solar evaporators.

Owner:SHAANXI UNIV OF SCI & TECH

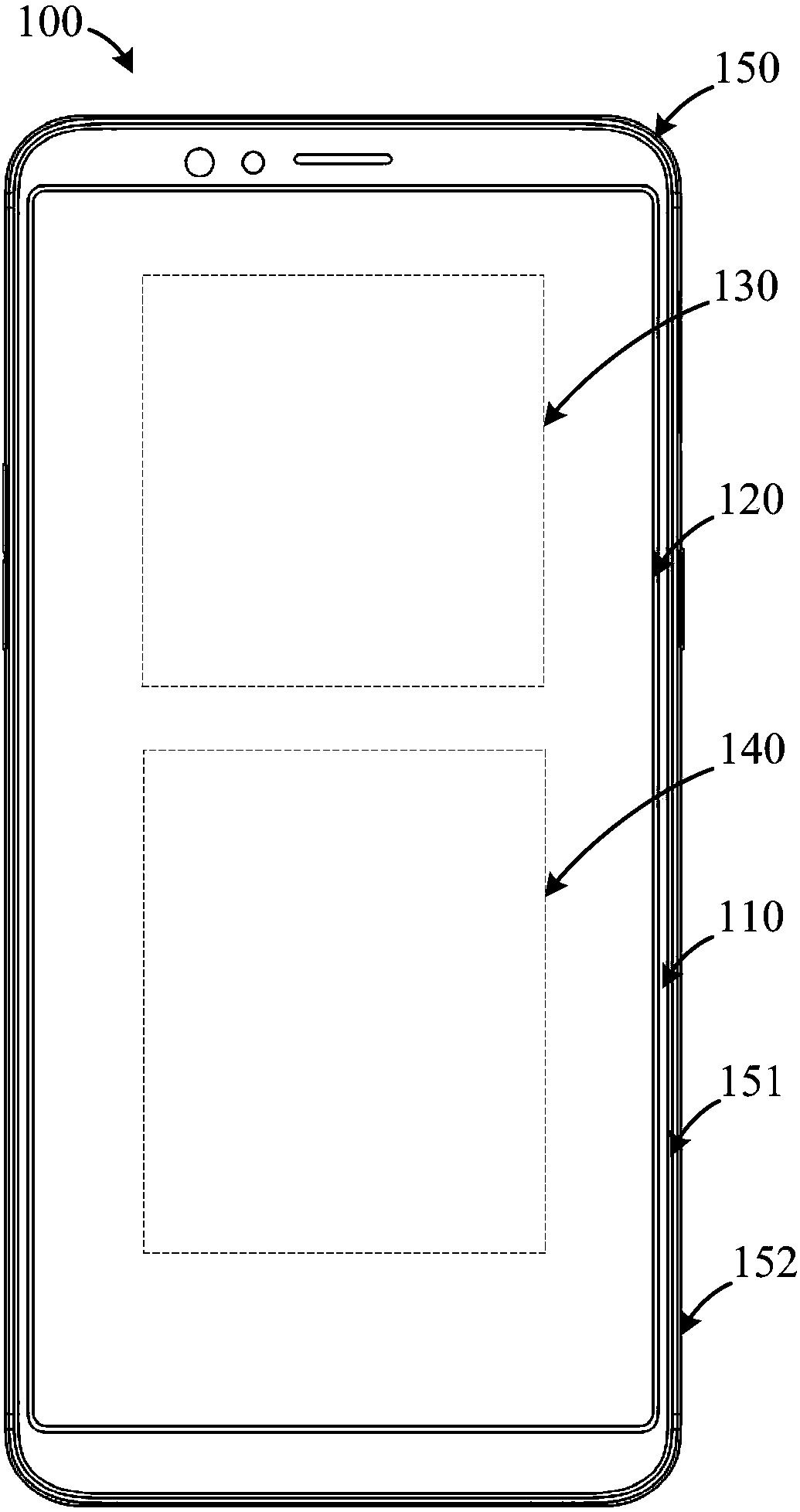

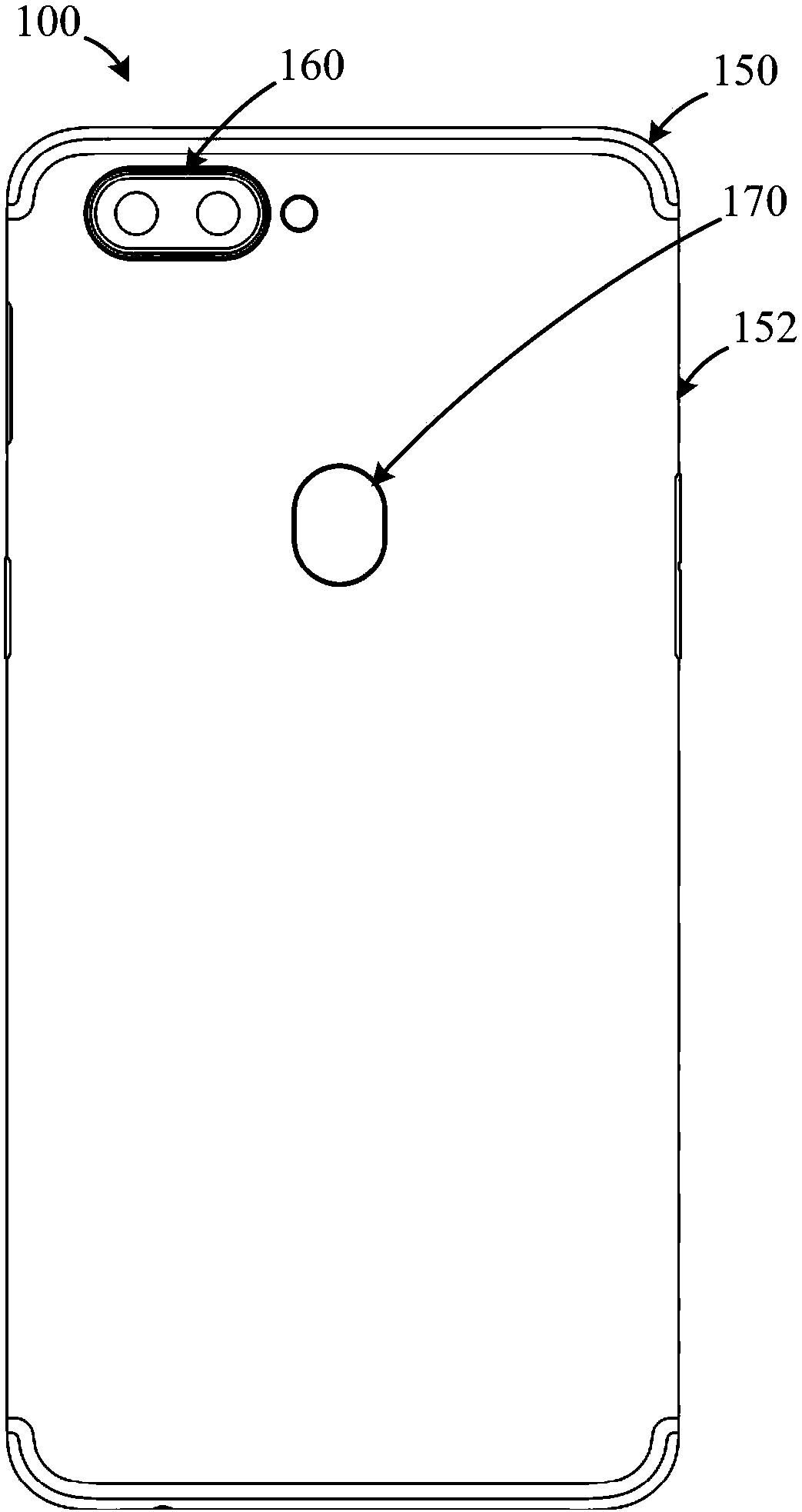

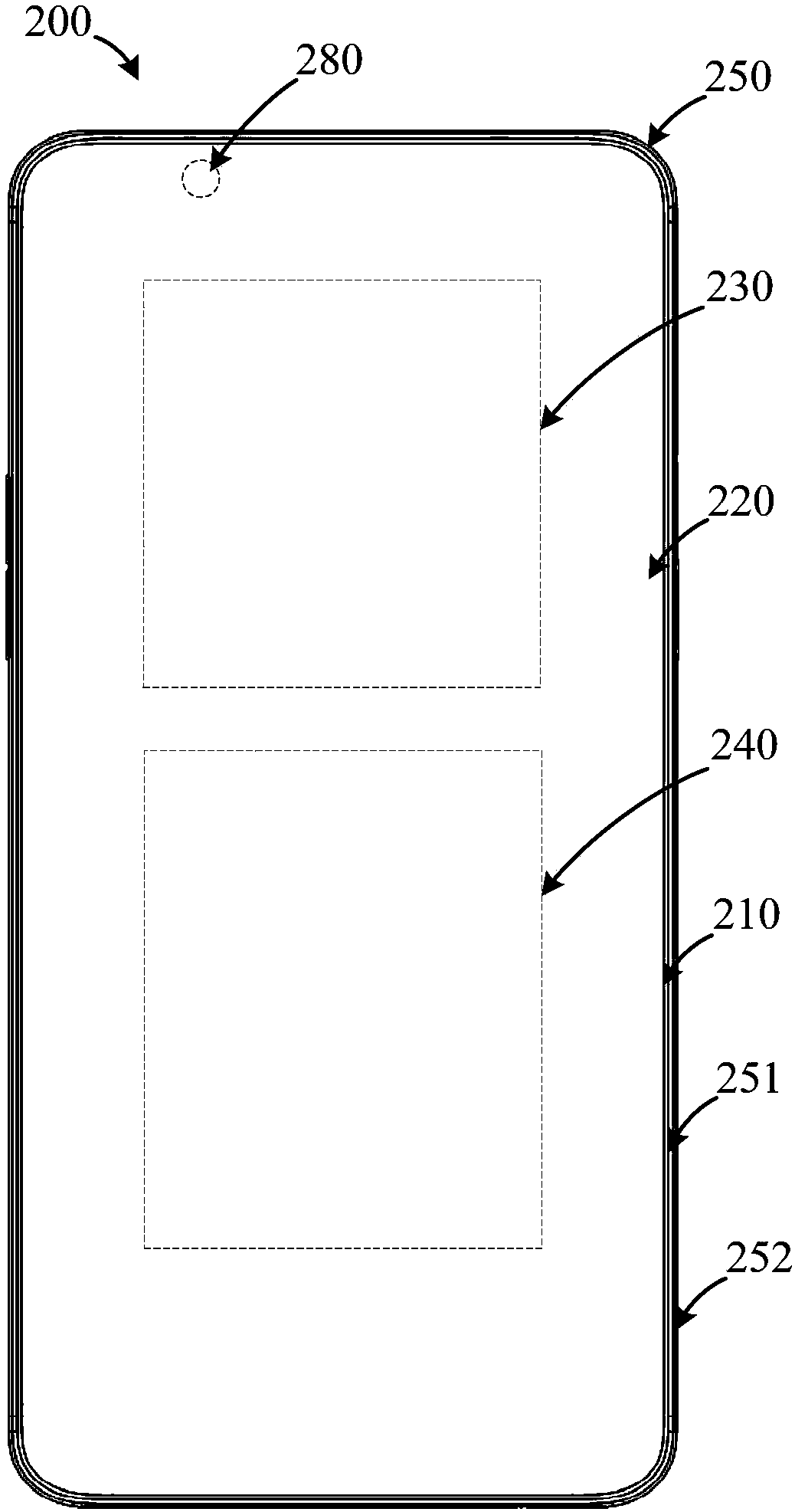

Display screen component and electronic device

InactiveCN108153025AImprove waterproof performanceImproves bond stabilityNon-linear opticsEngineeringHigh surface

