Patents

Literature

59results about How to "Improve brazing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

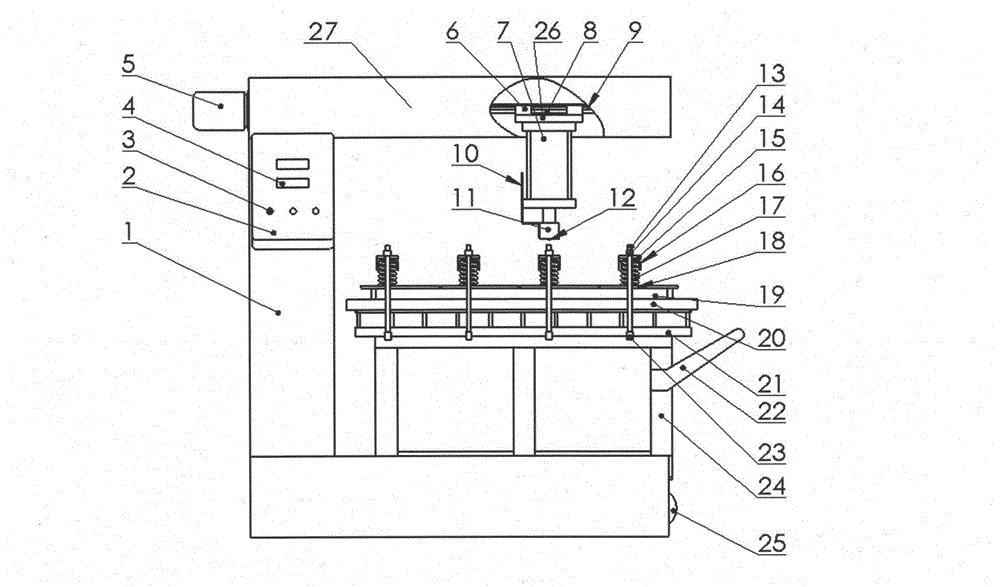

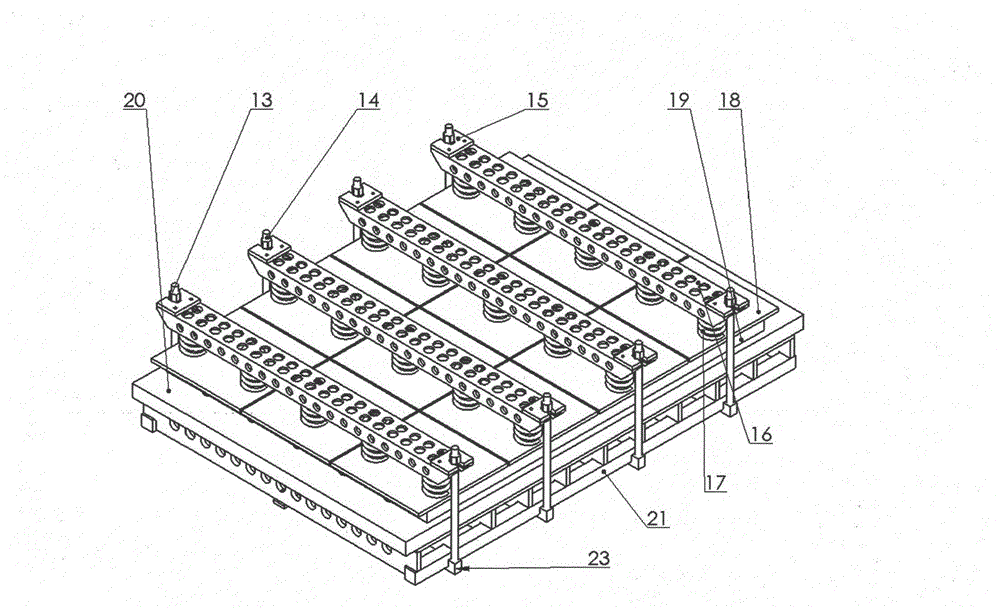

