Patents

Literature

53 results about "Ultrasonic soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic soldering is a flux-less soldering process that uses ultrasonic energy, without the need for chemicals to solder materials, such as glass, ceramics, and composites, hard to solder metals and other sensitive components which cannot be soldered using conventional means. Ultrasonic (U/S) soldering, as a flux-less soldering process, is finding growing application in soldering of metals and ceramics from solar photovoltaics and medical shape memory alloys to specialized electronic and sensor packages. U/S soldering has been reported since 1955 as a method to solder aluminum and other metals without the use of flux.

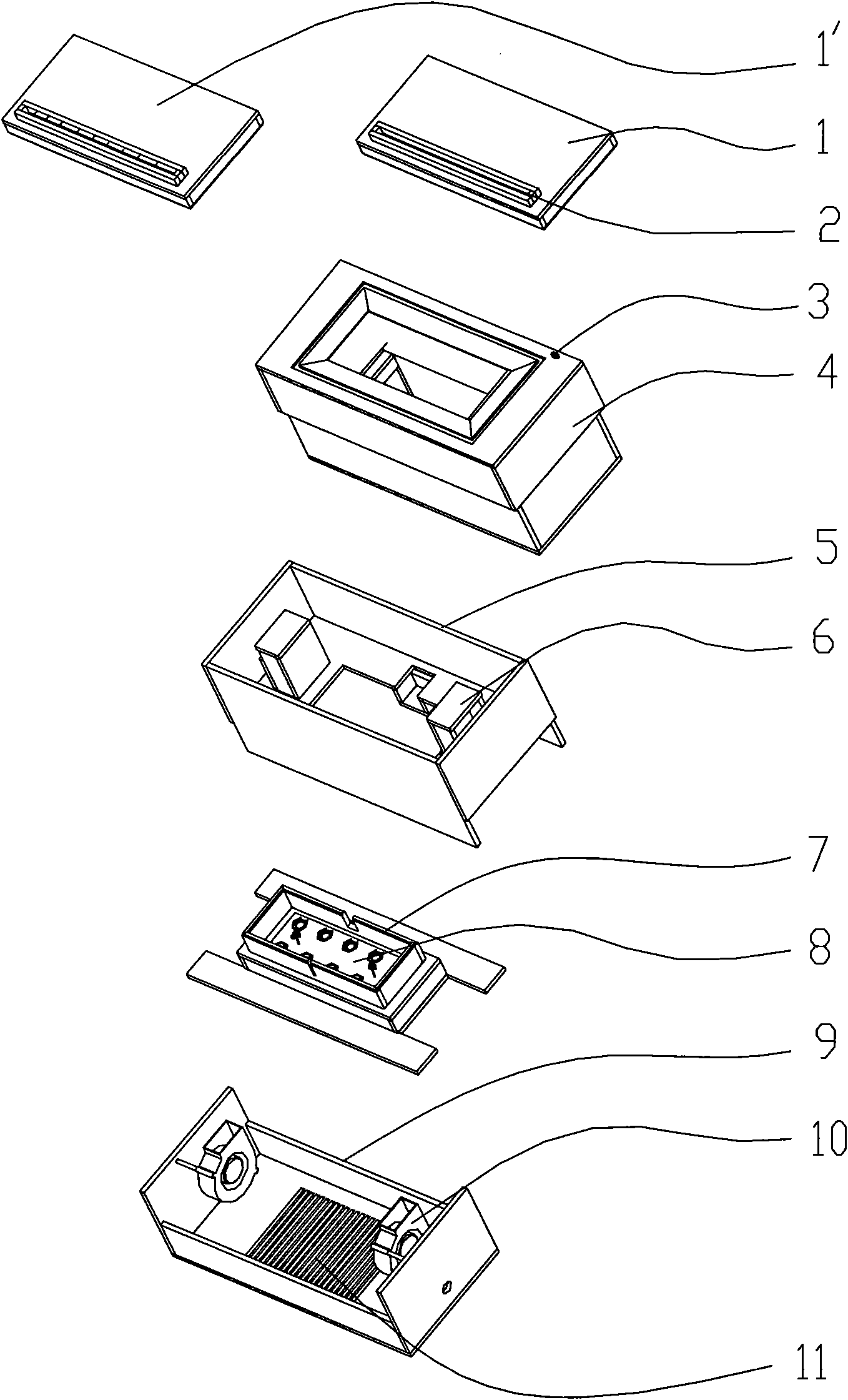

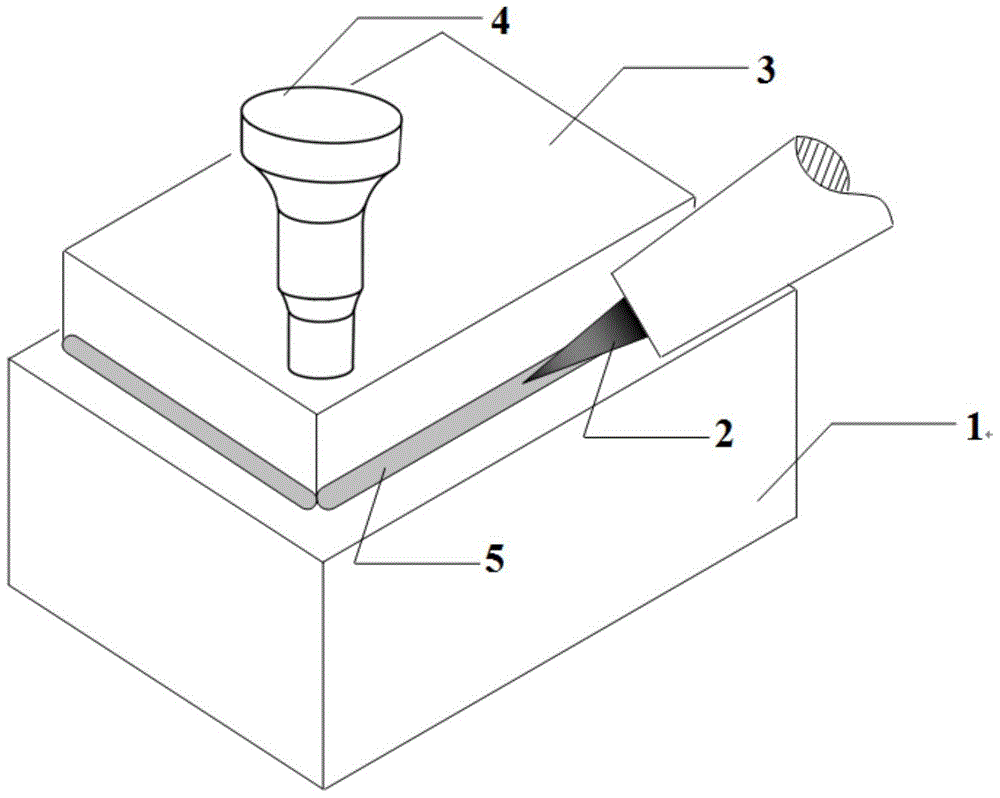

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

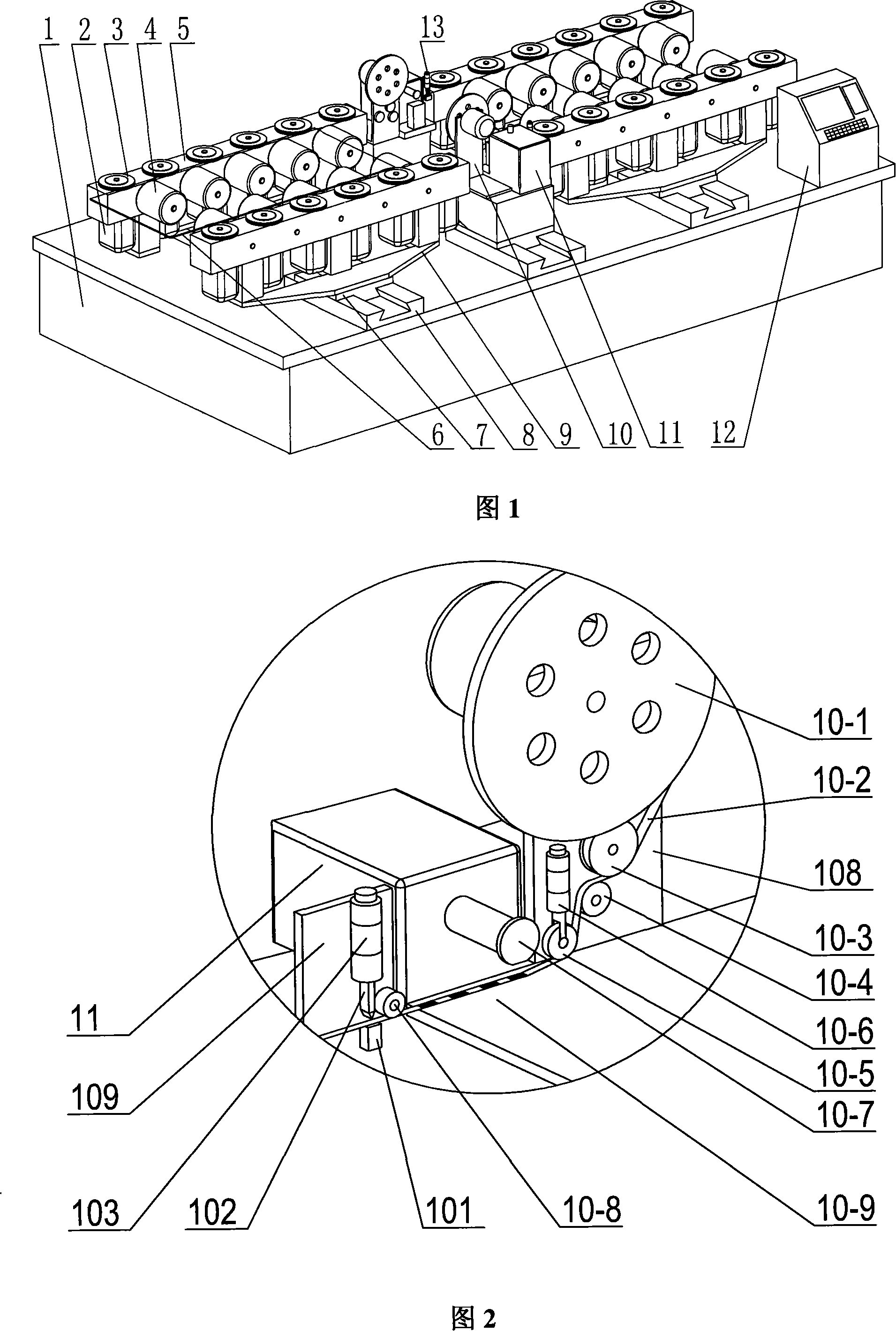

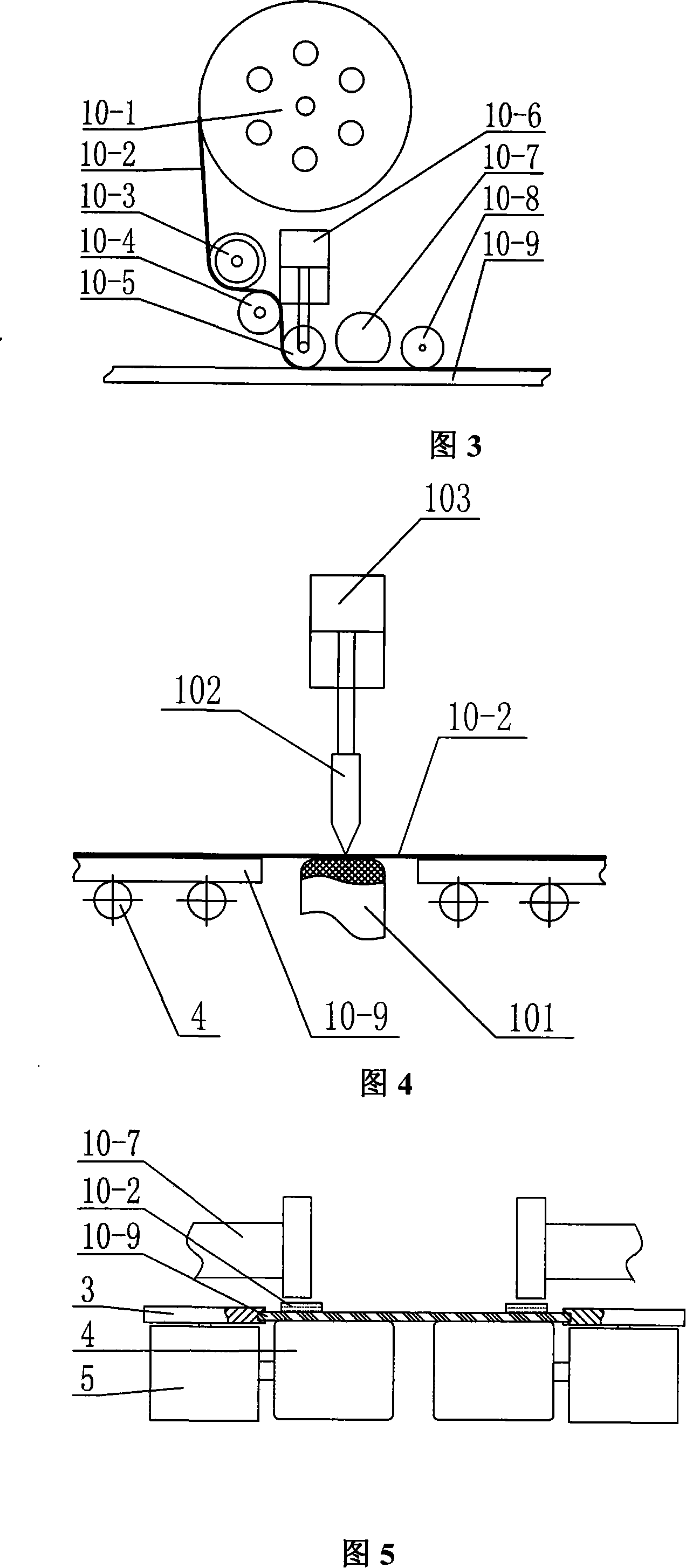

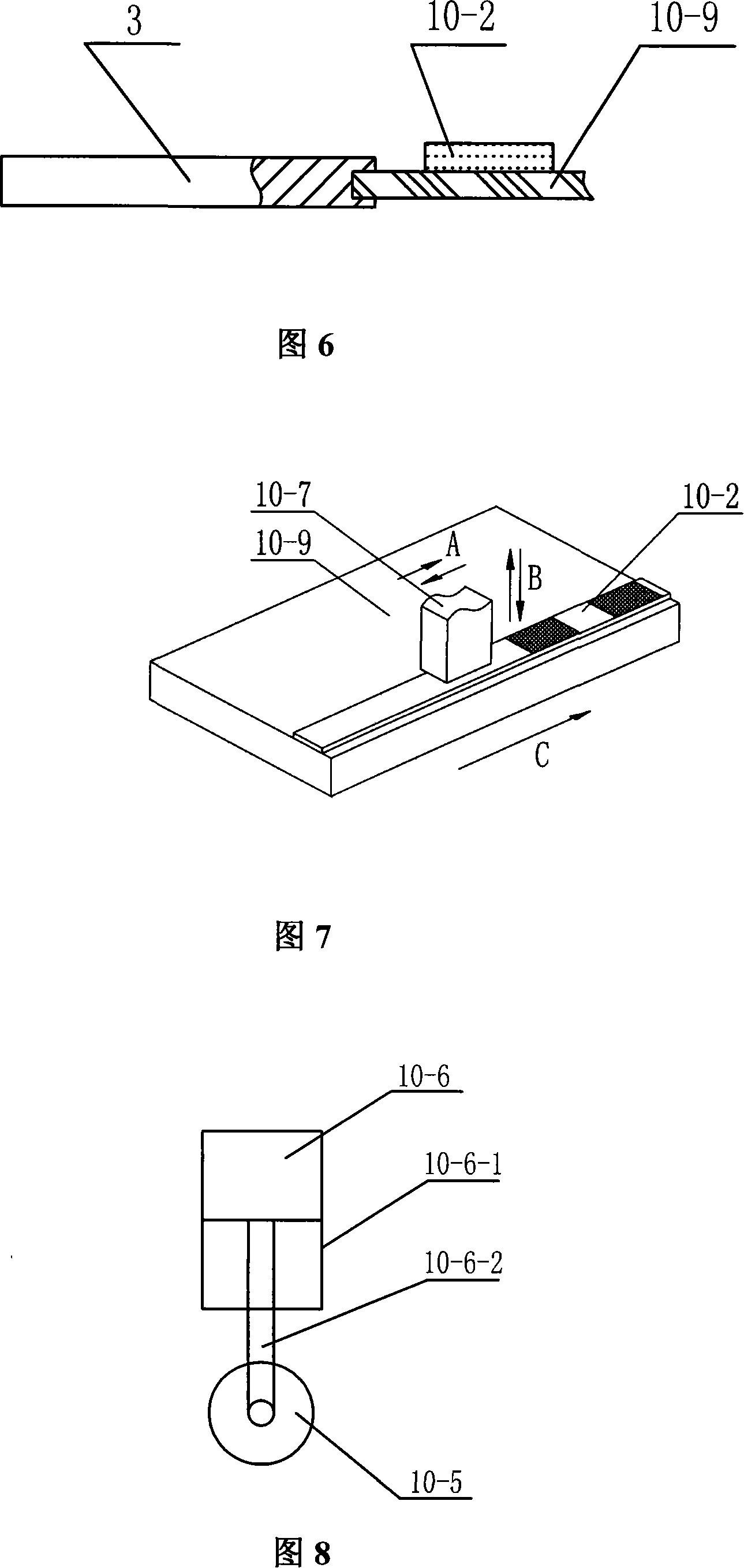

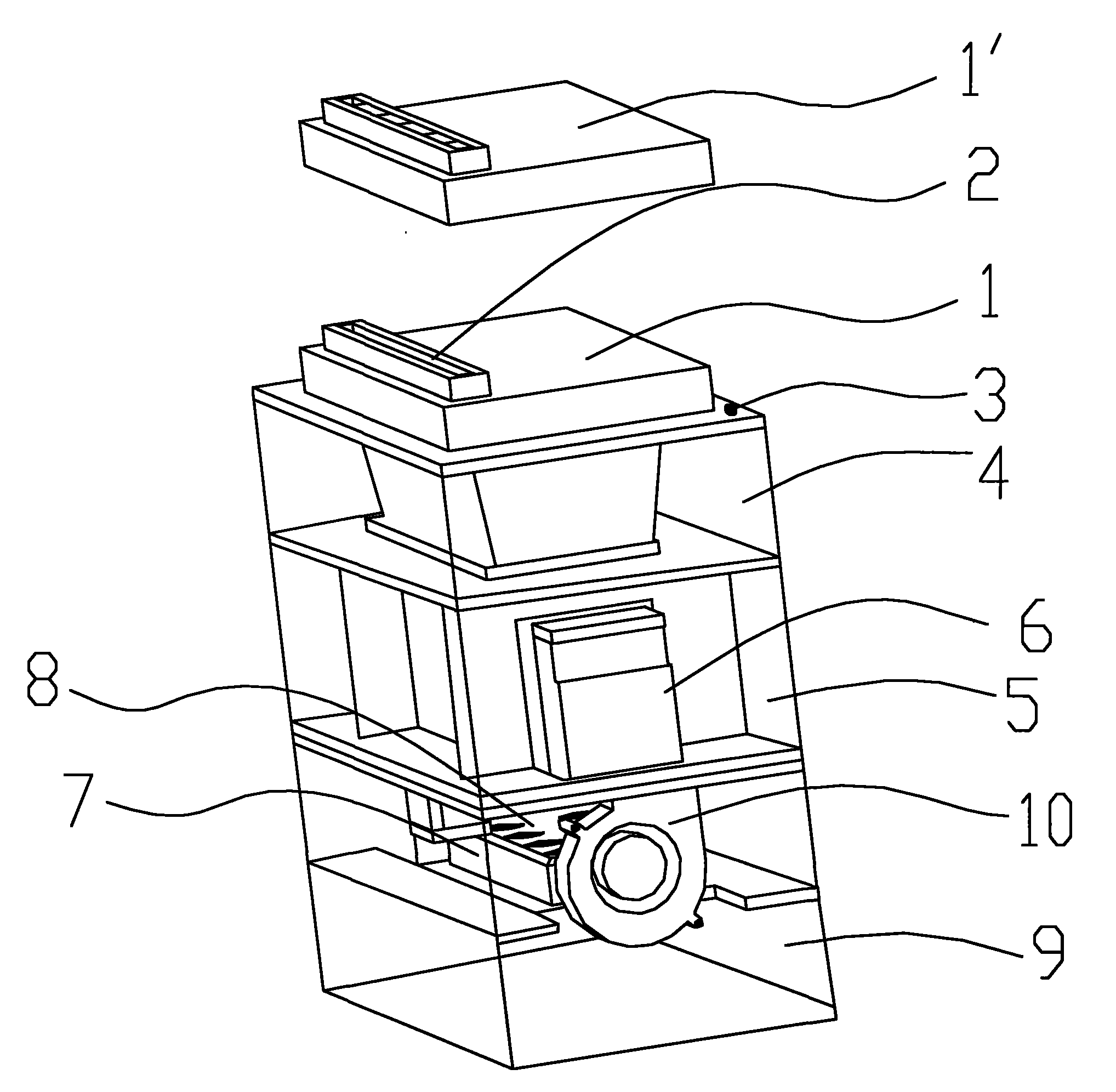

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

Method And Apparatus For Ultrasonic Bonding

ActiveUS20100280646A1Accurate and reliable assessmentEasy to FeedbackSemiconductor/solid-state device testing/measurementSolid-state devicesBond qualityTransducer

