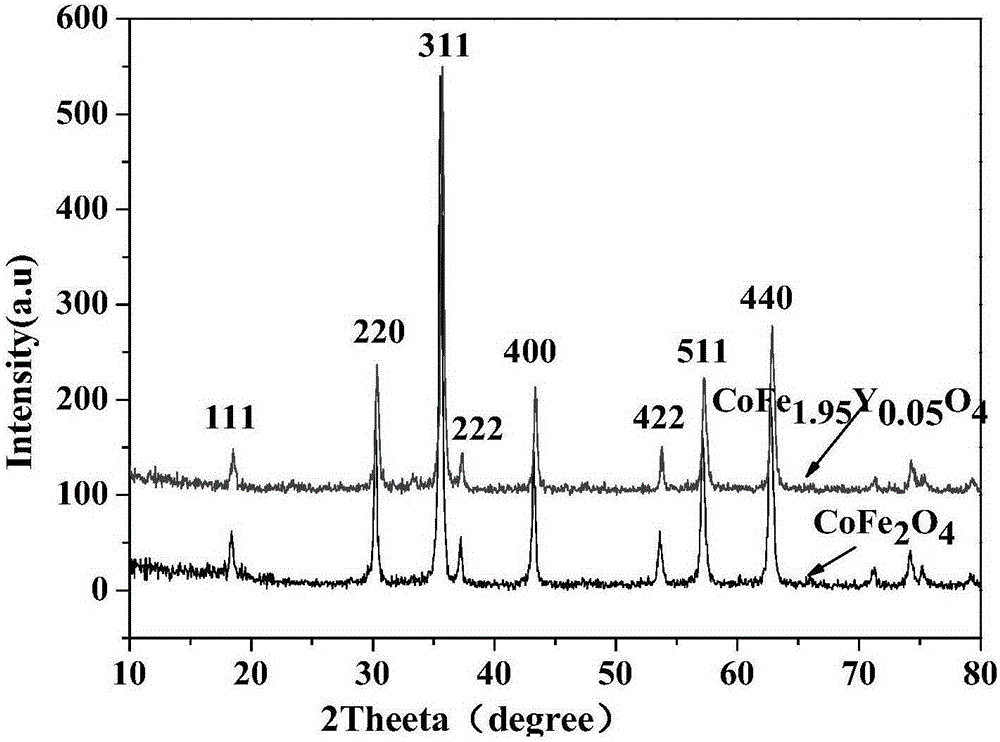

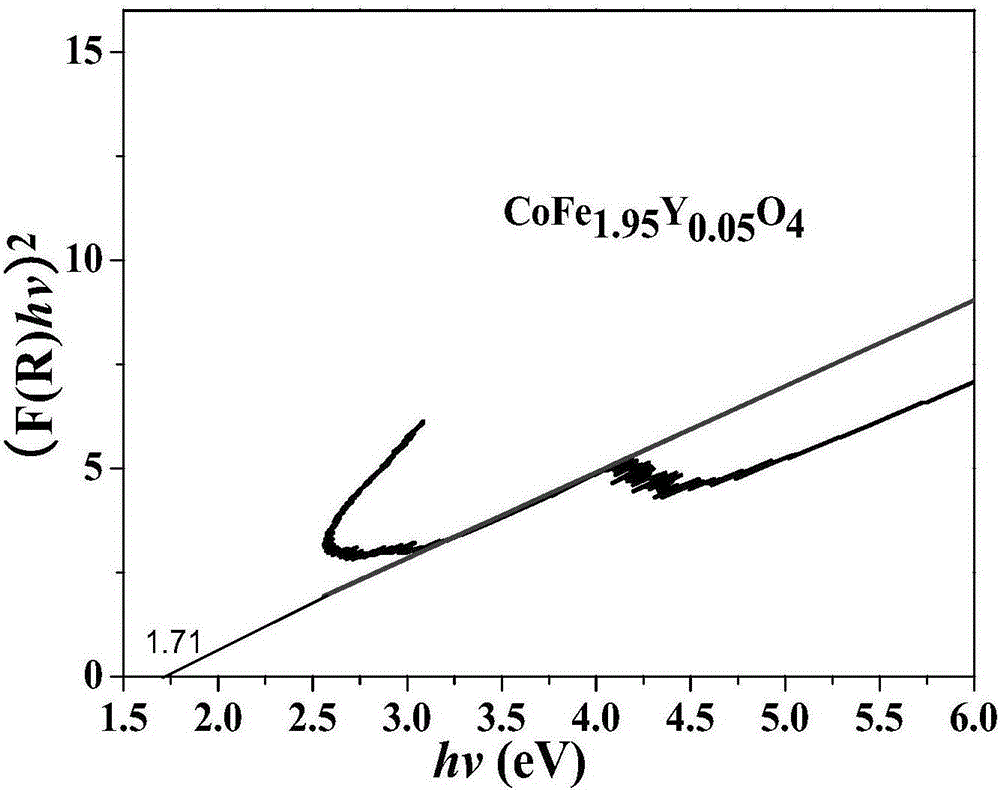

Method for preparation of nano-CoFe1.95Y0.05O4 powder and catalytic degradation of methyl orange

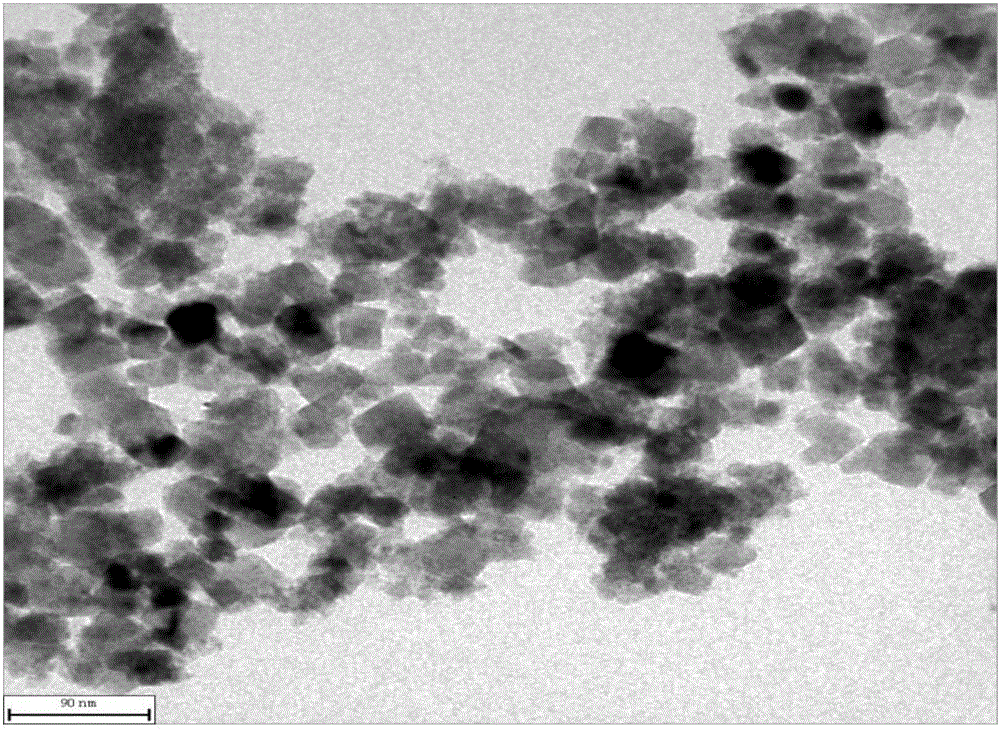

A technology of cofe1.95y0.05o4, catalytic degradation, applied in chemical instruments and methods, light water/sewage treatment, water pollutants, etc. To achieve the effect of good dispersion, saving reaction time and strong magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Nano CoFe of this embodiment 1.95 Y 0.05 O 4 The method for preparing powder and catalytically degrading methyl orange includes the following steps:

[0032] Step 1: Preparation of Nano CoFe 1.95 Y 0.05 O 4 Powder

[0033] (1) Put 0.01molCo(NO 3 ) 2 ·6H 2 O, 0.02molFe(NO 3 ) 3 ·9H 2 O, 0.0005molY(NO 3 ) 3 ·6H 2 O and 0.03mol citric acid are dissolved in deionized water to obtain an initial mixture. While stirring, heat the initial mixture to 70°C, stir vigorously for 2 hours and then add dropwise concentrated ammonia to adjust the pH of the solution to 7. During this heating process Keep stirring the solution at 70°C, the solution becomes a transparent sol after 2h. In the preparation of spinel CoFe 2-x Y x O 4 In the process, when x2-x Y x O 4 Spinel type may be transformed into perovskite type YFeO3, this experiment chooses x = 0.05. The use of citric acid can obtain composite oxides with small crystal grains and large specific surface area; citric acid is a chelating age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com