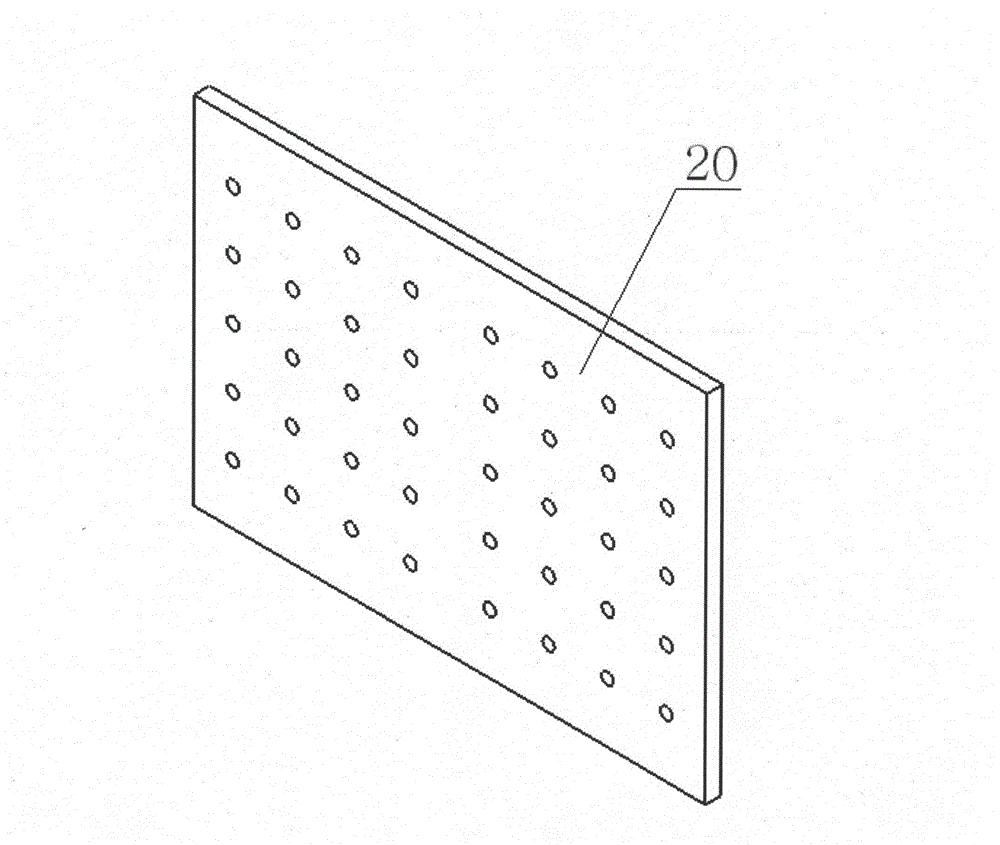

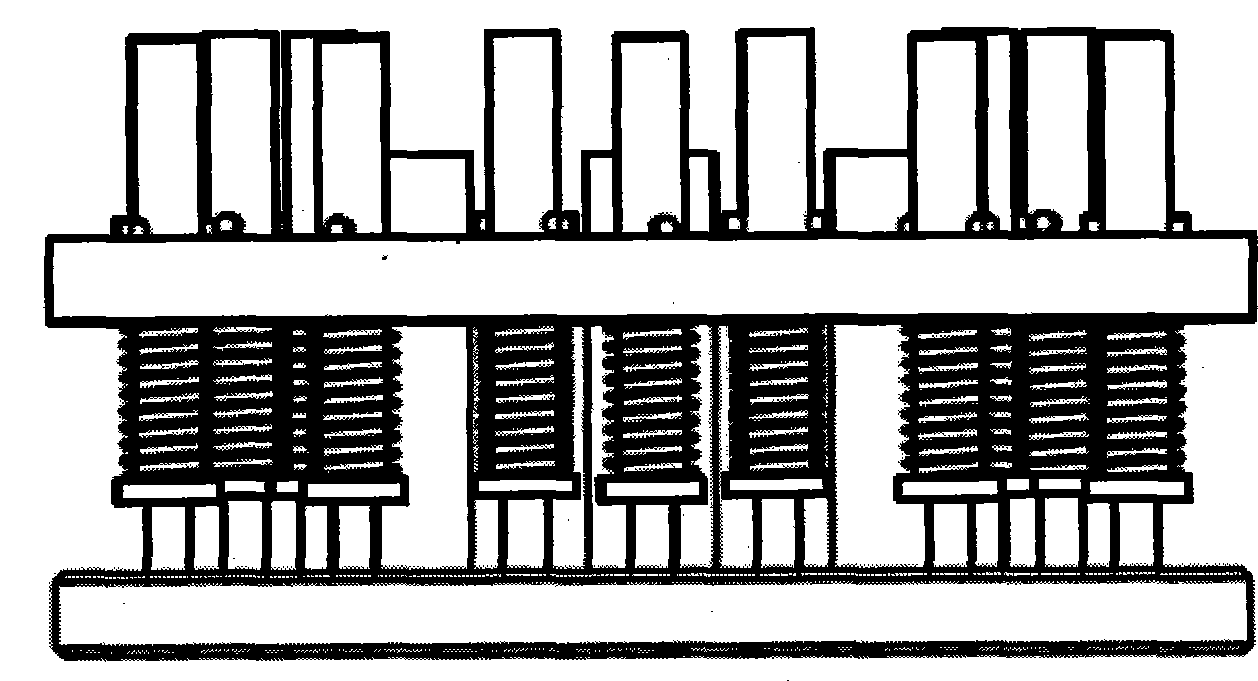

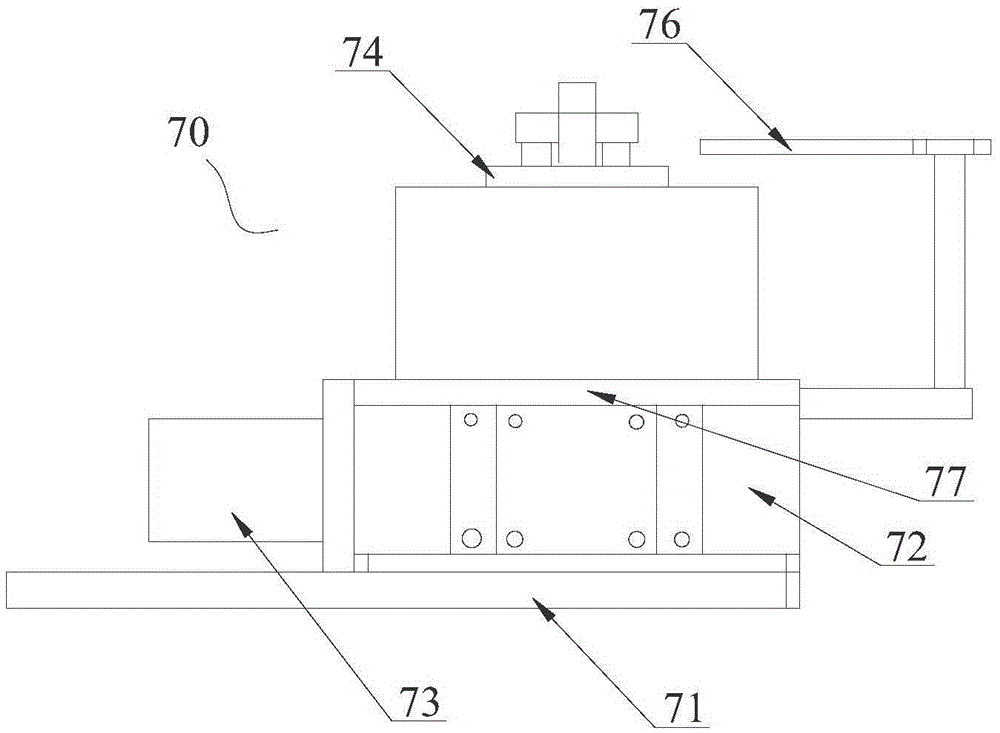

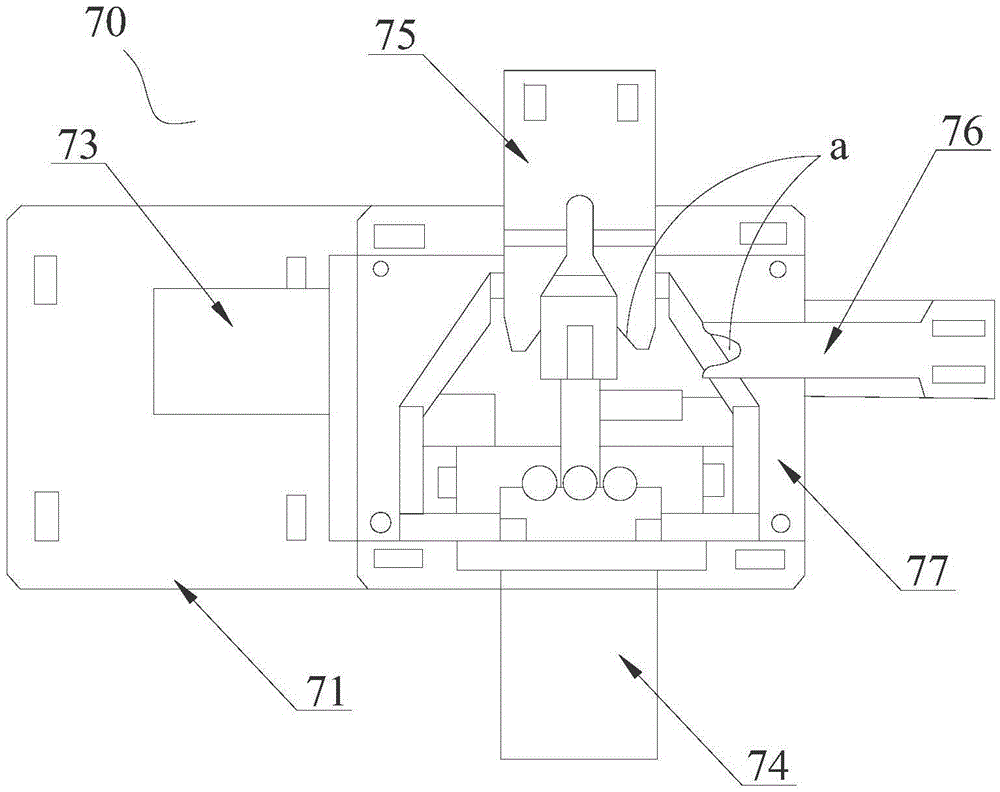

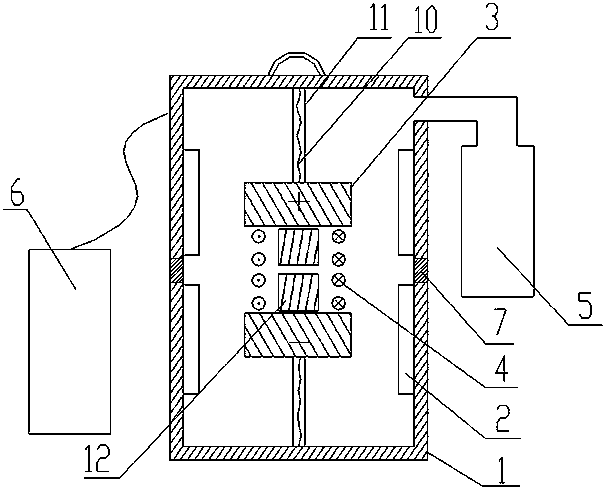

