Heat dissipation substrate for encapsulating power module

A heat dissipation substrate and power module technology, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., to achieve the effect of improving heat dissipation, increasing service life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

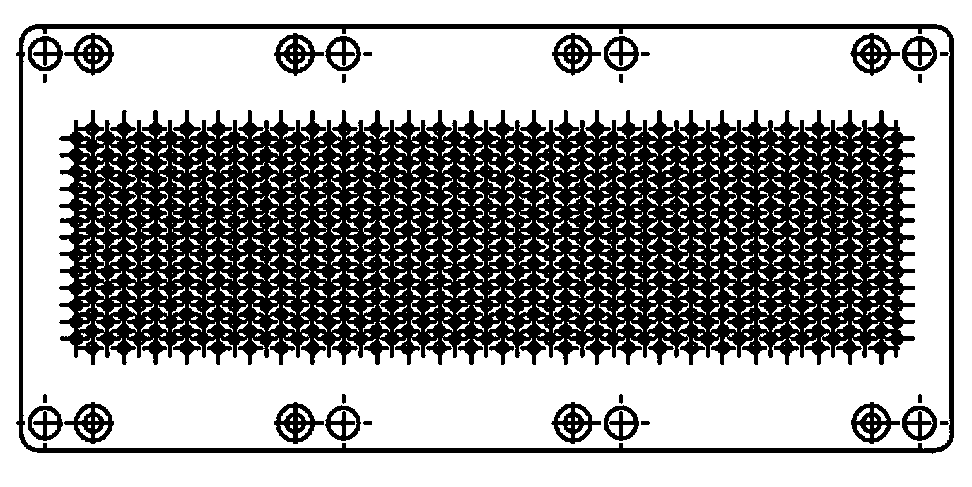

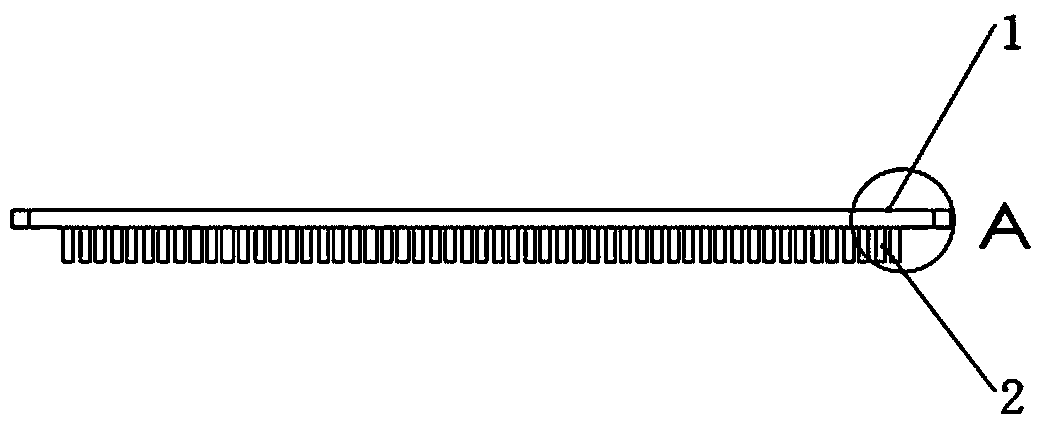

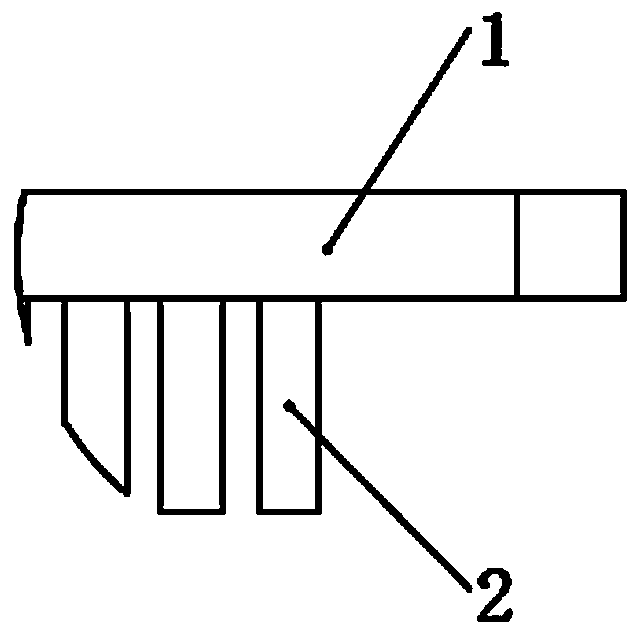

[0019] As shown in the figure, the thickness of the substrate 1 is between 1-10 mm; the area of the substrate 1 is between 0.01-0.5 square meters; the heat dissipation pin 2 is made of pure copper, copper alloy, pure aluminum, aluminum alloy One of the materials, its shape is one of cylinder, truncated cone, cube or rectangle, and the height of the cooling pin 2 is between 2-50 mm.

[0020] The substrate 1 and the cooling pin 2 are connected by welding. The welding uses Sn-containing welding materials in SnPb, SnAg, SnAgCu, and PbSnAg. The maximum welding temperature is controlled between 100-400°C.

[0021] The connection between the base plate 1 and the heat dissipation pin 2 is through press fit.

[0022] The substrate 1 and the cooling pin 2 are connected by ultrasonic welding.

[0023] The base plate 1 and the cooling pin 2 are molded by integral casting.

[0024] The base plate 1 and the cooling pin 2 are integrally formed by forging.

[0025] The base plate 1 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com