Adhesive tape

A tape and adhesive layer technology, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of single function and poor bonding stability, and achieve multiple functions and good bonding stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

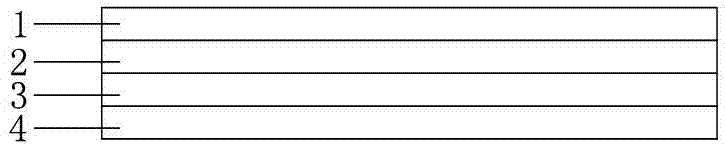

[0047] Embodiment one, such as figure 1 As shown, an adhesive tape includes an antistatic coating 1, a substrate layer 2, an adhesive layer 3 and a release film layer 4 that are stacked sequentially from top to bottom, and the substrate layer 2 is a PET film layer.

[0048] Wherein, the adhesive layer 3 includes the following materials by weight, specifically:

[0049] Butyl Acrylate 25%

[0050] Acrylic 5%

[0051] Epoxy resin 10%

[0052] Ethyl acetate 40%

[0053] Rosin resin 10%

[0054] Ethyl Methacrylate 10%.

[0055] It should be further pointed out that the antistatic coating 1 of the present embodiment includes the following materials by weight, specifically:

[0056] Glyceryl Monopalmitate 93%

[0057] Nano silver powder 3%

[0058] Phosphor 4%.

[0059] Through the above design, the adhesive tape of the first embodiment has the advantages of good adhesive performance, various functions, and has an antistatic effect; for the antistatic coating 1 of the first...

Embodiment 2

[0060] Embodiment 2, the difference between this embodiment 2 and embodiment 1 is that the adhesive layer 3 includes the following materials by weight, specifically:

[0061] Butyl Acrylate 20%

[0062] Acrylic 8%

[0063] Epoxy 12%

[0064] Ethyl acetate 40%

[0065] Rosin resin 10%

[0066] Ethyl Methacrylate 10%.

[0067] In addition, the antistatic coating 1 includes the following materials by weight, specifically:

[0068] Glyceryl Monopalmitate 90%

[0069] Nano silver powder 2%

[0070] Phosphor 8%.

Embodiment 3

[0071] Embodiment 3, the difference between this embodiment 3 and embodiment 1 is that the adhesive layer 3 includes the following materials by weight, specifically:

[0072] Butyl Acrylate 30%

[0073] Acrylic 5%

[0074] Epoxy 15%

[0075] Ethyl acetate 40%

[0076] Rosin resin 5%

[0077] Ethyl Methacrylate 5%.

[0078] In addition, the antistatic coating 1 includes the following materials by weight, specifically:

[0079] Glyceryl Monopalmitate 95%

[0080] Nano silver powder 2%

[0081] Phosphor 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com