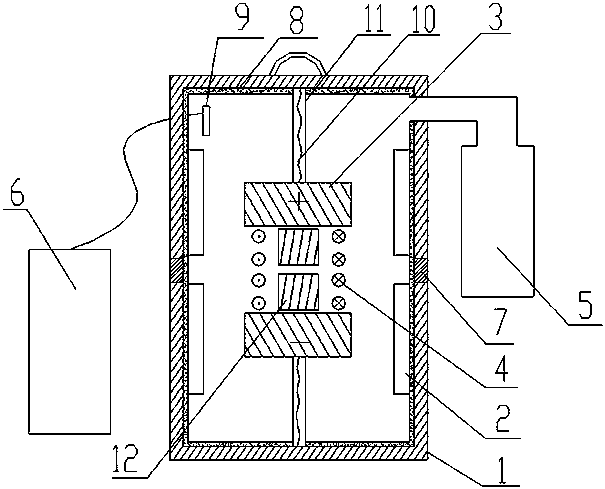

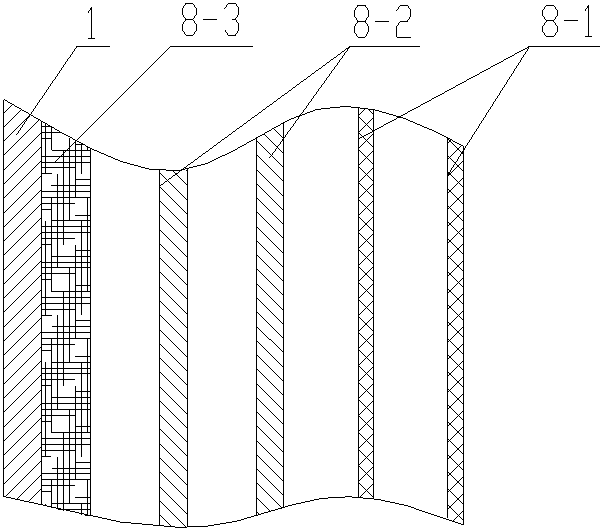

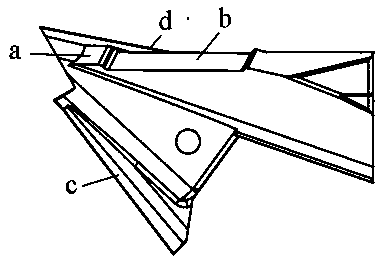

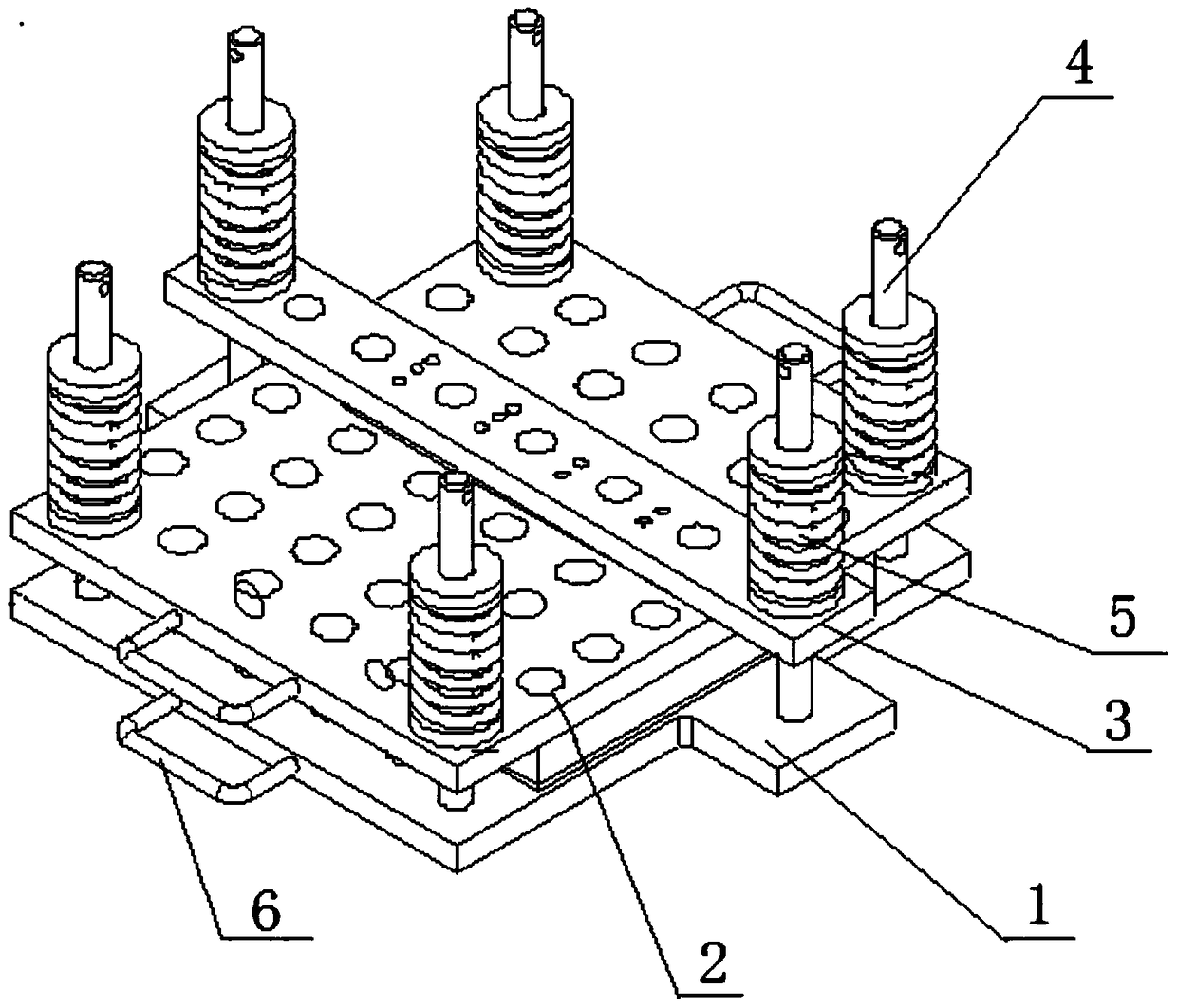

Vacuum brazing tool for water-cooling plate

InactiveCN102873491APrecisely control the total pressing forcePrecisely control the pressing forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal radiation

