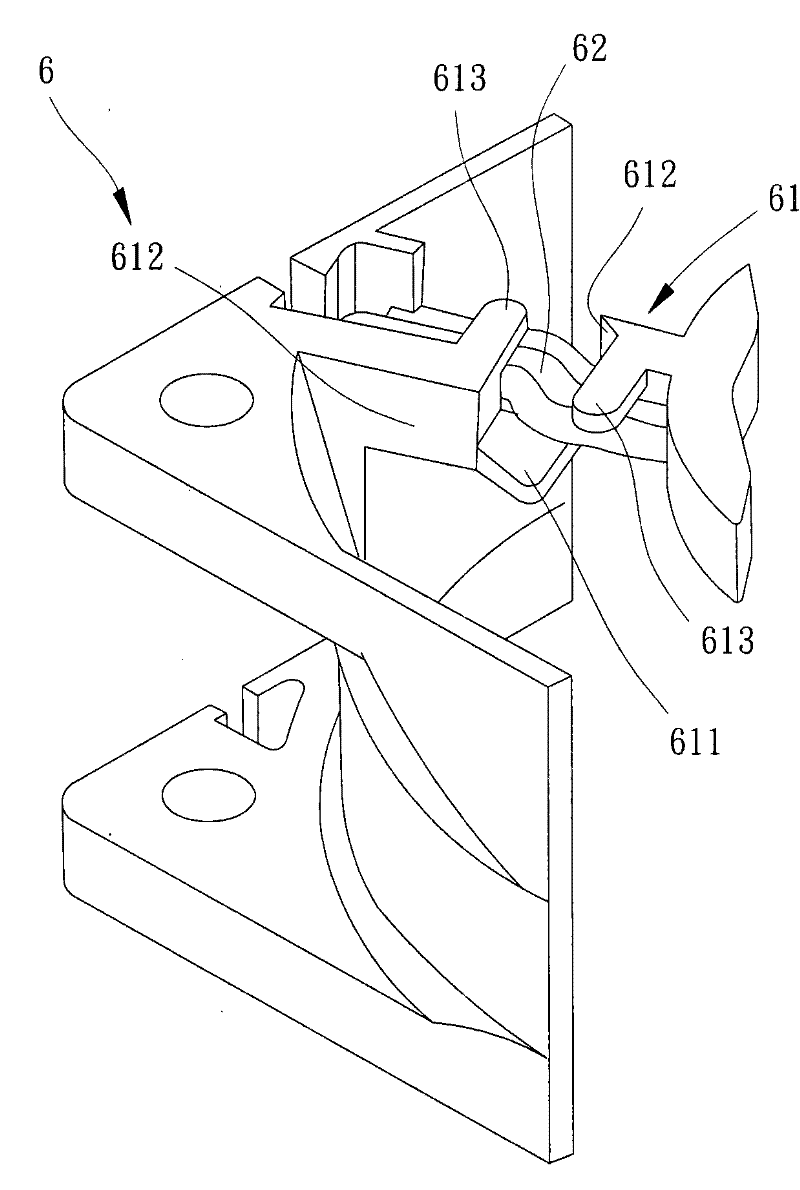

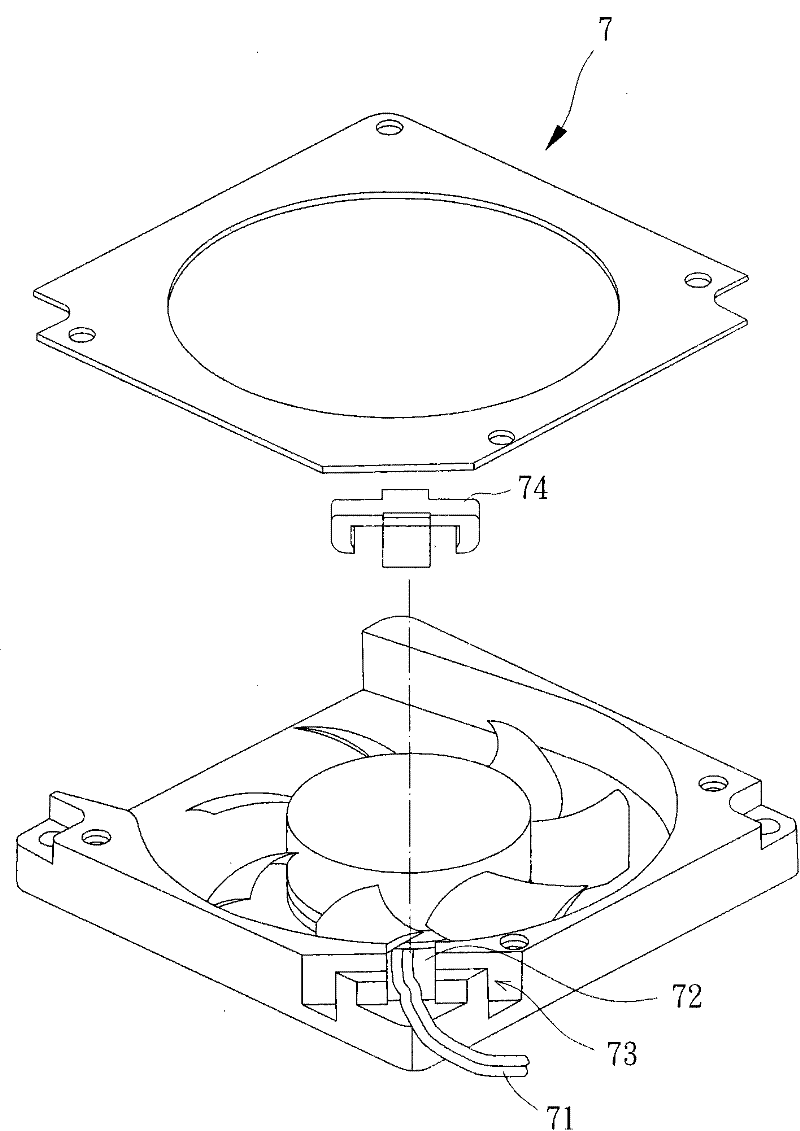

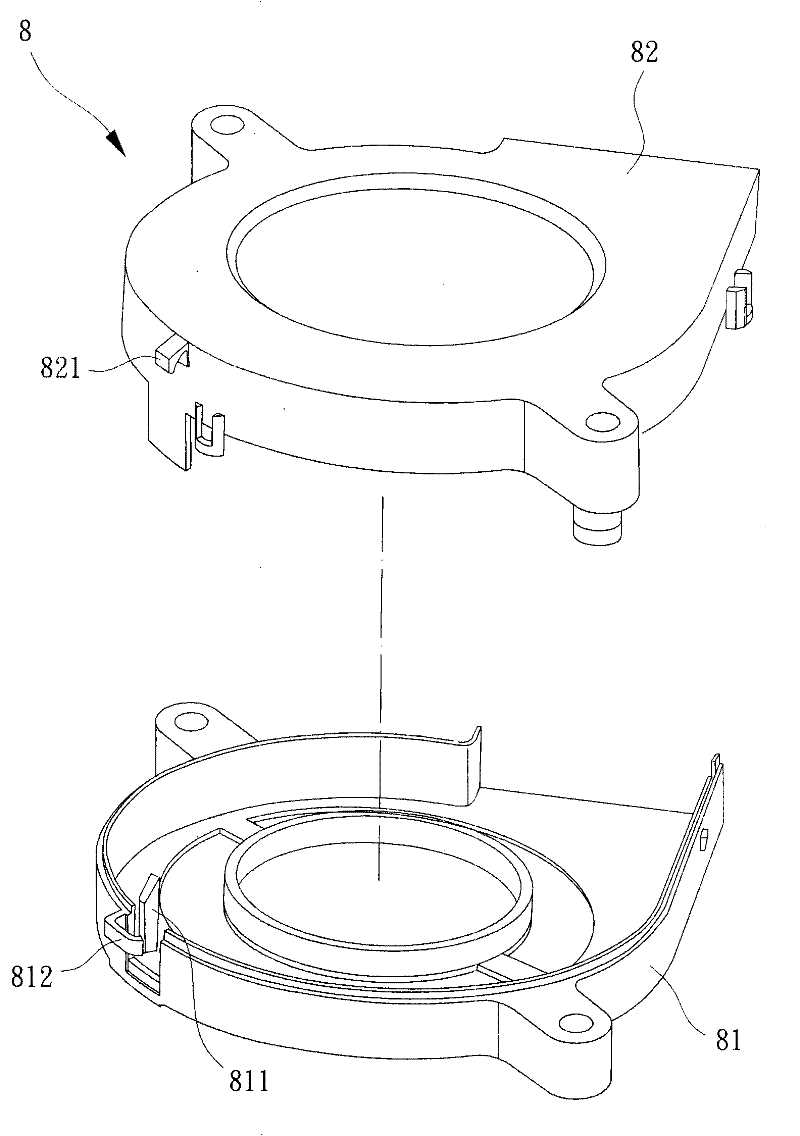

fan frame

A heat dissipation fan and fan frame technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of inability to provide wire 84 positioning and protection measures, and inconvenient disassembly and use , unable to provide wires and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0048] Please refer to Figure 5 and 6As shown, the fan frame of the cooling fan according to the preferred embodiment of the present invention includes at least a frame body 1 and a wire clamping member 2 . This frame body 1 has fan frame basic structures such as air inlet, air outlet and internal runner space, and this frame body 1 can be used for combining as motor 3 (such as Figure 6 Shown) or fan wheel and other components, in order to constitute a heat dissipation fan, the main technical features of the present invention will be further described below, the basic structure of the frame 1 and the assembly method of the heat dissipation fan can be understood by those with ordinary knowledge in the technical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com