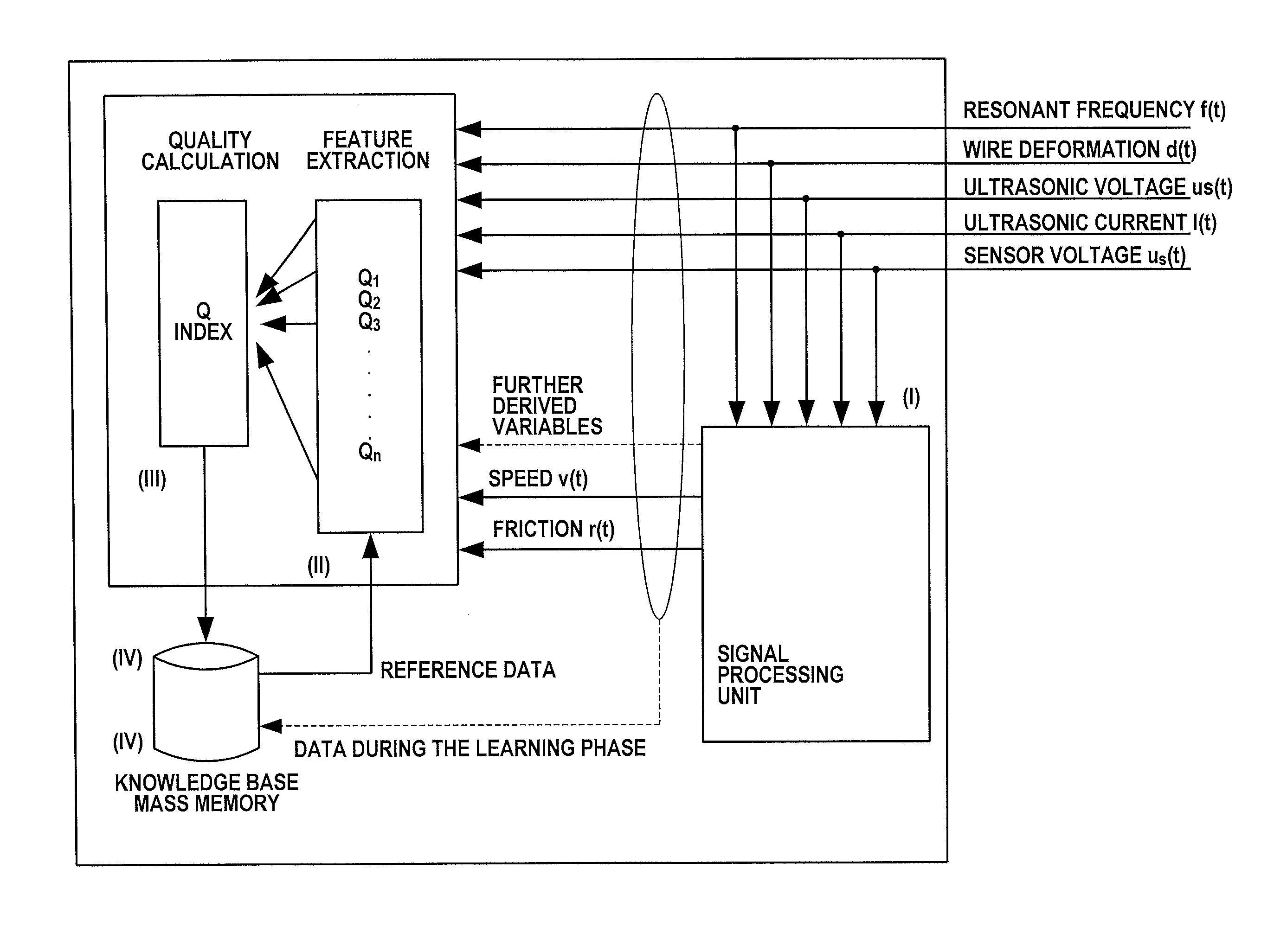

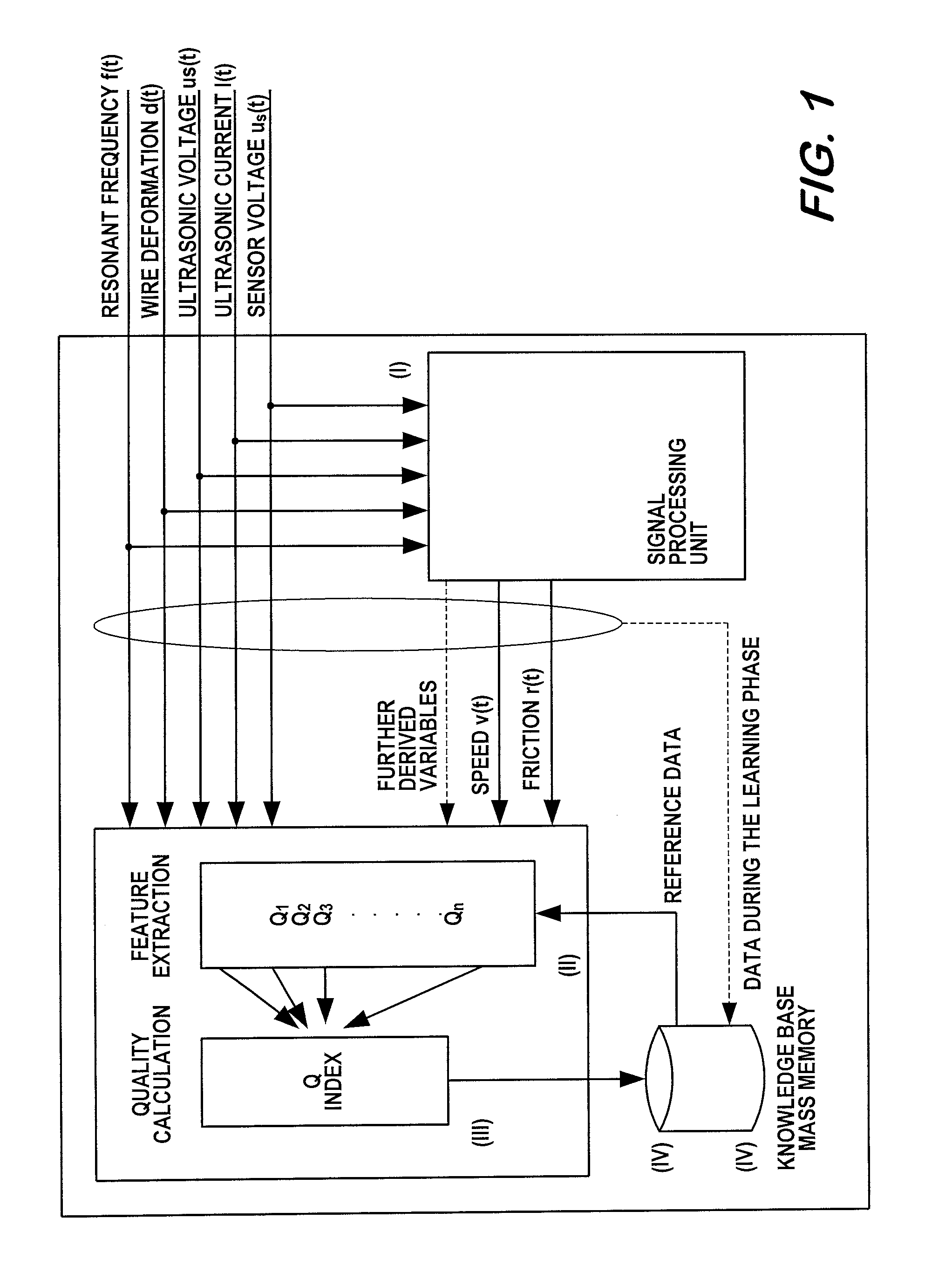

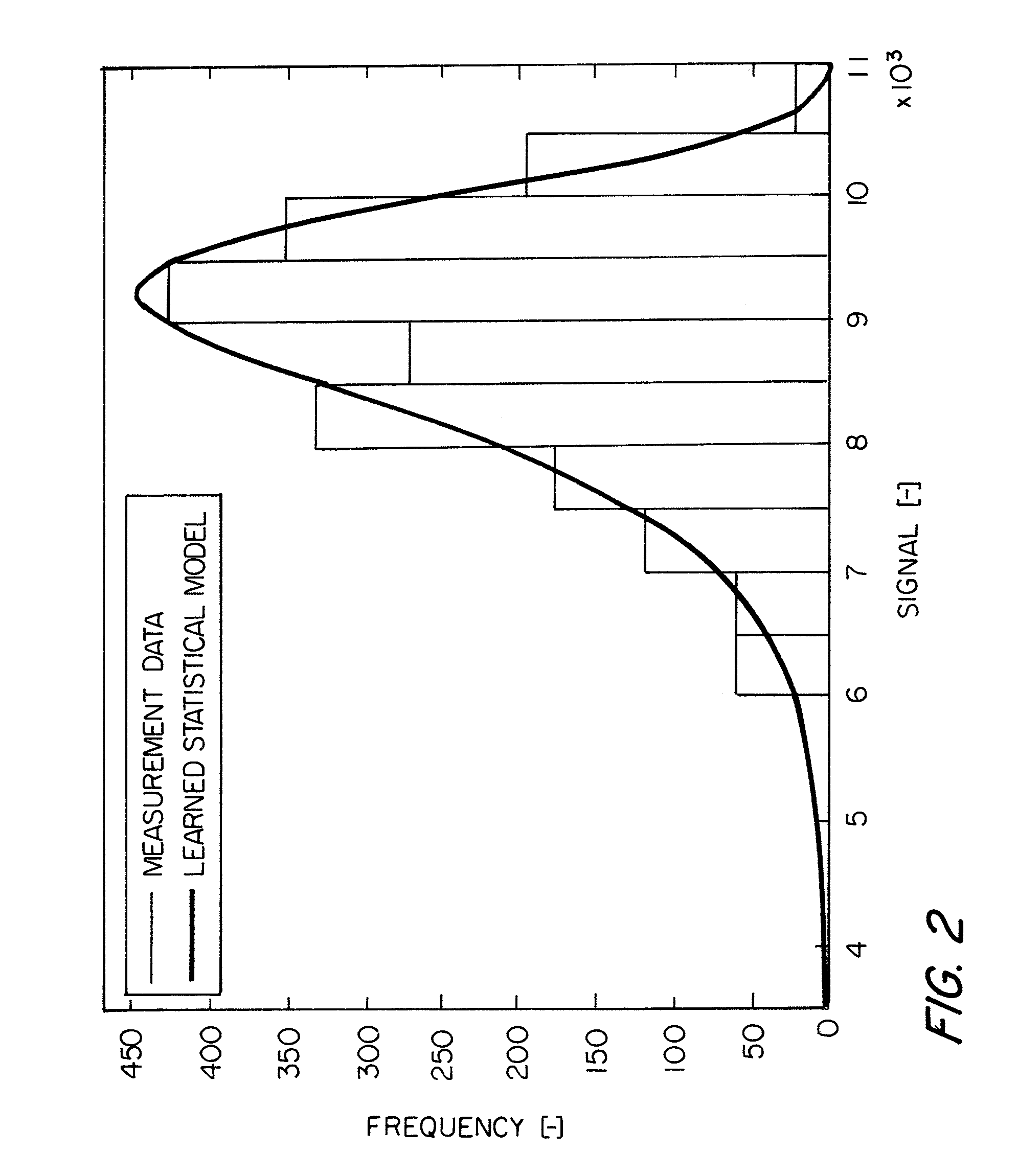

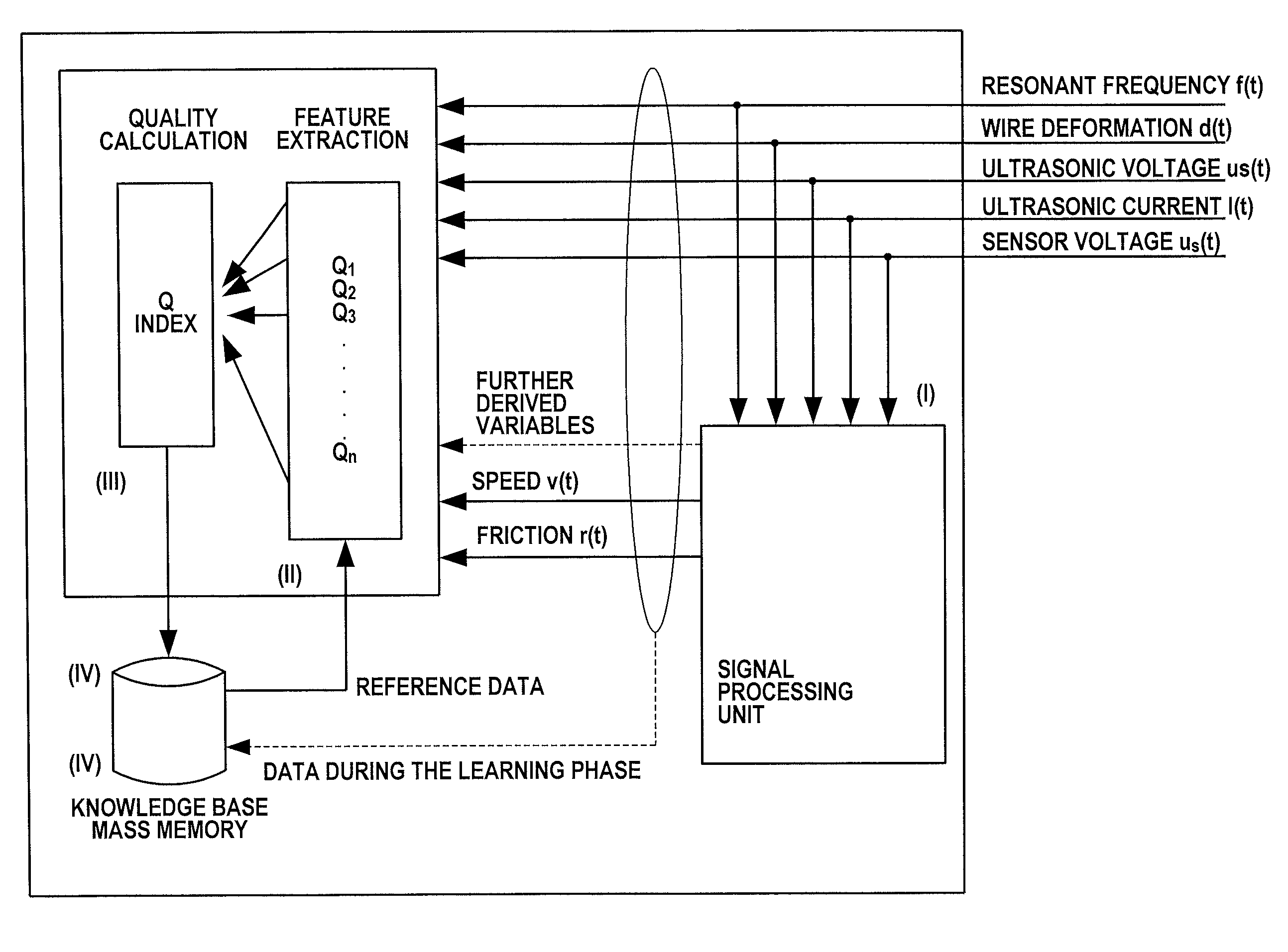

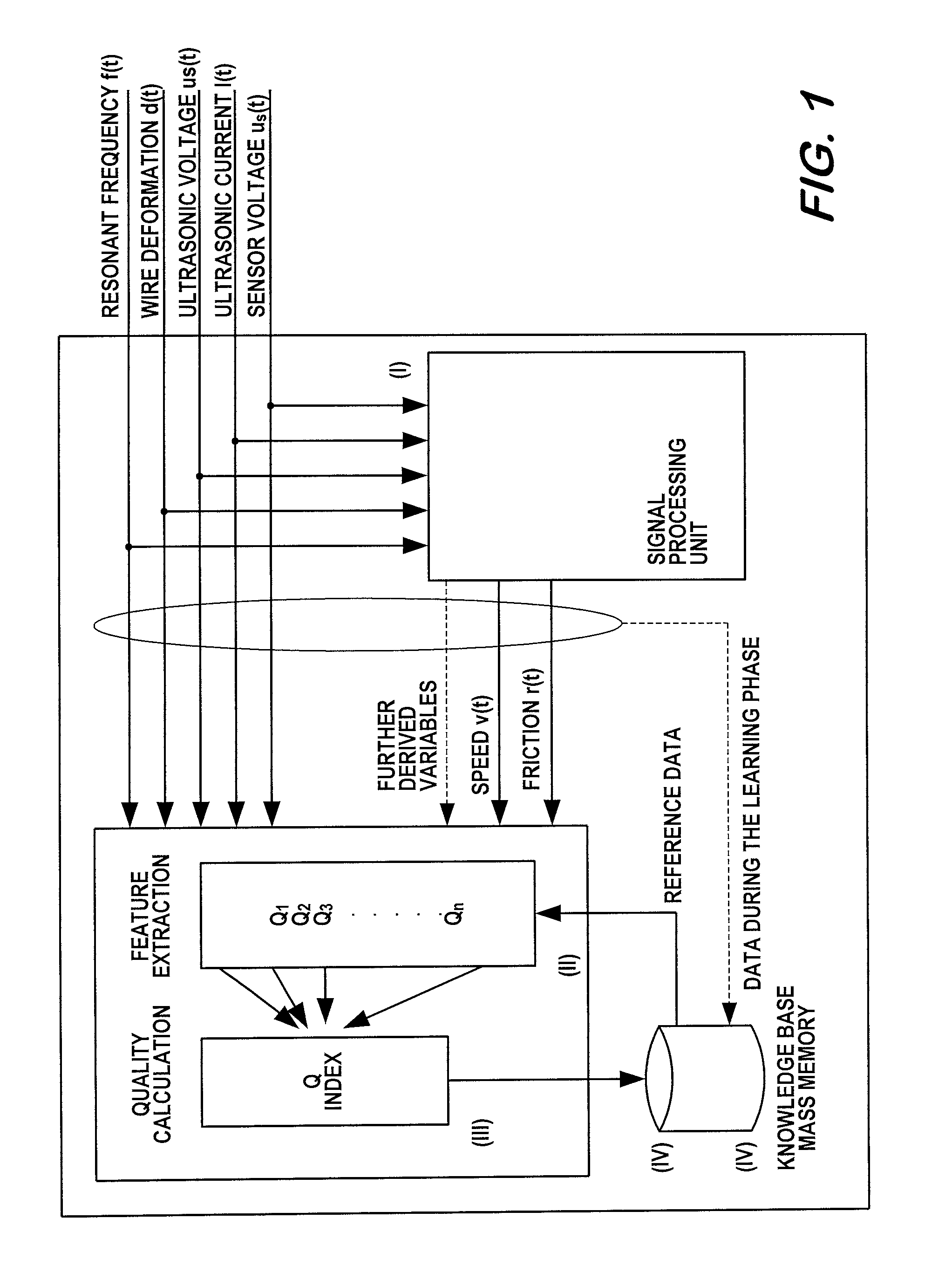

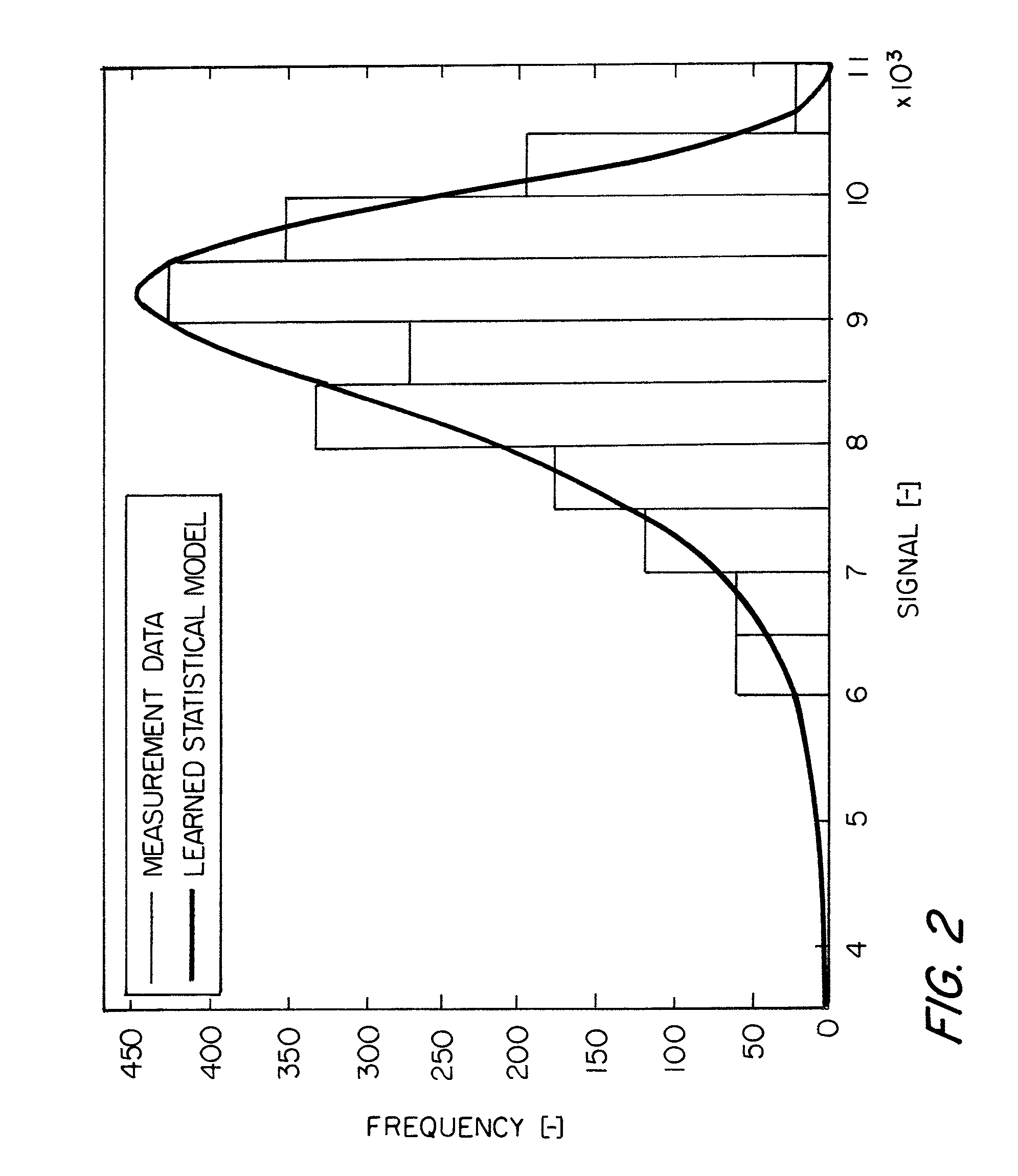

A method for quality control during ultrasonic bonding, in which a transducer bonding tool unit and an ultrasonic generator are used and in which, during the bonding, one or more sensors are used to sense measurement signals for one or more parameters, which can vary during the bonding, for assessing the bond quality and / or for influencing the bonding, and which proposes that, during the bonding, at least one speed profile measurement signal representing the time / speed profile of the tip of the ultrasonic tool in the direction of oscillation thereof be sensed. The invention also relates to a bonding apparatus which is suitable for carrying out the method. Furthermore, the invention relates to other quality control methods for ultrasonic bonding and to bonding apparatuses which are suitable for carrying out these methods.

Owner:HESSE

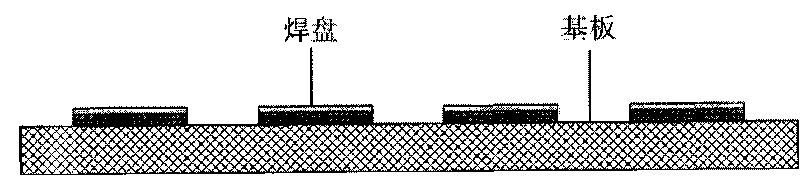

Room temperature ultrasonic soldering method for area array encapsulated electronic components

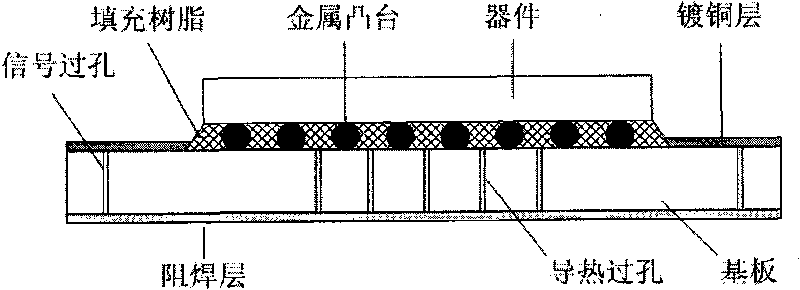

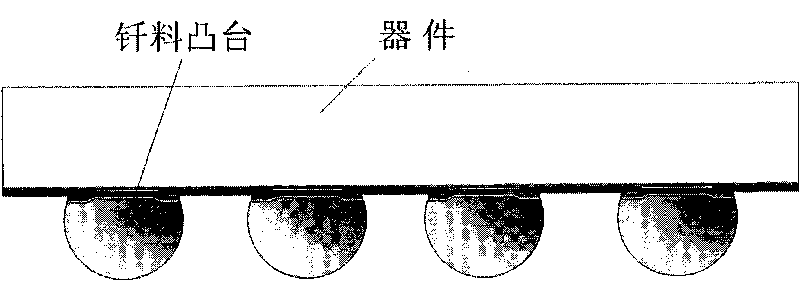

InactiveCN101728289AAvoid reheat cyclesProcess that avoids reheat cyclesSolid-state devicesSemiconductor/solid-state device manufacturingSurface cleaningElectron

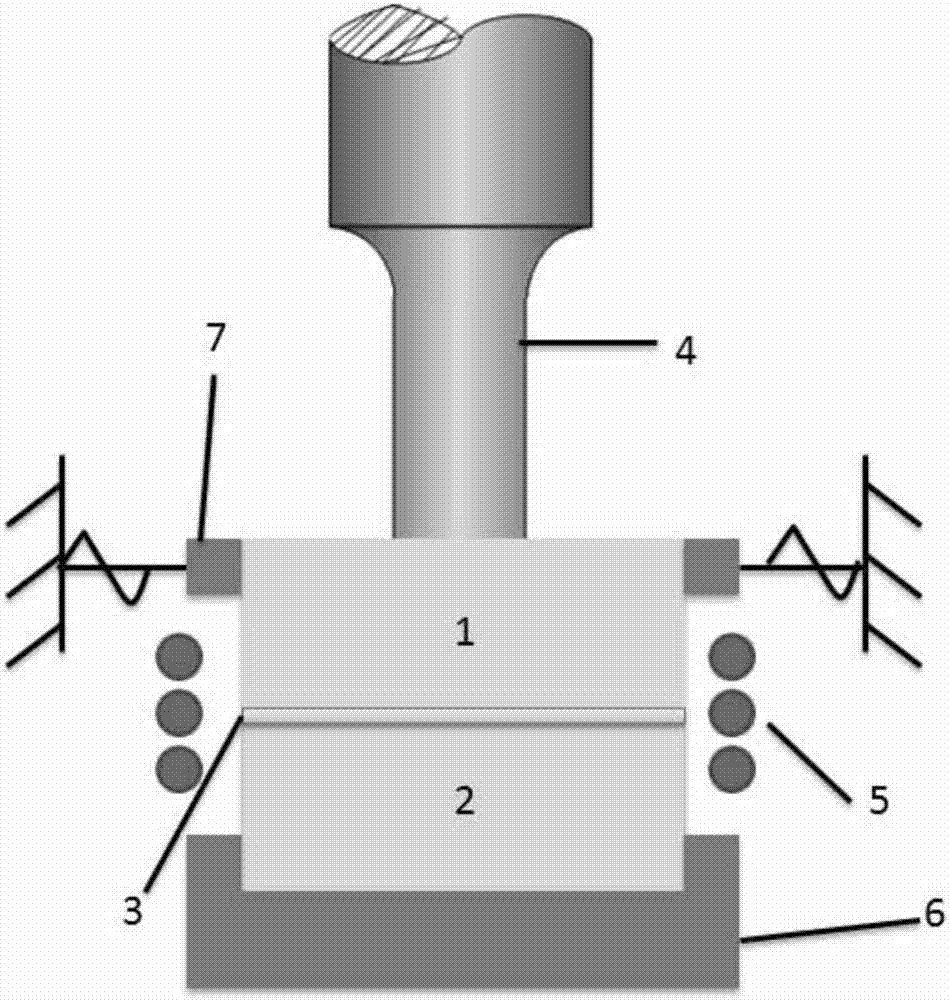

The invention relates to encapsulation and assembling interconnection methods of micro-electronic and optoelectronic devices, in particular to a room temperature ultrasonic soldering method for area array encapsulated electronic components. The method comprises the following steps of: (1) preparing an area array encapsulated device; (2) preparing a corresponding pad; (3) aligning the area array encapsulated device with the position of the pad; (4) applying certain supersonic vibration and longitudinal pressure on the area array encapsulated device by using a transverse vibration ultrasonic vibrator, so that the solder lug boss generates high-frequency friction with the corresponding pad surface, gradually falls down, and forms metallurgical connection with the pad of the base plate. The invention has the advantages that the tangential vibration ultrasonic waves are utilized at room temperature to connect the area array encapsulated device with the solder alloy solder joint, thereby preventing the soldered structure from undergoing the process of the reheating cycle, eliminating the formation of the heat stress, inhibiting the nucleation and grain growth of the intermetallic compounds and enhancing the reliability and the electrical performance of the joints. The method also has the advantages of simple procedure, high speed, no soldering flux, no need of strict surface cleaning, and the like.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL +1

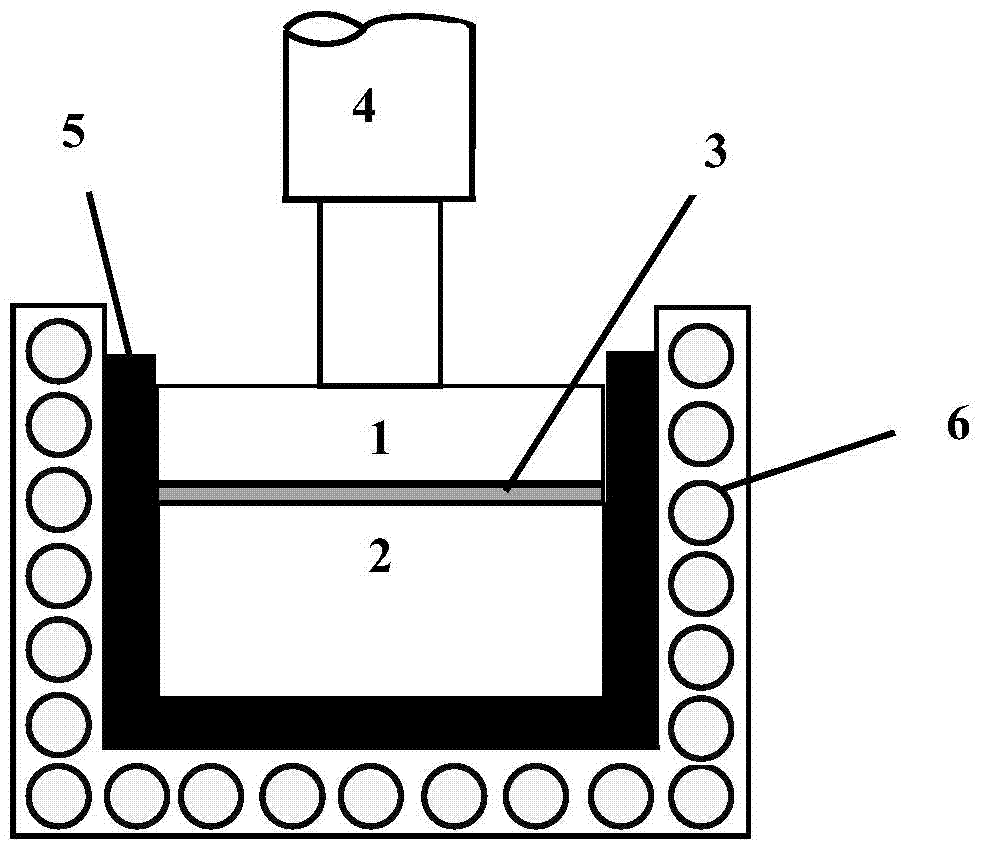

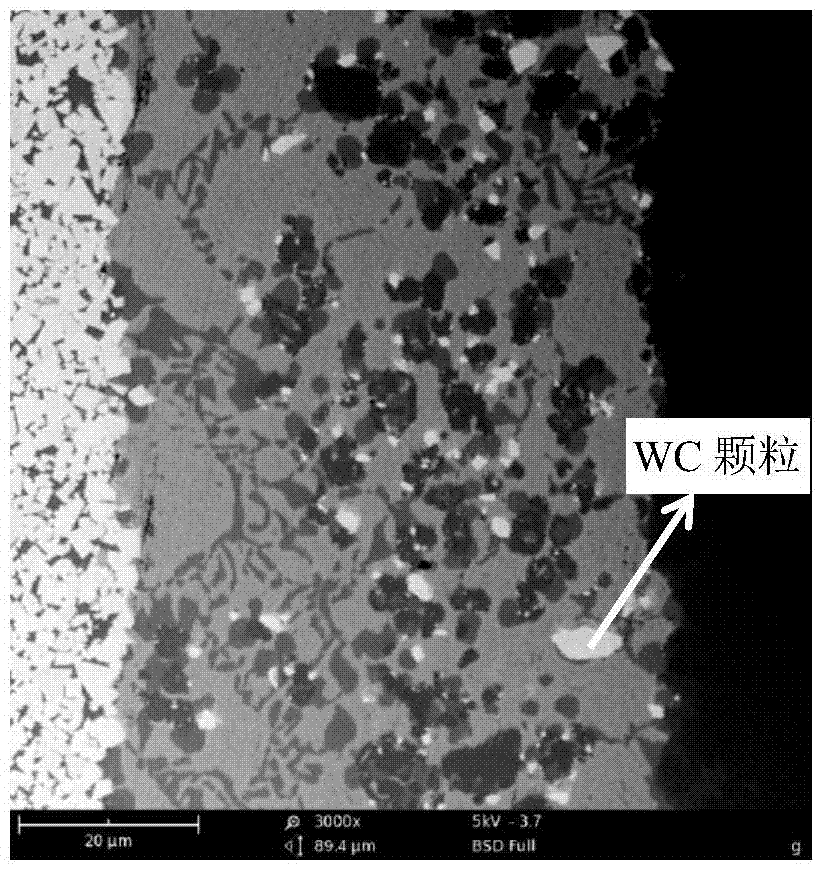

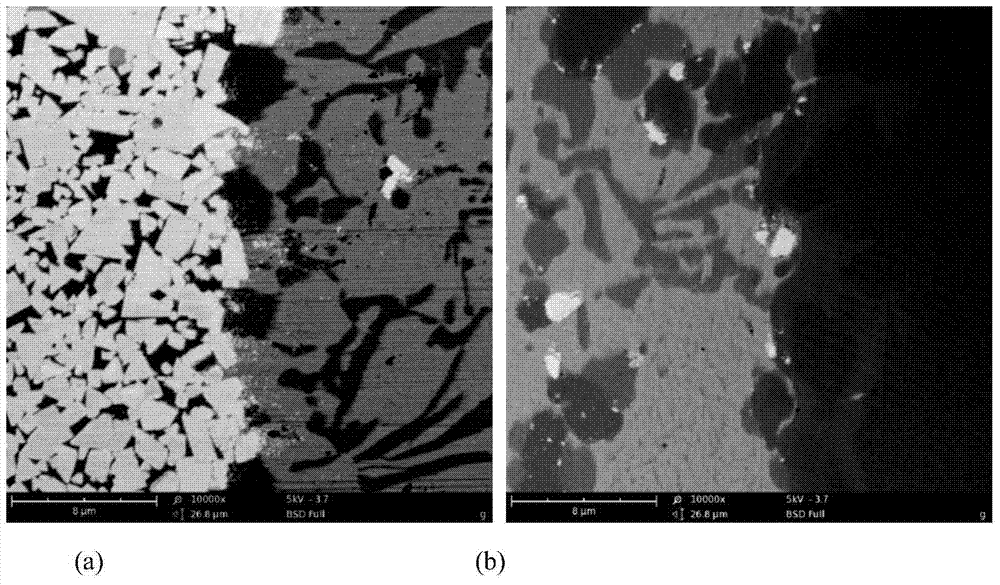

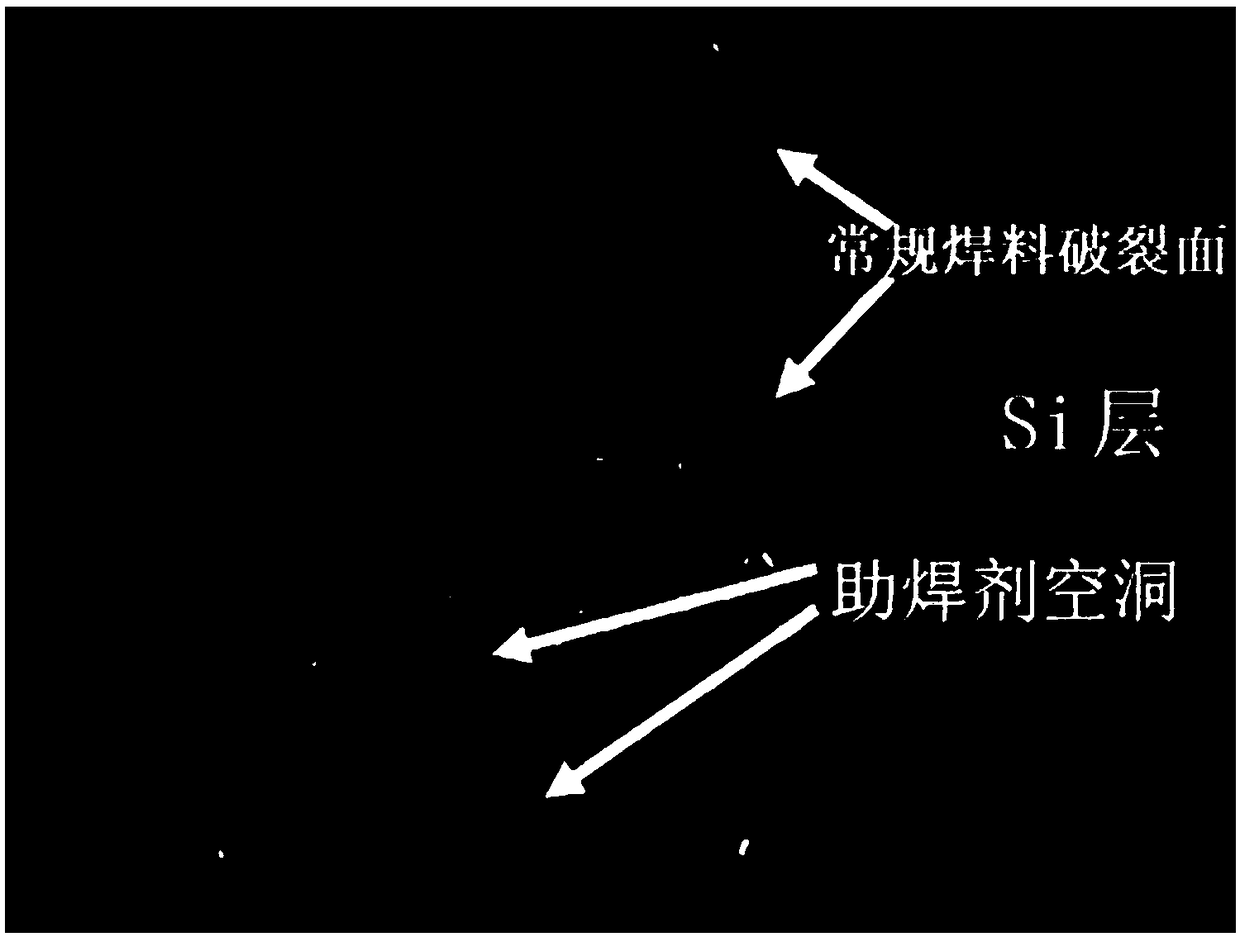

WC particle in-situ reinforced hard alloy and steel ultrasonic soldering method

ActiveCN104772542AImprove wettabilityImprove bindingSoldering apparatusWelding/soldering/cutting articlesUltrasonic cavitationFree cooling

The utility model discloses a WC particle in-situ reinforced hard alloy and steel ultrasonic soldering method, which is used for the high-quality soldering of a sheet hard alloy and steel. The method comprises the following steps: a, polishing a surface to be connected before soldering, and cleaning the polished surface with acetone; b, placing an Ag-based solder foil piece between the hard alloy and the steel before soldering; c, applying ultrasonic vibration to the hard alloy to be soldered and the steel to be soldered; d, implementing a soldering process by adopting a common heat source manner common in furnace soldering or high-frequency induction heating soldering and the like, wherein soldering temperature is 730 to 850 DEG C; e, after ultrasonic vibration, WC particle reinforced soldering seams are obtained by naturally cooling. According to the method, Co substrate adhesion-free WC particles are migrated into the soldering seams to form WC particle reinforced soldering seams by virtue of disturbance action of ultrasonic waves after a Co substrate in the hard alloy is dissolved by a solder, so that the mechanical performance of a joint is greatly improved; oxide films on the surfaces of the hard alloy and the steel are removed by virtue of action of ultrasonic cavitation, and soldering can be implemented in the atmosphere without a soldering flux, so that the process is simple, and the method is environment-friendly, high in welding efficiency and suitable for engineering application.

