Super-hydrophilic copper-based MOF photo-thermal material, preparation method and application thereof

A super-hydrophilic, copper-based technology, used in heat exchange materials, general water supply conservation, chemical instruments and methods, etc., can solve problems such as limiting solar heat conversion efficiency, limiting large-scale applications, and complex manufacturing processes, achieving excellent The effect of light absorption, excellent solar energy absorption performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] (1) First cut the commercial polyester fabric to the required size (eg 21cm -2 ), followed by washing with a solution of deionized water and acetone to clean the polyester fabric.

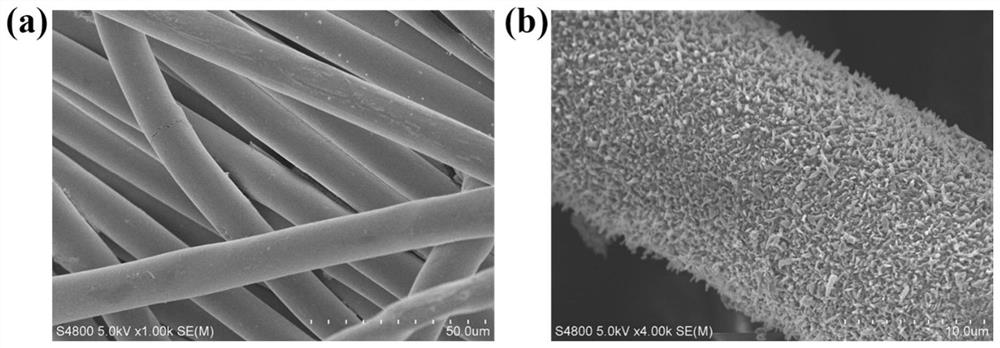

[0032] (2) Place the cleaned polyester fabric in a magnetron sputtering vacuum chamber. Select a DC power supply as the sputtering source, and pump the vacuum of the sputtering chamber to 9.0×10 through a mechanical pump and a molecular pump. -4 Pa, followed by Ar plasma etching at a pressure of 5 Pa for 10 min to improve the adhesion of the film. A high-purity copper target (99.9% pure) and argon gas were used during the deposition process, and the pressure in the vacuum chamber was adjusted to 0.5 Pa. Sputtering for 20 minutes under the conditions of Ar flow rate of 40 sccm and current of 0.25 A allowed the sputtered copper clusters to deposit on the surface of the textile to prepare a copper-coated polymer fabric film.

[0033] (3) Use dilute H 2 SO 4 (5 vol%), deionized water and ac...

specific Embodiment approach 2

[0038] (1) First cut the commercial polyester fabric to the required size (eg 21cm -2 ), followed by washing with a solution of deionized water and acetone to clean the polyester fabric.

[0039] (2) Place the cleaned polyester fabric in a magnetron sputtering vacuum chamber. Select a DC power supply as the sputtering source, and pump the vacuum of the sputtering chamber to 9.0×10 through a mechanical pump and a molecular pump. -4 Pa, followed by Ar plasma etching at a pressure of 5 Pa for 15 min to improve the adhesion of the film. A high-purity copper target (99.9% pure) and argon gas were used during the deposition process, and the pressure in the vacuum chamber was adjusted to 0.5 Pa. Sputtering for 20 minutes under the conditions of Ar flow rate of 40 sccm and current of 0.25 A allowed the sputtered copper clusters to deposit on the surface of the textile to prepare a copper-coated polymer fabric film.

[0040] (3) Use dilute H 2 SO 4 (5 vol%), deionized water and ac...

specific Embodiment approach 3

[0045] (1) First cut the commercial polyester fabric to the required size (eg 21cm -2 ), followed by washing with a solution of deionized water and acetone to clean the polyester fabric.

[0046] (2) Place the cleaned polyester fabric in a magnetron sputtering vacuum chamber. Select a DC power supply as the sputtering source, and pump the vacuum of the sputtering chamber to 9.0×10 through a mechanical pump and a molecular pump. -4 Pa, followed by Ar plasma etching at a pressure of 5 Pa for 20 min to improve the adhesion of the film. A high-purity copper target (99.9% pure) and argon gas were used during the deposition process, and the pressure in the vacuum chamber was adjusted to 0.5 Pa. Sputtering for 20 minutes under the conditions of Ar flow rate of 40 sccm and current of 0.25 A allowed the sputtered copper clusters to deposit on the surface of the textile to prepare a copper-coated polymer fabric film.

[0047] (3) Use dilute H 2 SO 4 (5 vol%), deionized water and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com