Electrolytic copper foil having heat resistance and lithium ion secondary battery comprising same

An electrolytic copper foil, a secondary technology, applied in the direction of secondary batteries, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of tabs falling off, unable to provide sufficient protection for copper foil, high current resistance, etc., to achieve excellent The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

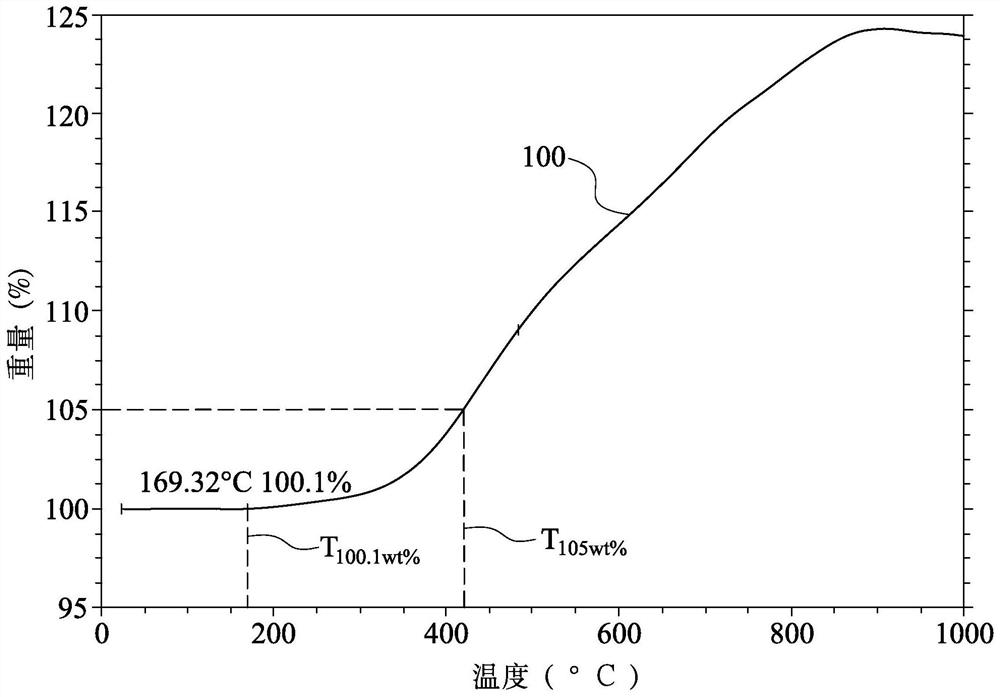

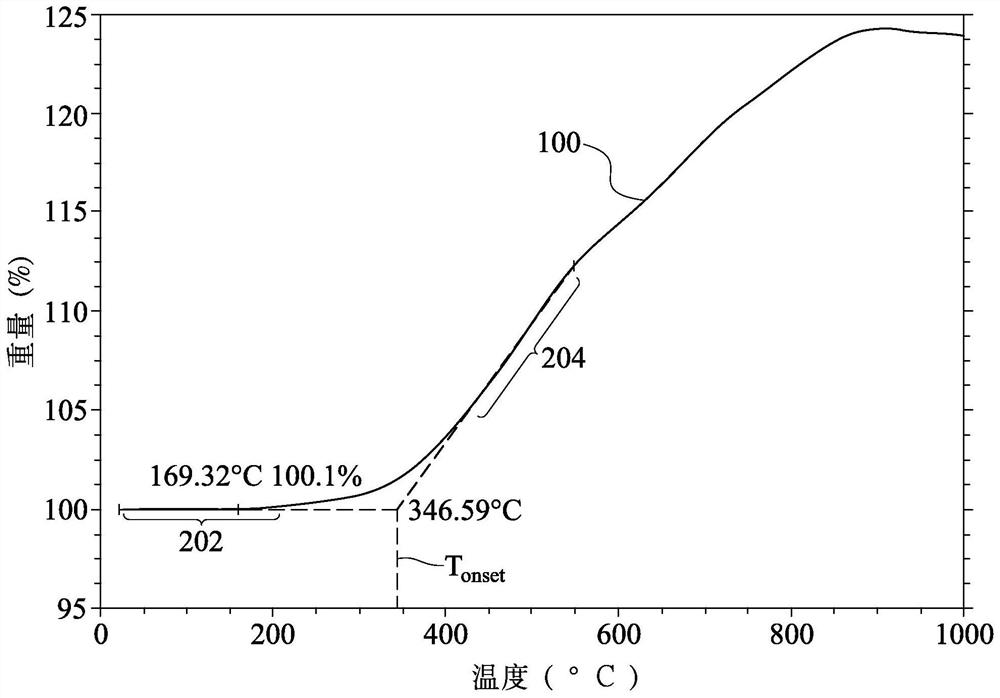

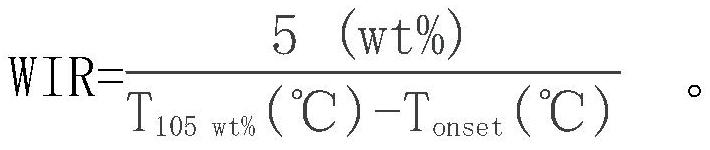

[0023] The electrodeposited copper foil described herein is made using roller deposition, and the electrodeposited copper foil has a roller side and a deposition side. The copper foil has excellent heat resistance, and can be used as a current collector of a lithium ion secondary battery. The copper foil has a roughness Rz controlled to be less than or equal to 2 μm, and has characteristic thermal properties determined by TGA, for example, a major weight increase of 105 wt% in a temperature range of 350°C to 501°C. Ultrasonic welding between copper foil and nickel foil tabs provides an excellent solder joint with low separation to provide good mechanical and electrical contact.

[0024] As used herein, the "roller side" of the copper foil is the surface of the copper foil that comes into contact with the roll used during the electrodeposition process, while the "deposition side" is the opposite side or contact surface during the electrodeposition process to form the copper foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com