Preparation method of bondable polyfluortetraethylene plate anti-corrosion lining

A technology of polytetrafluoroethylene board and anti-corrosion lining, applied in the direction of adhesive types, chemical instruments and methods, non-polymer adhesive additives, etc., can solve the overall decline in pipe performance, the difficulty of obtaining PTFE boards, and the neglect of internal Lining adhesion performance and other issues, to achieve the effect of short drying time, low construction labor cost, high adhesion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a bondable polytetrafluoroethylene board anticorrosion lining comprises: polishing the polytetrafluoroethylene board with sandpaper, washing it with acetone, and putting it into a mixed solution of sodium, naphthalene and tetrahydrofuran for surface activation treatment; Afterwards, the surface of the PTFE plate is coated with epoxy resin pre-coating adhesive, and the treated PTFE plate is immediately pasted; then, the steel plate and the PTFE plate are laminated by epoxy hot-melt adhesive , Bonded together, after curing for 24 hours, the anti-corrosion lining is obtained.

[0030] The specific steps are (1) in a 500ml three-necked flask, add naphthalene and tetrahydrofuran solution sequentially according to the amount of each substance in the following examples, and stir until completely dissolved; at room temperature, add sodium into the three-necked flask in 5 times, and pass Dry nitrogen, stir at a speed of 300r / min, and keep the temperature ...

Embodiment 1

[0036] The specific components and proportions of the sodium / naphthalene / tetrahydrofuran corrosive solution are as follows:

[0037] Naphthalene 100g

[0038] Sodium 8g

[0039] Tetrahydrofuran 1200ml;

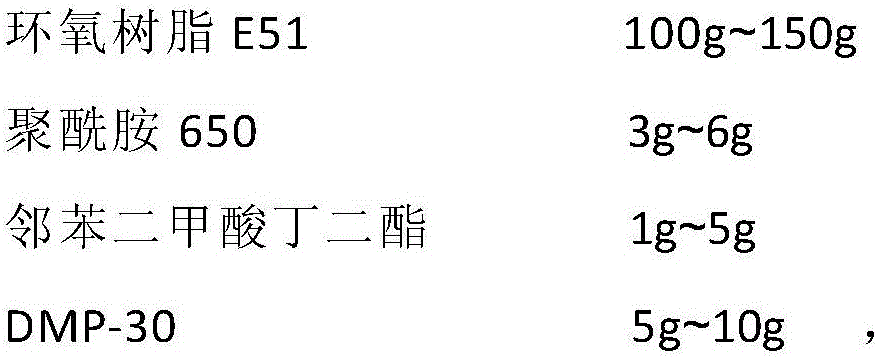

[0040] The components and proportions of the epoxy resin pre-coating adhesive are as follows:

[0041]

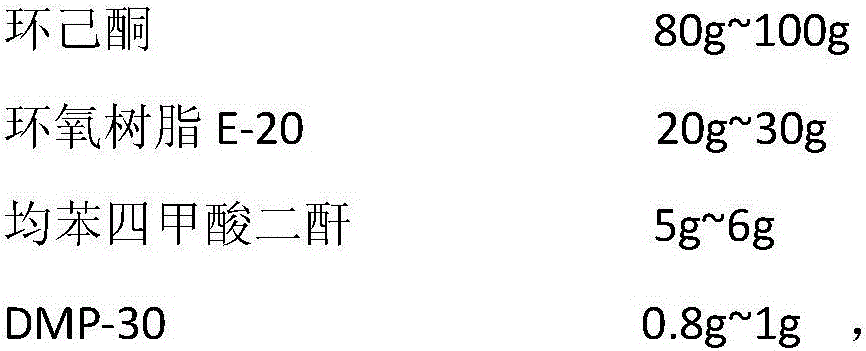

[0042] The components contained in the epoxy hot melt adhesive and the proportions of each component are as follows:

[0043]

[0044] Bonding tensile strength > 1.8MPa, drying time 1 year, maximum use temperature of hot melt adhesive > 150°C.

Embodiment 2

[0046] The specific components and proportions of the sodium / naphthalene / tetrahydrofuran corrosive solution are as follows:

[0047] Naphthalene 110g

[0048] Sodium 20g

[0049] Tetrahydrofuran 800ml;

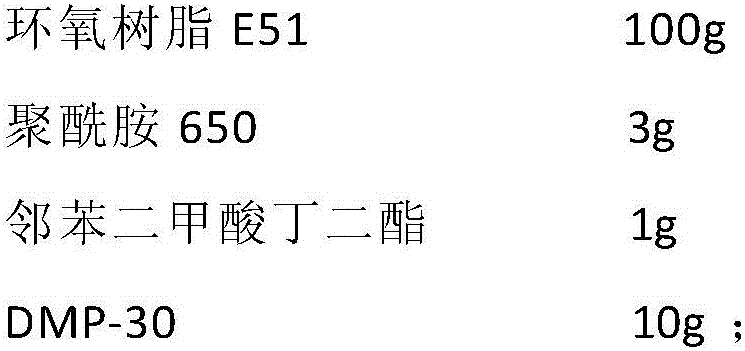

[0050] The components and proportions of the epoxy resin pre-coating adhesive are as follows:

[0051]

[0052] The components contained in the epoxy hot melt adhesive and the proportions of each component are as follows:

[0053]

[0054] Bonding tensile strength > 1.7MPa, drying time 1.5 years, maximum use temperature of hot melt adhesive > 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com