Owner:SOUTHWEST JIAOTONG UNIV

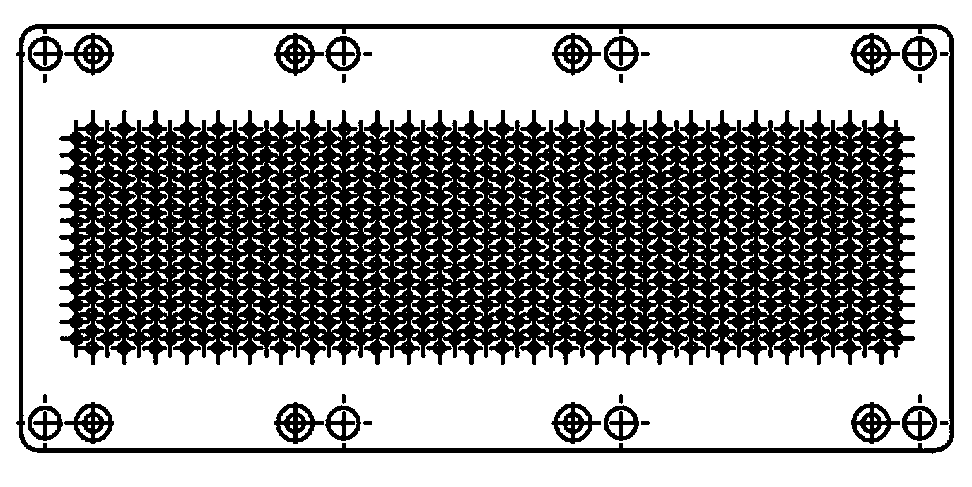

Heat dissipation substrate for encapsulating power module

InactiveCN103779291AImprove cooling effectExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesComputer moduleCopper alloy

A heat dissipation substrate for encapsulating a power module comprises a substrate made of pure copper or copper alloy or pure aluminum or aluminum alloy, and heat dissipation needles are fixedly connected on the surface of the substrate by adopting a soldered joint method or an ultrasonic soldering method or an integral press fit method or an integral casting method or an integral forging method. The thickness of the substrate is 1-10mm, and the area of the substrate is 0.01-0.5sqm. The heat dissipation needles are made of pure copper or copper alloy or pure aluminum or aluminum alloy, and are in the shape of a cylinder or a circular truncated cone or a cube or a rectangle, and the height of the heat dissipation needles is 2-50mm. The heat dissipation substrate for encapsulating the power module can improve heat dissipation capacity of a traditional module, prolong the service life of the power module, and improve the reliability of the power module.

