Adhesive sheet for water jet laser dicing

A technology of laser cutting and adhesive sheet, which is applied in the direction of laser welding equipment, film/sheet adhesive, welding/welding/cutting items, etc. It can solve the problem of chip peeling, prevent peeling and improve adhesion , good permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The acrylic polymer can be produced by, for example, polymerizing one or two or more monomers or a mixture thereof using known methods such as solution polymerization, emulsion polymerization, bulk polymerization, and suspension polymerization. Among them, the solution polymerization method is preferable. Examples of the solvent used here include polar solvents such as ethyl acetate and toluene. The solution concentration is usually about 20 to 80% by weight.

[0046] In the preparation of polymers, polymerization initiators can be used. Examples of the polymerization initiator include peroxides such as hydrogen peroxide, benzoyl peroxide, and t-butyl peroxide. It is preferably used alone, but it can also be used in combination with a reducing agent as a redox type polymerization initiator. Examples of the reducing agent include ionized salts such as sulfites, bisulfites, iron, copper, and cobalt salts, amines such as triethanolamine, and reducing sugars such as aldo...

Embodiment

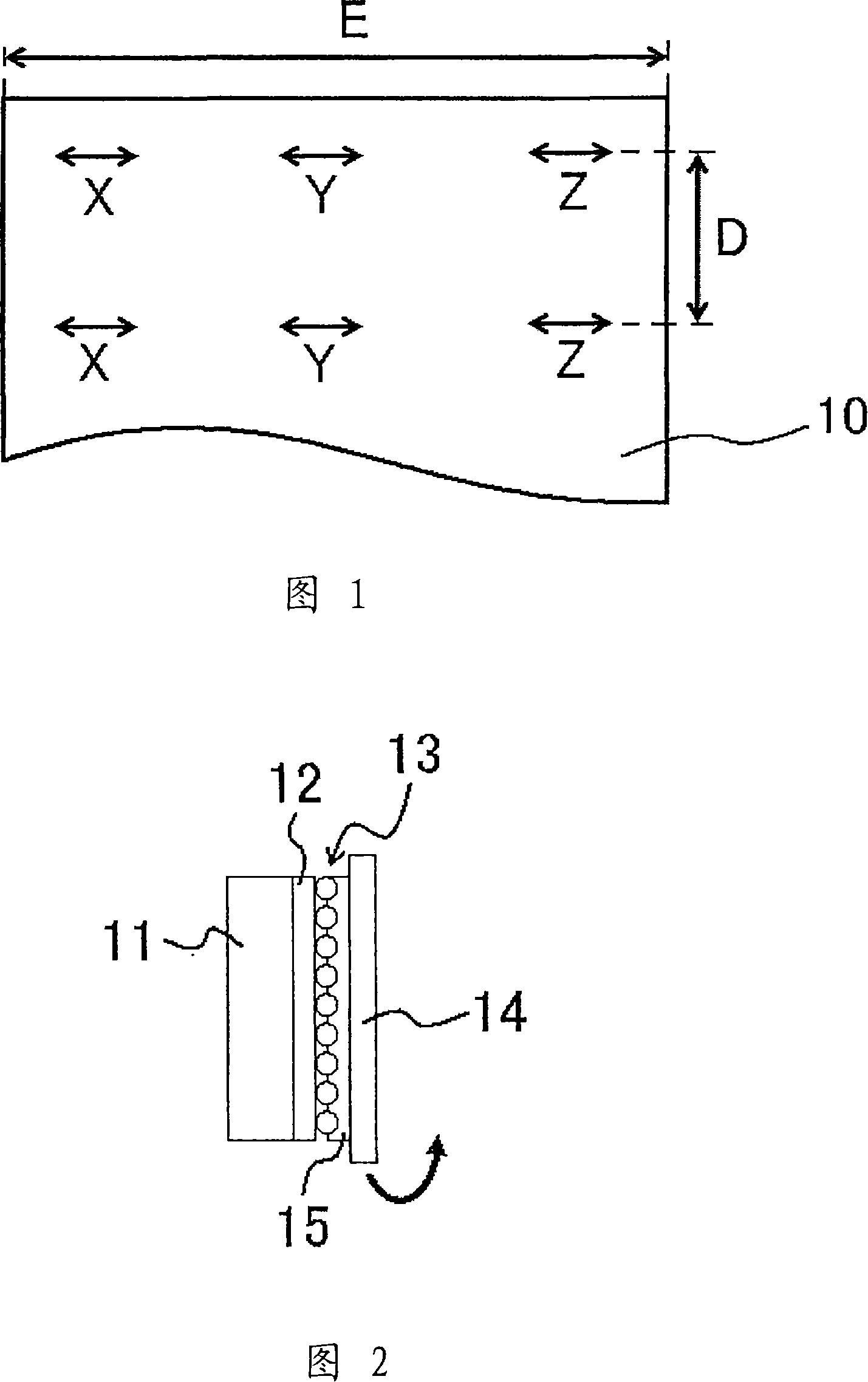

[0056] Examples of the pressure-sensitive adhesive sheet for water jet laser cutting of the present invention will be described in detail below.

[0057] (formation of adhesive layer)

[0058] In ethyl acetate, 60 parts by weight of methyl acrylate, 35 parts by weight of 2-ethylhexyl acrylate, and 5 parts by weight of acrylic acid were copolymerized by a conventional method. Thus, a solution containing an acrylic copolymer having a weight average molecular weight of 700,000 was obtained.

[0059]Next, to the solution containing the acrylic copolymer, 100 parts by weight of an ultraviolet curable oligomer (viscosity at 25°C: 10 Pa·sec) obtained by reacting pentaerythritol triacrylate and diisocyanate, 3 parts by weight A photopolymerization initiator (trade name "イルガキユア 651", manufactured by Chiba Speciaru Tei One Chemical Co., Ltd.) and 2 parts by weight of a polyisocyanate compound (trade name "Coroneto L", manufactured by Nippon Polyurethane Co., Ltd.) to obtain an acrylic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com