An embodiment of the invention provides a display screen component and an electronic device. The display screen component comprises a frame, a backlight module, a display structure and a rubber frame,the frame is provided with a bottom wall and side walls, the side walls surround the bottom wall to form a containing space, high-surface-energy materials are arranged on the outer surfaces of the side walls, the backlight module is arranged in the containing space, the display structure is arranged on the frame and the backlight module, and the rubber frame covers the periphery of the display structure and extends onto the high-surface-energy materials. The water resistance of the display screen component can be improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

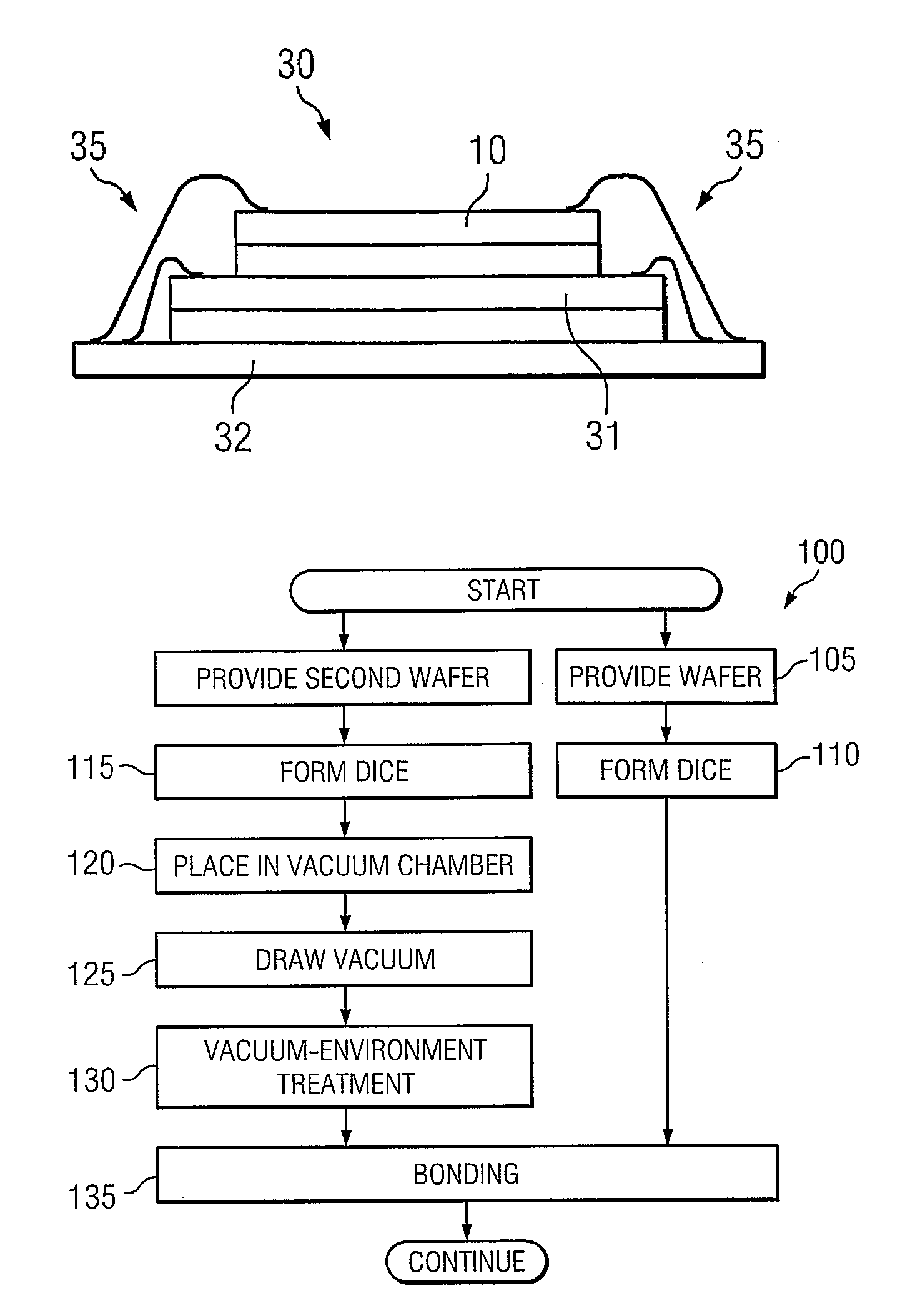

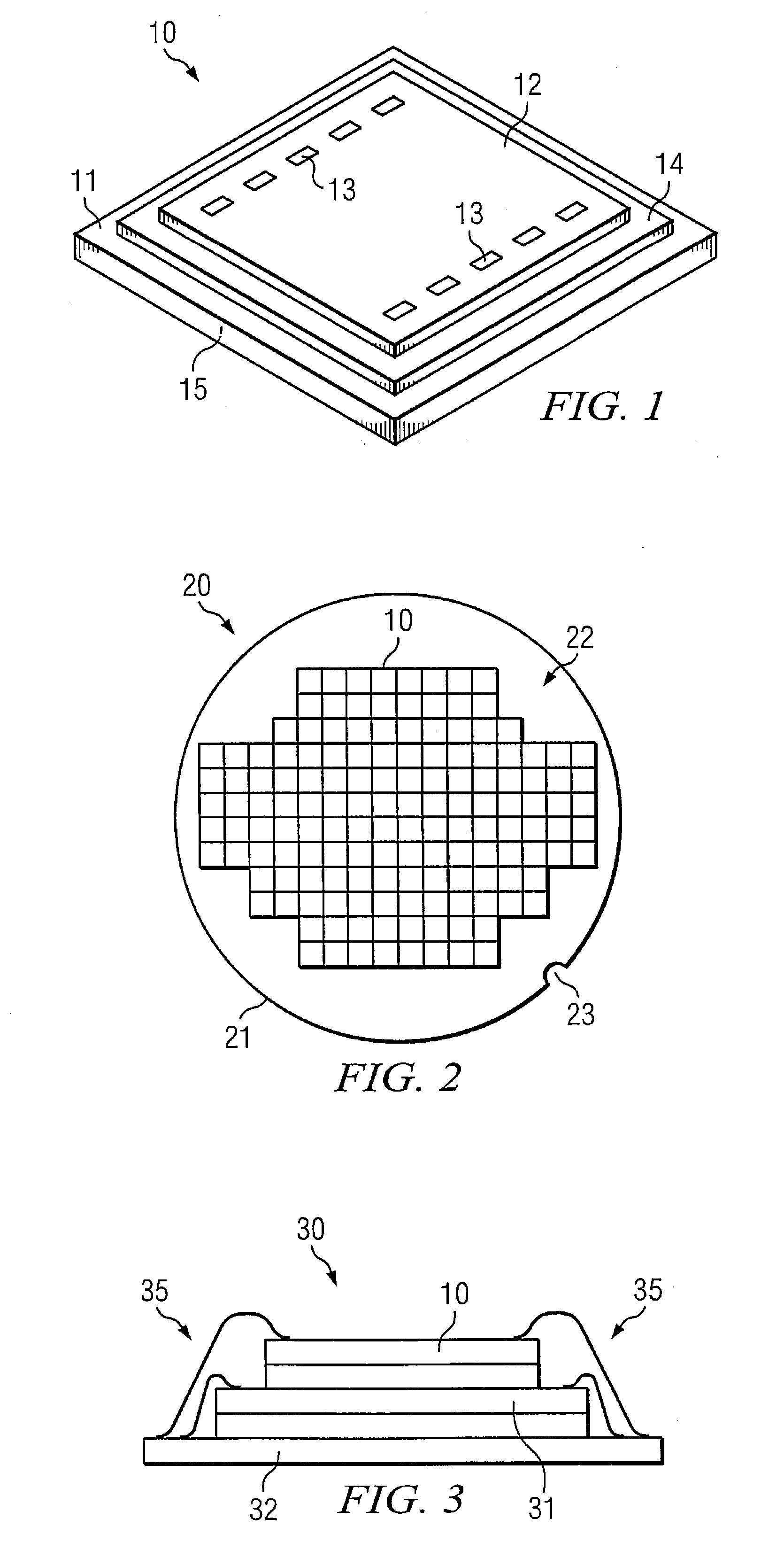

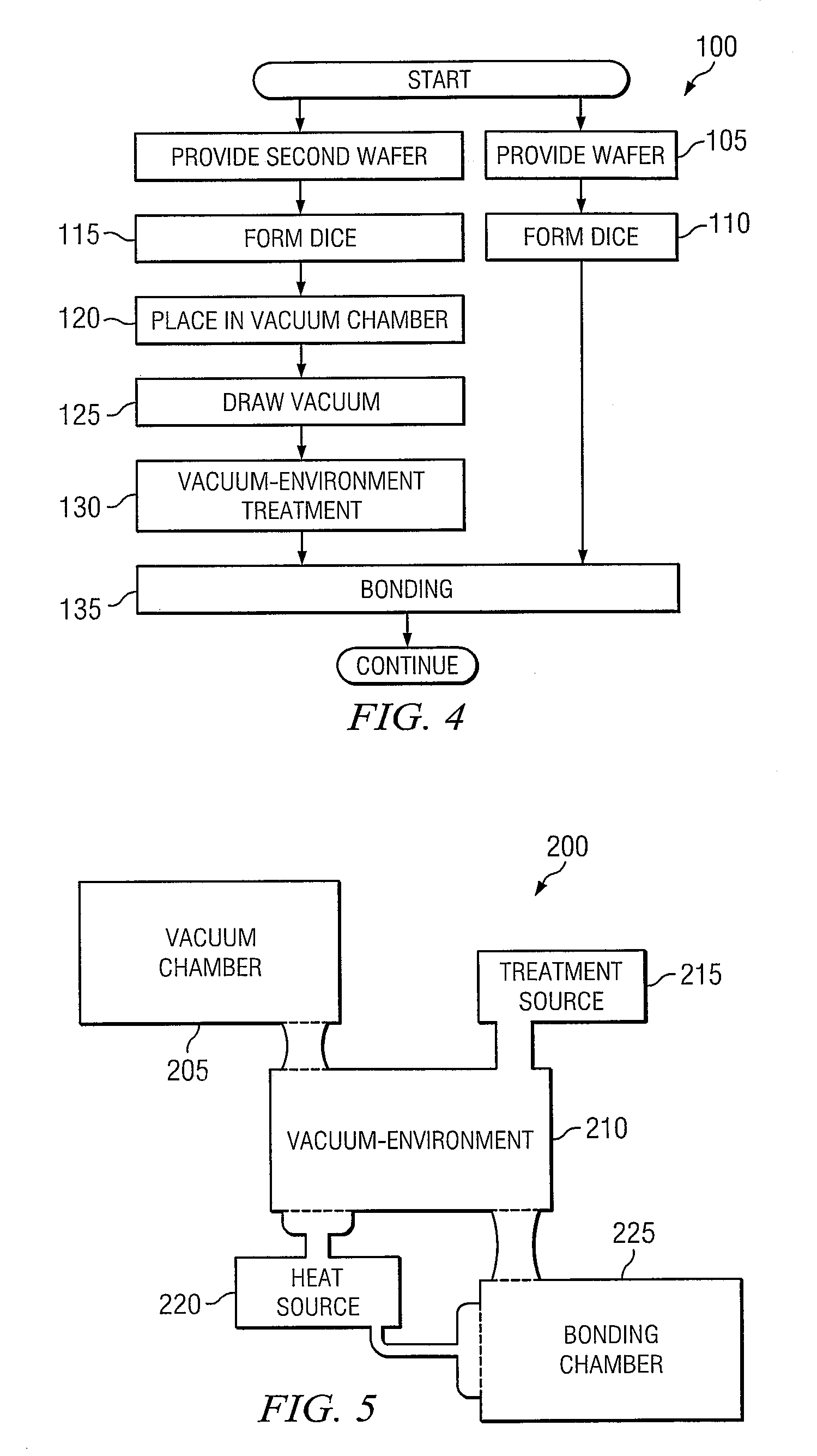

Method and system for bonding 3D semiconductor devices

InactiveUS8048717B2Improve adhesionImproves bond stabilitySolid-state devicesSemiconductor/solid-state device manufacturingHydrogenSemiconductor chip