Owner:嘉兴斯达微电子有限公司

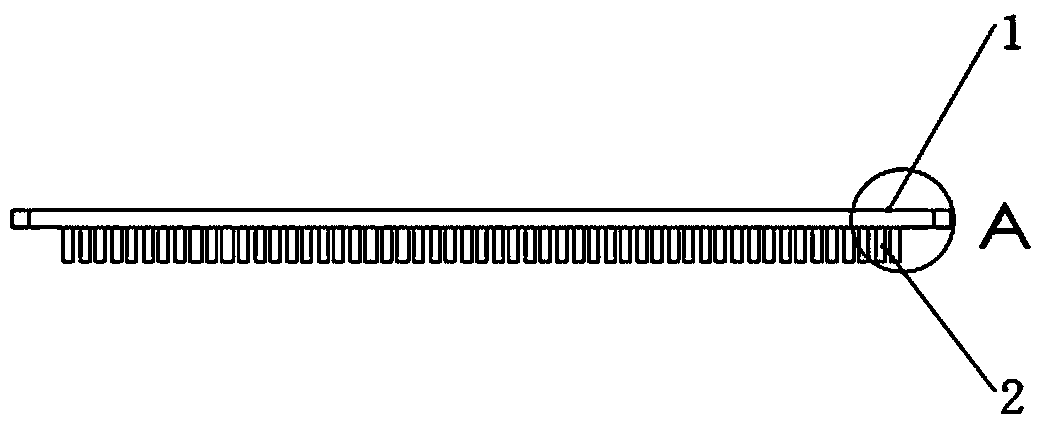

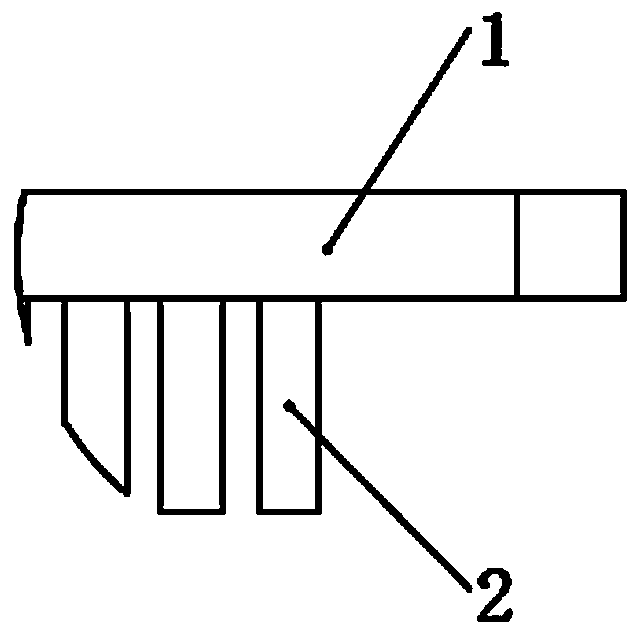

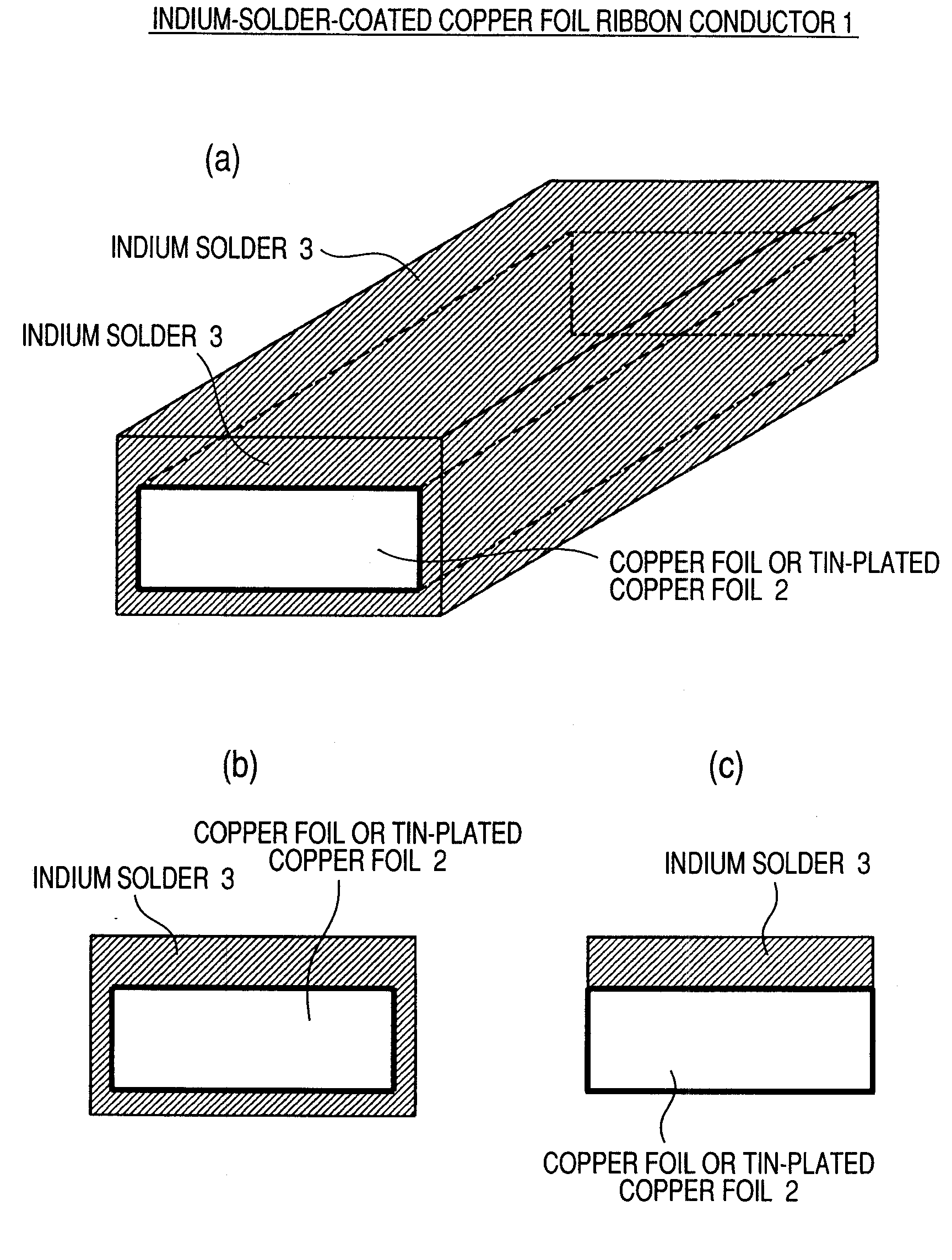

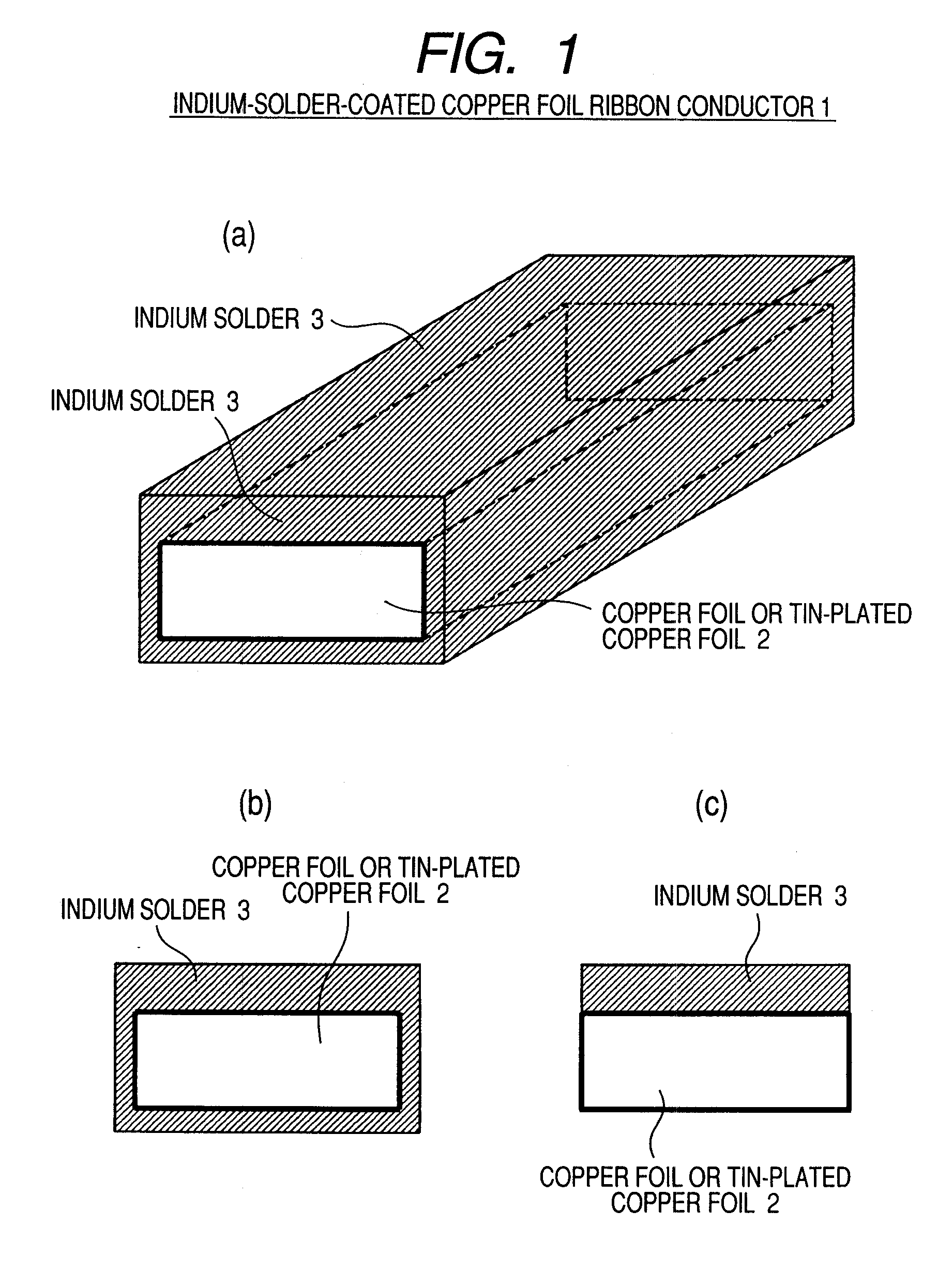

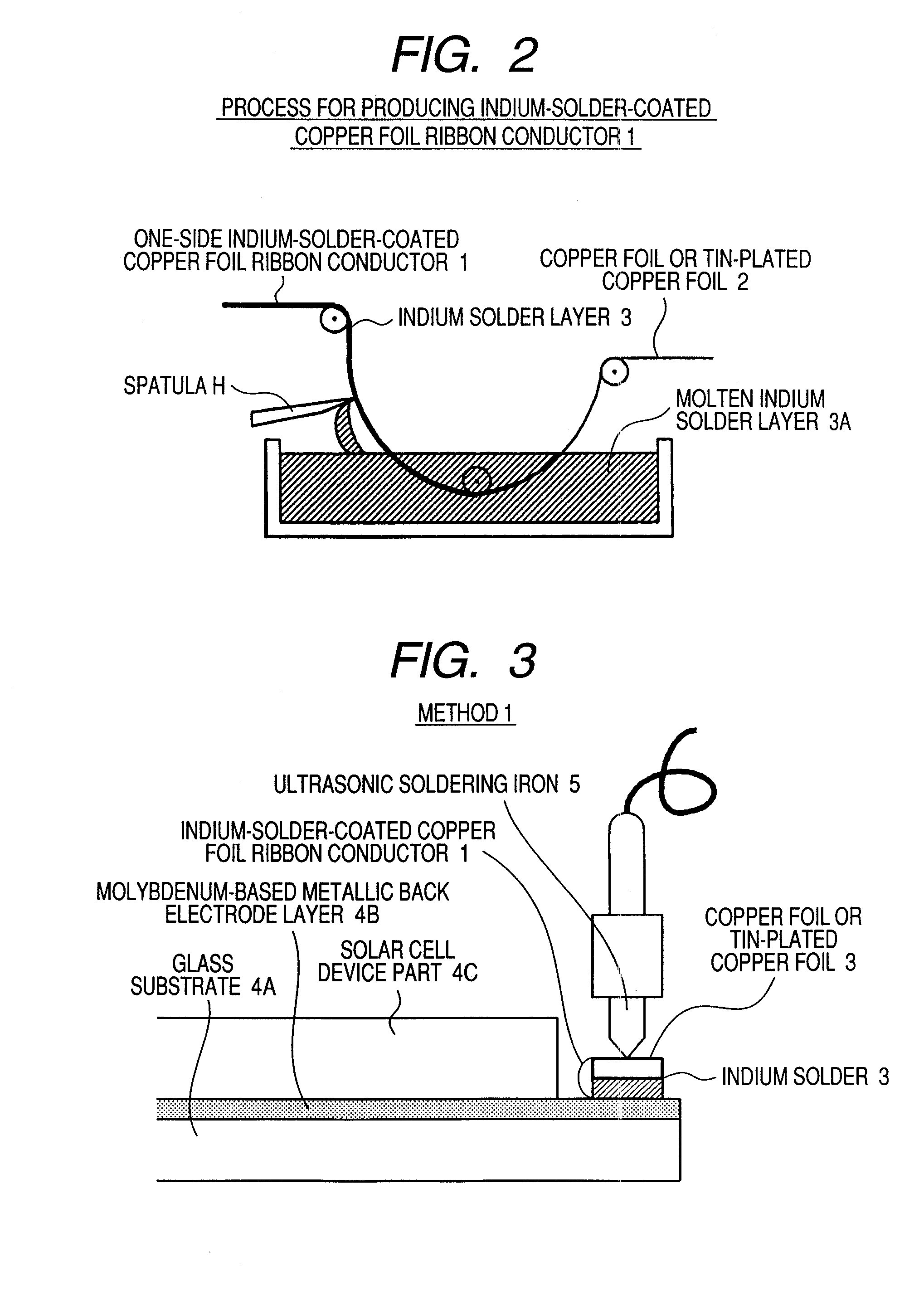

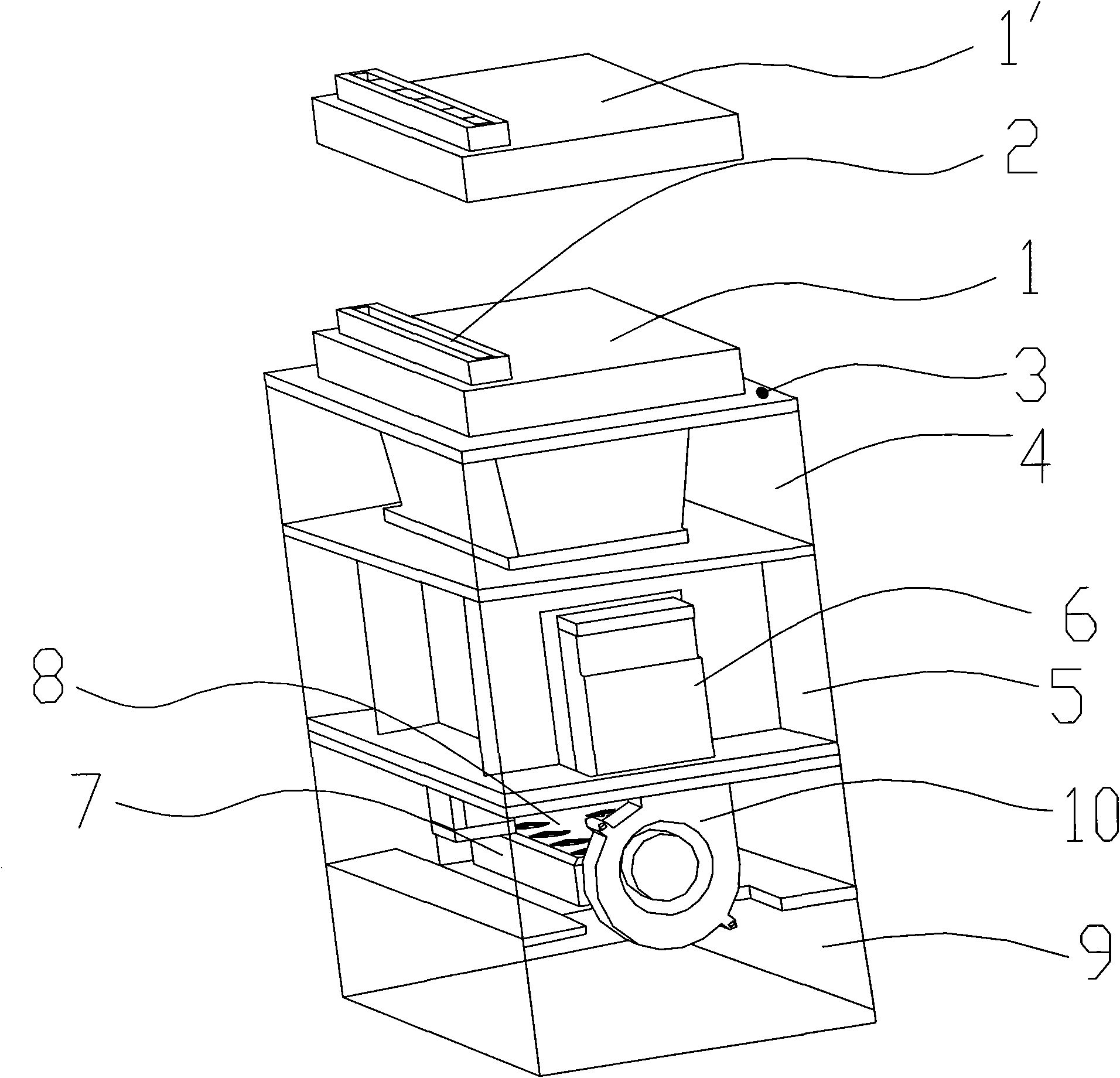

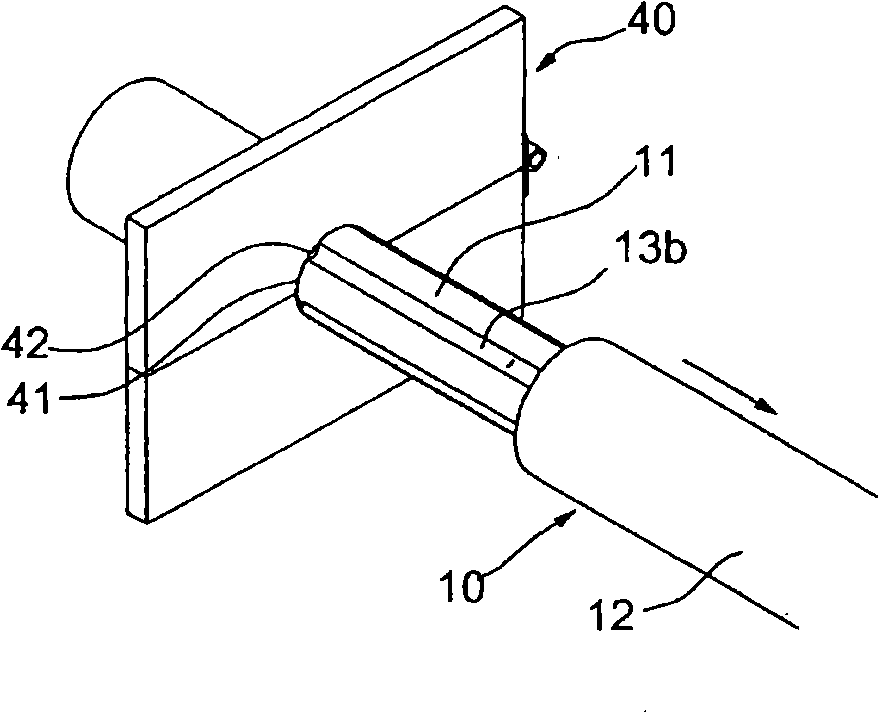

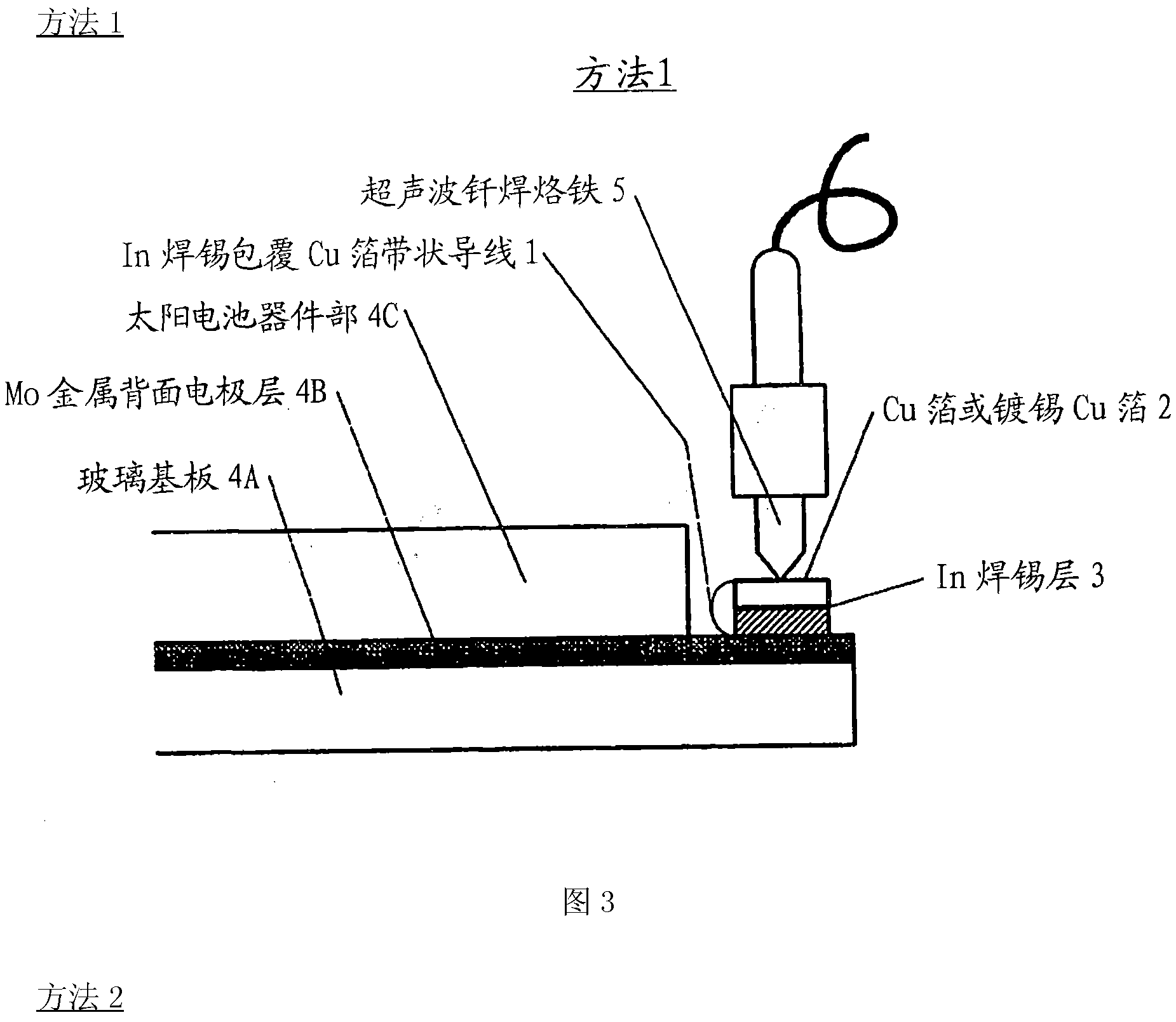

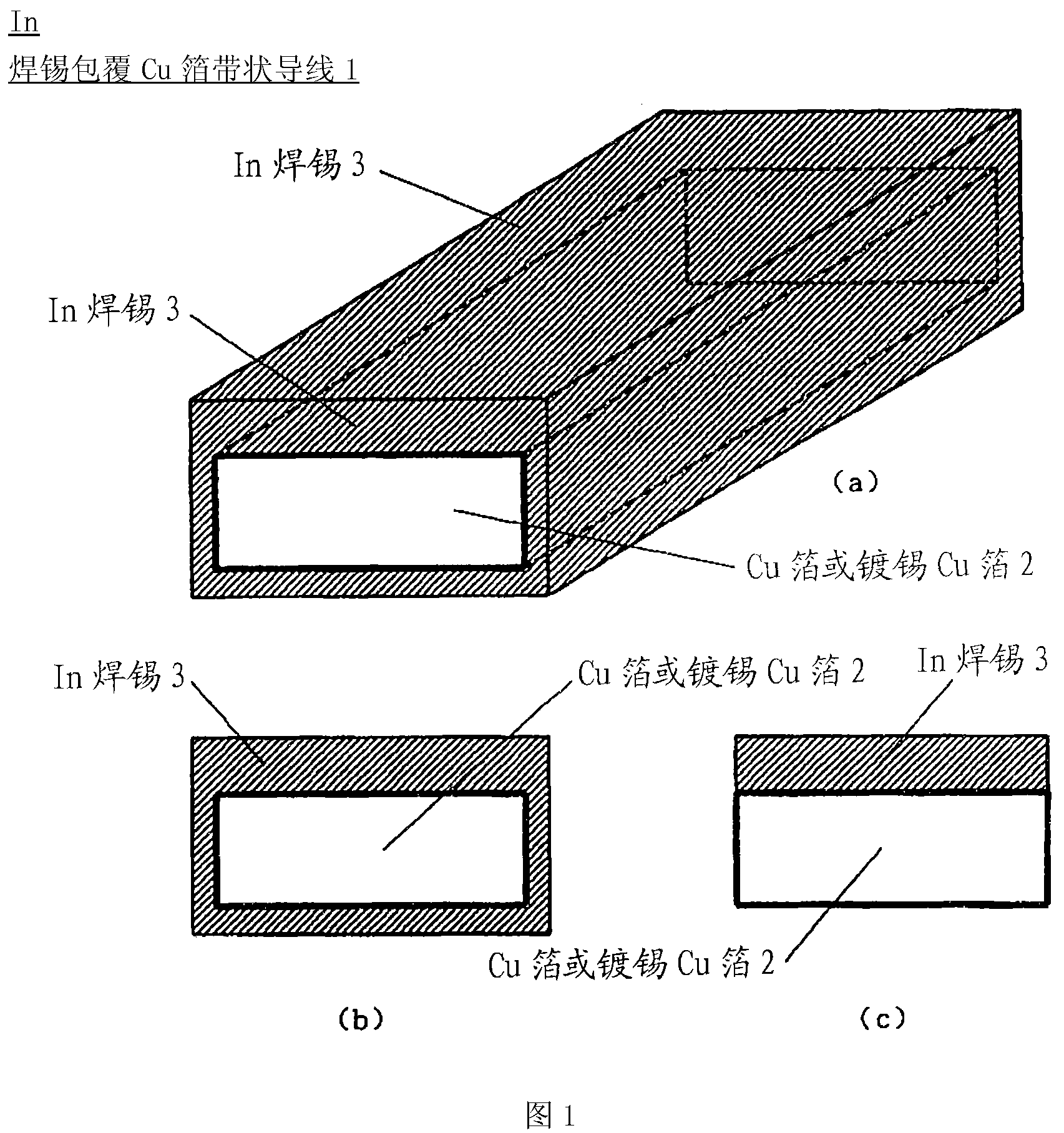

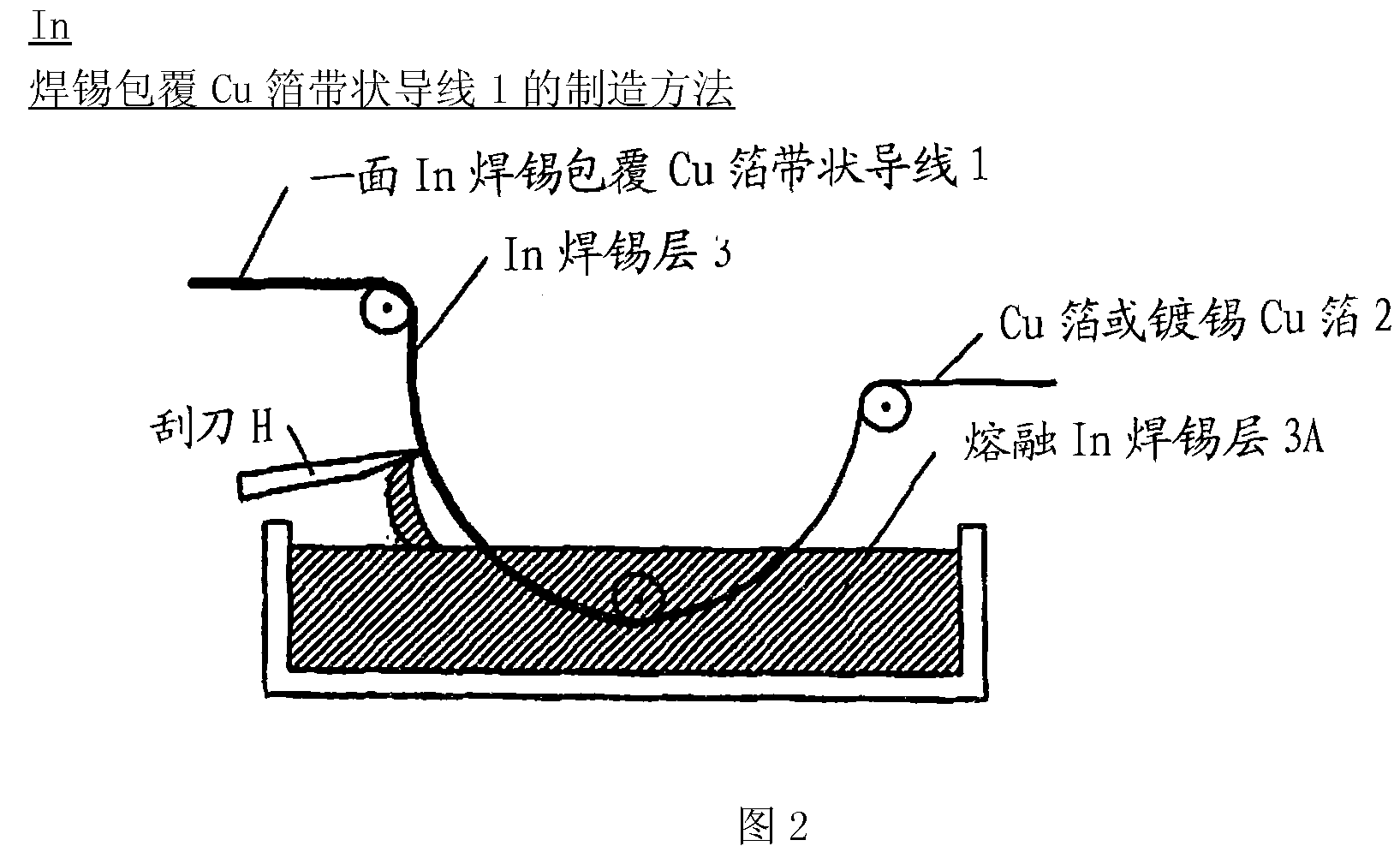

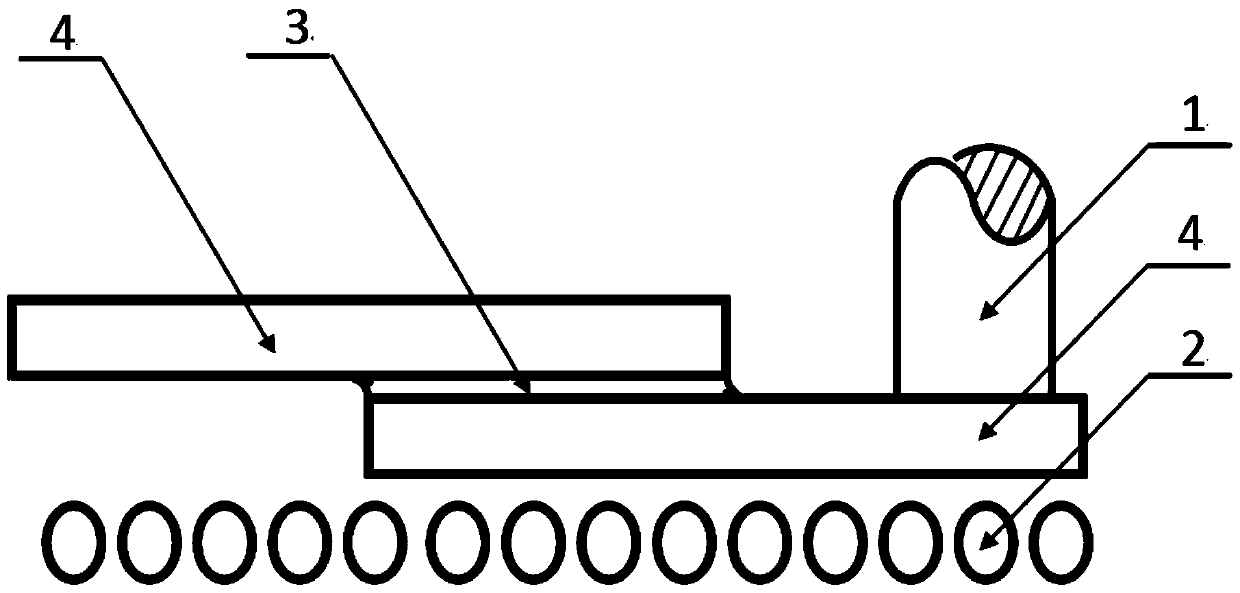

Indium-solder-coated copper foil ribbon conductor and method of connecting the same

InactiveUS20090044966A1Reduce the amount requiredRelieve pressureLine/current collector detailsFinal product manufactureTinningIndium

A method for tenaciously connecting a conductor electrode on a glass substrate to a ribbon conductor with certainty at low cost without causing damage. An indium-solder-coated copper foil ribbon conductor 1 obtained by depositing an indium solder 3 (100-90% indium and 10-0% silver) in a thickness of 100 μm or smaller on one side of a copper foil or tin-coated copper foil 2 having a thickness of 300 μm or smaller and optionally further depositing the solder thinly on the other surfaces of the foil is placed on an exposed part of a molybdenum-based metallic back electrode layer 4B on a glass substrate 4A. An ultrasonic soldering iron 5 is then placed against the upper side of the copper foil ribbon conductor 1 to melt the indium solder 3 and connect the copper foil ribbon conductor 1 to the electrode layer 4B.Another method includes soldering an indium solder 3 (having the same composition as shown above) to the electrode layer 4B beforehand, subsequently placing a ribbon-form copper foil or tin-plated copper foil 2 thereon, and connecting the copper foil 2 to the electrode layer 4B with an ultrasonic soldering iron 5.

Owner:SHOWA SHELL SEKIYU KK

Ultrasonic soldering method for fast forming ceramic-metal interconnection

InactiveCN106563861AQuality improvementAddress reliabilitySoldering apparatusWelding/soldering/cutting articlesMolten stateSurface oxidation

The invention belongs to the technical field of welding, and particularly relates to a simple, fast and easily-implemented ultrasonic soldering method for fast forming ceramic-metal interconnection. The ultrasonic soldering method for fast forming ceramic-metal interconnection is characterized by including the following steps that surface treatment is carried out on base materials to be interconnected; then, the base materials to be interconnected are assembled into a sandwiching structure of the first base material / the middle layer / the third base material and placed on a heating table; the structure in the second step is heated and pressurized so that the middle layer can melt; and ultrasonic application is stopped, ballasting on a test piece is canceled, the test piece is taken down after the test piece is cooled, and the interconnection process is completed. Compared with the prior art, the ultrasonic soldering method for fast forming ceramic-metal interconnection is advantageous in that a joint compact and uniform in structure can be obtained in extremely short time, and the reliability problem caused by too long isothermal holding time is avoided; and in addition, oxide films on surfaces to be interconnected are destroyed by the ultrasonic effect, wetting and spreading of the middle layer in a molten state on the base materials are facilitated, and the quality of the joint is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

Ultrasonic soldering flux coating process and device

InactiveCN101869885AEvenly dispersedStrong adhesionPrinted circuit assemblingLiquid surface applicatorsPrinted circuit boardCentrifugal fan

The invention discloses an ultrasonic soldering flux coating process which comprises the following process steps of: 1. injecting a soldering flux into a soldering flux box; 2. selecting a proper spraying head plate, and simultaneously regulating the input current of a high-frequency ultrasonic atomizer as required, thereby controlling the atomized quantity of the soldering flux and the concentration of the atomized soldering flux sprayed out of a spraying head; 3. when a PCBA (Printed Circuit Board Assembly) conveyed by a conveying belt is induced by a position sensor installed on an ultrasonic soldering flux coated box body, beginning the work of the high-frequency ultrasonic atomizer and a centrifugal fan, and uniformly spaying the small-granular soldering flux atomized by the high-frequency ultrasonic atomizer onto the PCBA from the spraying head of the spraying head plate at constant speed; and 4. when the PCBA leaves, stopping the work of the high-frequency ultrasonic atomizer and the centrifugal fan until the next PCBA is induced by the position sensor, and returning to the step 3. The invention also discloses an ultrasonic soldering flux coating device for realizing the process. The invention has the advantages of uniform spraying, easy control, random regulation on the size, the height and the width of sprays as required, waste reduction of the soldering flux and reduction of environmental pollution caused by soldering flux flying.

Method for quality control during ultrasonic

ActiveUS8783545B2Reliable determinationAccurate monitoringSemiconductor/solid-state device testing/measurementSolid-state devicesBond qualityTransducer

A method for quality control during ultrasonic bonding, in which a transducer bonding tool unit and an ultrasonic generator are used and in which, during the bonding, one or more sensors are used to sense measurement signals for one or more parameters, which can vary during the bonding, for assessing the bond quality and / or for influencing the bonding, and which proposes that, during the bonding, at least one speed profile measurement signal representing the time / speed profile of the tip of the ultrasonic tool in the direction of oscillation thereof be sensed. The invention also relates to a bonding apparatus which is suitable for carrying out the method. Furthermore, the invention relates to other quality control methods for ultrasonic bonding and to bonding apparatuses which are suitable for carrying out these methods.

Owner:HESSE

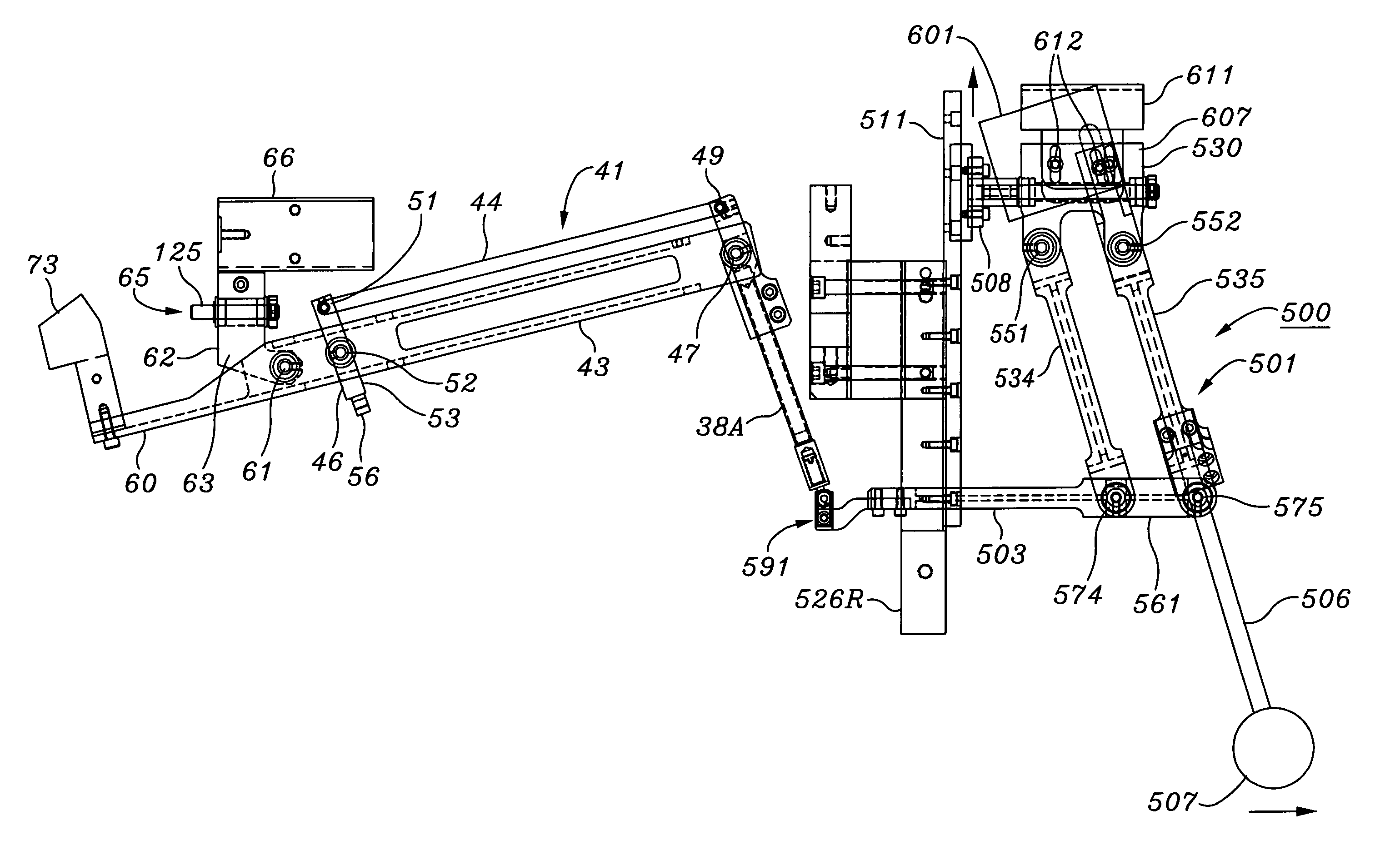

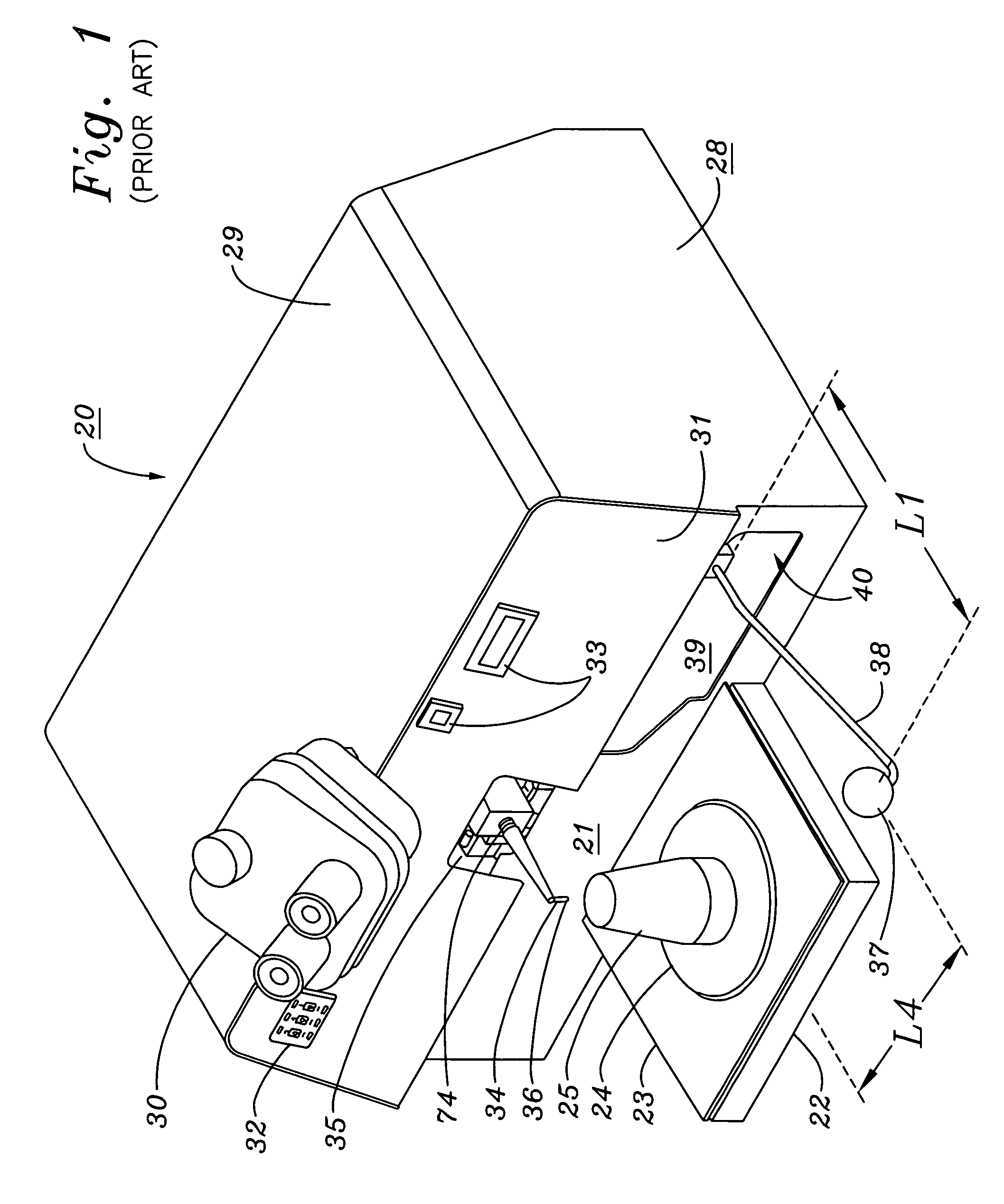

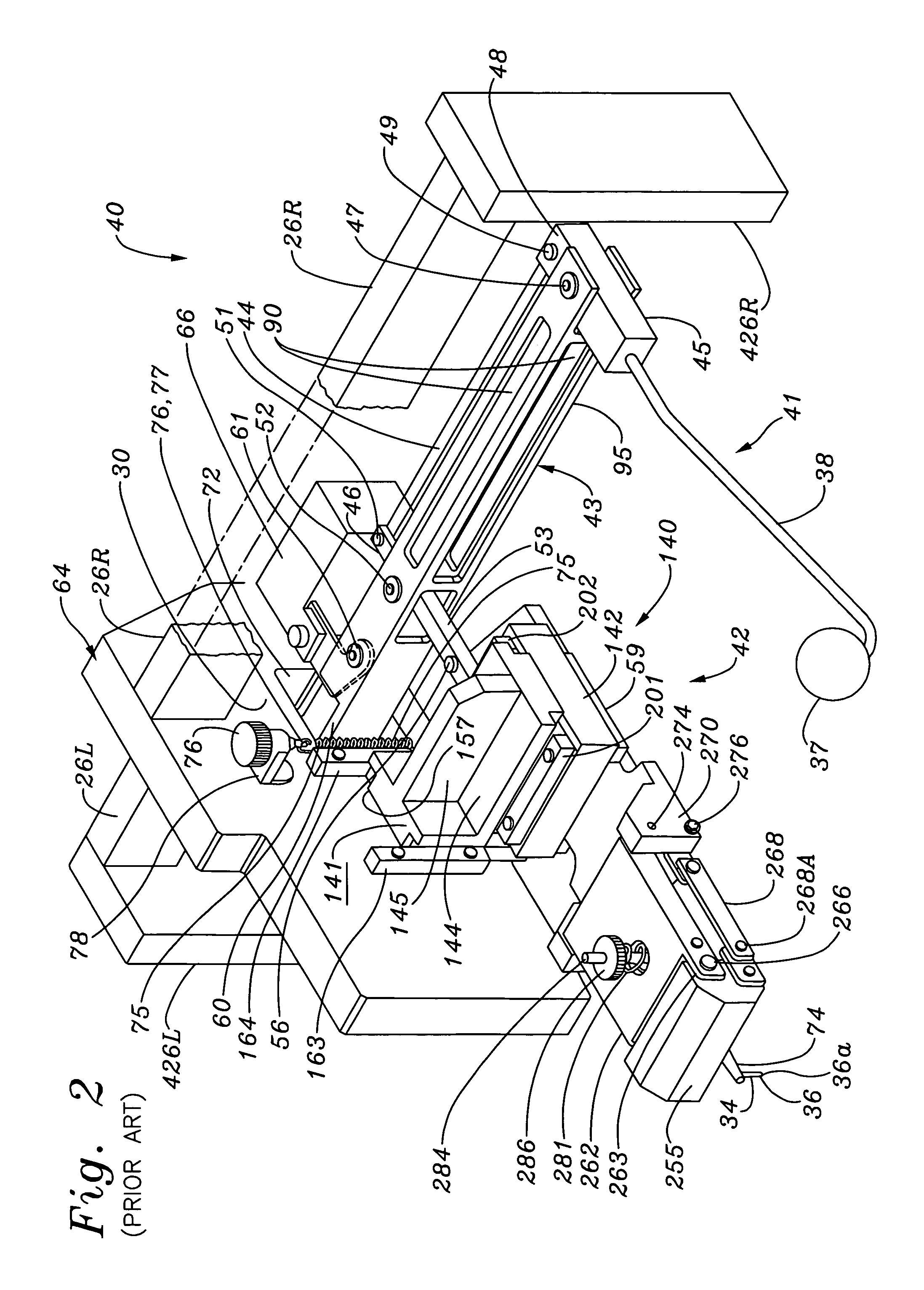

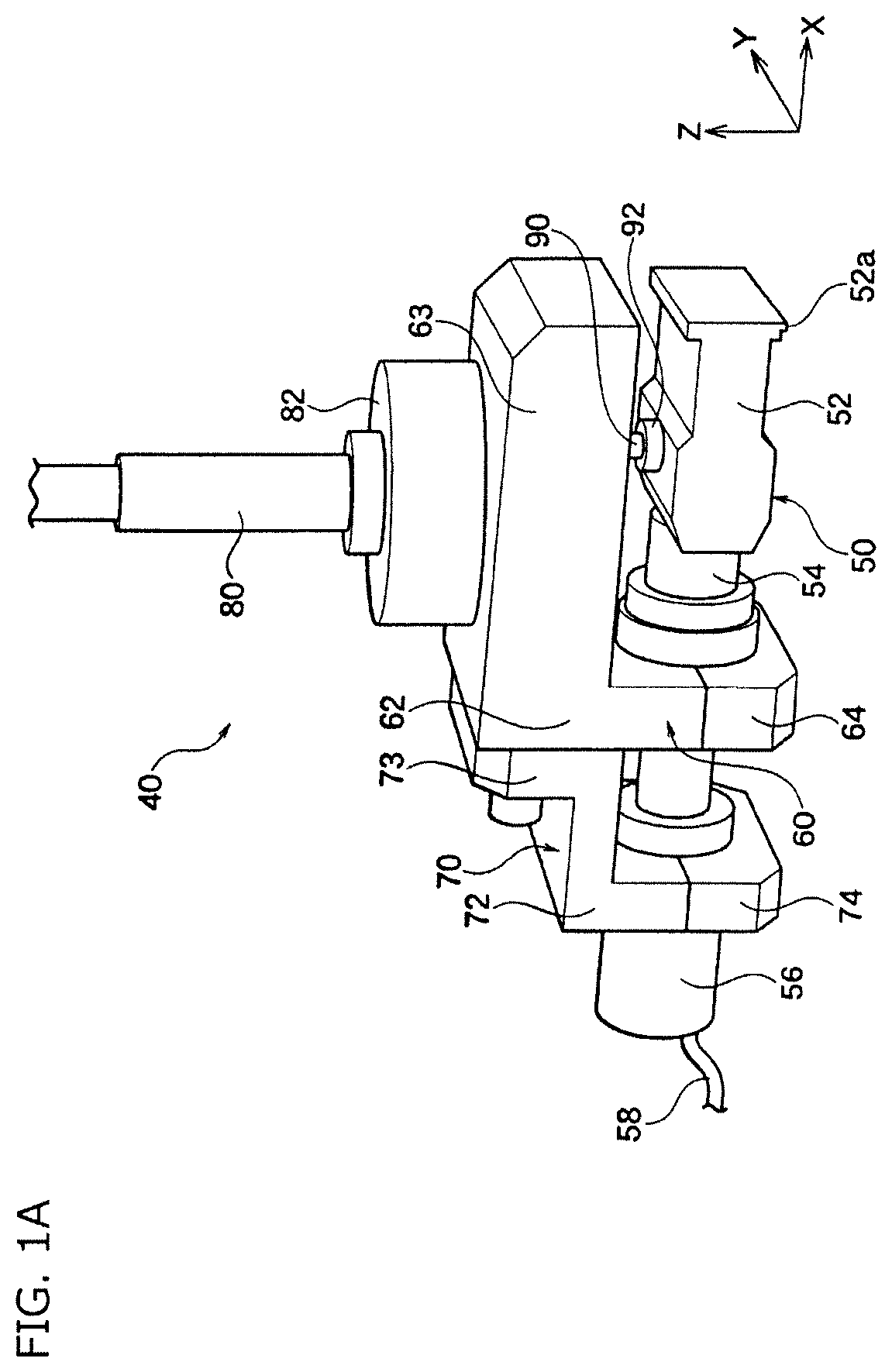

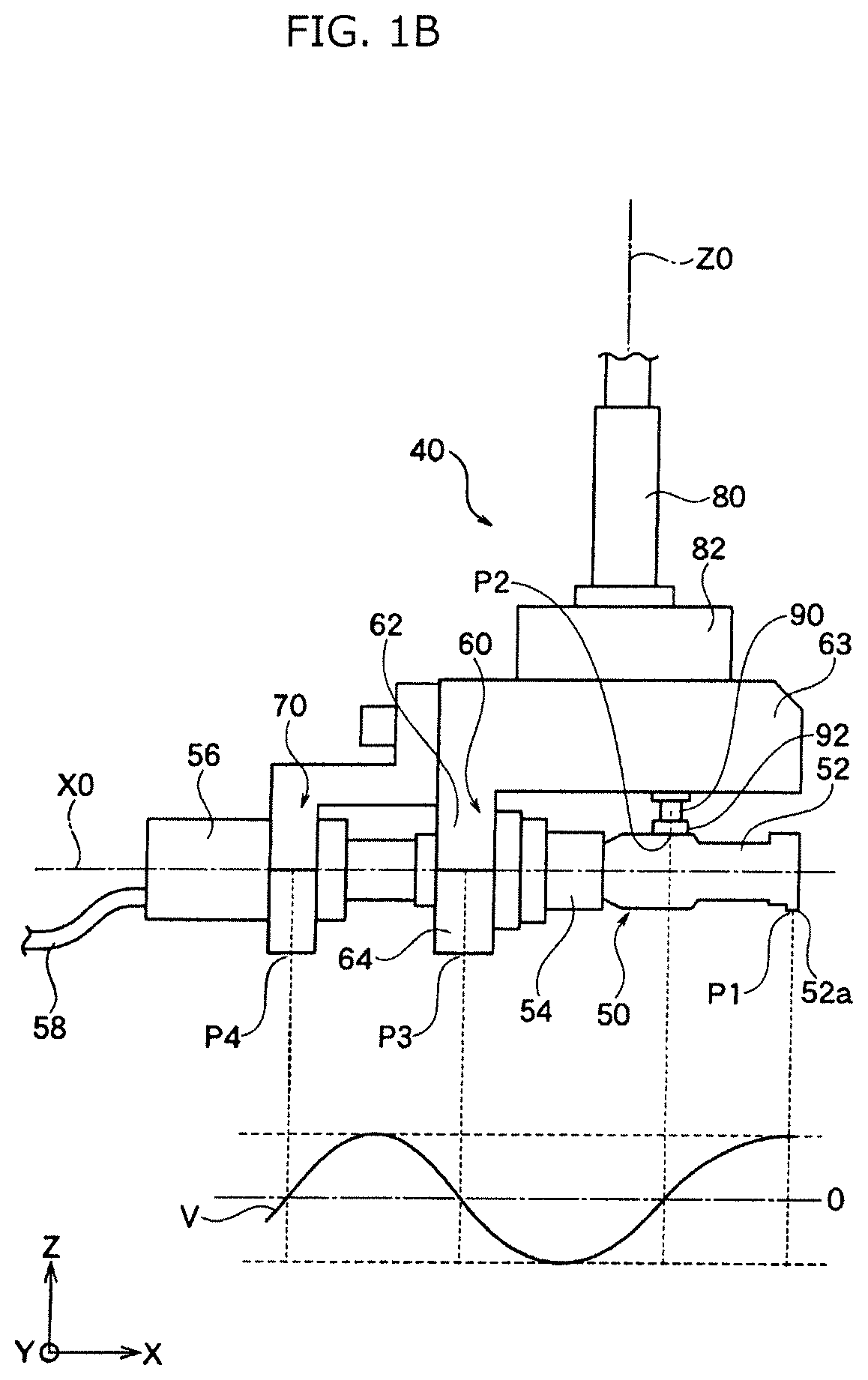

Auxiliary control apparatus for micro-manipulators used in ultrasonic bonding machines

