Joint coating repairing anticorrosion layer structure for in-service pipeline

An anti-corrosion layer and repair technology, which is used in pipeline anti-corrosion/anti-rust protection, pipeline protection, damage protection, etc. The mechanical strength or insulation performance of the vinyl anti-corrosion layer does not match, so as to achieve the effect of convenient construction technology, low surface treatment requirements, and tolerant surface treatment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

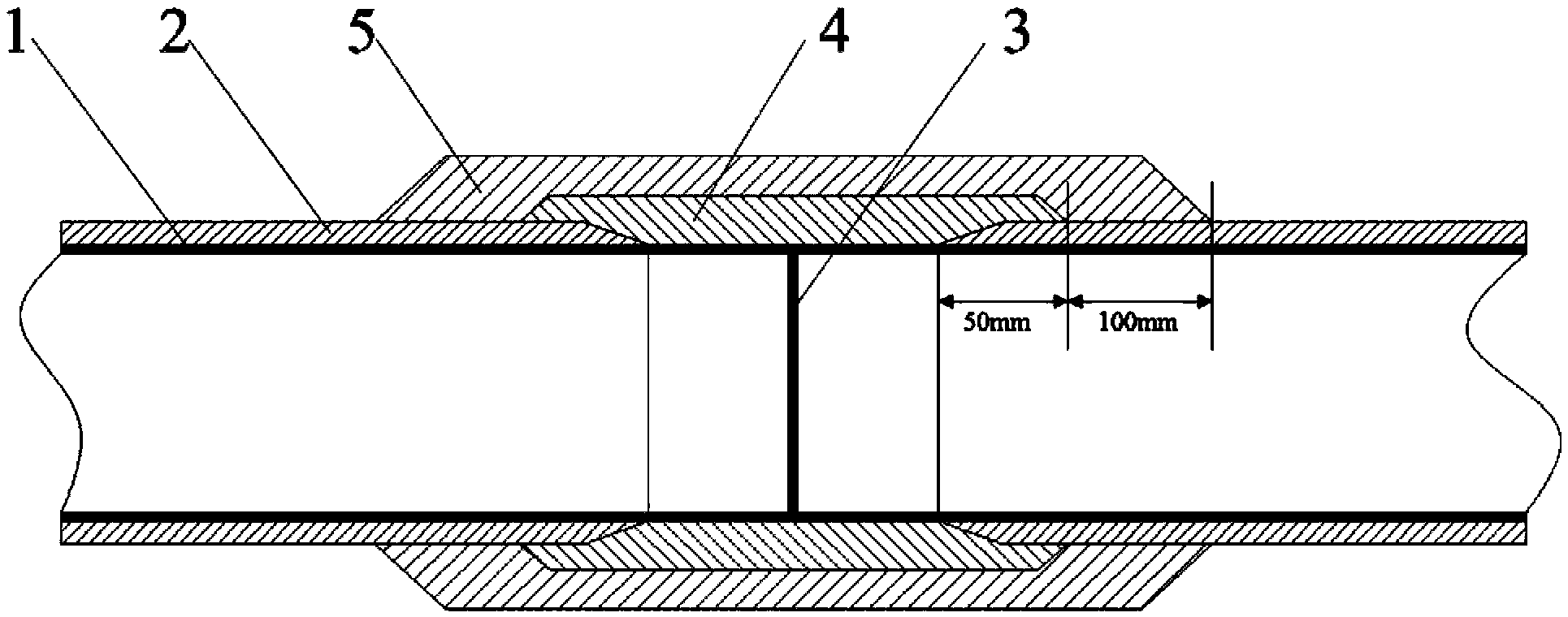

[0020] This embodiment provides an anti-corrosion layer structure for in-service pipeline joint repair, please refer to figure 1 , the in-service pipeline has a steel pipe 1 buried underground, an anti-corrosion layer 2 and a joint metal girth weld 3. Since the oil and gas pipeline in service is connected by multiple steel pipes welded to each other, that is, the two sections of steel pipe 1 are connected by joint metal 3 girth welds are welded to each other, and the anti-corrosion layer 2 is wrapped on the steel pipe 1 . Since the weld between the steel pipe 1 and the steel pipe 1 is easily damaged, it often needs to be repaired. The structure of the anti-corrosion layer for repairing the joint of the pipeline in this service is:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com