A method and system and for fabricating 3D (three-dimensional) SIC (stacked integrated chip) semiconductor devices. The system includes a vacuum chamber, a vacuum-environment treatment chamber, and a bonding chamber, though in some embodiments the same physical enclosure may serve more than one of these functions. A vacuum-environment treatment source in communication with the vacuum-environment treatment chamber provides a selected one or more of a hydrogen (H2)-based thermal anneal, an H2-based plasma treatment, or an ammonia (NH3)-based plasma treatment. In another embodiment, a method includes placing a semiconductor chip in a vacuum environment, performing a selected vacuum-environment treatment, and bonding the chip to a base wafer. A plurality of chips formed as dice on a semiconductor wafer may, of course, be simultaneously treated and bonded in this way as well, either before or after dicing.

Owner:TAIWAN SEMICON MFG CO LTD

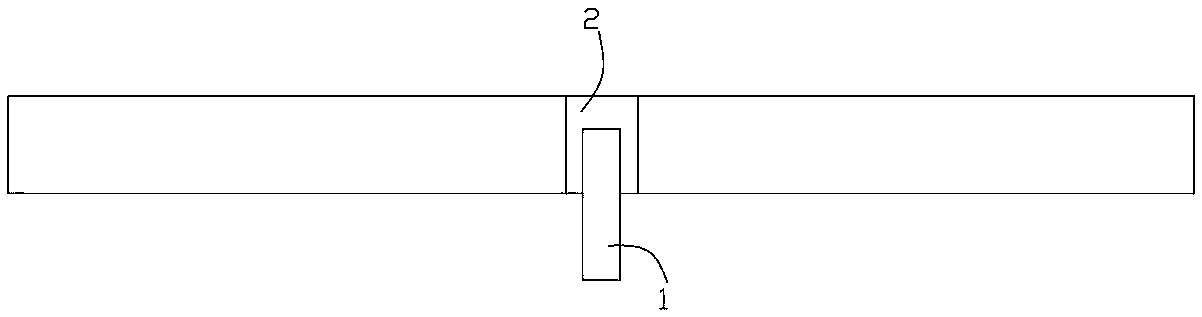

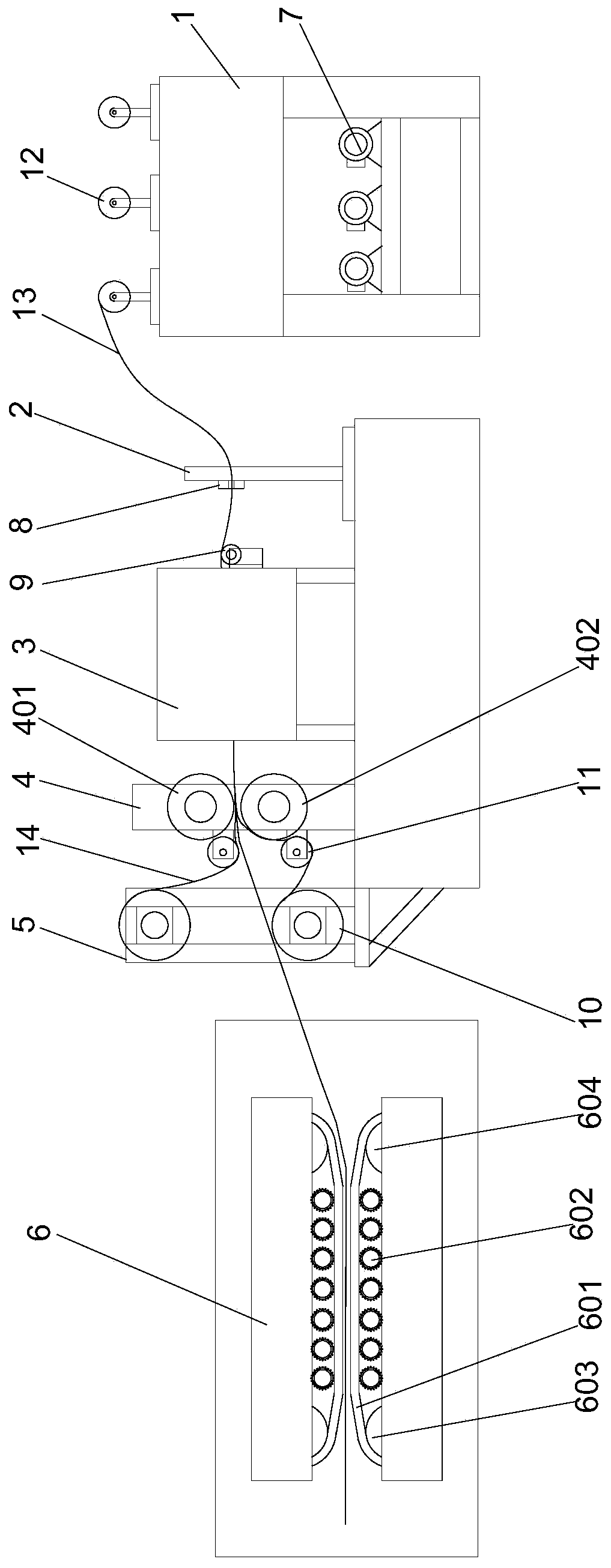

Welding method and device of lithium battery electrode lug

InactiveCN105364296AImproves bond stabilityIncreased bending spaceMetal working apparatusLaser beam welding apparatusEngineeringUltrasonic soldering

The invention discloses a welding method of a lithium battery electrode lug. A lithium battery comprises the electrode lug, an electrode piece and a cap, wherein one end of the electrode lug is stuck in the middle of the electrode piece through high temperature glue, then the electrode lug and the electrode piece are welded through ultrasonic soldering, and the other end of the electrode lug is welded to the lower portion of the cap through laser welding. The invention further discloses a welding device used for accurate welding between the electrode lug and the cap. The electrode lug is welded through the high temperature glue and ultrasonic waves, the sticking stability between the electrode lug and the electrode piece is improved, the electrode lug is located in the middle of the electrode piece, the bending space of the electrode lug is greatly improved, the probability of contact of the electrode lug and the inner wall of a battery shell if the electrode lug is too long is reduced, and safety is improved. The internal resistance of a battery cell can be effectively reduced, and the battery performance is improved. The welding device is adopted for welding between the electrode lug and the cap, so that the welding efficiency is improved, and welding between the cap and the electrode lug is more accurate through a limiting rod, a shell fixing device and a fixing clip.

Owner:慈溪市双佳电器有限公司

Method for improving stability of fuel cell proton exchange membrane frame surface adhesive

InactiveCN111509260AImprove high temperature resistanceImprove low temperature resistanceSealing/support meansColloidal silicaFuel cells

Owner:SHANGHAI SHENLI TECH CO LTD

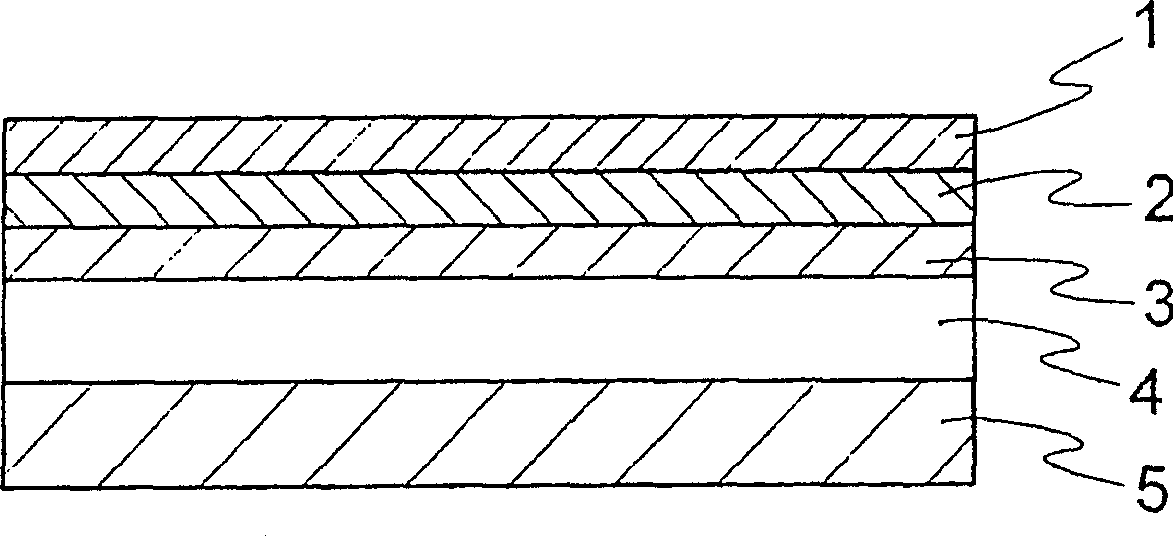

Adhesive tape

InactiveCN106905881AImproves bond stabilityFunction increaseMacromolecular adhesive additivesOrganic non-macromolecular adhesiveMethacrylateEpoxy

The invention discloses an adhesive tape, which comprises, from top to bottom, an anti-static coating, a substrate layer, an adhesive layer and a release film layer which are arranged layer by layer. The substrate layer is a PET film layer; the adhesive layer comprises the following materials, by weight part, 20-30% of butyl acrylate, 5-8% of acrylic acid, 10-20% of an epoxy resin, 40-50% of ethyl acetate, 5-15% of a rosin resin, and 5-10% of ethyl methacrylate; and the anti-static coating comprises the following materials, by weight part, 90-95% of glycerol monopalmitate, 2-3% of nanometer silver powder and 3-8% of fluorescent powder. Through the design above, the adhesive tape is good in bonding stability and multiple in functions and has an anti-static effect.