ActiveUS7493191B1Increase in sizeImprove performanceWelding/cutting auxillary devicesFeeding apparatusInput controlEngineering

An auxiliary control apparatus mechanically couples forces exerted on a manually operable auxiliary hand control knob to an input member of a micro-manipulator of the type used to move a point of an object such as an ultrasonic bonding tool tip relative to a workpiece in scaled ratios of motions at an end of the micro-manipulator input member. The apparatus includes a 4-bar parallelogram linkage which is mounted to a structural support member of a micro-manipulator, and which includes a rear laterally disposed lateral linkage bar pivotably connected to inner and outer parallel longitudinally disposed linkage bars which are pivotably coupled at front ends thereof to a front laterally disposed linkage bar. An input control arm protrudes downwardly from and forward of the outer longitudinal linkage bar, and a connector arm protrudes laterally inwardly from an inner end of the front lateral linkage bar, inwardly of the inner longitudinal linkage bar; the inner lateral end of the connector arm is pivotably connected to a forward end of the micro-manipulator input member. The rear lateral linkage bar is pivotably mounted onto a pivot axle which protrudes laterally outwards from a trolley block rollably mounted on a fore-and-aft disposed linear bearing guide rail mounted to an outer longitudinal surface of the support structure. Motions of the hand control knob in fore-and-aft left and right, and up and down directions cause corresponding motions of the micro-manipulator input control member and tool tip.

Owner:MILLER CHARLES F

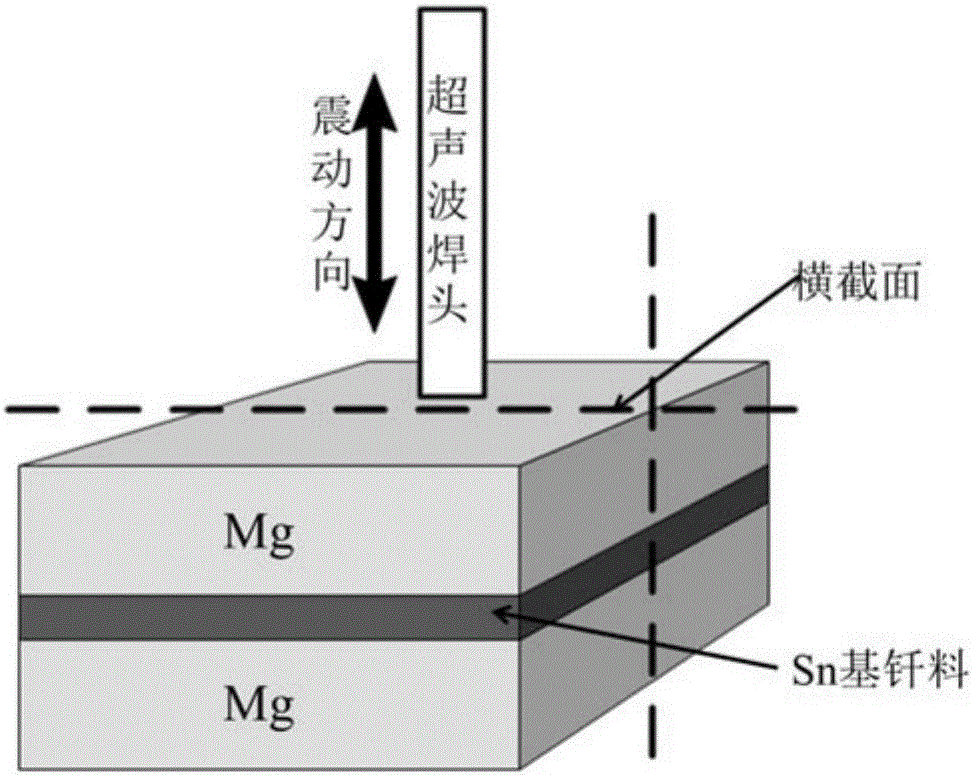

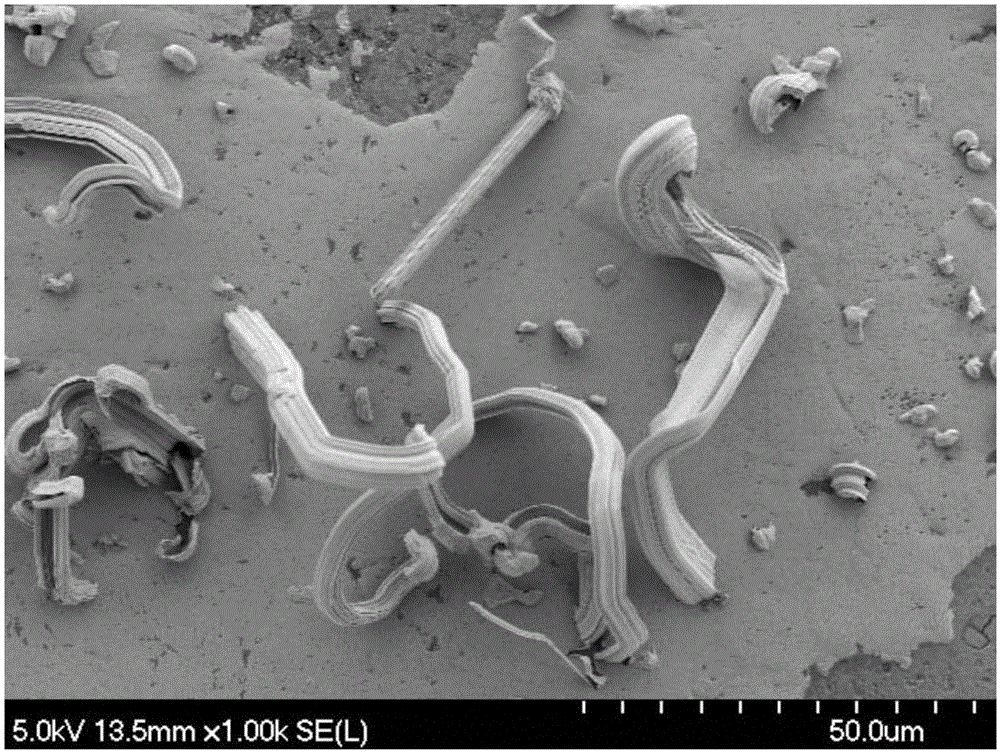

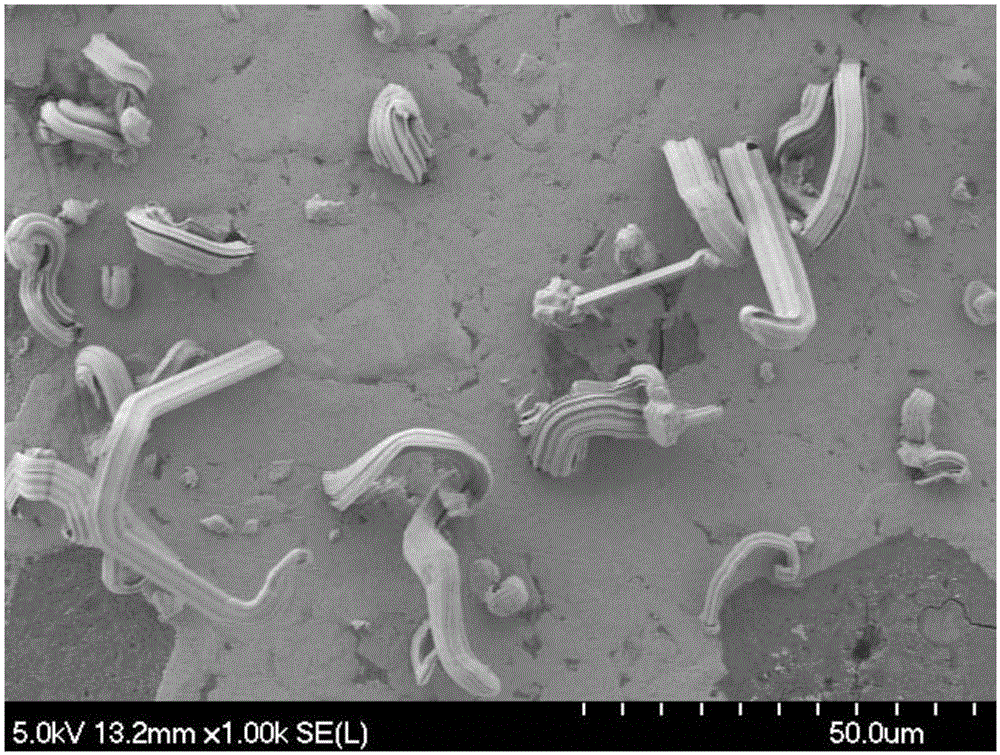

Method for rapidly evaluating growth tendency of Sn crystal whiskers of Sn-based solder

The invention provides a method for quickly evaluating the growth tendency of Sn whiskers of Sn-based solder, which provides a carrier for the growth of whiskers by preparing Mg / Sn-based solder / Mg ultrasonically assisted brazing joints. In the process of ultrasonic brazing, due to the action of ultrasonic waves, a large number of Mg atoms enter the liquid solder, and most of the Mg atoms combine with Sn atoms to generate Mg at the interface and inside the solder. 2 Sn; another part of Mg atoms exists in the solder in the form of solid solution. After the solder is solidified, the solid-dissolved Mg atoms are in a thermodynamically unstable state, and Mg atoms react with Sn atoms to form new Mg atoms. 2 Sn, and produce volume expansion, which in turn creates stress in the weld. Sn whiskers grow rapidly under stress. The invention can compare the Sn whisker growth tendencies of different solders by statistically comparing the whisker growth conditions on the surface of welds prepared by different Sn-based solders, and provide important solder reliability parameters for the electronic industry.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

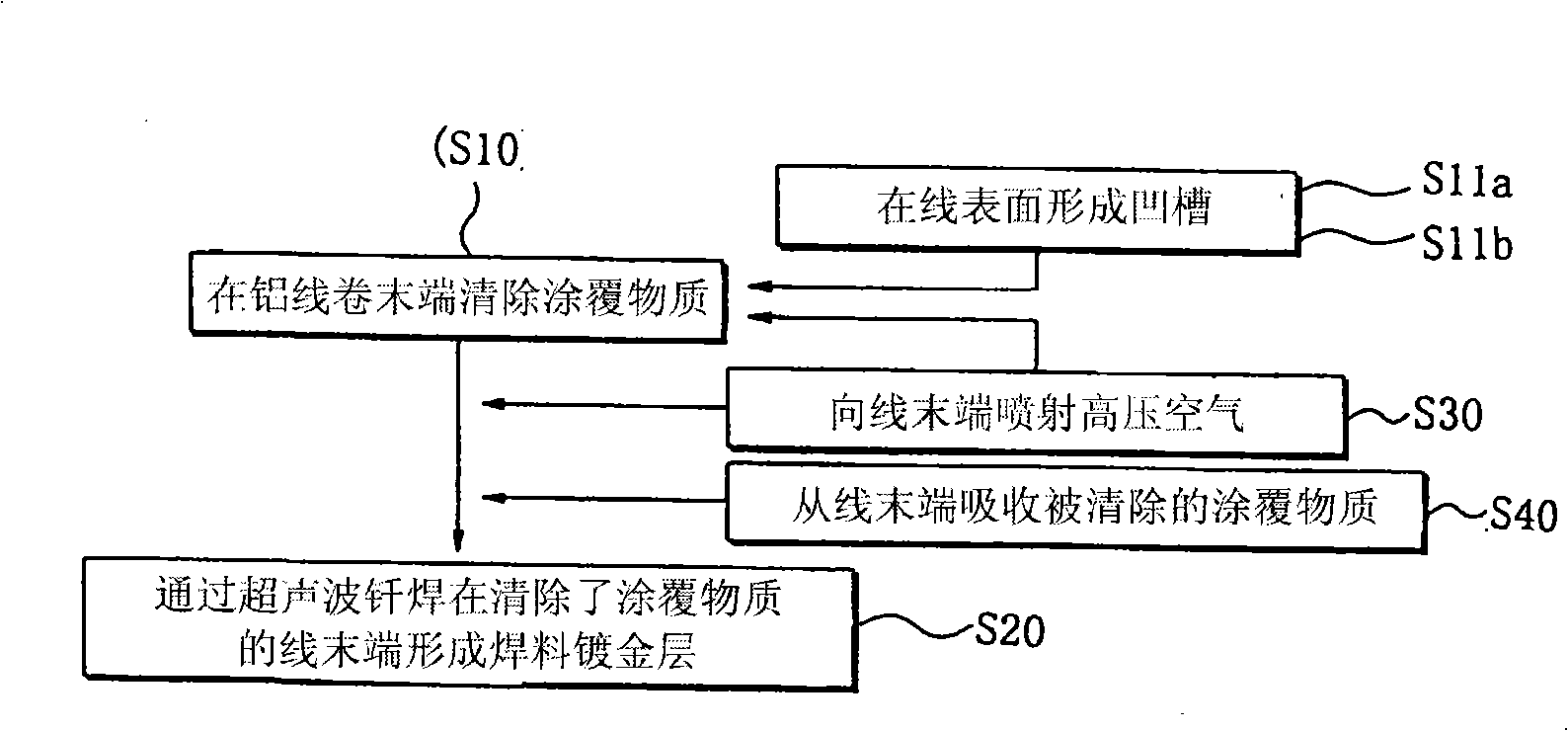

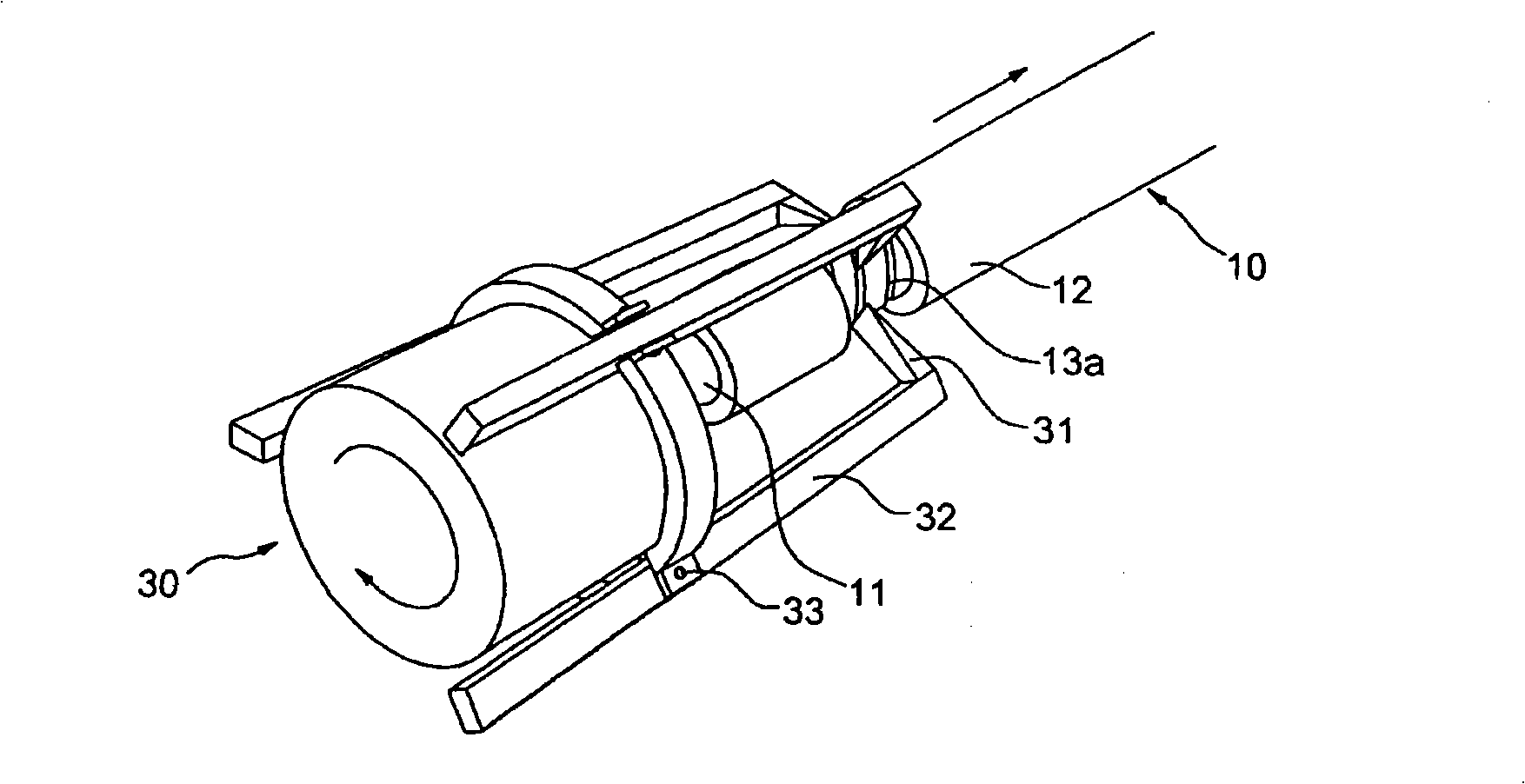

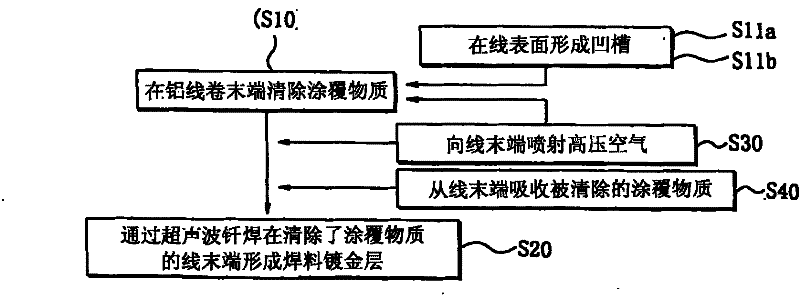

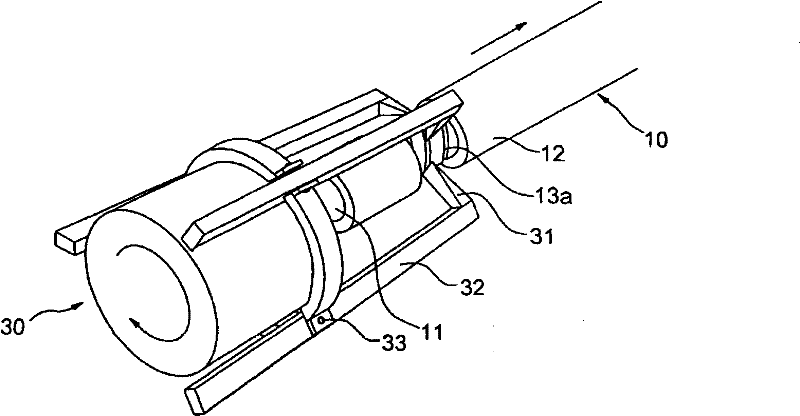

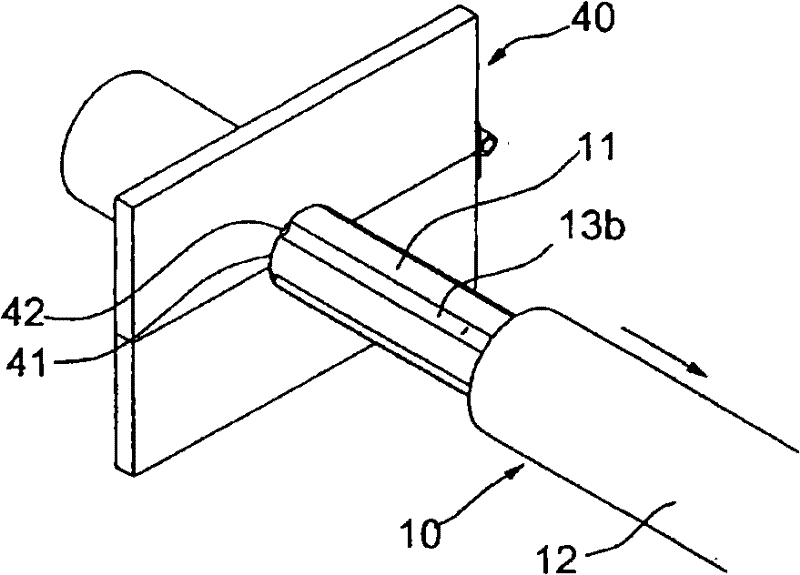

Supersonic soldering aluminum coil and its production method

The invention provides an aluminium wire coil made by ultrasonic soldering and manufacturing method thereof. The invention plates on surface of wire by ultrasonic soldering so as to improve soldering force between the printed circuit board and copper foils and ensure the conductive property, omit pretreatment of soldering and increase work efficiency and production efficiency, prevent environmental pollution caused by using flux. The invention provides an aluminium wire coil made by ultrasonic soldering, comprising steps of forming insulating coating on surface of aluminium wire, dipping a wire end on which the coating is removed into a solder box applied ultrasonic wave to form a solder plated layer by ultrasonic soldering.

Owner:南通迪皮茜电子有限公司

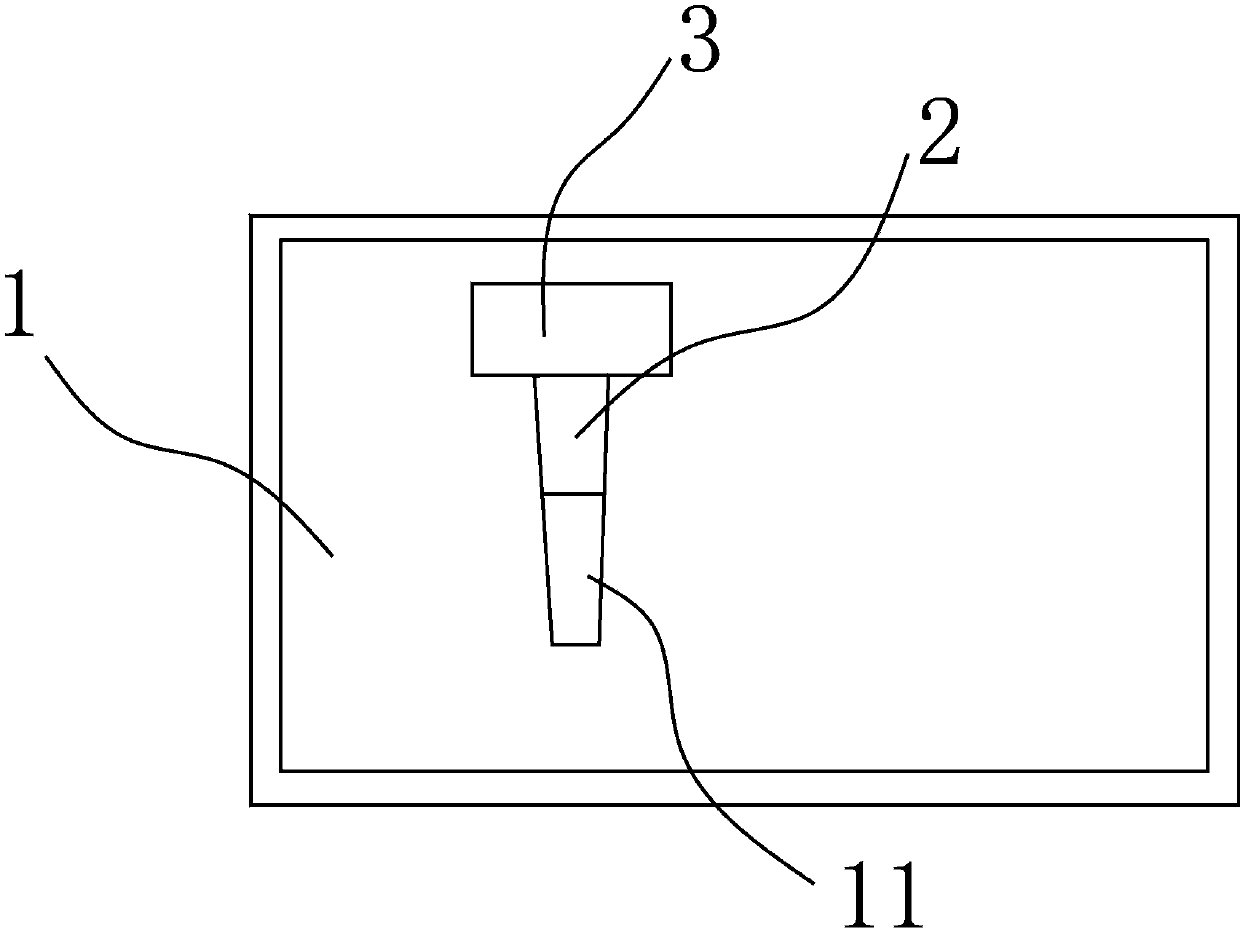

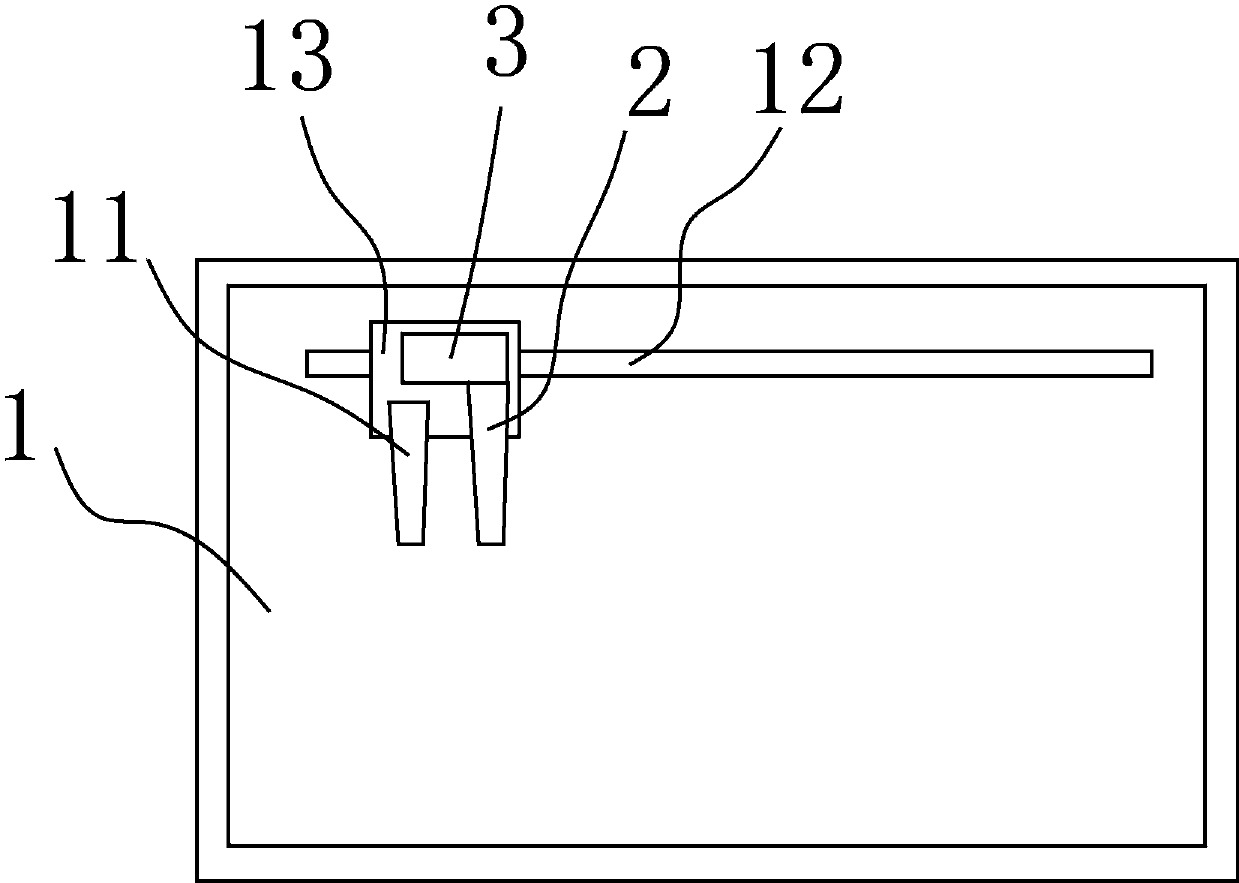

Ultrasonic soldering device

InactiveCN103418876AHigh precisionImprove brazing efficiencySoldering auxillary devicesUltrasonic generatorUltrasound

The invention discloses an ultrasonic soldering device, which comprises a soldering machine. An ultrasonic transducer is arranged on the soldering machine. The ultrasonic transducer is connected with an ultrasonic generator. Oxide films can be removed very quickly before soldering by using ultrasonic waves, only the oxide films instead of parts which are not oxidized are removed by adjusting the frequency of the ultrasonic waves, and the removing accuracy is high.