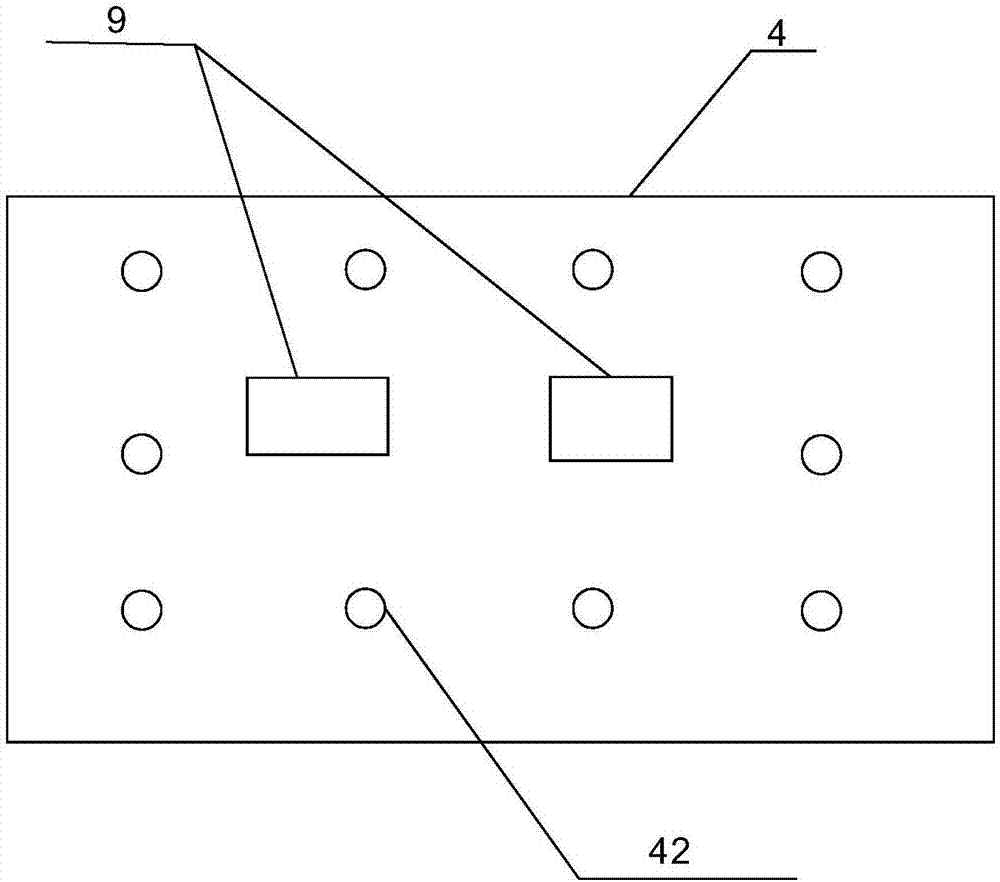

The invention discloses a vacuum brazing tool for a water-cooling plate. The vacuum brazing tool comprises a movable trolley, wherein a clamping device is arranged on the movable trolley and comprises a bottom board, a cover plate and at least one group of clamping device, wherein the bottom board and the cover plate are vertically superposed; and the vacuum brazing tool is characterized by further comprising a C-shaped main frame, wherein a suspension beam is arranged on the upper part of the C-shaped main frame, a vertical moving device which can move along the direction of the suspension beam is arranged on the lower side of the suspension beam, a pressing block is arranged on the bottom end of the vertical moving device, and at least one load sensor is arranged on the bottom of the pressing block. According to the tool, total press fitting force on the water-cooling plate can be accurately controlled, the press fitting force on each part of the water-cooling plate is basically consistent, and thus, the deformation of each clamp is slight and consistent, the service life of each clamp is prolonged, round hole structures of parts such as the bottom board and a pressing board are beneficial to the internal radiation heat adsorption and heat dissipation of a product in a vacuum brazing furnace, so that the brazing efficiency is improved, after the tool is adopted to weld the water-cooling plate, the once finished product rate can reach above 90%, and the tool can be widely applied to the assembling of the water-cooling plate before the vacuum brazing.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

Low-temperature nickel-based solder for soldering

InactiveCN101898283AExcellent high temperature strengthExcellent corrosion resistanceWelding/cutting media/materialsSoldering mediaDecompositionNitrogen

The invention discloses low-temperature nickel-based solder for soldering. The nickel-based solder based on a NiCrSiP system comprises the following components by weight percentage: 21.5%-28% of Cr, 2.0%-3.5% of Si, 7.0%-9.0% of P and 59.5%-69.5% of Ni. The solder of the invention is superior to BNi-5 solder in both high-temperature strength and corrosion resistance, and the nickel-based solder is applicable to both the vacuum-soldering method and the method for soldering in a continuous soldering furnace under the protective atmosphere (such as nitrogen and ammonia decomposition atmosphere) and particularly suitable for soldering the metal carriers (stainless steel materials) in the automobile exhaust purifiers and automobile EGR (exhaust gas recirculation) system, thus absolutely substituting the existing BNi-5 solder.

