In solder covered copper foil ribbon conductor wire and its connection method

A strip wire, tinned copper foil technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., to achieve the effect of reducing usage and alleviating deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

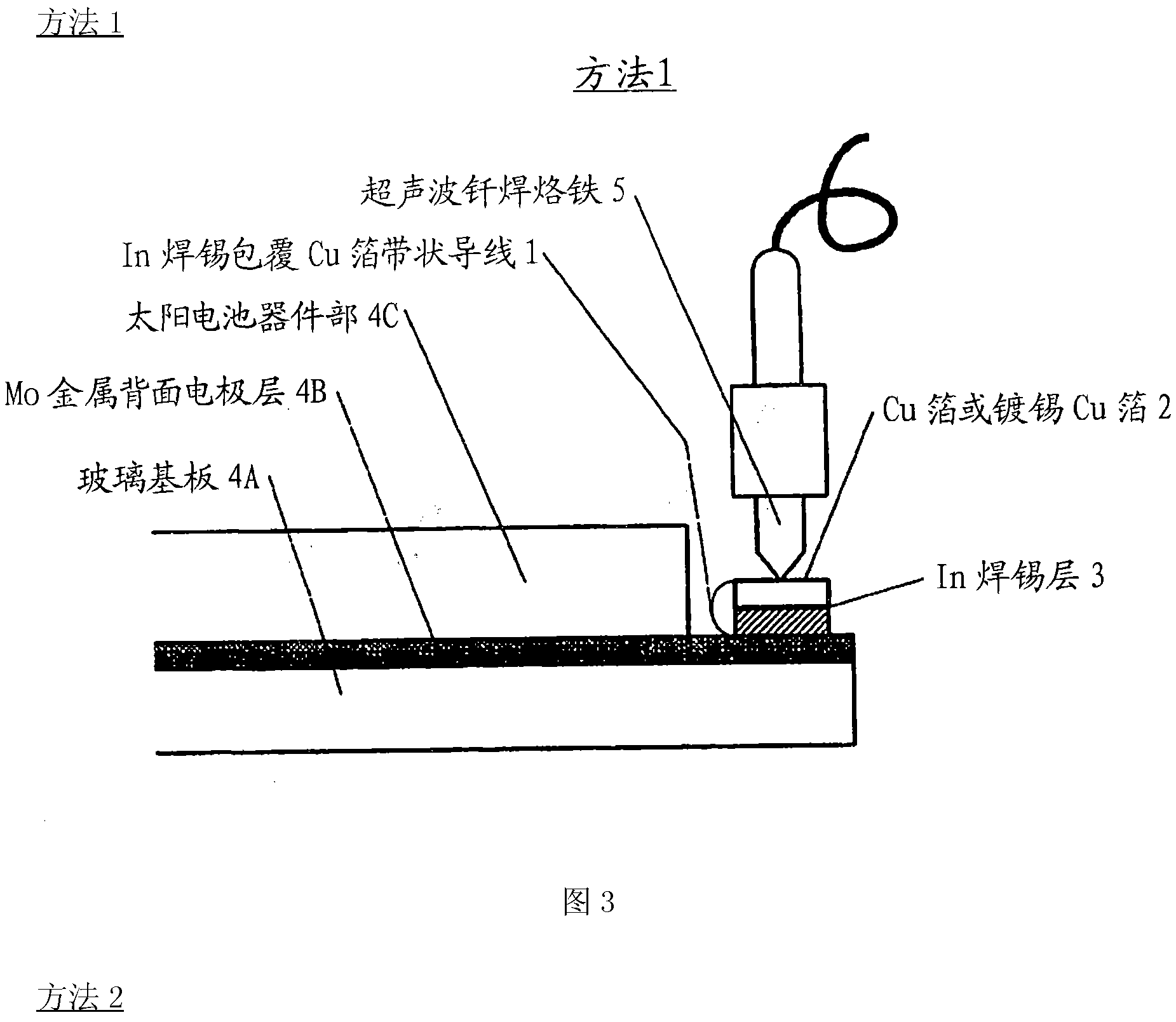

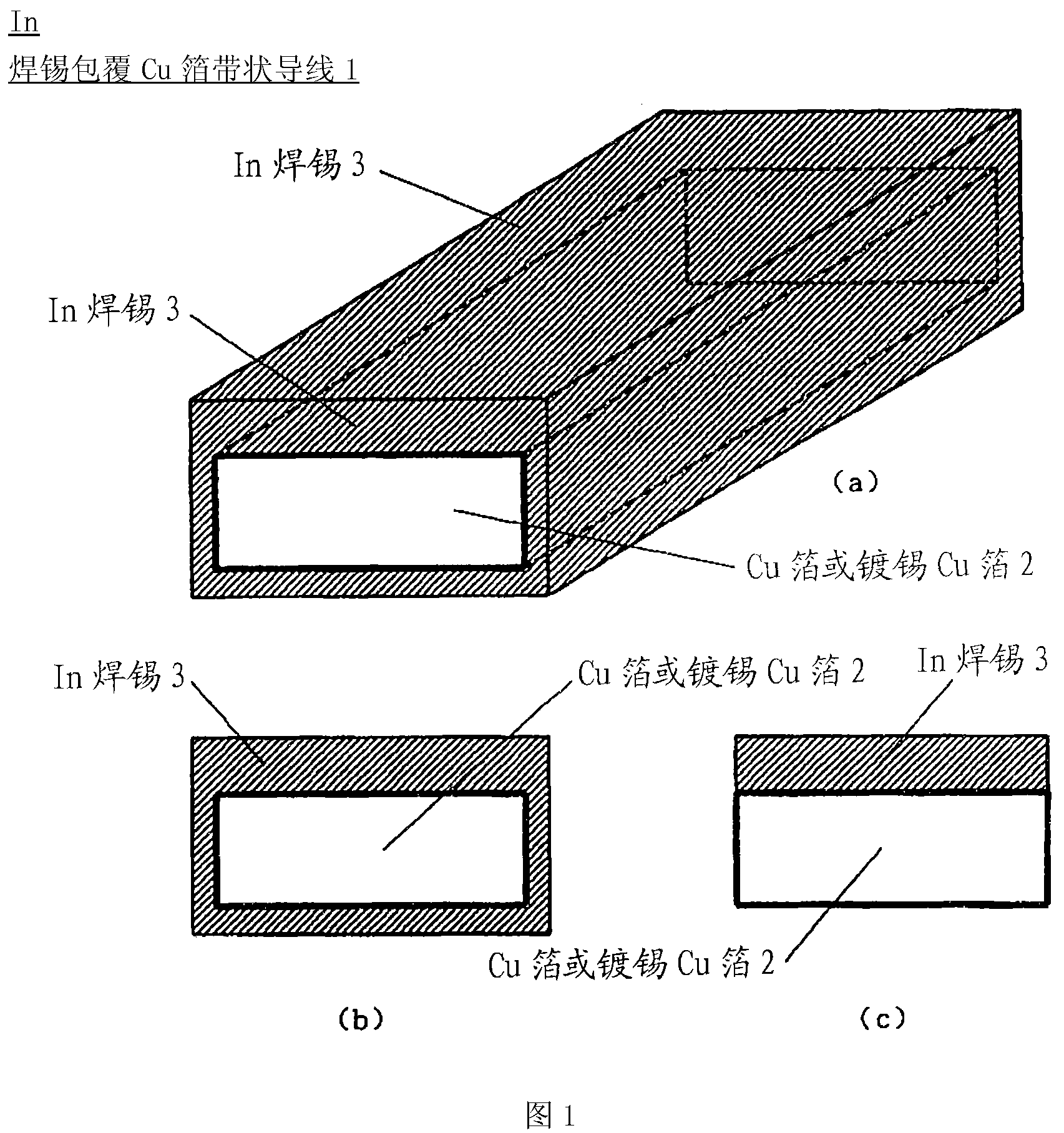

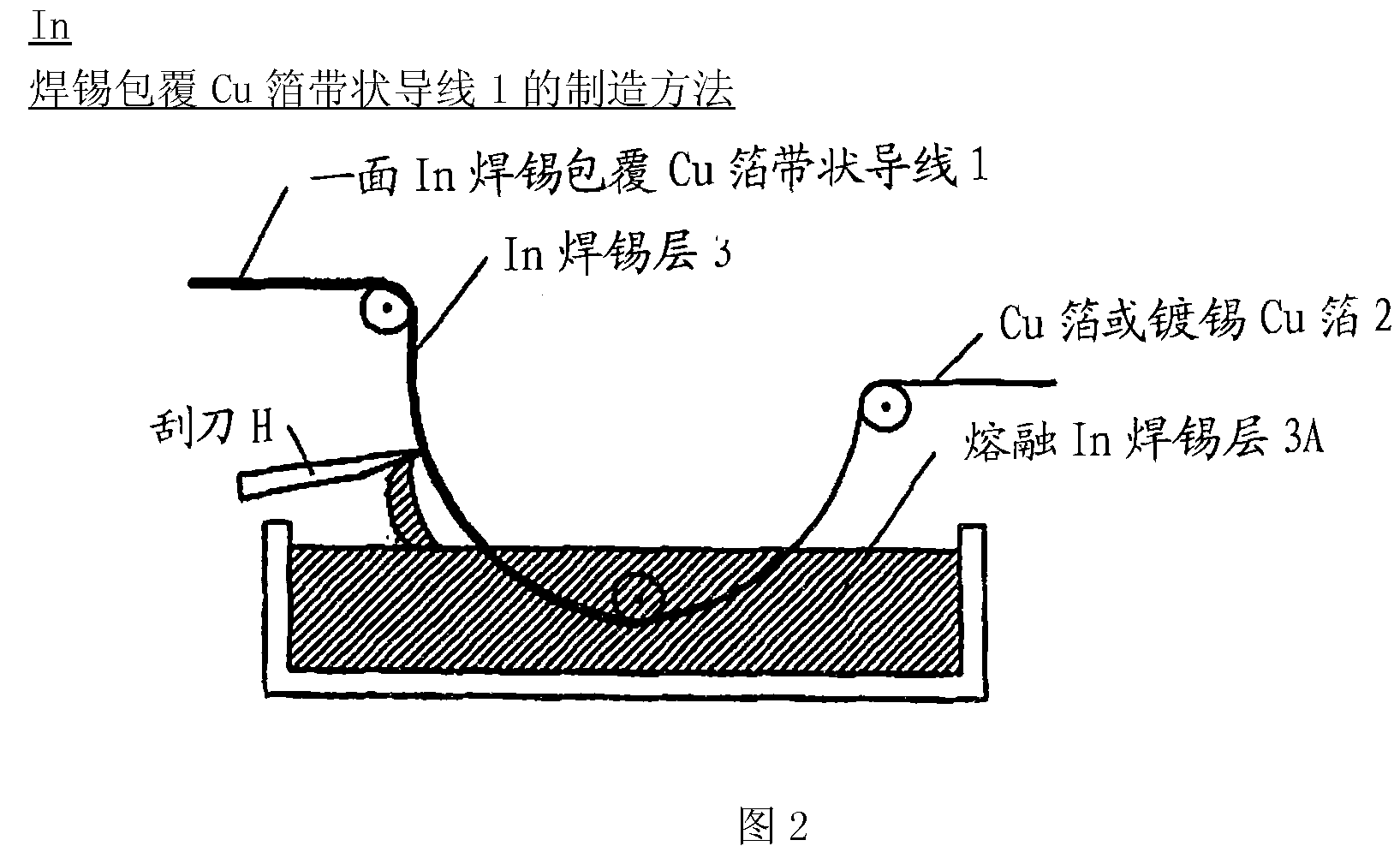

[0036] The present invention relates to an electrode film (or layer) or conductive film ( or layer) In solder-clad copper foil ribbon wires that are conductor-connected to ribbon wires (copper foil or tinned copper foil ribbon wires) and In solder or In solder-clad tinned copper foil ribbon wires conductor connection method.

[0037] Since the electrode film (or layer) or conductive film (or layer) of the above-mentioned electronic device is formed on the glass substrate, therefore, its material uses metals such as Mo or ITO (transparent conductive film) other than Cu, and the film (or layer) The thickness is extremely thin, the mechanical strength is low, and it is easy to break.

[0038] Therefore, the solder used for conductor connection of an electronic device mounted on a substrate other than a glass substrate, or a conductor connection method using the solder cannot be directly used.

[0039] Therefore, first of all, electrode films or conductive films and strip wires ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com