Owner:GUANGDONG YUEHUI TECH CO LTD

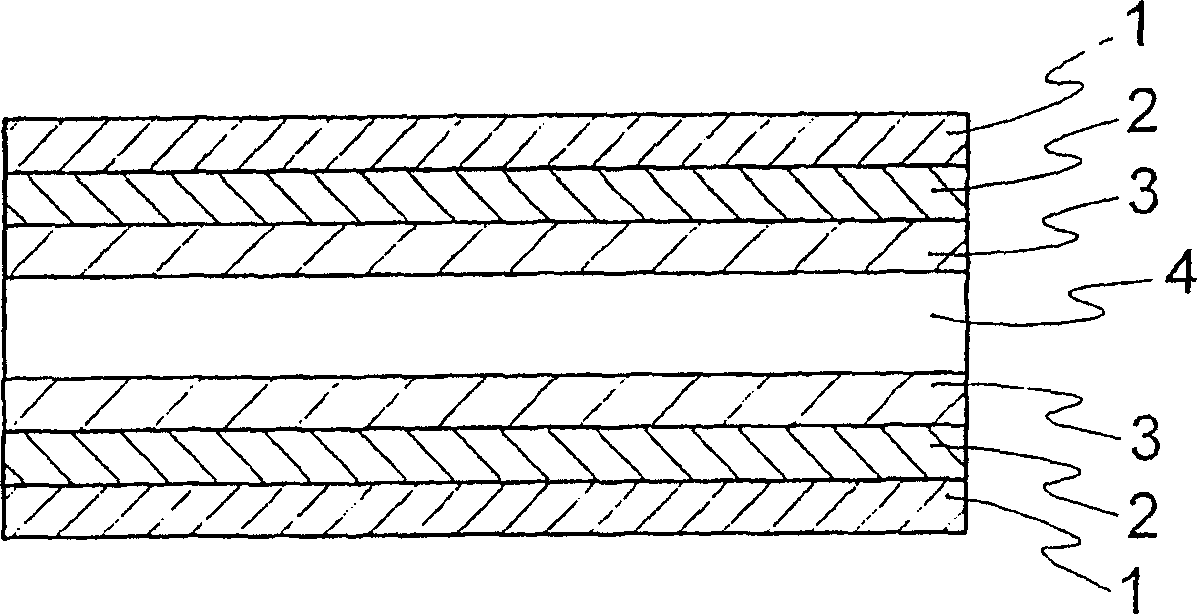

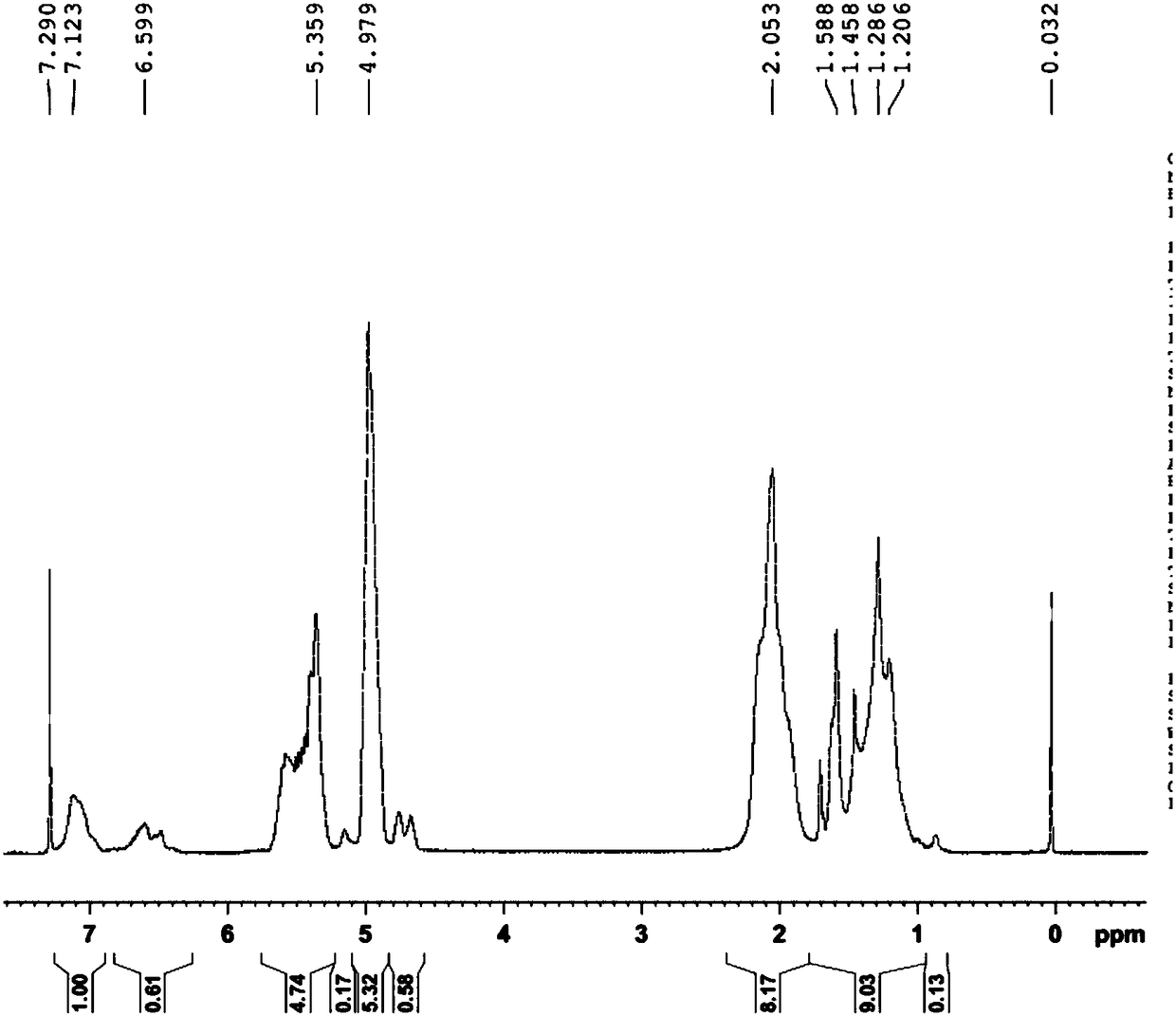

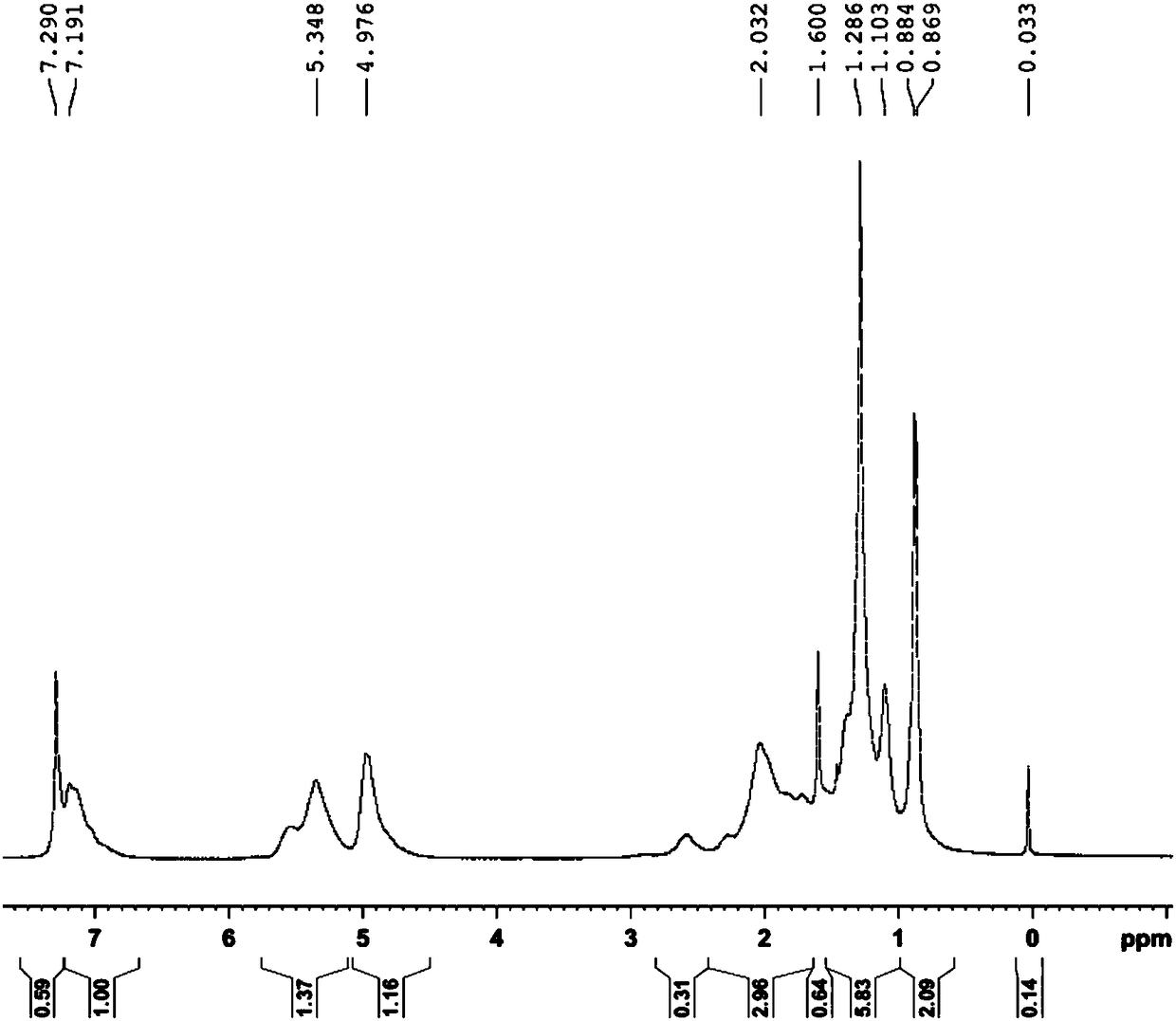

Oxide semiconductor electrode, dye-sensitized solar cell, and, method of producing the same

InactiveCN101667493AImprove energy conversion efficiencyImproves bond stabilityLight-sensitive devicesFinal product manufactureSemiconductor electrodeSilanes

An oxide semiconductor electrode is provided with a base material; a bonding layer formed on the base material made of a thermoplastic resin; a first electrode layer formed on the bonding layer made of a metal oxide; and a porous layer formed on the first electrode and made of the fine particle of a metal oxide semiconductor, wherein the thermoplastic resin includes a silane-modified resin. The present invention further provides a method of producing an oxide semiconductor electrode. The method is characterized by comprising a step of forming a laminate for oxide semiconductor electrode, a step of forming an oxide semiconductor electrode having a heat-resistive substrate by carrying out the substrate forming step on the first electrode layer on the laminate for oxide semiconductor electrode, a step of peeling off the heat-resistive substrate on the oxide semiconductor electrode having heat-resistive substrate, wherein the step comprises: a step of forming pattern for sandwich layer, astep of forming a layer for oxide semiconductor layer, a step of forming a sandwic.