Owner:宁波海融电器有限公司

Active brazing filler metal and preparation method and application thereof

ActiveCN108188613AGood welding performanceReduce contact resistanceFinal product manufactureWelding/cutting media/materialsElectrical resistance and conductanceSilver paste

The invention discloses active brazing filler metal which is prepared from, by mass, 3-10% of Zn, 1-3% of Ti, 0.01-0.1% of Ce, 35-45% of Sn and the balance Pb, wherein the total mass percentage of thecomponents is 100%. The invention further provides a preparation method and application of the active brazing filler metal. The active brazing filler metal has good soldering performance below 220 DEG C, circuits are directly soldered on a photovoltaic cell panel with an ultrasonic soldering iron, silver paste is replaced, meanwhile, a solder strip plated with the active brazing filler metal is subjected to series-parallel soldering without scaling powder, a joint point of the active brazing filler metal has low contact resistance and high strength, and the alloy cost is low.

Owner:SHENZHEN FUMOSUO METAL PROD

Plasma display panel and chamber for manufacturing plasma display panel

ActiveUS20110220384A1Low melting pointLow costAddress electrodesSustain/scan electrodesEngineeringSealant

A structure of a panel which can be thinned down to about a panel thickness of a PDP and a manufacturing method thereof are provided. A gas filling hole is provided to a surface of a rear glass substrate of a PDP, the surface coming in contact with a front glass substrate of the PDP. Vacuuming and filling of a discharge gas are performed through the gas filling hole. After filling of the discharge gas, a mechanism for lifting solder iron up and down and supplying solder provided inside a chamber inserts a tip of an ultrasonic soldering iron into the gas filling hole to start supplying a solder which is a material for a plug sealant. When a series of forming steps of the plug sealant are finished, the ultrasonic soldering iron is retreated before the solder is solidified to finish formation of the plug sealant.

Owner:PANASONIC CORP

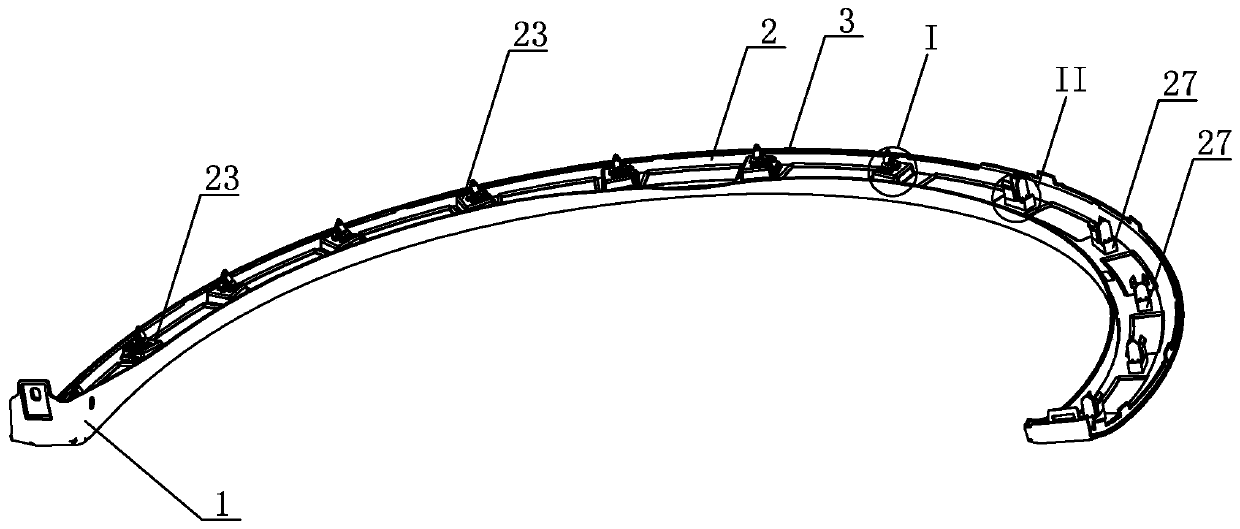

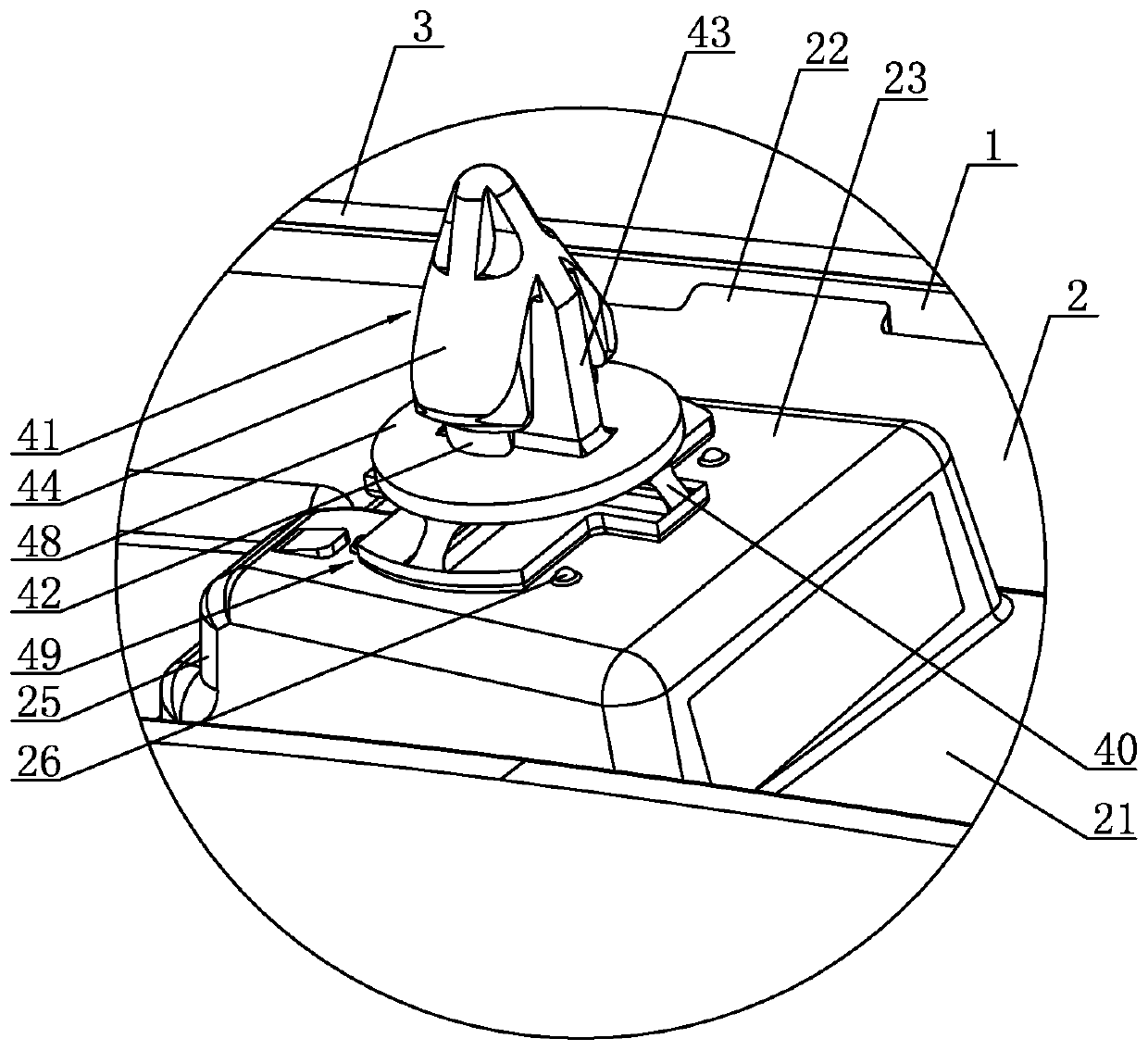

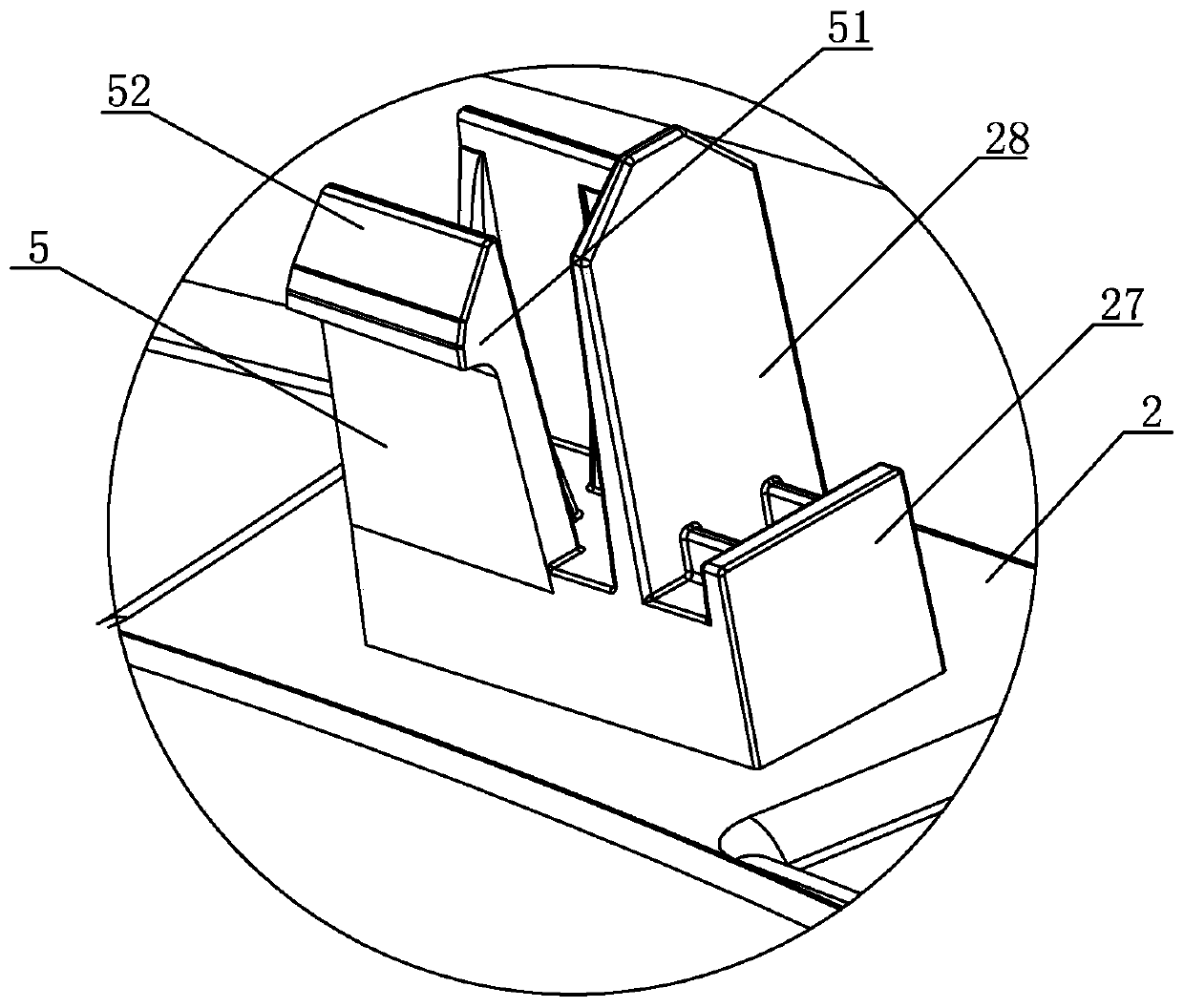

Automobile wheel brow

PendingCN110758276AGuaranteed installation effectFirmly assembledVehicle componentsInternal combustion piston enginesEngineeringStructural engineering

The invention discloses an automobile wheel brow. The automobile wheel brow comprises a wheel brow body and a bracket; the bracket is welded and fixed to the wheel brow body in an ultrasonic way; a plurality of first buckle units and a plurality of second buckle units are installed on the bracket; each first buckle unit comprises a first buckle; each first buckle comprises an anchor-shaped conicalguide end; a metal plate of the body side is provided with first clamping holes matched with the conical guide ends; the bottom end of each conical guide end is integrally provided with a thin-wallpart matched with the wall of the corresponding clamping hole; each second buckle unit comprises a second buckle; and an automobile bumper is provided with second clamping holes matched with the second buckles. According to the automobile wheel brow, the wheel brow body and the bracket are firmly connected and do not drop, so abnormal sounds generated in a running process of an automobile are prevented. After the first buckles are assembled, the thin-wall parts of the first buckles make surface contact with the metal plate of the body side so that the first buckles can be firmly and reliably assembled on the metal plate of the body side; loosening of the first buckles is effectively prevented; and the installation effect of the wheel brow is guaranteed.

Owner:宁波汇驰汽车部件有限公司

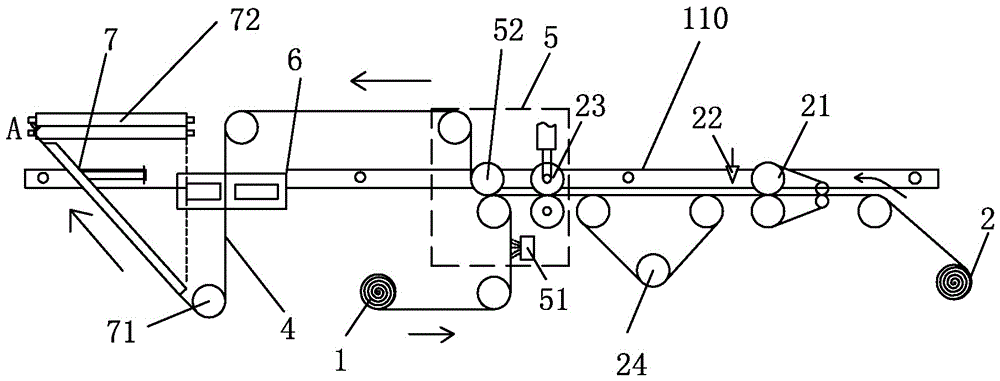

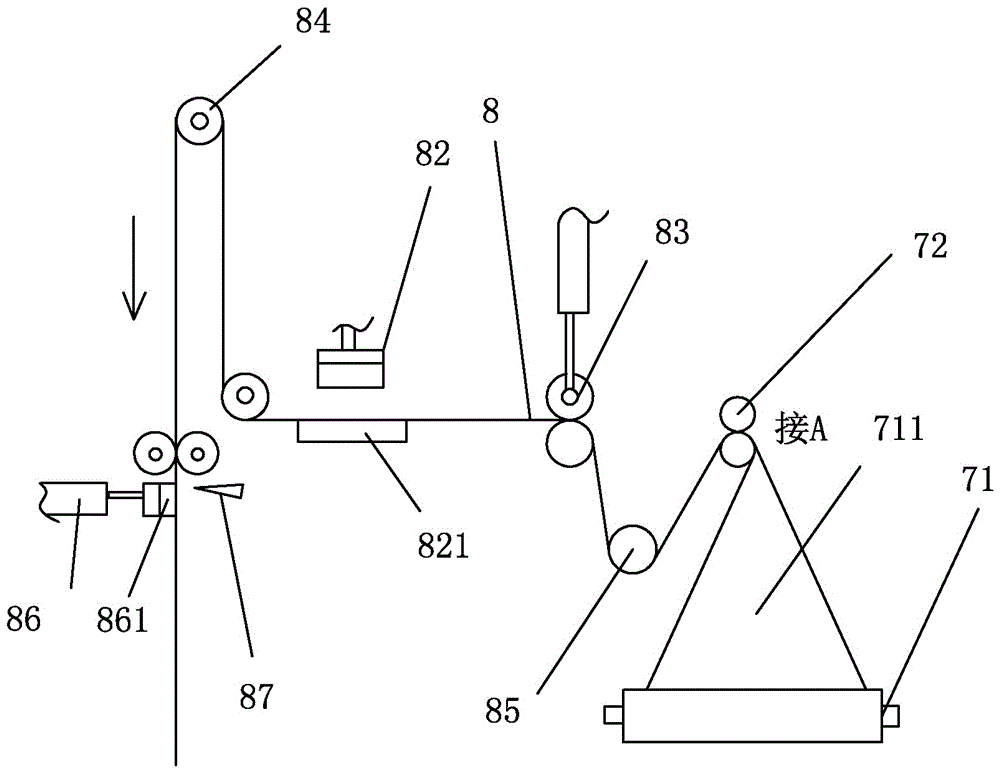

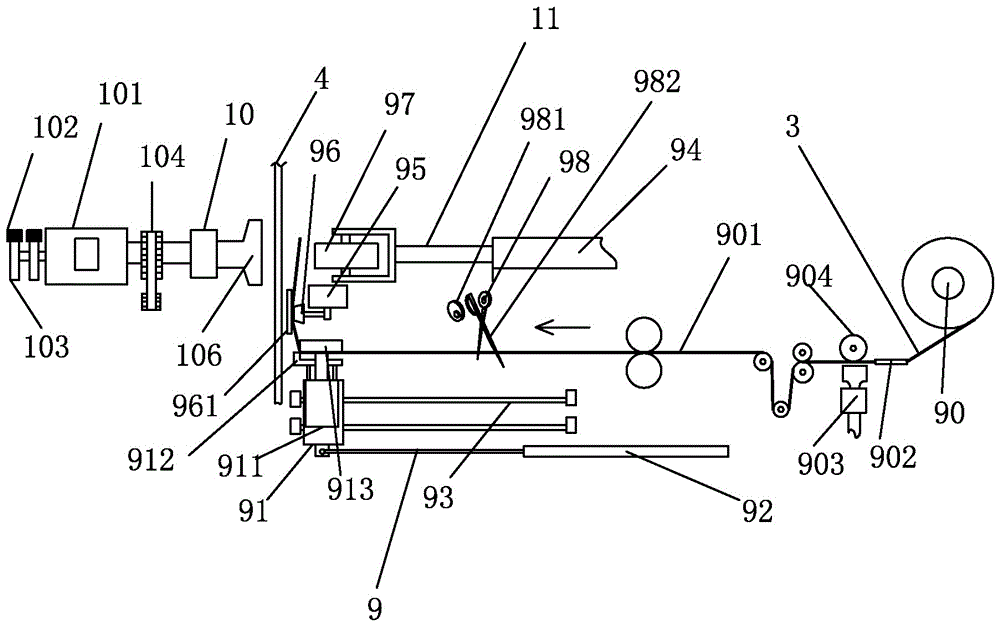

Non-woven fabric clothes production line

PendingCN106617442AQuality improvementReduce usageClothes making applicancesProduction lineAdhesive belt

The invention discloses a non-woven fabric clothes production line. The non-woven fabric clothes production line comprises a rack, a non-woven fabric raw material roll and a film roll are arranged on the rack, the non-woven fabric clothes production line is composed of multiple processing units, each processing unit can independently conduct small-lot flowline production, thus production efficiency is drastically improved, mutual collaborate can be achieved, production tasks of large-scale products can be accomplished, and production is flexible. A solder strip device is of a strip manufacturing and strip soldering integrated structure, non-woven fabric strips can be processed and manufactured on the line, solder strip infusion and adhesion are conducted, the solder strip device adopts an ultrasonic soldering head, the use of adhesive tape can be avoided, infusion and adhesion of the non-woven fabric strips are achieved by utilizing ultrasonic wave, thus the qualification rate of products is increased, and resources are saved; meanwhile, the ultrasonic soldering head can conveniently and fast achieve adhesion of the non-woven fabric strips, and certain processing cost is saved. Through the match of a clothes collar cutting device and a cloth folding device, non-woven fabric can be precisely processed so as to fast make a non-woven fabric clothes collar shaped.

Owner:XIANTAO ZHONGTAI PROTECTIVE PROD

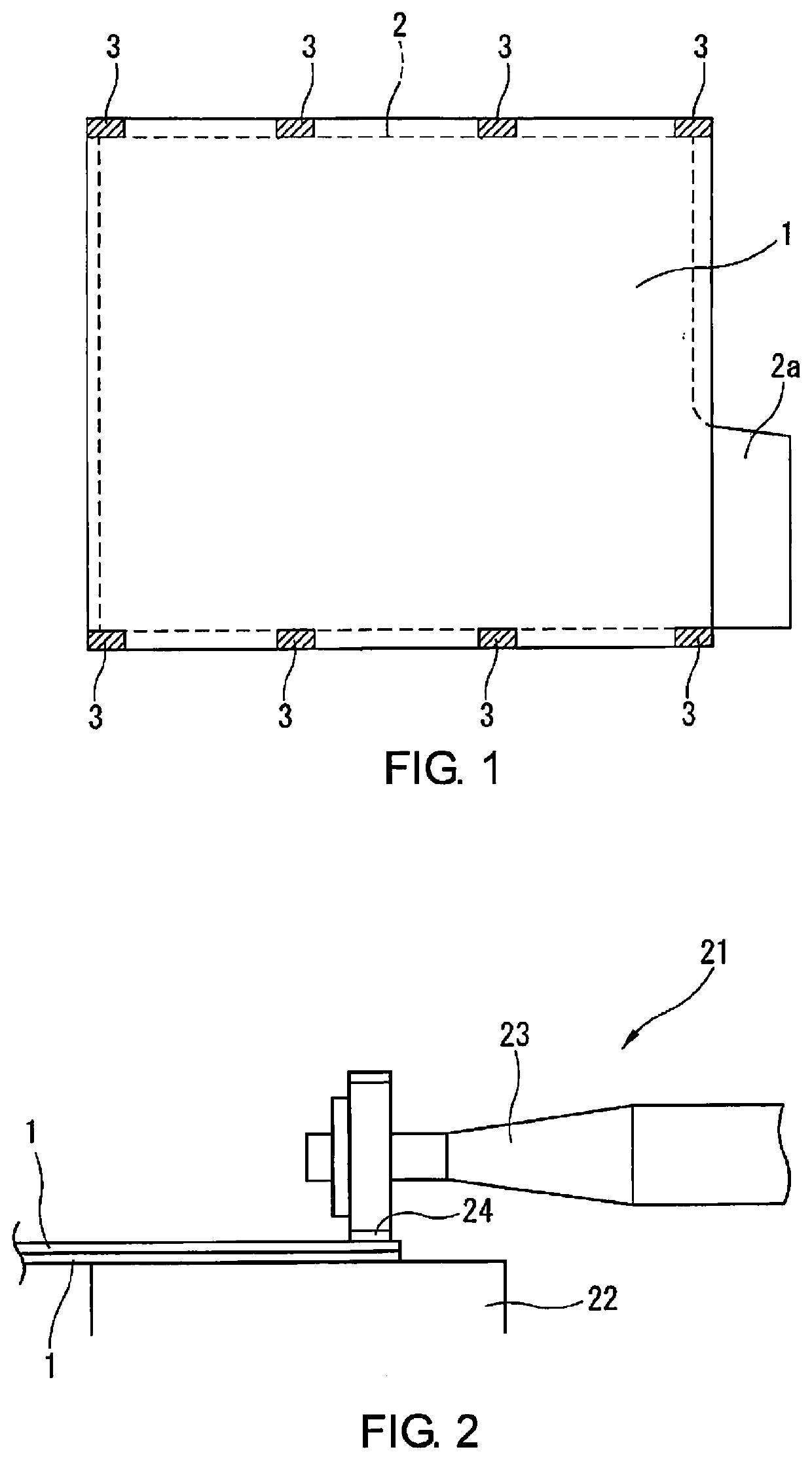

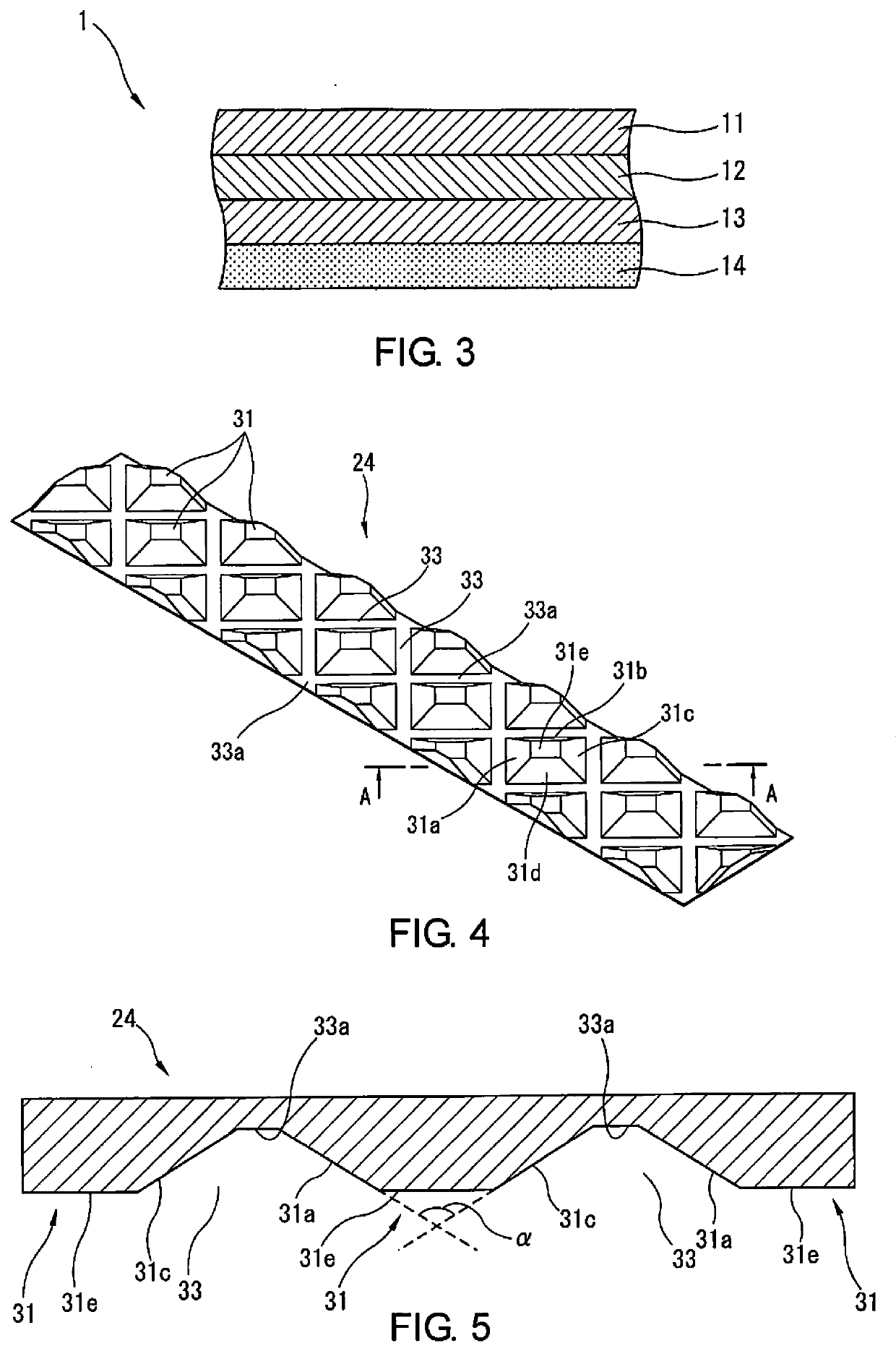

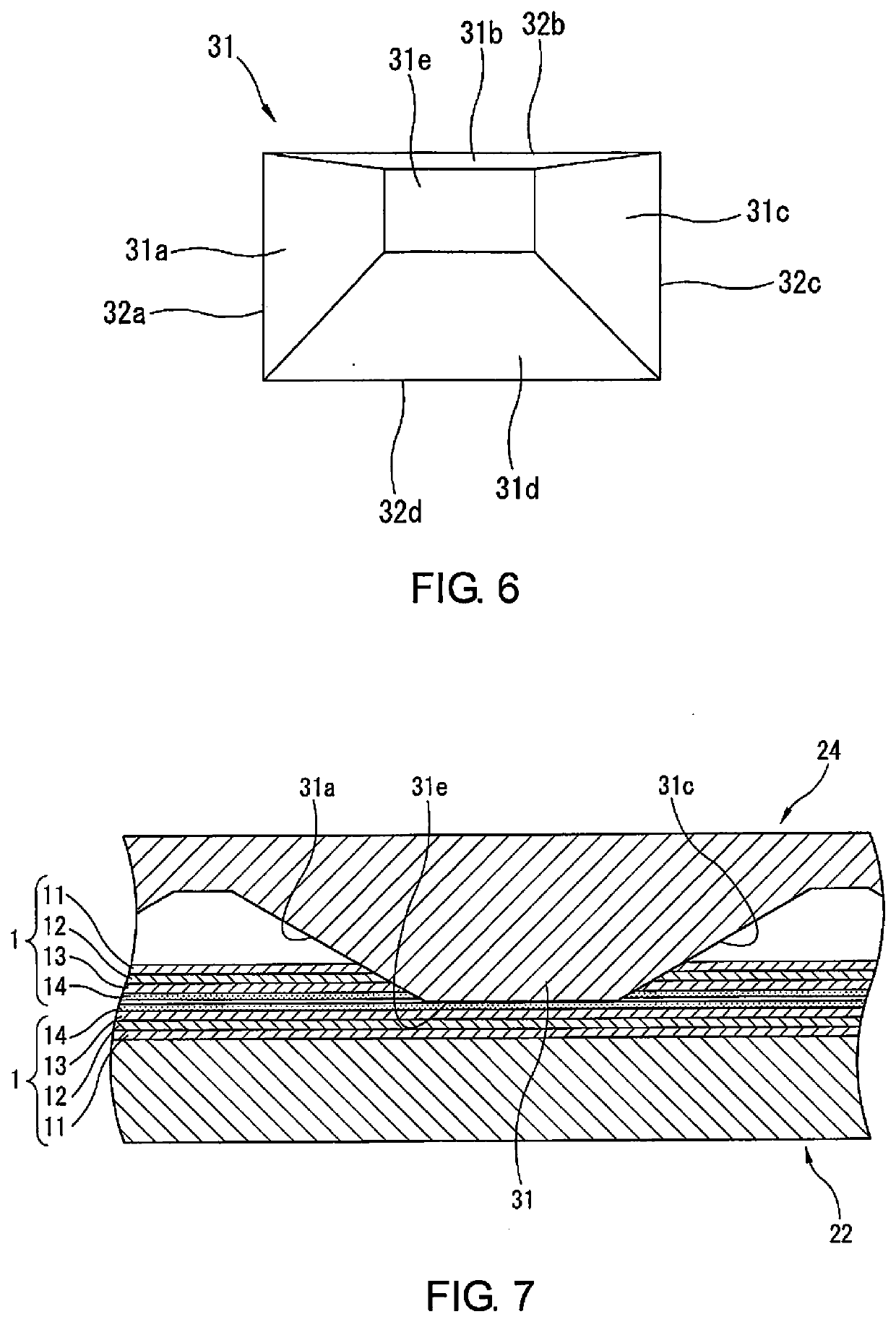

Ultrasonic bonding tool and ultrasonic bonding method

ActiveUS20200070431A1Avoid stickingSuppress a phenomenon of the workpiece becoming affixedCell component detailsDomestic articlesPolymer sciencePolypropylene

An ultrasonic bonding tool is used on a horn side or anvil side of an ultrasonic joining device in which two synthetic resin sheets that include a polyethylene layer, a polypropylene layer and a ceramic heat-resistant layer are superposed and joined together so that the heat-resistant layers face each other. The ultrasonic bonding tool includes a plurality of protrusions shaped as quadrangular pyramids having a flat top surface. Each of the protrusions has an apex angle formed by two mutually opposite side surfaces that is within a range of 110-130°. When two separators of a battery cell are joined together using the ultrasonic bonding device with the ultrasonic bonding tool, a force with which the separators adhere to the protrusions is weak. In this way, the separators do not adhere to the horn during ultrasonic bonding of the synthetic resin sheets.