Owner:李昕

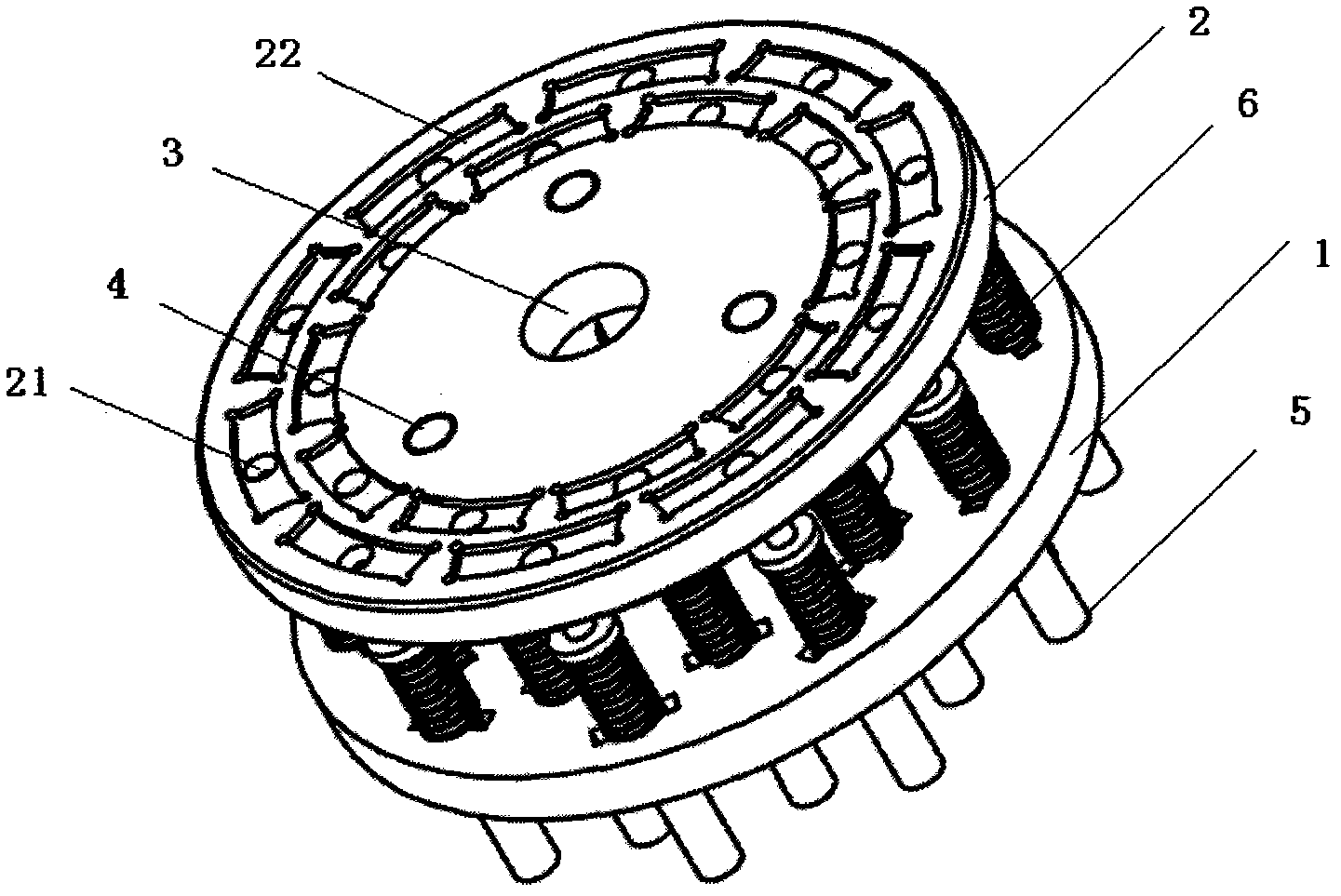

Welding fixture

The invention relates to a welding fixture which comprises an upper pressure plate and a lower pressure plate, wherein the upper pressure plate and the lower pressure plate comprise central positioning holes which are arranged coaxially, the lower pressure plate is provided with a tooth block positioning hole, a tooth block mounting groove is arranged on the lower surface of the lower pressure plate and the welding fixture is characterized in that a tooth block positioning screw rod and a tooth block pressure spring are mounted between the upper pressure plate and the lower pressure plate. The welding fixture is simple in structure and can always keep the fastening connection between a tooth block and the welding surface of a basal body by high-temperature welding and avoid the phenomena of looseness and poor welding.