Owner:DAI NIPPON PRINTING CO LTD

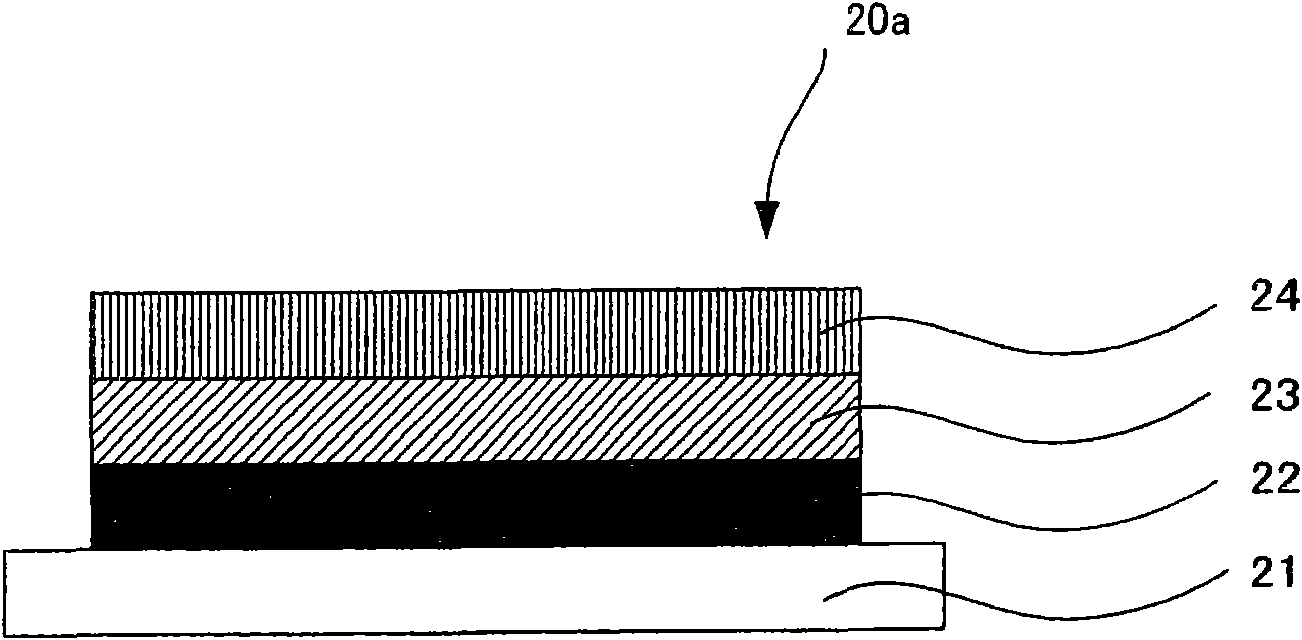

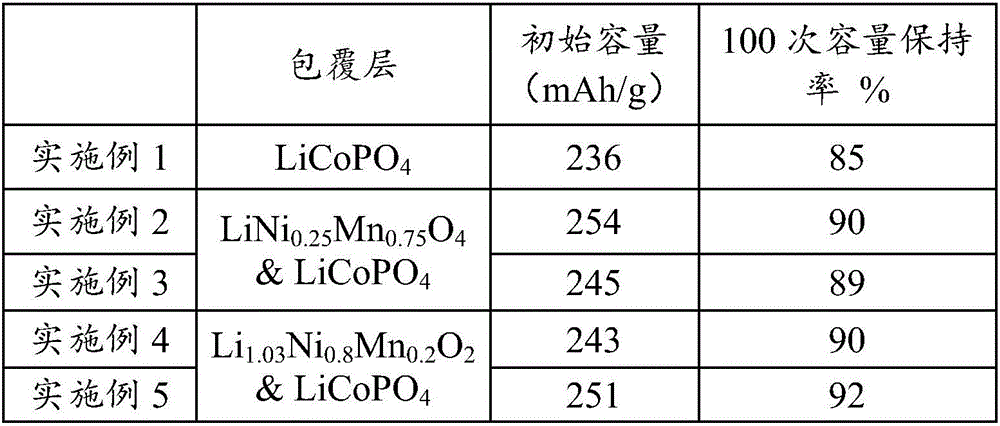

Lithium cobaltate composite material and preparation method thereof as well as positive electrode material

ActiveCN106654224AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsElectric capacityLanthanum

The invention provides a lithium cobaltate composite material and a preparation method thereof as well as a positive electrode material. The lithium cobaltate composite material is a material formed by coating lithium cobalt phosphate LiCoPO4 on surfaces of lithium cobaltate oxide particles; the molecular formula of the lithium cobaltate oxide particles is Li1+xCo1-yMyO2 and M is selected from one or more of magnesium, aluminum, zirconium, titanium, lanthanum, zinc and vanadium; the mass of the lithium cobalt phosphate is 0.25 percent to 10 percent of the mass of the lithium cobaltate oxide particles. By adopting the lithium cobaltate composite material, the problems that lithium cobaltate has poor circulating performance at high temperature or under high pressure and the electric capacity is low are solved.

Owner:HUNAN RESHINE NEW MATERIAL

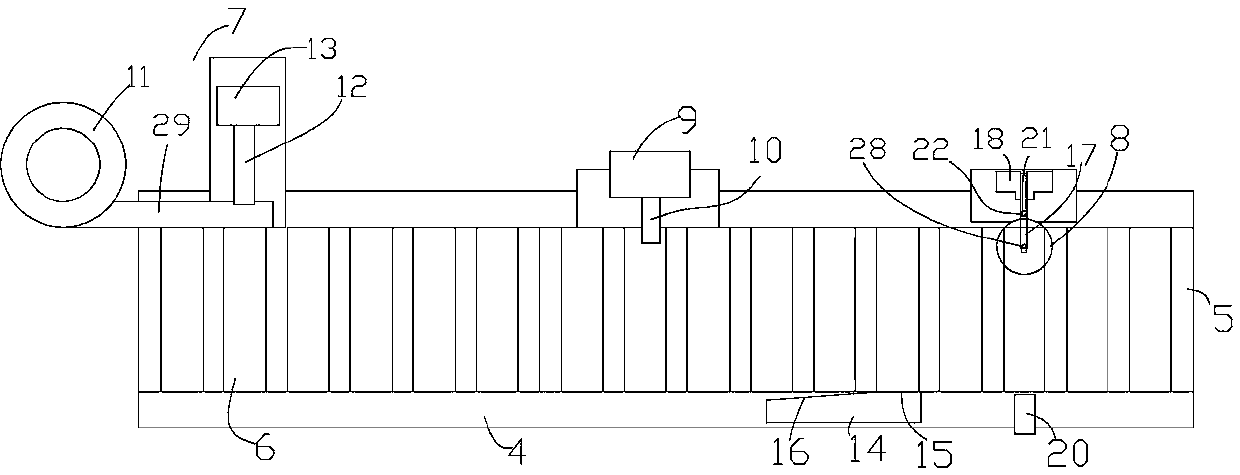

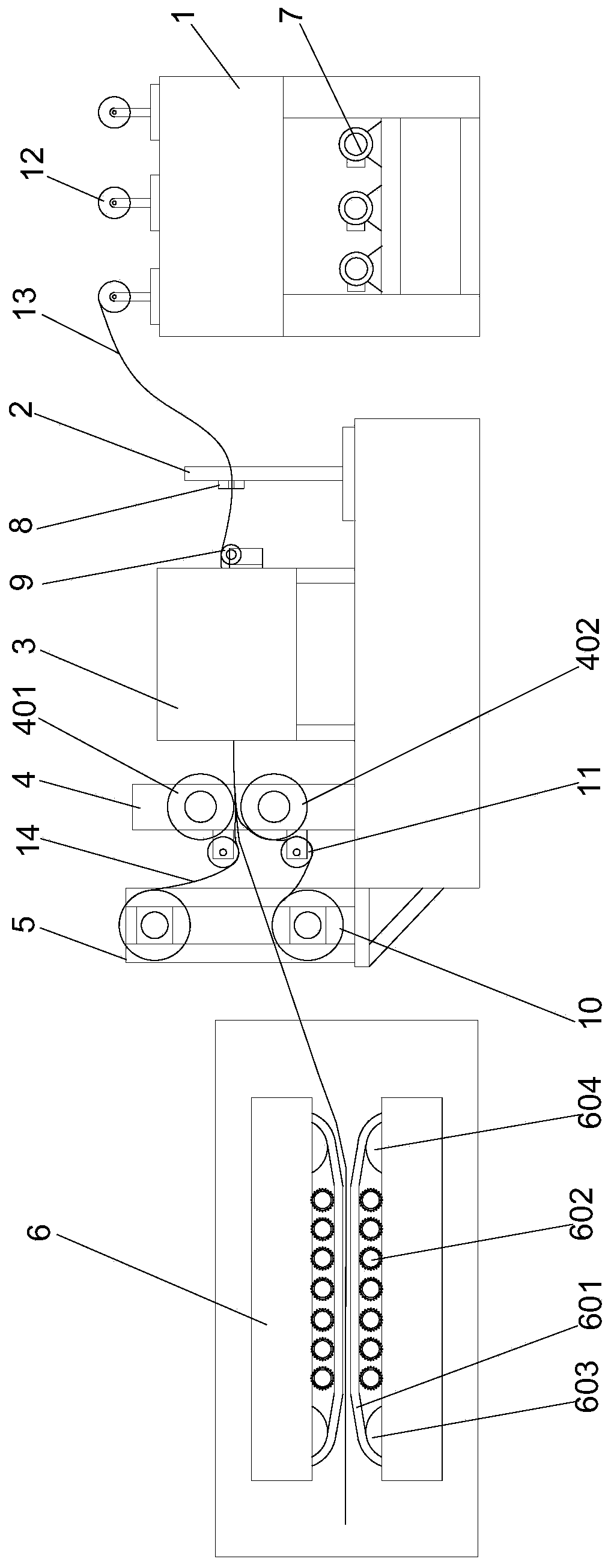

Flat ribbon cable bonding equipment

PendingCN110010304AGuaranteed tensionNo misalignmentFlat/ribbon cablesManufacturing wire harnessesRibbon cableEngineering

The invention discloses flat ribbon cable bonding equipment, which comprises a wire arrangement frame, a preheating oven, a heating mold, a coating belt placement frame and a laminating device, wherein the wire arrangement frame is provided with a wire arrangement plate, the wire arrangement plate is provided with a plurality of wire arrangement holes, wires pass through the wire arrangement holesand then enter the preheating oven, the heating mold is provided with an upper heating roller and a lower heating roller, the coating belt placement frame is provided with two coating belt placementwheels, each coating belt placement wheel is wound with a coating belt, the wires and the coating belts enter a part between the upper heating roller and the lower heating roller, the upper heating roller and the lower heating roller heat to enable the coating belts to be bonded on the wires so as to form a cable, the laminating device includes two crawler belts and multiple pressing wheels, the pressing wheels act on the crawler belts, and the crawler belts apply pressure to the cable and drag the cable. The equipment is utilized to produce flat ribbon cables, the cable tension during the production can be guaranteed, there is no dislocation of the wires during bonding, the bonding stability is good, the cable is not deformed when being laminated, and the final quality of the cable is ensured.