Owner:ENVISION AESC JAPAN LTD

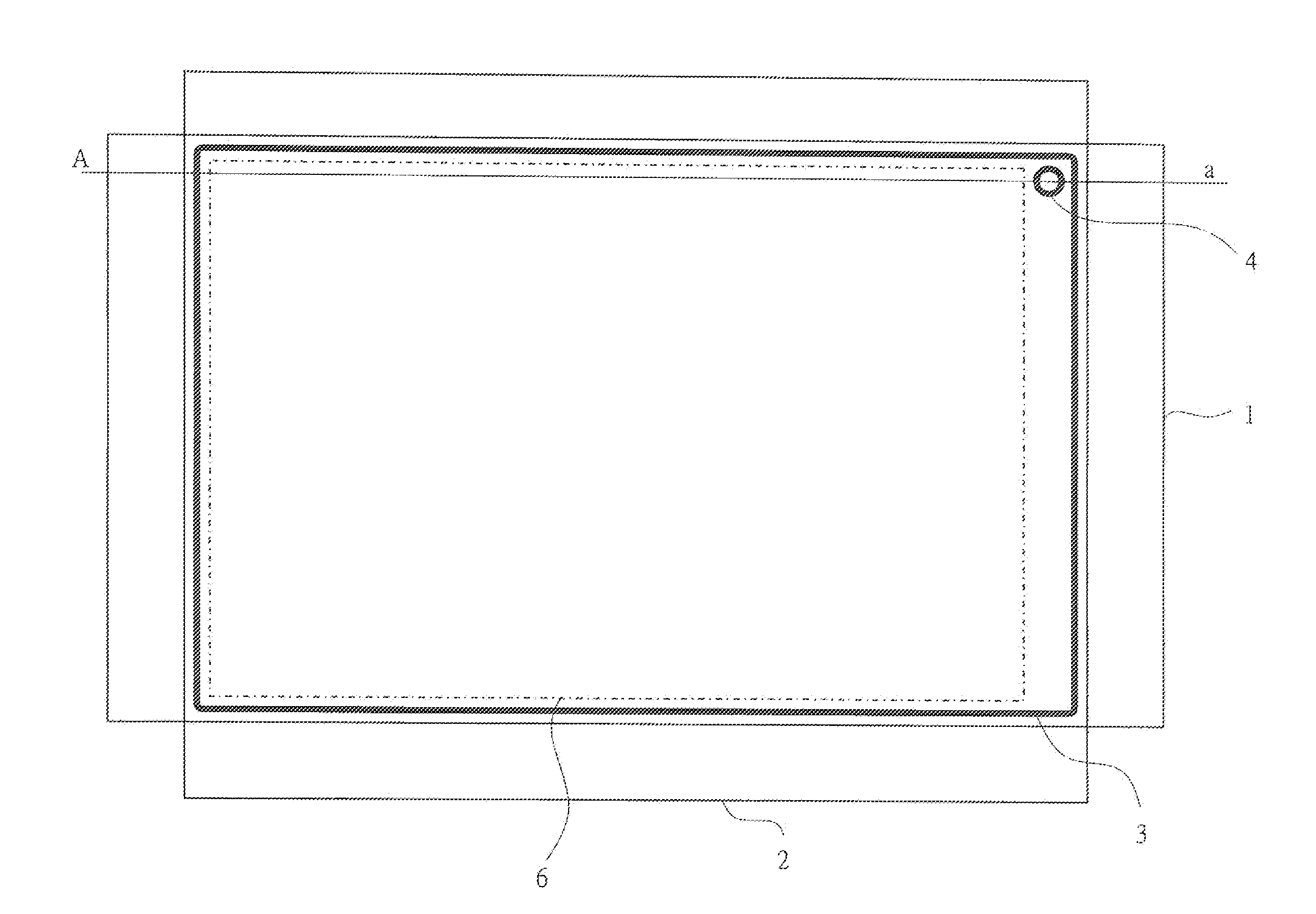

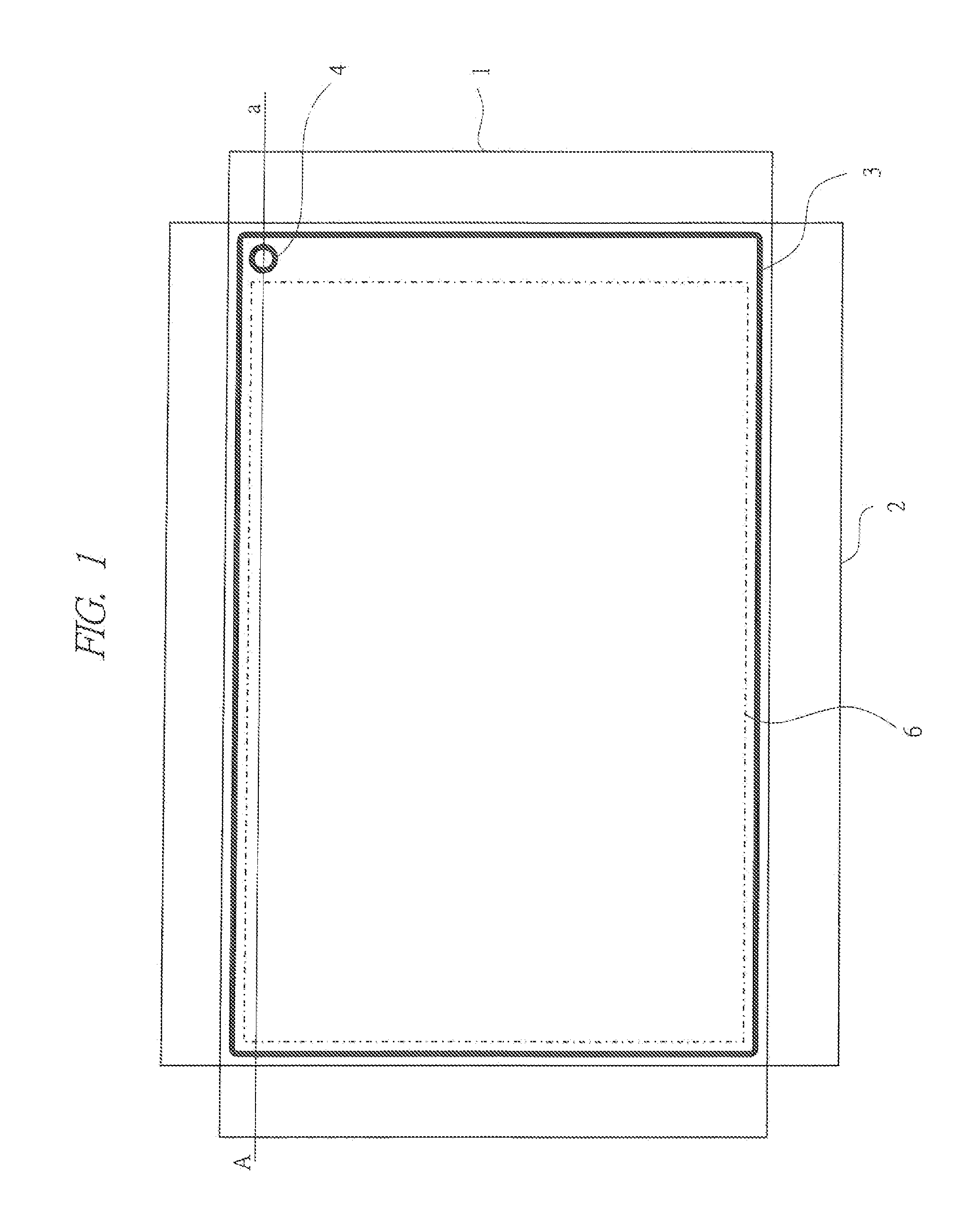

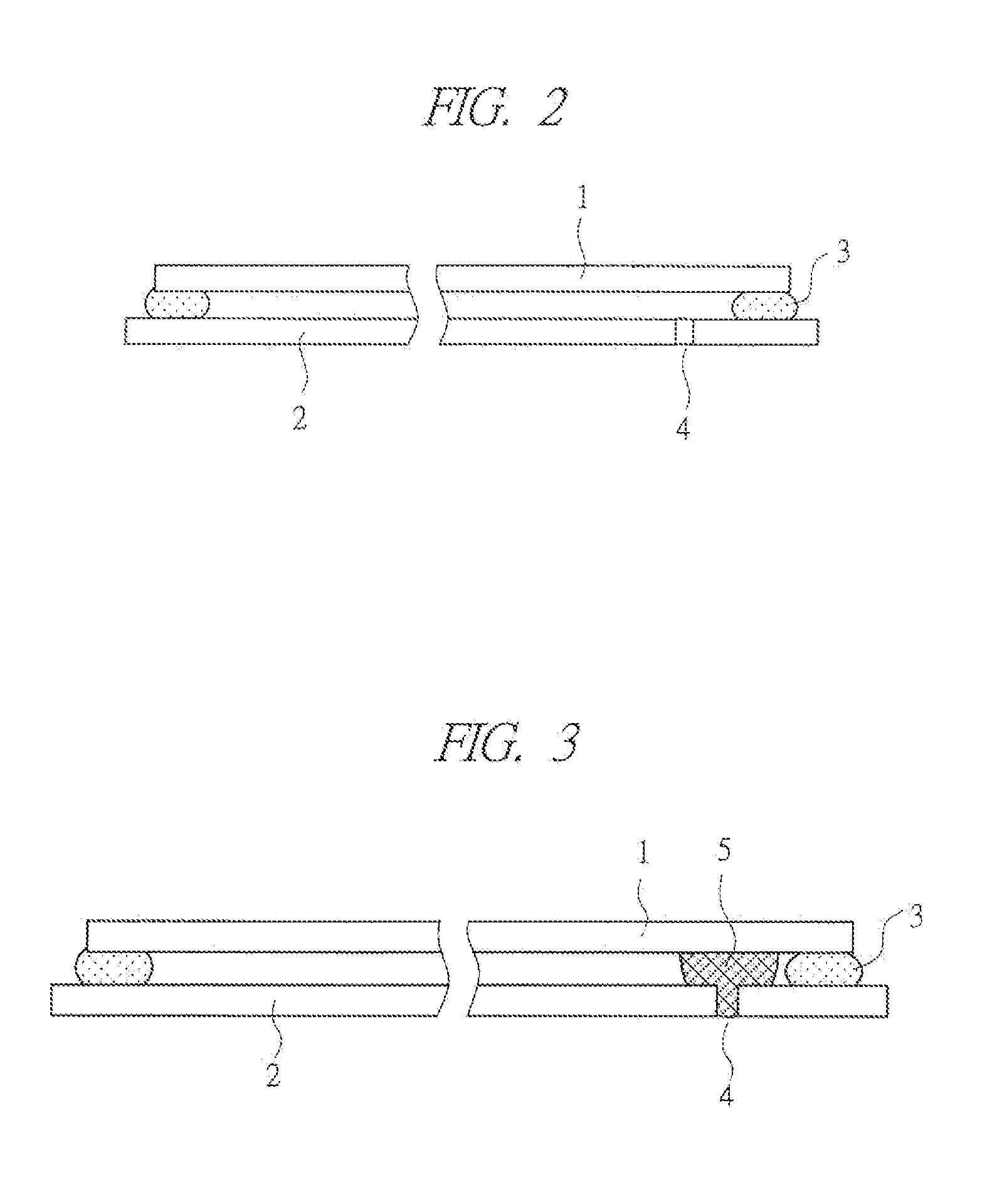

In solder covered copper foil ribbon conductor wire and its connection method

InactiveCN101375412BReduce usageFirmly connectedHot-dipping/immersion processesFinal product manufactureTinningElectrical conductor

The invention provides an In tin-coated copper foil stripe lead and connecting method thereof. The method tenaciously connects a conductor electrode on a glass substrate to a ribbon conductor with certainty at low cost without causing damage. An indium-solder-coated copper foil ribbon conductor (1) obtained by depositing an indium solder (3) (100-90% indium and 10-0% silver) in a thickness of 100um or smaller on one side of a copper foil or tin-coated copper foil (2) having a thickness of 300 um or smaller and optionally further depositing the solder thinly on the other surfaces of the foil is placed on an exposed part of a molybdenum-based metallic back electrode layer (4B) on a glass substrate (4A). An ultrasonic soldering iron (5) is then placed against the upper side of the copper foil ribbon conductor (1) to melt the indium solder (3) and connect the copper foil ribbon conductor 1 to the electrode layer (4B). Another method includes soldering an indium solder (3) (having the same composition as shown above) to the electrode layer (4B) beforehand, subsequently placing a ribbon-form copper foil or tin-plated copper foil (2) thereon, and connecting the copper foil (2) to the electrode layer 4B with an ultrasonic soldering iron (5).

Owner:太阳能先锋株式会社

Local Flame Heating Ultrasonic Brazing Method of Aluminum Alloy Sealing Structure

ActiveCN104625289BReduce heatFlexible heating methodHeating appliancesWelding/soldering/cutting articlesLiquid stateFree cooling

The invention discloses an aluminum alloy seal structure local flame heating ultrasonic braze welding method which is used for conducting sealing and braze welding encapsulation on aluminum alloy cavities of built-in electronic components. The aluminum alloy seal structure local flame heating ultrasonic braze welding method comprises the first step of polishing and clearing an aluminum alloy surface of a joint to be brazed through abrasive paper; the second step of placing low-temperature Sn-based brazing filler metal on one side of the lap joint end of an aluminum alloy sealing surface; the third step of conducting local reciprocating heating on the brazing filler metal through gas flame flow to make the brazing filler metal melt and maintain a liquid state, and no heating on parent metal; the fourth step of applying ultrasonic vibration on a cavity of the aluminum alloy to be welded; the fifth step of finishing sealing the test piece through natural cooing after the ultrasonic vibration is finished. According to the aluminum alloy seal structure local flame heating ultrasonic braze welding method, overall heating is not conducted when the aluminum alloy seal structure is welded, local heating is conducted only on the brazing filler metal area, heating on a sealing element is extremely small, and the electronic components in the sealing element are not affected by heat. The aluminum alloy seal structure local flame heating ultrasonic braze welding method has the advantages of being simple in technology, high in welding efficiency, and suitable for the engineering application.

Owner:SOUTHWEST JIAOTONG UNIV

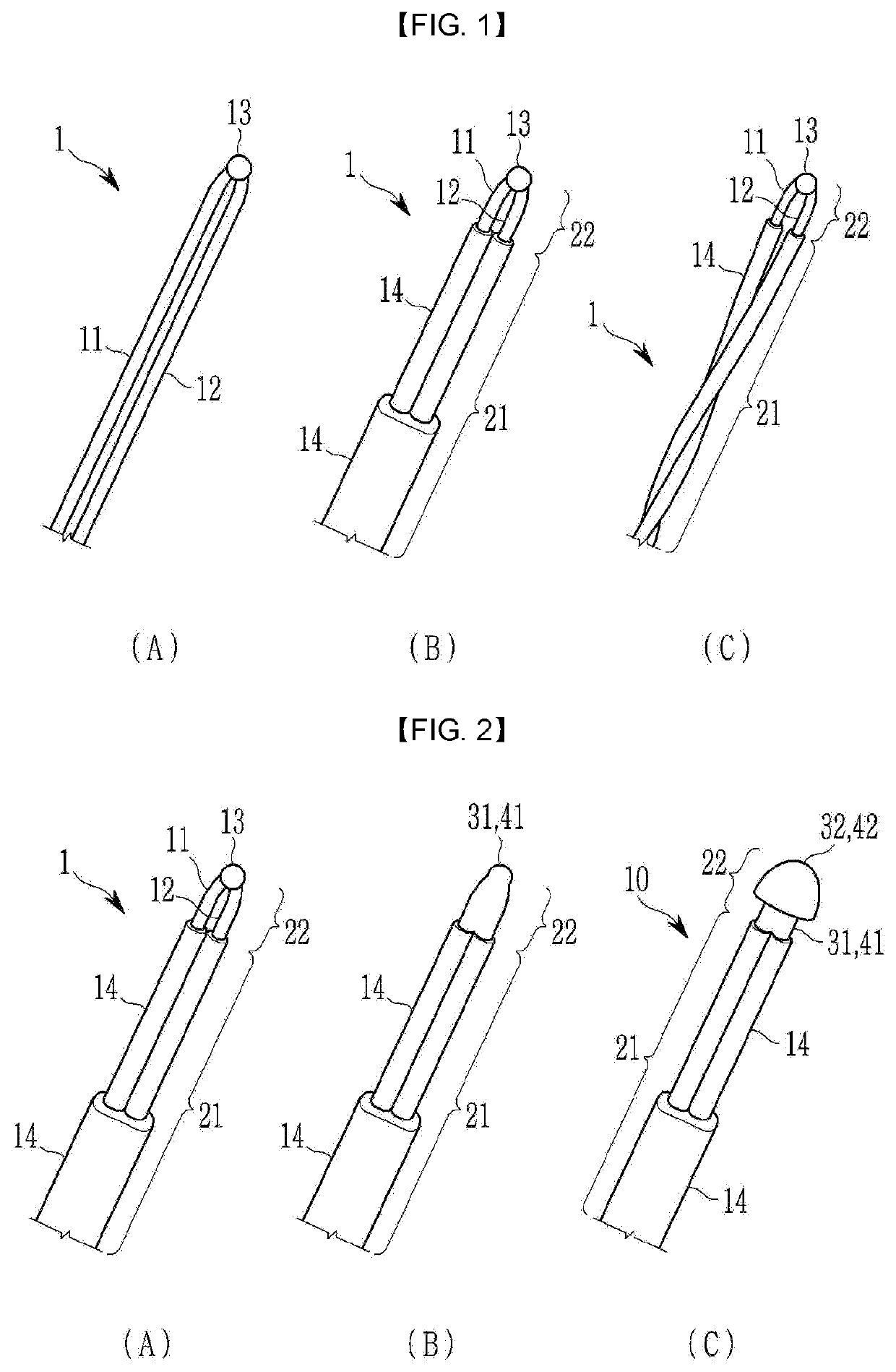

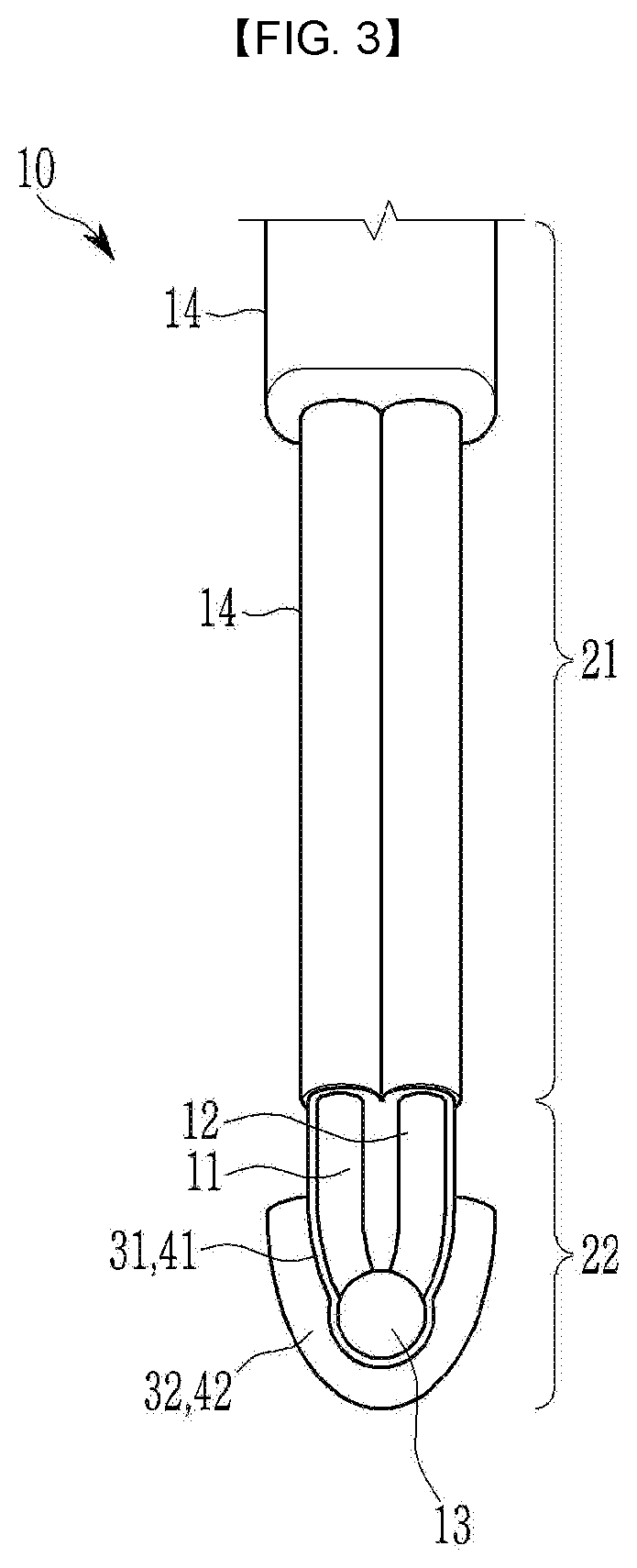

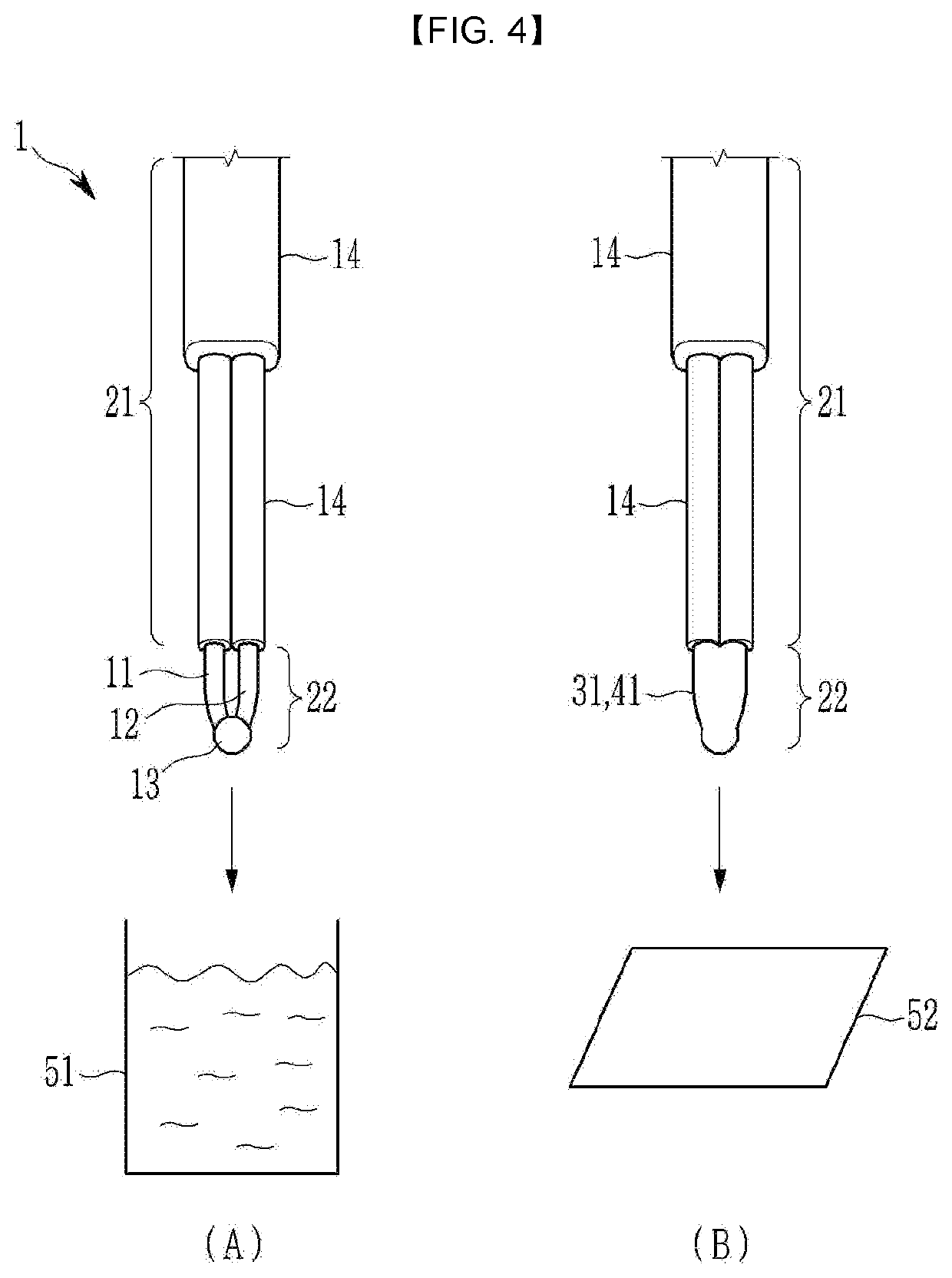

Thermocouple, bonding tool for thermocouple, battery module, method for manufacturing thermocouple, and method for bonding thermocouple

ActiveUS20200295420A1Long-term stable connectionGuaranteed long-term connectionThermometer detailsHot-dipping/immersion processesElectrical batteryMetallic materials

A thermocouple for temperature measurement according to an embodiment may include a first wire of a first metallic material and a second wire of a second metallic material different from the first metallic material, a first section in which the first wire and the second wire are electrically insulated from each other, a second section in which the first wire and the second wire are connected to each other to form a measuring junction, a first layer of a thermally conductive and electrically insulating first material enclosing the second section, and a second layer of an ultrasonic-weldable second material enclosing at least part of the first layer.

