Hydrogenated styrene-conjugated diene copolymer as well as preparation method and application thereof in self-adhesive films

A hydrogenated styrene and conjugated diene technology, applied in adhesives, film/sheet adhesives, film/sheet without carrier, etc., can solve problems such as dimensional stability limitations, and achieve excellent adhesive strength, Excellent adhesion stability and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

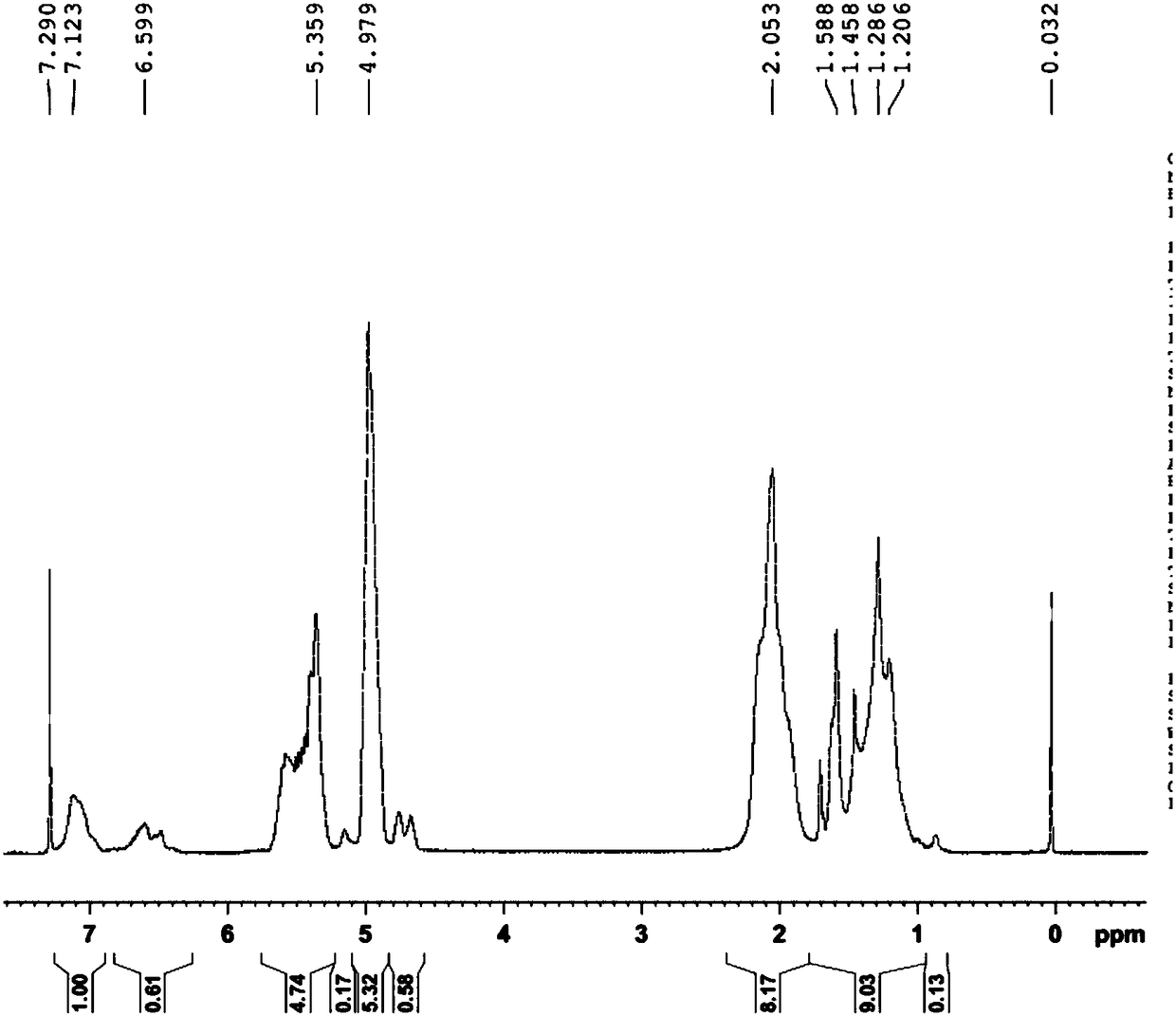

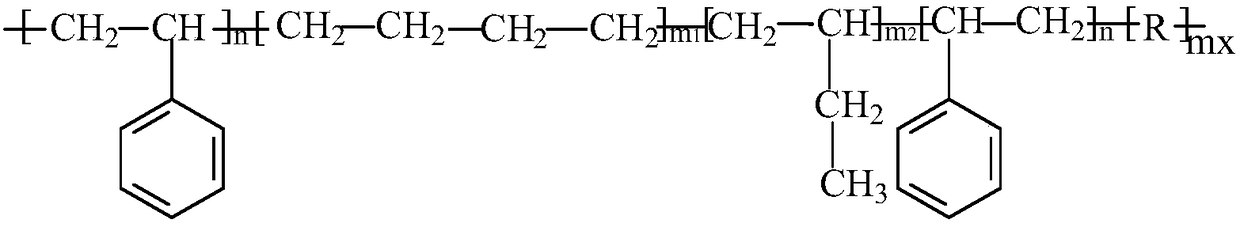

[0063] Preparation of hydrogenated styrene-conjugated diene copolymer:

[0064] Add 3 liters of pure cyclohexane (water value <20ppm), 21mL styrene, 6.5mL regulator (furan) into a 5-liter polymerization kettle purified by nitrogen, start stirring, raise the temperature to 45-55°C, add the initiator Butyllithium (or sec-butyllithium), react for 30min, then add 400mL butadiene, react for 50min, control the maximum temperature not to exceed 65°C, then add 21mL styrene, react at 60-65°C for 30min, finally add 18mL iso Pentadiene, reacted for 20min. After the polymerization reaction is completed, the glue solution is introduced into a 5-liter hydrogenation tank, the temperature is raised to 70°C, a hydrogenation catalyst is added, the hydrogenation pressure is 0.8-1.5Mpa, and the hydrogenation reaction lasts for 120 minutes. After the hydrogenation reaction is completed, the reaction is terminated, the glue solution is purified, the material is discharged, an antioxidant is added,...