Owner:南通信昌线缆有限公司

Production process of metal face composite curtain wall plate

ActiveCN108453470AImproves bond stabilityShort curing timeNon-macromolecular adhesive additivesLaminationMetalCuring time

The invention belongs to the technical field of building curtain walls, and particularly relates to a production process of a metal face composite curtain wall plate. According to a production methodof the metal face composite curtain wall plate, based on an existing production method of the metal face composite curtain wall plate, through selection of a metal bonder shorter in curing time and higher in curing performance, curing of the bonder can be achieved at lower hot-pressing temperature in the hot-pressing curing step of curtain wall plate production, meanwhile, the curing time is shorter, and the bonding stability of the manufactured metal curtain wall plate is more excellent.

Owner:SHANDONG HONGXING NEW MATERIAL TECH CO LTD

Adhesive used for shoemaking

InactiveCN104388035AReduce manufacturing costSimple processPolyureas/polyurethane adhesivesNitrocellulosePolyol

The invention discloses an adhesive used for shoemaking. The adhesive is prepared from the following raw materials in parts by weight: 25-30 parts of toluene diisocyanate, 10-18 parts of poly(1,4-butanediol) adipate glycol, 8-12 parts of polyol, 5-10 parts of hydroquinone, 3-5 parts of nano wollastonite powder, 1-3 parts of nitrocellulose and 40-50 parts of water. The adhesive used for shoemaking is low in production cost, simple in process and light in environmental pollution, has moderate viscosity, good flowability, good bonding stability and better water and acid and base resistance, has good bonding effects and is conducive to improving the quality of shoes and prolonging the service lives of the shoes.

Owner:赵冯

Production technology of automobile front-wall heat-insulation pad and foam punching die

The invention provides a production technology of an automobile front-wall heat-insulation pad, comprising the following two processing steps: 1) plastic uptake shaping; and 2) foam punching. The invention also provides a foam punching die used in the production technology. The invention has advantages and positive effects as follows: 1) production pace is accelerated; 2) consistency of a product is good; 3) VOC performance of the product is improved; and 4) production cost of the product is reduced: two post-procedure operators are saved, there is no superfluous binder, and production cost is controlled effectively.

Owner:GREAT WALL MOTOR CO LTD

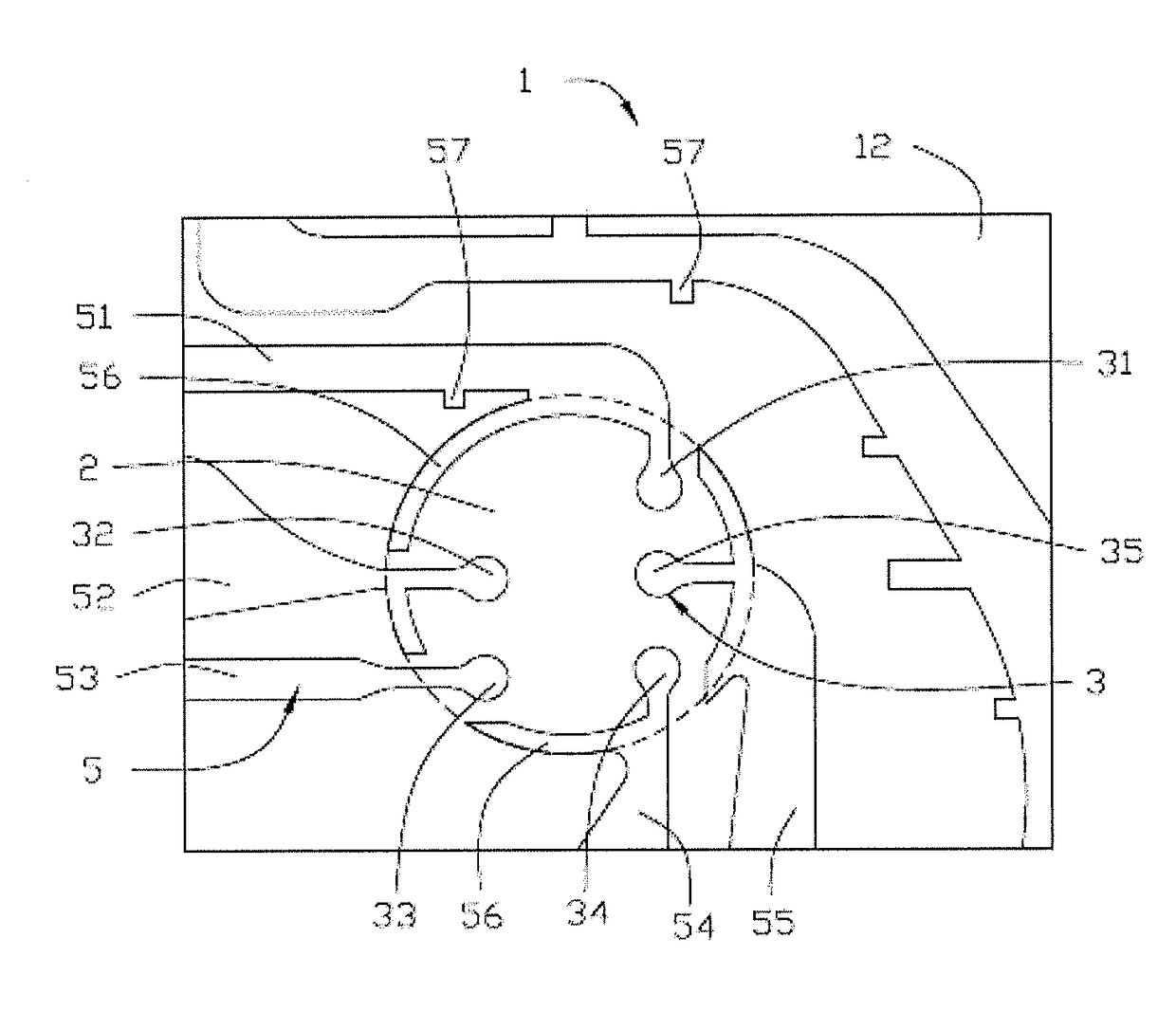

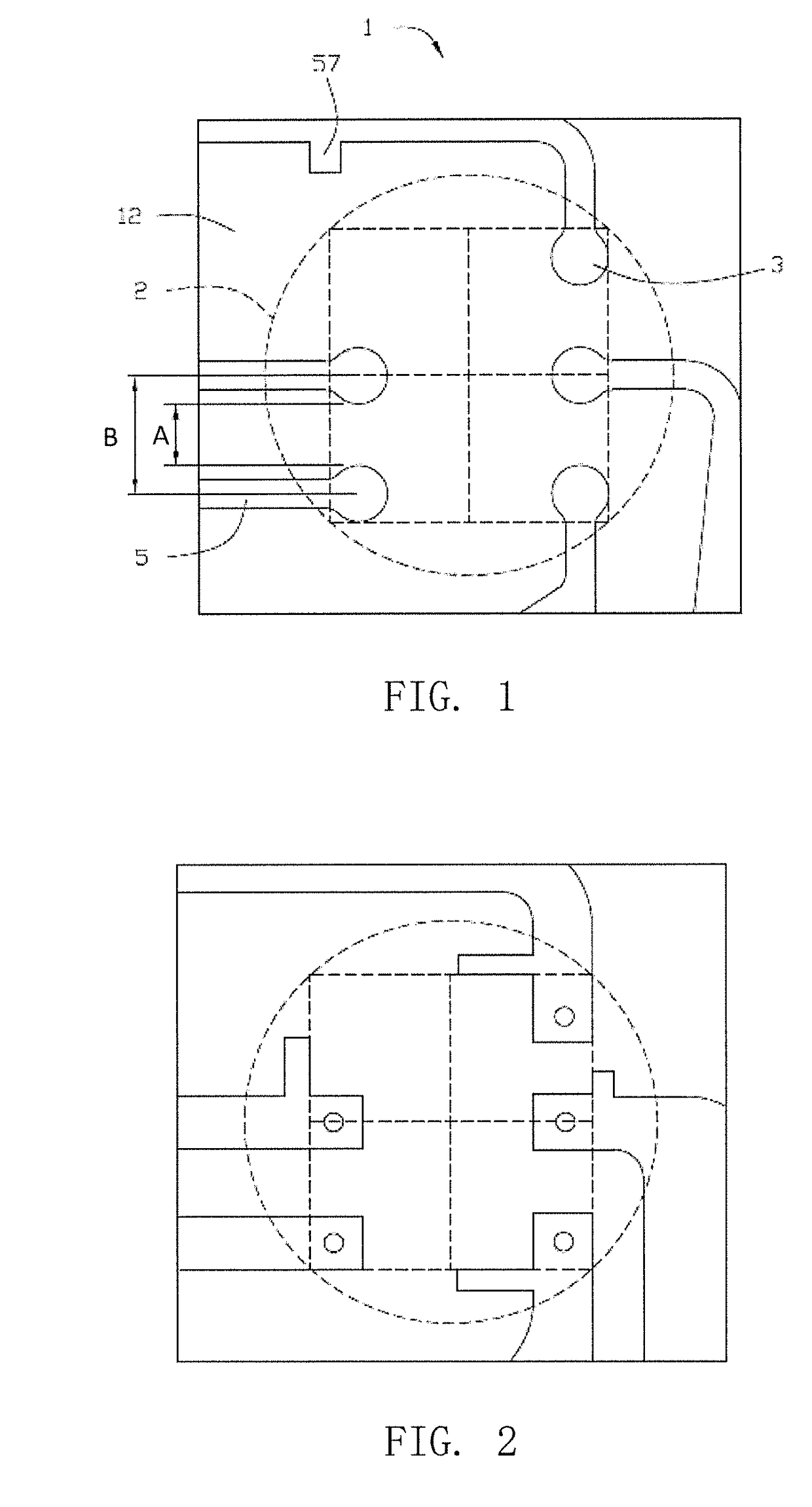

Circuit Board and Smart Card Module and Smart Card Utilizing the Same

ActiveUS20170221806A1Easy to controlLess areaSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringElectronic component

A circuit board and a smart card module and a smart card employing the circuit board are provided. The circuit board includes a substrate and a pad region provided on the substrate. The pad region is configured for mounting an electronic component, and comprises a plurality of pads spaced from each other and traces connected to their respective pads. At least one of the pads has an arc edge. In the present invention, the distance between the pads is easy to be controlled during fabrication, and the stability of the adhesion between the chip and pad region is enhanced.

