Lithium cobaltate composite material and preparation method thereof as well as positive electrode material

A technology of composite materials and lithium cobalt oxide, which is applied in the chemical industry, can solve the problems of low capacitance and poor cycle performance of lithium cobalt oxide, and achieve the goal of increasing capacitance, improving comprehensive electrical conductivity, improving high temperature and high pressure cycle performance and rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

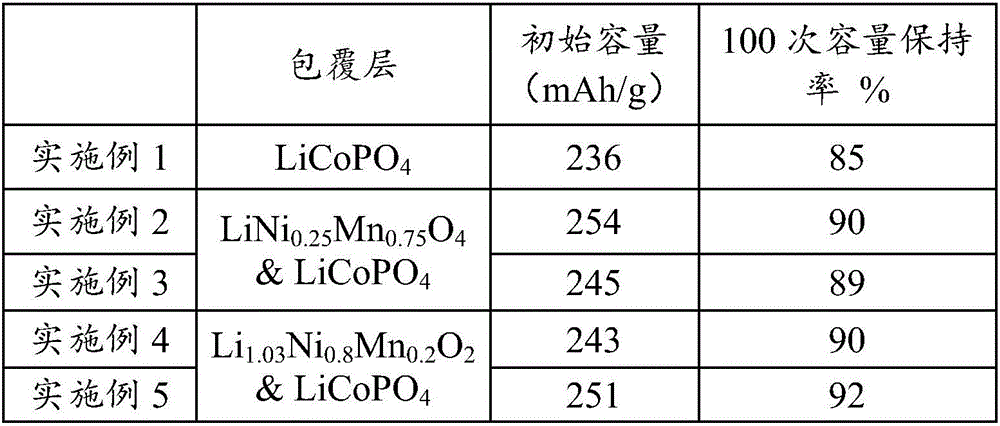

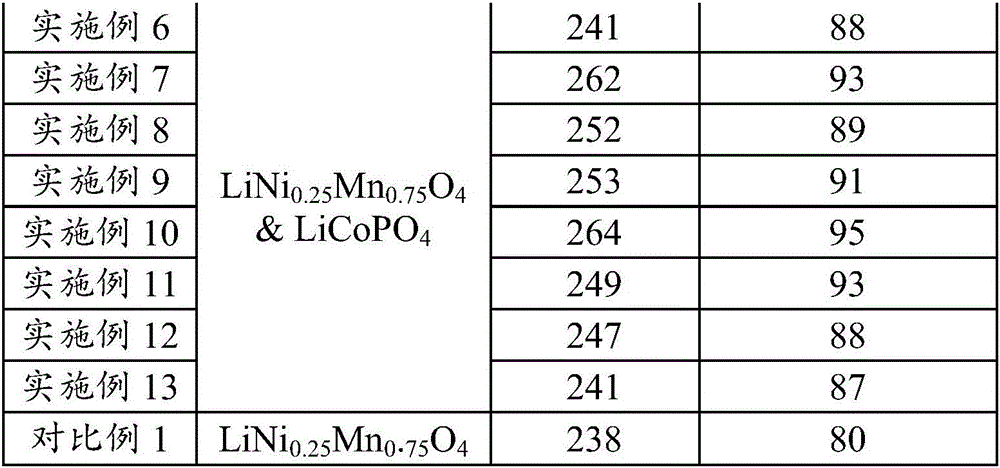

Embodiment 1

[0045] In Comparative Example 2, first cobalt nitrate (Co(NO 3 ) 2 ) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were respectively dissolved in deionized water to form solutions with a concentration of 0.1 mol / L. Then mix a certain amount of lithium cobaltate oxide particles with appropriate pure water as the base liquid, and slowly add the cobalt nitrate solution and diammonium hydrogen phosphate solution prepared above dropwise by using a peristaltic pump while stirring, and continuously stir and disperse for 1 hour , the speed is 1400r / min, until the generated CoPO 4 The nanoparticles are evenly attached on the surface of the matrix, and then dried in a water bath at 90°C. Subsequently, the temperature was raised to 800°C at a rate of 3°C / min and kept for 3 hours. After the calcination was completed, the product to be obtained was lowered to 100°C, and then the calcined product was dispersed and sieved to obtain the final lithium cobalt phosphate Coated lithi...

Embodiment 2

[0047] Lithium carbonate (Li 2 CO 3 ) powder, nickel hydroxide (Ni(OH) 2 ) powder and manganese carbonate (MnCO 3 ) powder in molar ratio Li 2 CO 3 : Ni(OH) 2 : MnCO 3 =1:0.5:1.5 mixed to obtain LiNi 0.25 mn 0.75 o 4 The precursor powder, the precursor powder is processed by sand milling or ball milling until the average particle size becomes 1 μm or less, the resulting slurry is mixed with the lithium cobaltate matrix, and then cobalt nitrate (Co(NO 3 ) 2 ) and diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) were respectively dissolved in deionized water to form solutions with a concentration of 0.1 mol / L. While stirring, use a peristaltic pump to slowly add the above-mentioned cobalt nitrate solution and diammonium hydrogen phosphate solution dropwise, and keep stirring and dispersing for 1 hour at a speed of 1400r / min until the generated Co 3 (PO 4 ) 2 The nanoparticles were uniformly attached on the surface of the substrate, and then dried in a water bath ...

Embodiment 3

[0049] The difference from Example 2 is only that the final calcination heat treatment temperature is different, which is 700°C. Other experimental parameters are the same as in Example 2 to obtain a multilayer composite lithium cobaltate cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com