Owner:江苏华昌工具制造有限公司

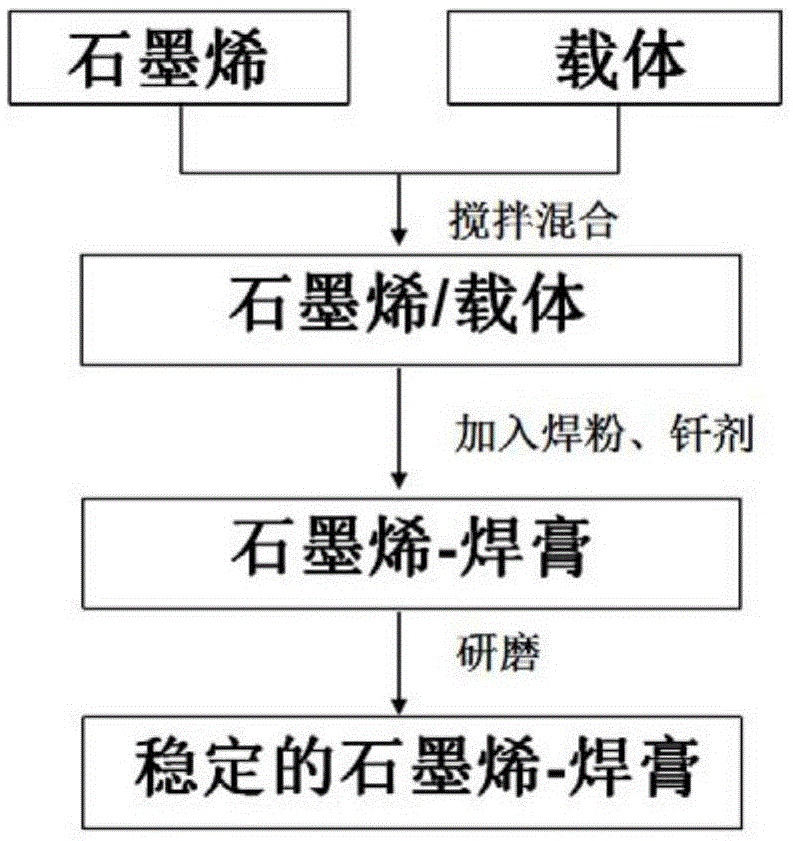

Silver brazing paste and preparation method thereof

ActiveCN105643148AImprove the problem of poor thermal and electrical conductivityAccelerates the brazing processWelding/cutting media/materialsSoldering mediaElectricityGraphite

The invention provides silver brazing paste and a preparation method thereof. The method comprises the following steps: (1) graphene is dispersed in a carrier with a certain viscosity to obtain a graphene / carrier dispersion system; (2) silver welding powder and a brazing agent are added in the graphene / carrier dispersion system to obtain a graphene / carrier / silver welding powder / brazing agent mixed system; and (3) the mixed system, obtained in the step (2), is grinded to obtain the high heat conductivity and high electricity conductivity type solver brazing paste with uniformly dispersed graphene. The silver brazing paste can effectively solve the problems of weak electricity and heat conductivity and long welding time in traditional welding paste. The method has such advantages as simple operation and high practicability, and greatly improves all performances of the traditional welding paste.