Owner:PARLEX PACIFIC LTD

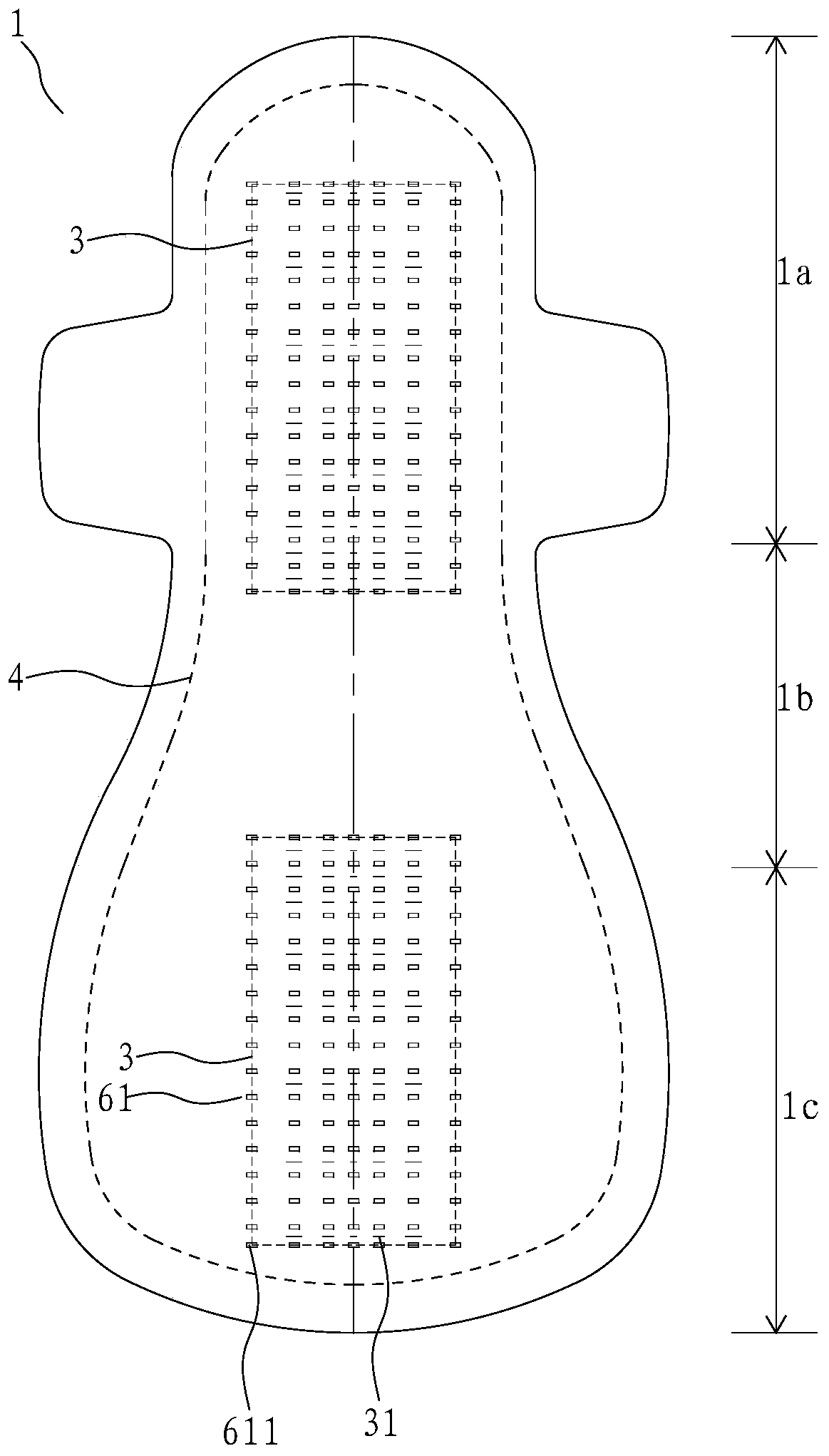

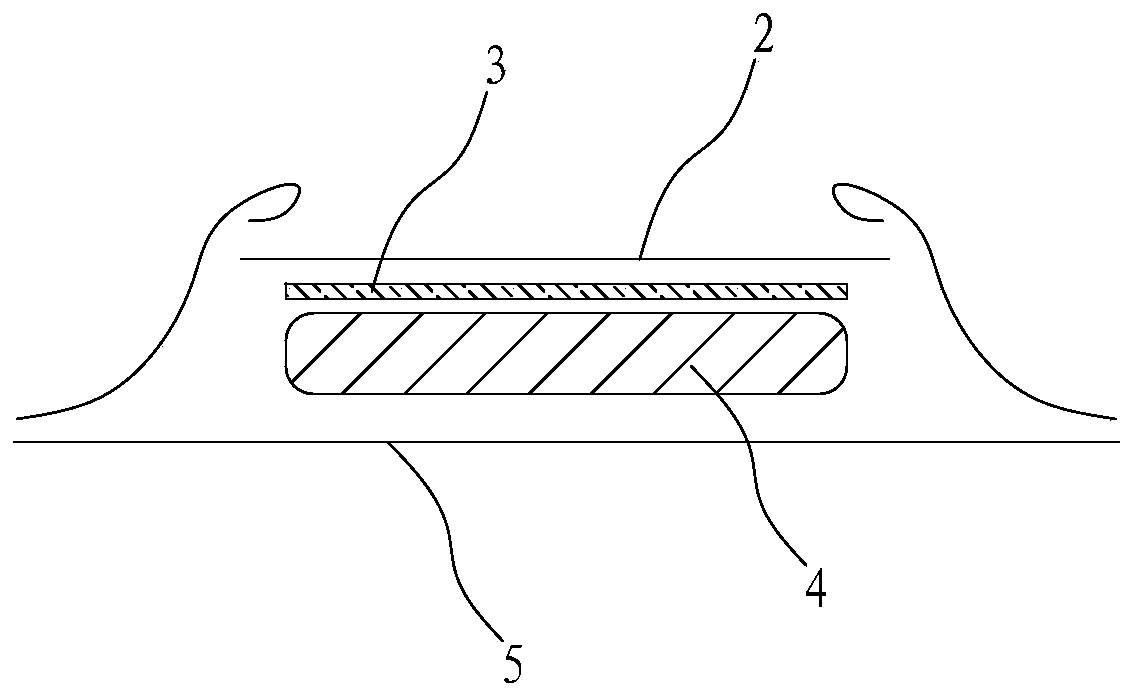

Elastically-attached disposable sanitary towel

The invention relates to the field of disposable sanitary products, in particular to an elastically-attached disposable sanitary towel. The elastically-attached disposable sanitary towel comprises a body, wherein the body is sequentially provided with a liquid-permeable surface layer, an elastic material layer, an absorption core and a liquid-impermeable bottom layer from top to bottom in a stacked mode, the body comprises a front end part, a middle part and a rear end part, the width of the elastic material layer is smaller than that of the absorption core, the elastic material layer is composed of two elastic bodies, the two elastic bodies are arranged at intervals in the length direction of the body, one elastic body stretches across the front end part and the middle part, the other elastic body stretches across the rear end part and the middle part, an elastic non-woven fabric is a hydrophilic elastic non-woven fabric, the elastic material layer is bonded to the absorption core through a glue layer, the glue layer is composed of a plurality of glue strips which are transversely arranged at intervals, each glue strip is composed of a plurality of glue points, and the distance between every two adjacent glue points is gradually increased from the middle part to the two transverse sides. The technical problem that a user feels uncomfortable when wearing an existing sanitary towel is solved.