Embodiment 2

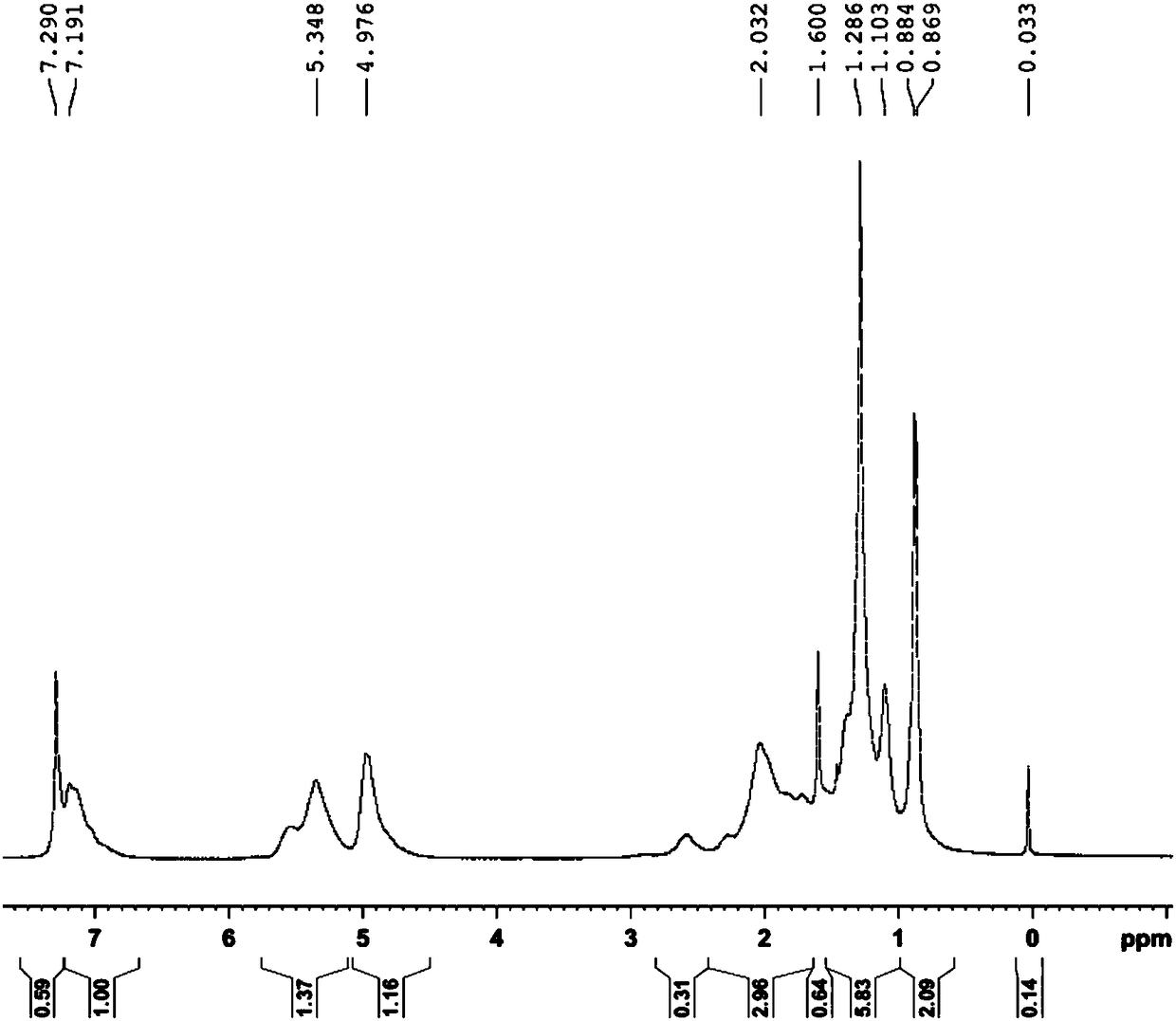

[0071] Preparation of hydrogenated styrene-conjugated diene copolymer:

[0072] Add 3 liters of pure cyclohexane (water value<20ppm), 21mL styrene, 6.5mL regulator (tetrahydrofurfuryl alcohol ethyl ether), 1mL furan into the 5 liter polymerization kettle purified by nitrogen, start stirring, and heat up to 45 ~55°C, add initiator n-butyllithium (or sec-butyllithium), react for 30min, then add 400mL butadiene, react for 50min, control the maximum temperature not to exceed 65°C, then add 21mL styrene, at 60~65°C ℃ for 30 minutes, and finally add 20 mL of butadiene, and react for 20 minutes. After the polymerization reaction is completed, the glue solution is introduced into a 5-liter hydrogenation tank, the temperature is raised to 70°C, a hydrogenation catalyst is added, the hydrogenation pressure is 0.8-1.5Mpa, and the hydrogenation reaction lasts for 120 minutes. After the hydrogenation reaction is completed, the reaction is terminated, the glue solution is purified, the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com