Owner:SAMSUNG SDI CO LTD

Preparation method of lithium ion capacitor

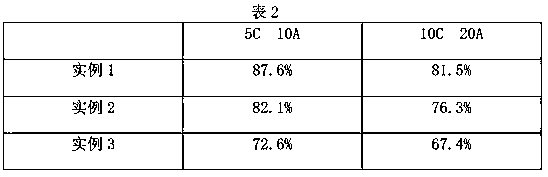

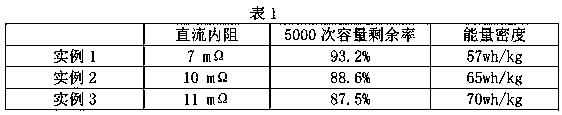

ActiveCN108493005AWork lessIncrease energy densityHybrid capacitor electrodesDouble layer capacitorsHigh rateInternal resistance

The invention provides a preparation method of a lithium ion capacitor. The preparation method comprises the following steps that: a positive-pole current collector is prepared; 2, a positive-pole electrode sheet is prepared; 3, a negative-pole current collector is prepared; 4, a negative-pole electrode sheet is prepared; 5, a diaphragm is prepared; 6, a material for preparing electrolyte is selected; 7, an aluminum-plastic film is prepared; 8, materials for preparing electrode lugs are selected; and 9, the capacitor is prepared. According to the step 9, the positive-pole electrode sheet, thediaphragm and the negative-pole electrode sheet are laminated so as to form a battery core; the positive-pole electrode lug and the positive-pole current collector are welded by means of ultrasonic soldering; the negative-pole electrode lug and the negative-pole current collector are welded by means of ultrasonic soldering; the battery core is packaged with the aluminum-plastic film at temperaturefrom 100 to 250 DEG C; the electrolyte is injected from a liquid injection opening, the liquid injection opening is sealed; standing, formation, liquid extraction and grading are performed, so that the lithium ion capacitor can be prepared. The energy density of the lithium ion capacitor prepared by using the preparation method of the invention can achieve 60 wh / kg; the voltage of the lithium ioncapacitor ranges from 4.2 to 2.8 V; and the energy density and voltage of the lithium ion capacitor prepared by using the preparation method are significantly improved compared with the energy density and voltage of a general super-capacitor; the internal resistance of the capacitor can be reduced; and the high-rate cycle life of the capacitor can be prolonged.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

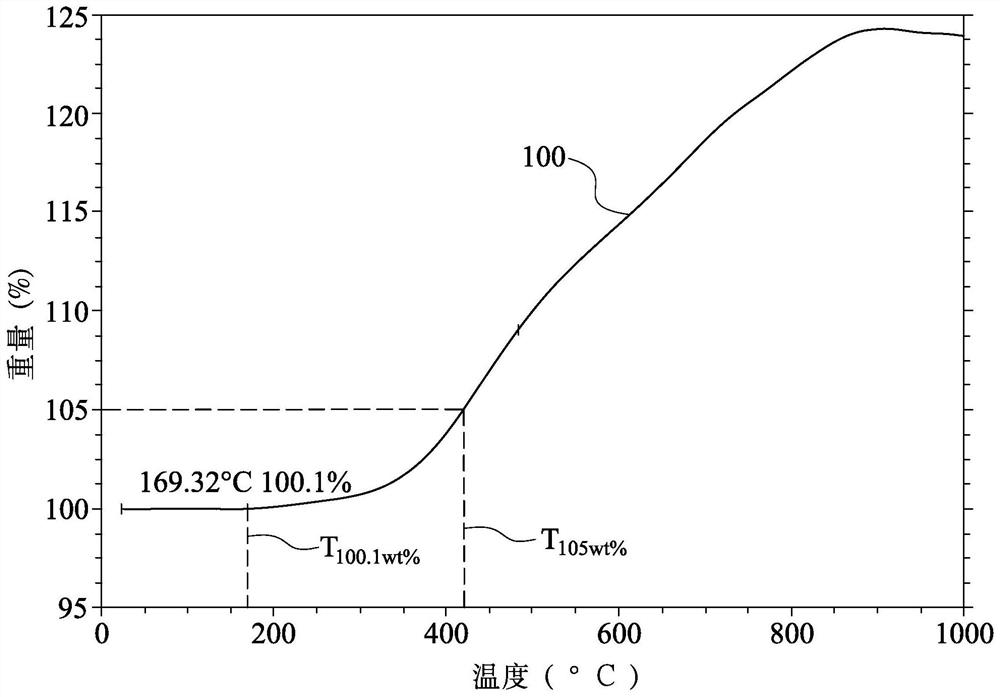

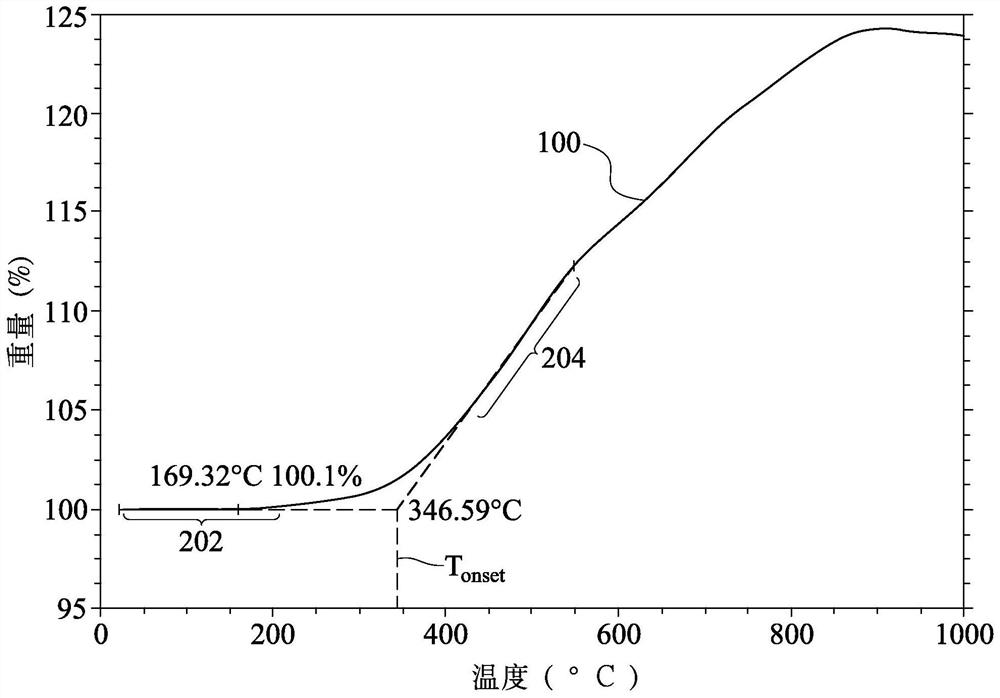

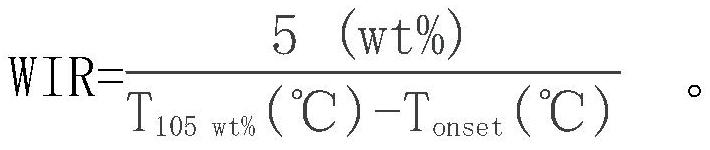

Electrolytic copper foil having heat resistance and lithium ion secondary battery comprising same

PendingCN112751035AImprove heat resistanceFinal product manufactureElectrode carriers/collectorsElectrolysisMetallurgy

An electrolytic copper foil having improved thermal properties. The electrolytic copper foil comprises a roller surface and a deposition surface, each of the two surfaces having a roughness Rz of less than or equal to 2 [mu] m, and wherein the electrolytic copper foil has a main weight increase of 105 wt% when the electrolytic copper foil is subjected to thermogravimetric analysis (TGA) and a main temperature (T105 wt%) is reached during TGA, and wherein the T105 wt% is in the range of 350 DEG C to 501 DEG C. Characteristics of the TGA include heating at a rate of 5 DEG C / min and an airflow of air at a rate of 95 mL / min. Ultrasonic soldering of the copper foil to the nickel foil provides an excellent weld with low separability, thereby providing good mechanical and electrical contact for applications such as in lithium ion secondary batteries.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

An Ultrasonic-Assisted Low-Temperature Glass Brazing Method

ActiveCN105522244BPromote wettingReduce complexitySoldering apparatusUltrasonic assistedUltrasonic vibration

The invention relates to an ultrasonic-assisted low-temperature glass brazing method. The ultrasonic-assisted low-temperature glass brazing method aims at solving the problems that in the existing process of brazing through low-temperature glass, as the viscosity of fusion glass under low temperature is large and a welding line is narrow, wetting spreading is not sufficient, and air hole remaining exists. The brazing method includes the steps that (1) low-temperature sealing glass powder and a binding material are mixed to obtain low-temperature glass brazing soldering paste; (2) a to-be-soldered raw material is cut and molded; (3) a soldered piece is subject to ultrasonic washing and polishing; (4) the low-temperature glass brazing soldering paste is coated to pre-connecting positions of the soldered piece; (5) the pre-connecting positions of the soldered piece are attached to form a to-be-soldered piece; and (6) heating is carried out to fuse the low-temperature glass brazing soldering paste, secondary ultrasonic vibration is applied to the surface of the to-be-soldered piece, and furnace cooling is carried out after vibration is stopped. The low-temperature sealing glass used in the method is low in sealing temperature, effective wetting spreading on the surface of the welded piece is carried out under the ultrasonication, obtained brazing connectors are free of macroscopic defects such as cracks and air holes, the residual stress is small, the strength is high, and the gas tightness is good.

Owner:HARBIN INST OF TECH

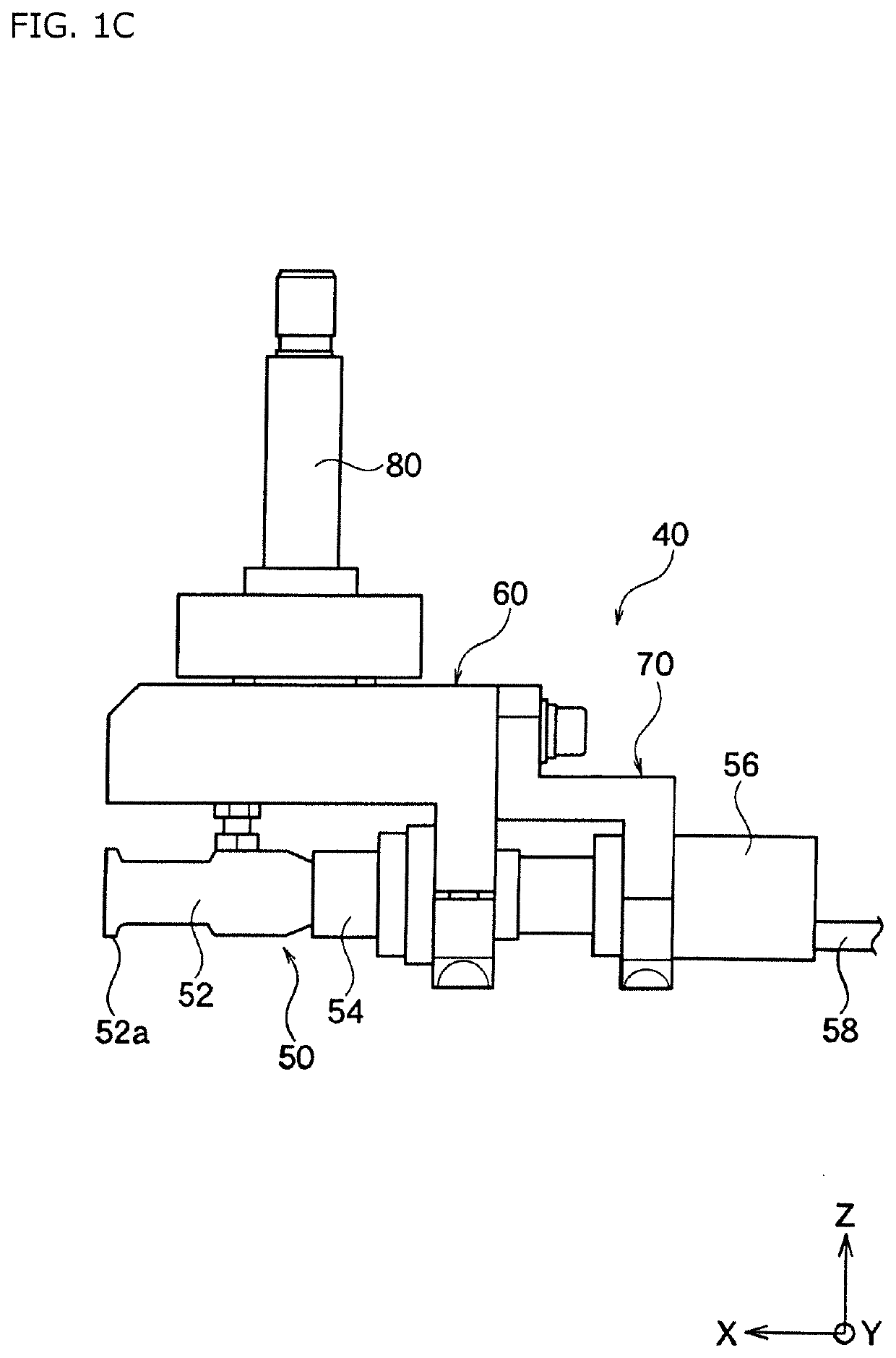

Ultrasonic bonding head, ultrasonic bonding device, and ultrasonic bonding method

ActiveUS20200001391A1Increase ultrasonic vibrationDownsizeSoldering apparatusSolid-state devicesUltrasonic bondingMechanical engineering

An ultrasonic bonding head includes a vibrator unit, a holder, and a pressurizing shaft. The vibrator unit includes a press part formed at a tip of the vibrator unit in a longitudinal axis thereof and configured to press a bonding scheduled part to be bonded. The holder holds a base of the vibrator unit in a cantilever manner so that the tip is a free end. The pressurizing shaft is connected with the holder and transmits a force of pressing the press part against the bonding scheduled part so that the vibrator unit moves substantially perpendicularly to the longitudinal axis. The holder is provided with a restraint portion. The restraint portion contacts with the vibrator unit at a counterforce dispersion position located between a main hold position for holding the vibrator unit by the holder and the free end.

Owner:TDK CORPARATION

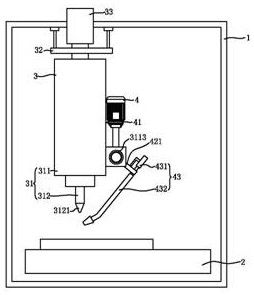

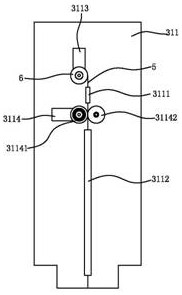

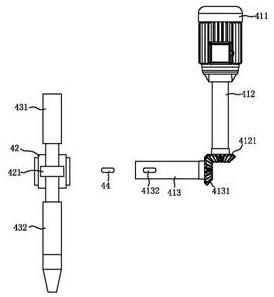

A kind of ultrasonic soldering method

ActiveCN111097982BLimited wiggle roomAvoid swingingMetal working apparatusSoldering auxillary devicesMechanical engineeringMaterials science

The invention provides an ultrasonic soldering method, comprising an ultrasonic soldering device, the ultrasonic soldering device includes a frame, a heating device, a discharging mechanism and an ultrasonic mechanism; the discharging mechanism is arranged at the upper end of the frame, and the heating device is arranged at the lower end of the frame; the ultrasonic mechanism It is connected with the discharge mechanism; the present invention controls the amount of tin when soldering is different through the different sizes of the pads; avoiding that the size of the pads is large and the amount of tin is too small, causing the LED chip to be unable to be firmly welded on the pads; at the same time, it can avoid If the size of the pad is too small and the amount of tin is too much, the LED chip moves on the pad, resulting in unreliable connection; soldering through an ultrasonic mechanism can accurately control the amount of tin with high precision.

Owner:广州市鸿利显示电子有限公司

Method for increasing glass welding speed

The invention provides a method for increasing the glass welding speed. The method comprises the following steps: controlling the overall plate temperature of glass within 60-80 DEG C; an area heating device being arranged at the ultrasonic soldering bit, moving along with the ultrasonic soldering bit and being aligned with an area to be welded; and the area heating device being used for heating the glass in the area to be welded before welding, so that the glass meets the temperature requirement of ultrasonic welding. According to the method for increasing the glass welding speed, the welding speed is increased on the premise of ensuring that the glass does not deform.

Owner:维爱吉(厦门)科技有限责任公司

Supersonic soldering aluminum coil and its production method

The invention provides an aluminium wire coil made by ultrasonic soldering and manufacturing method thereof. The invention plates on surface of wire by ultrasonic soldering so as to improve soldering force between the printed circuit board and copper foils and ensure the conductive property, omit pretreatment of soldering and increase work efficiency and production efficiency, prevent environmental pollution caused by using flux. The invention provides an aluminium wire coil made by ultrasonic soldering, comprising steps of forming insulating coating on surface of aluminium wire, dipping a wire end on which the coating is removed into a solder box applied ultrasonic wave to form a solder plated layer by ultrasonic soldering.

Owner:南通迪皮茜电子有限公司

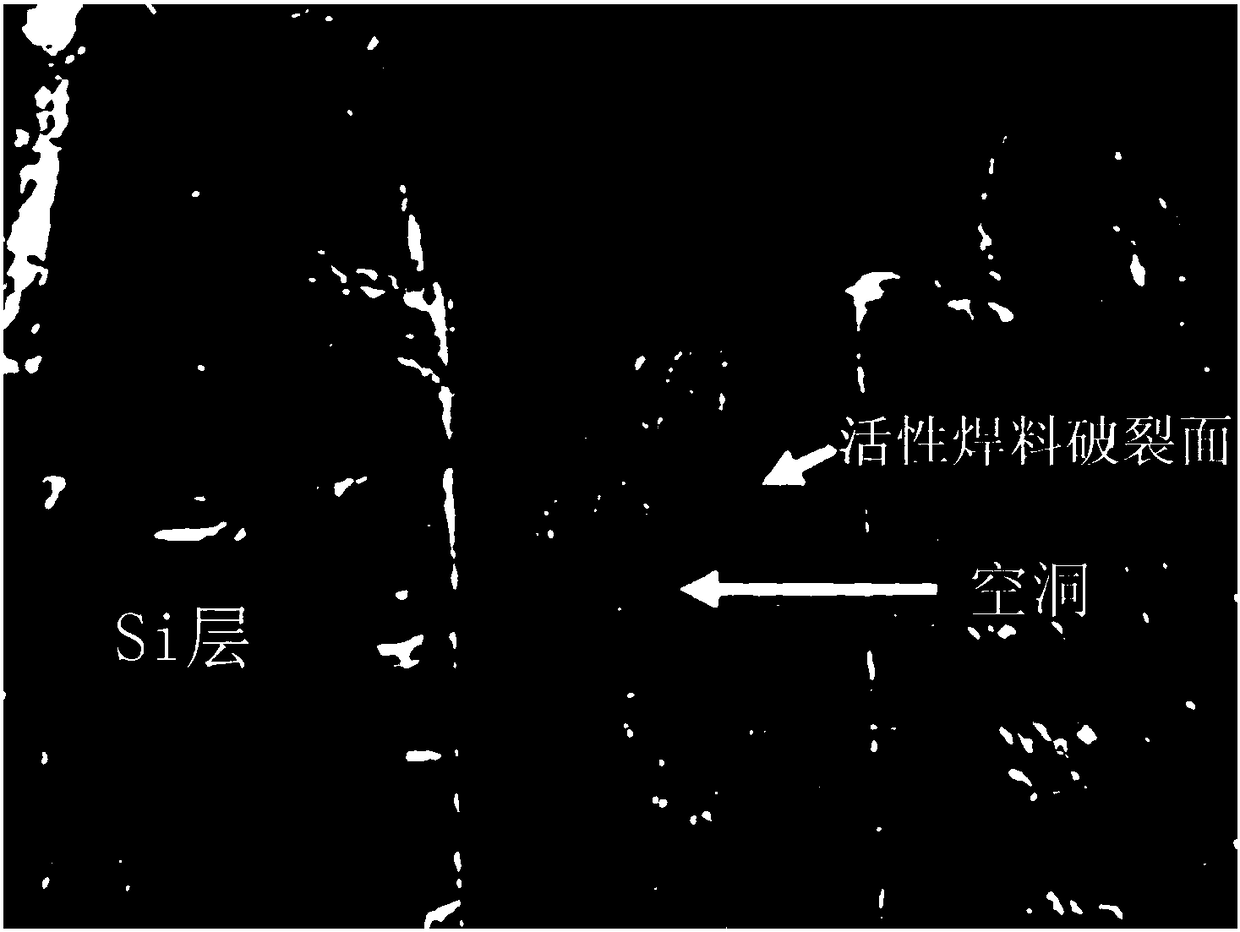

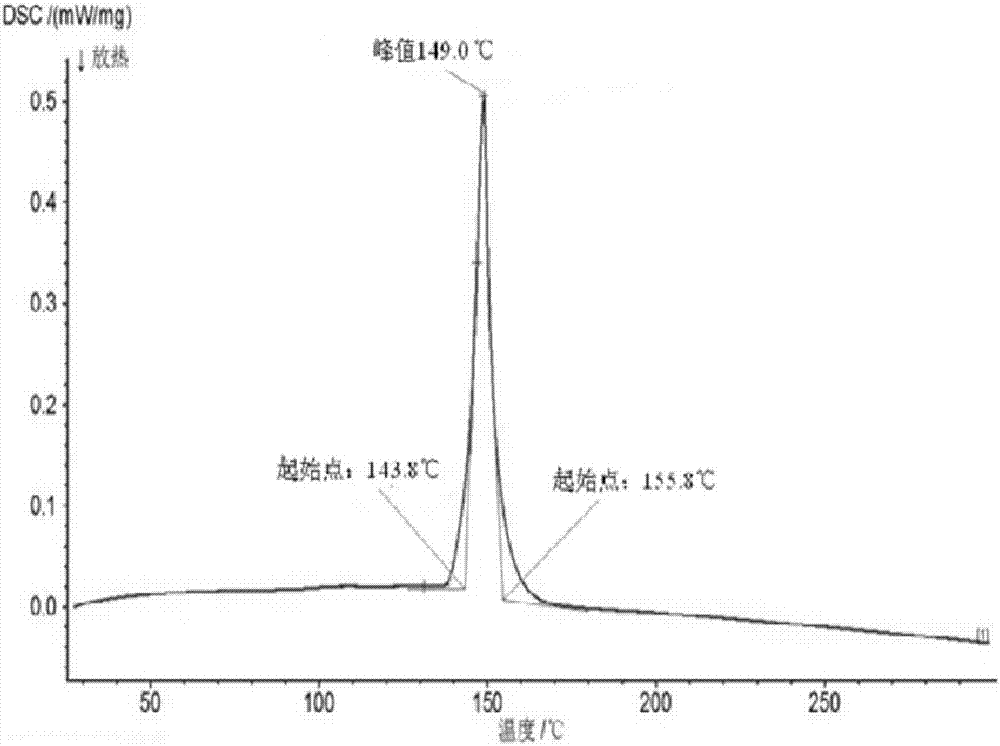

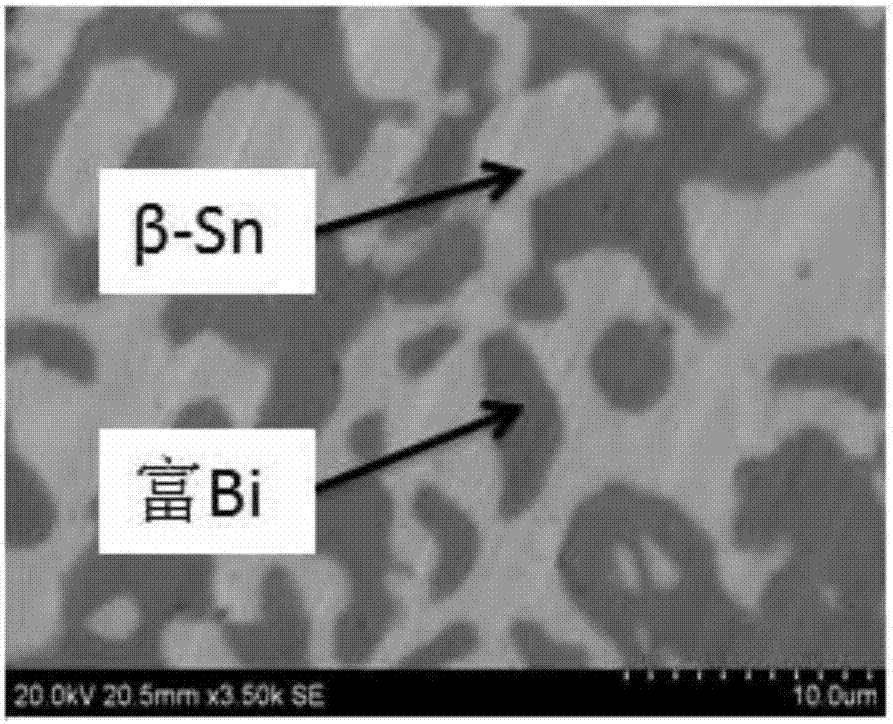

Low-temperature ultrasonic SNBI-based solder and its preparation method, and its method for ultrasonically brazing ceramics and/or ceramic matrix composites

ActiveCN104889594BActive connectionAvoid generatingWelding/cutting media/materialsSoldering mediaCeramic compositeCrucible

Owner:HARBIN INST OF TECH

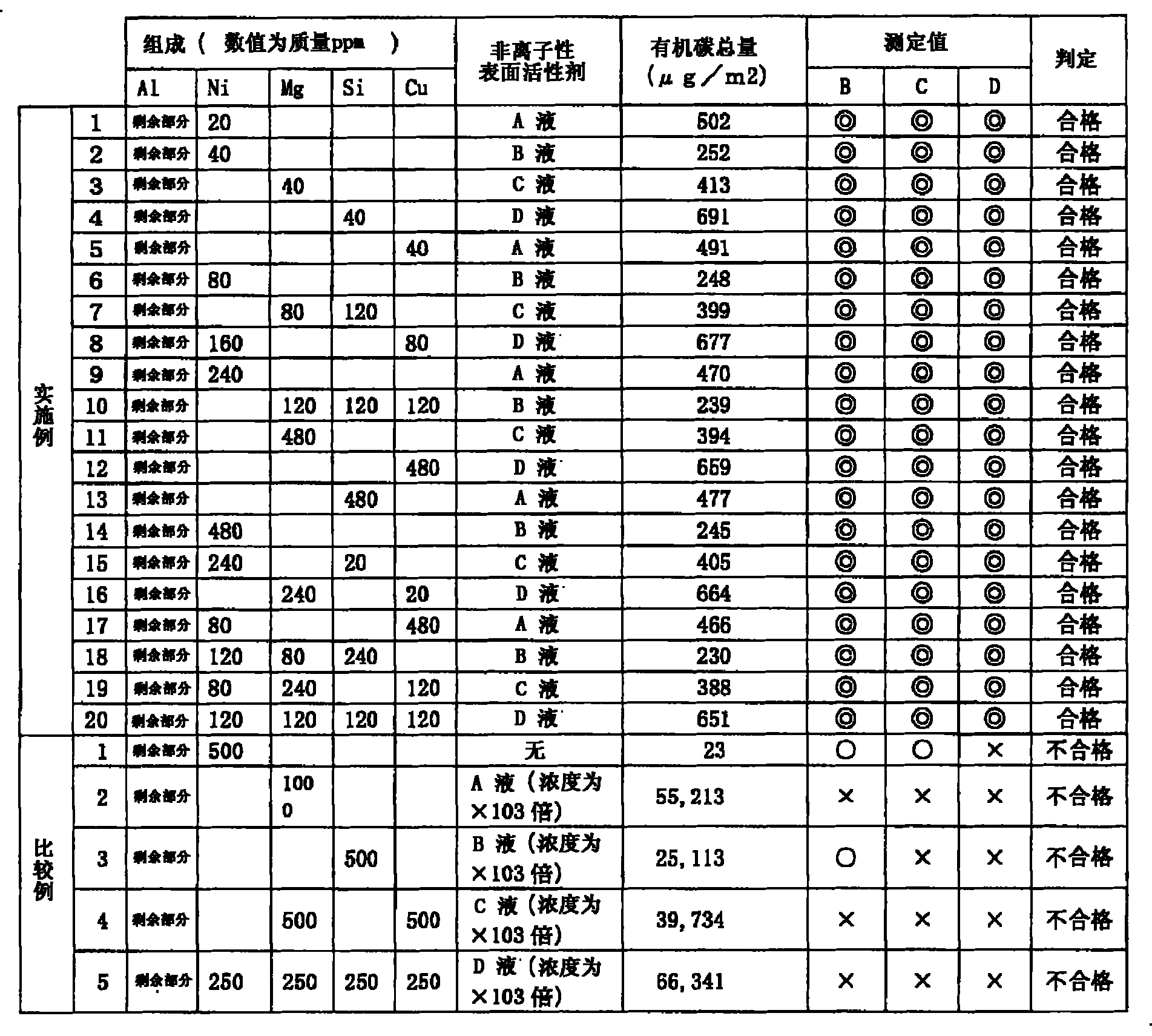

Aluminum ribbon for ultrasonic bonding

InactiveCN102326242BAvoid pollutionPrevent getting involvedSolid-state devicesSemiconductor/solid-state device manufacturingAlloyAluminum metal

[Issues to be Solved] To provide an aluminum ribbon for ultrasonic bonding, is able to realize the high bonding strength and is able to maintain defined level of bonding strength, during several ten thousand bonding cycles. [Means to be Solved] An aluminum ribbon for ultrasonic bonding is consisted aluminum metal or aluminum based alloy, the purity of aluminum is more than 99.99 wt %, and total amount of organic carbon non-ionic surfactant less than 500 molecular weight vaporized and adhered is 100-1,000 μg / m2 on the mirror finished bright surface of aluminum ribbon.

Owner:TANAKA DENSHI KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com