Owner:FUJIAN HENGAN HLDG CO LTD +2

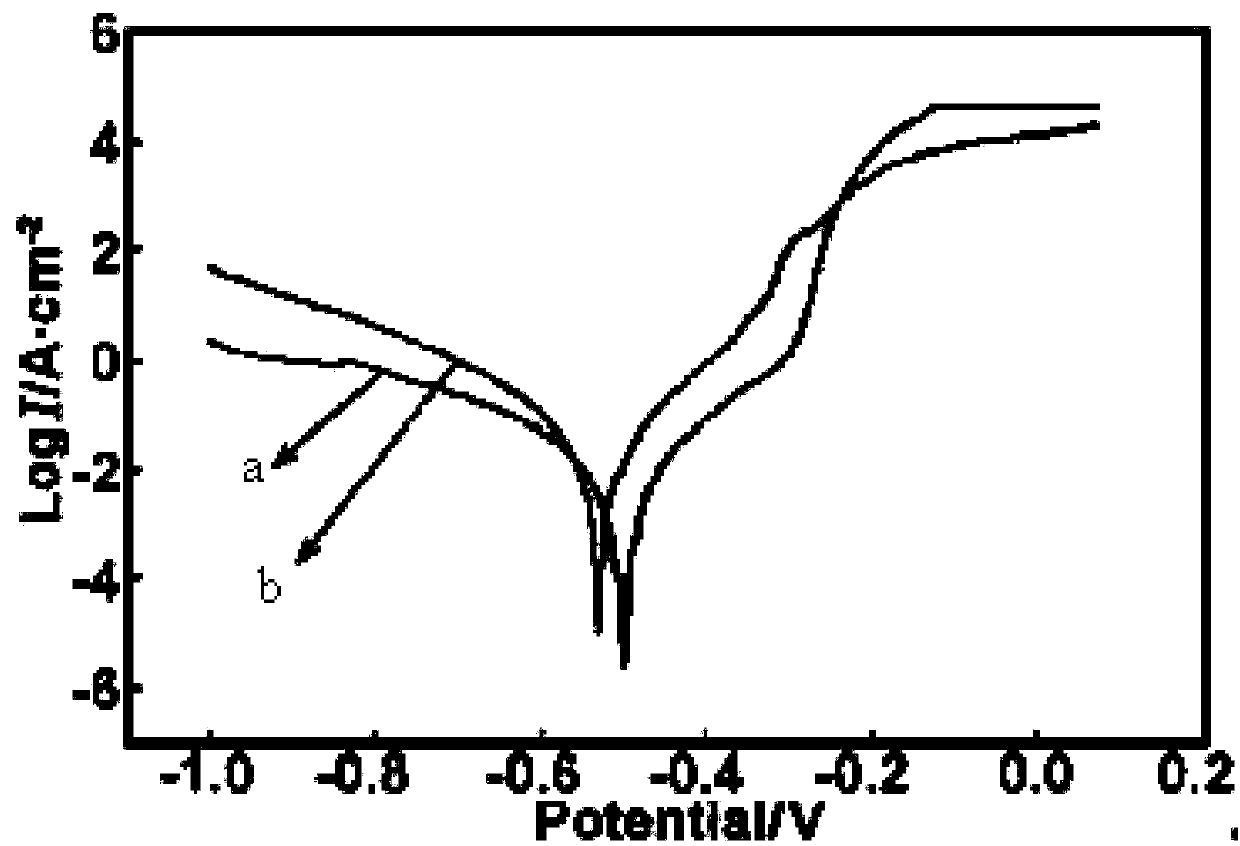

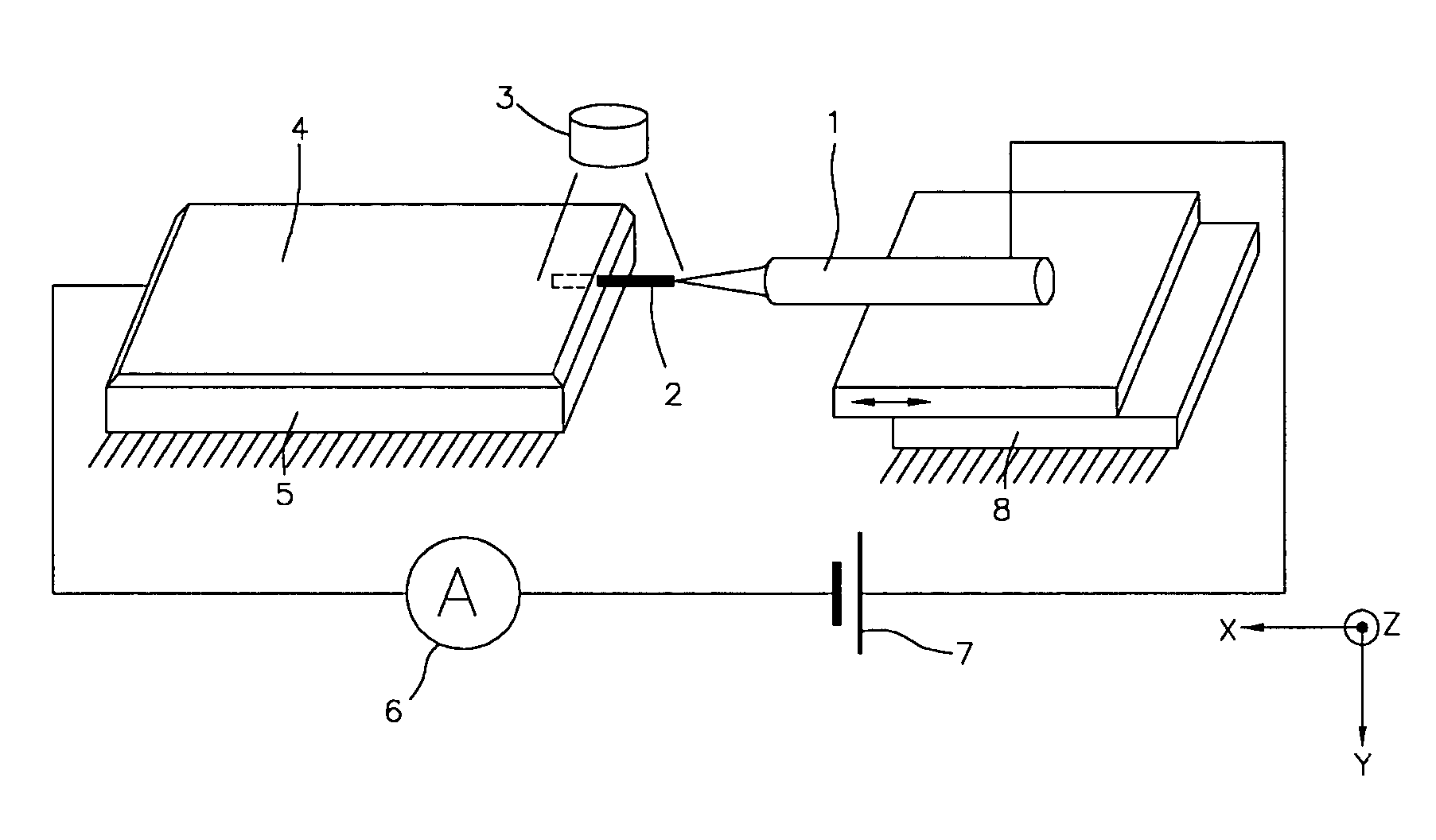

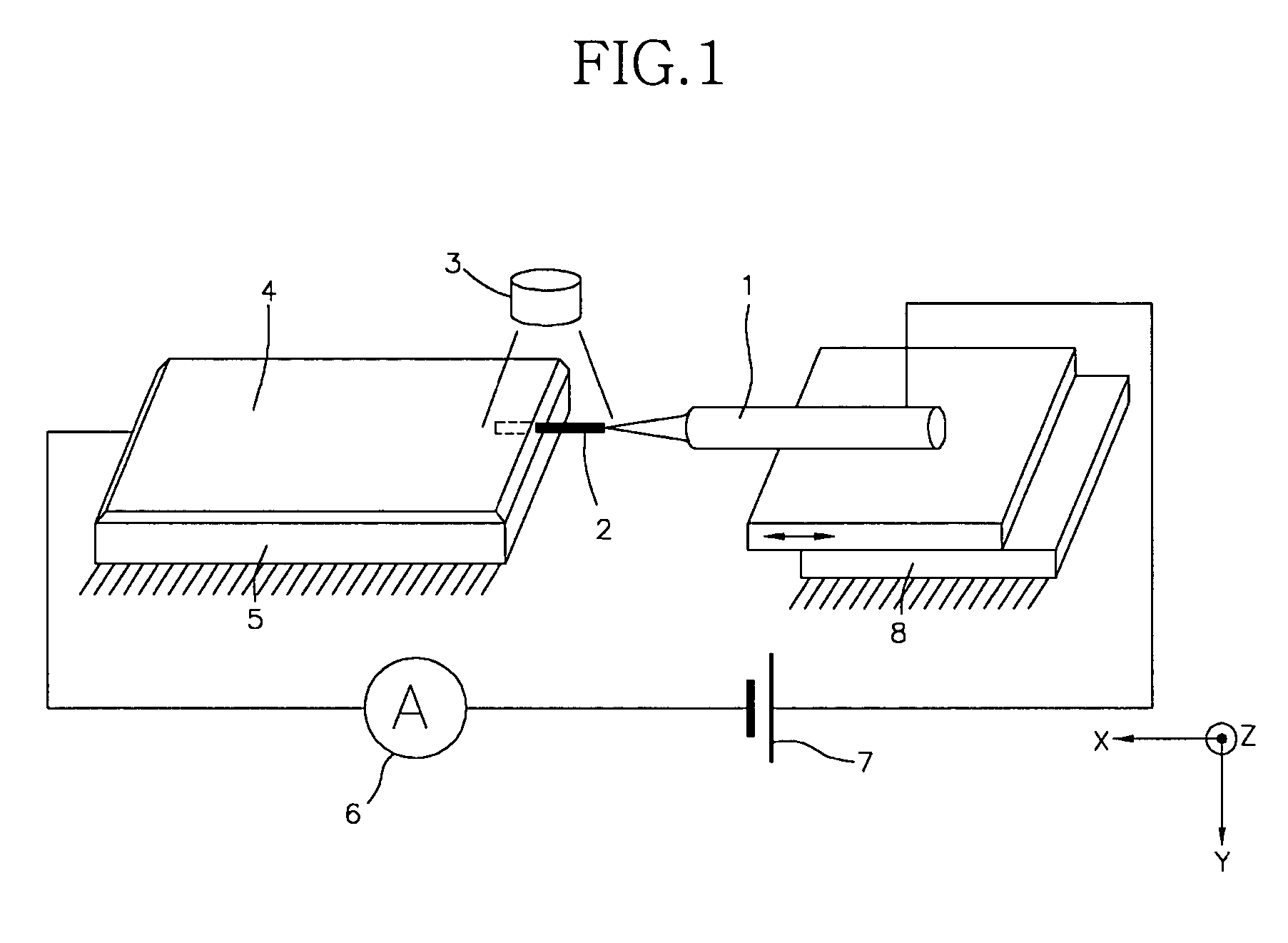

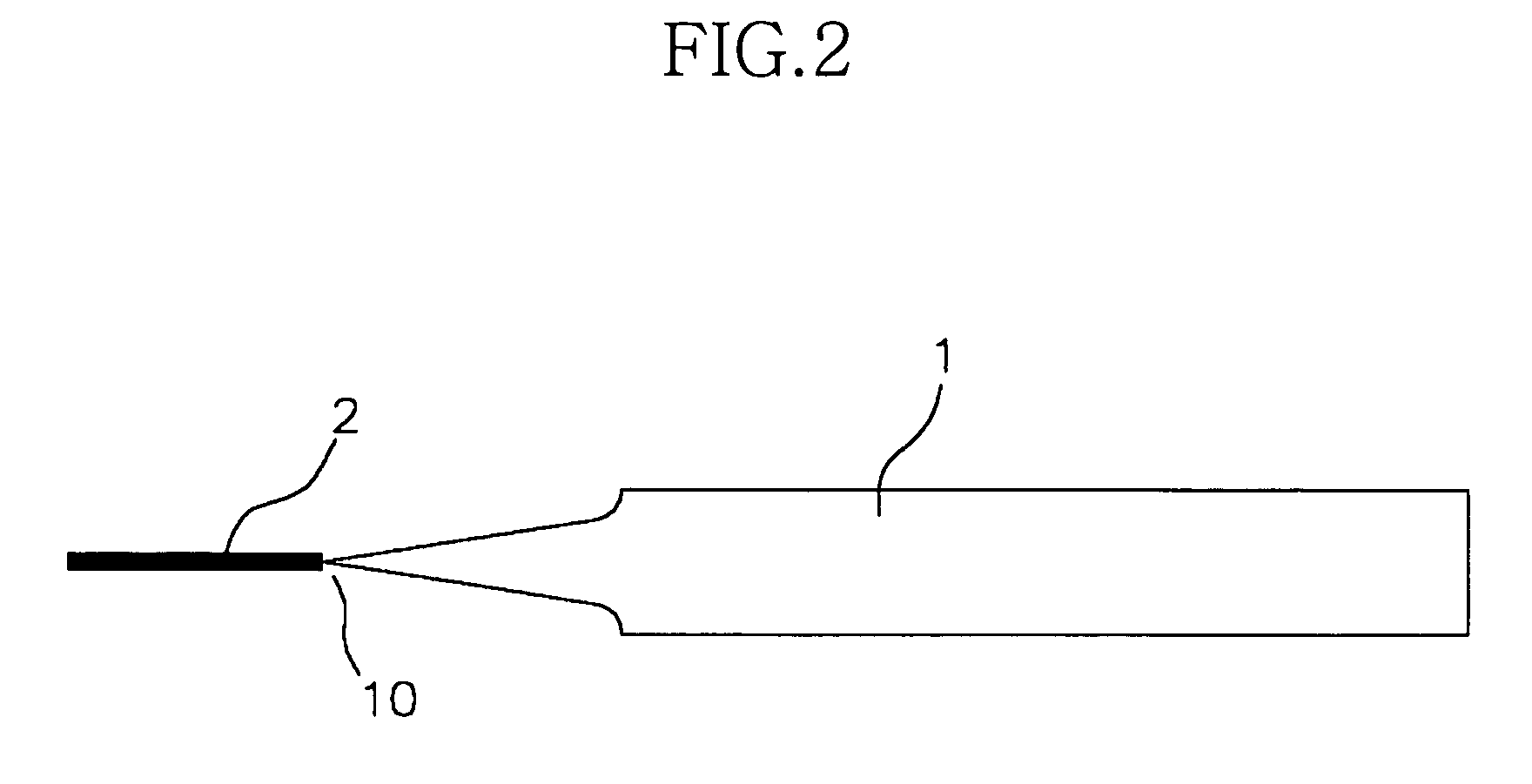

Apparatus for and method of bonding nano-tip using electrochemical etching

InactiveUS7452432B2Improves bond stabilityMaterial nanotechnologyNanostructure manufactureElectrolytic agentAdhesive

Disclosed herein are an apparatus for and a method of bonding a nano-tip using electrochemical etching, in which a good bonding stability can be provided. The nano-tip bonding apparatus comprises a glass plate having a top surface of a certain desired area. An electrolytic solution having conductivity is placed on the top surface of the glass plate by means of surface tension. Means for moving reciprocally a base material having conductivity in opposite direction is provided. A carbon nano-tube is adhered to a pointed tip of the base material by means of an adhesive. An end portion of the carbon nano-tube is to be immersed in the electrolytic solution. A power supply is provided for applying an electric power to the electrolytic solution and the base material.

Owner:KOREA ADVANCED INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com