Owner:研迈电子材料(上海)有限公司

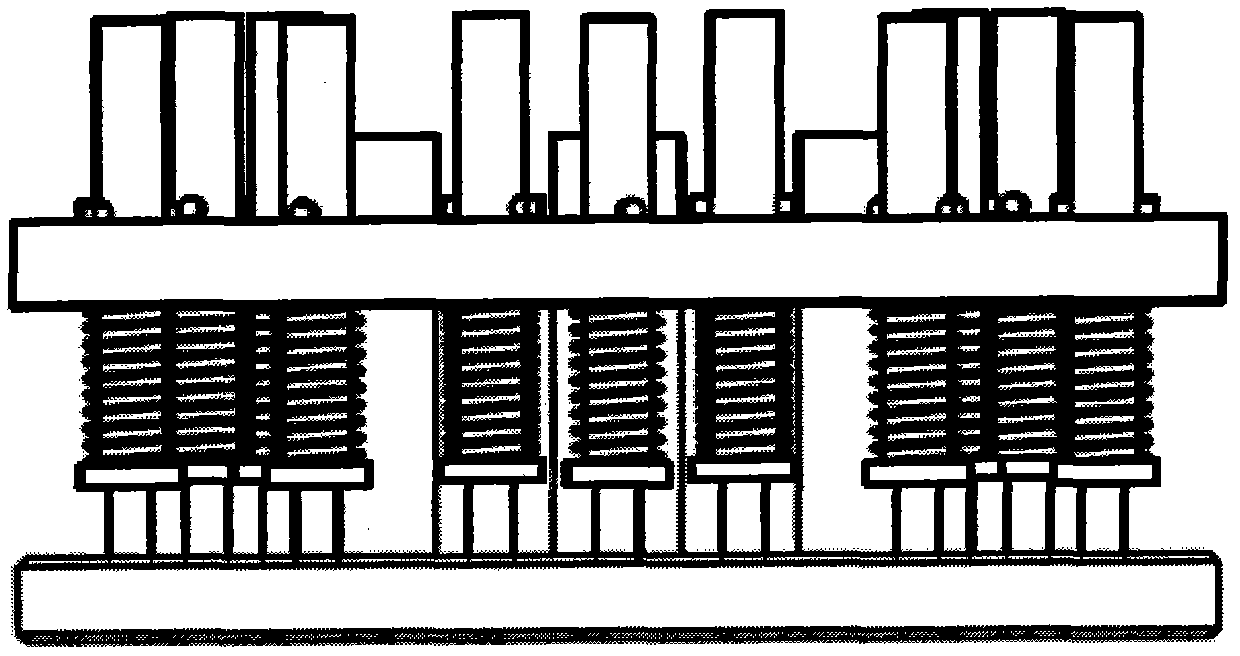

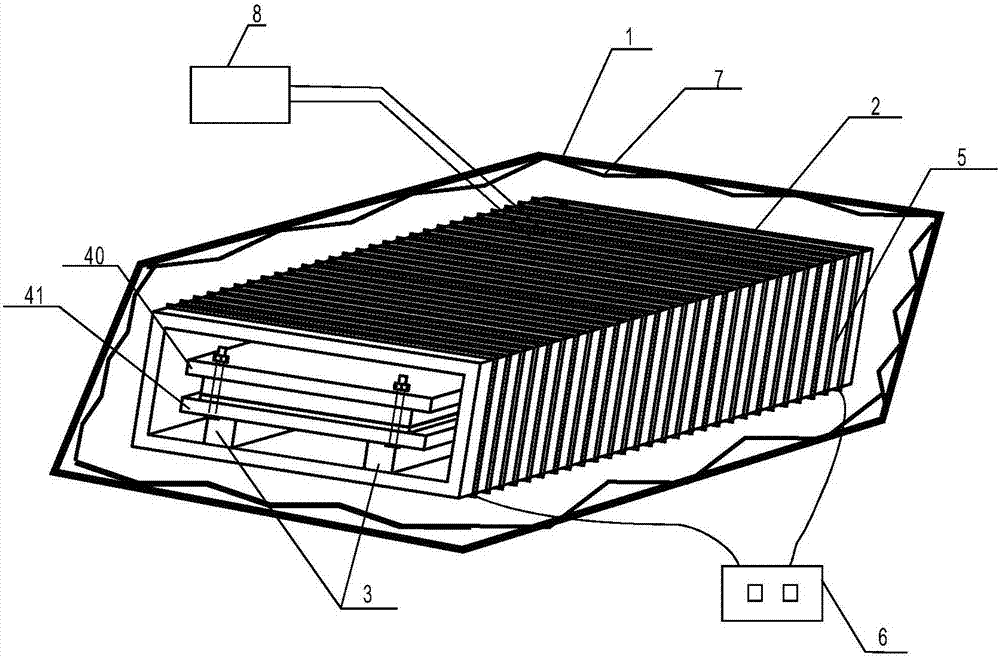

Lamination-based vacuum brazing method for core part of plate-fin type aluminum heat exchanger

ActiveCN102489814AImprove brazing efficiencyImprove consistencySoldering apparatusControllabilityPlate fin heat exchanger

The invention discloses a vacuum brazing technological method for a core part of a plate-fin type aluminum heat exchanger. A vacuum brazing technology adopted for brazing the core part of the plate-fin type aluminum heat exchanger comprises the steps of: laminating and assembling a plurality of heat-exchanger core parts with consistent side pate dimensions in a height direction and are fixed through a flexible clamp, additionally arranging a sandwiched structure composed of two layers of mica tapes and one layer of pure aluminum or a 3003 aluminum alloy plate between every two adjacent heat-exchanger core parts, feeding into a vacuum brazing furnace for brazing after assembly, and separating the plurality of brazed heat-exchanger core parts after the plurality of heat-exchanger core parts are brazed and discharged out of the furnace. According to the invention, as the plurality of heat-exchanger core parts are laminated and assembled for vacuum brazing, the advantages of simple process, strong operability, good controllability and high brazing efficiency are achieved, the production cost is effectively reduced, and the consistency in product quality is increased.

Owner:ZHEJIANG UNIV

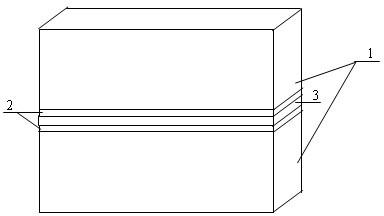

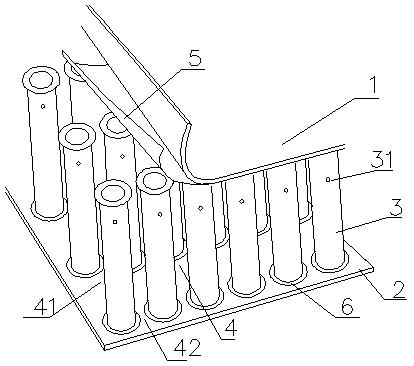

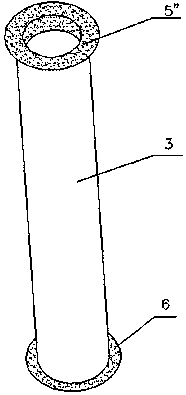

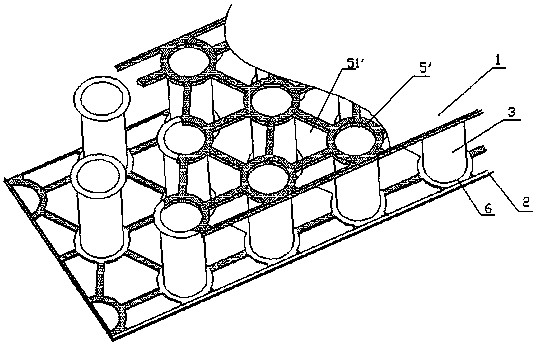

Sandwich metal plate

ActiveCN108397679APermanent service lifeLow intensitySheets/panelsMetal layered productsThermal insulationEngineering

The invention relates to a sandwich metal plate. The sandwich metal plate comprises an upper panel, a lower panel and a plurality of core tubes, wherein the multiple core tubes are arranged between the upper panel and the lower panel, penetrating air passages are arranged among the multiple core tubes, and the core tubes as well as the upper panel and the lower panel are brazed through fore-and-aft and / or left-and-right circulating heating by utilizing high-temperature gas through the air passages. On one hand, the sandwich metal plate has the advantages of light weight, high strength, heat insulation and the like, and on the other hand, the sandwich metal plate cannot be deformed by heat difference, so that the permanent service life of the sandwich metal plate is guaranteed.

Owner:张跃

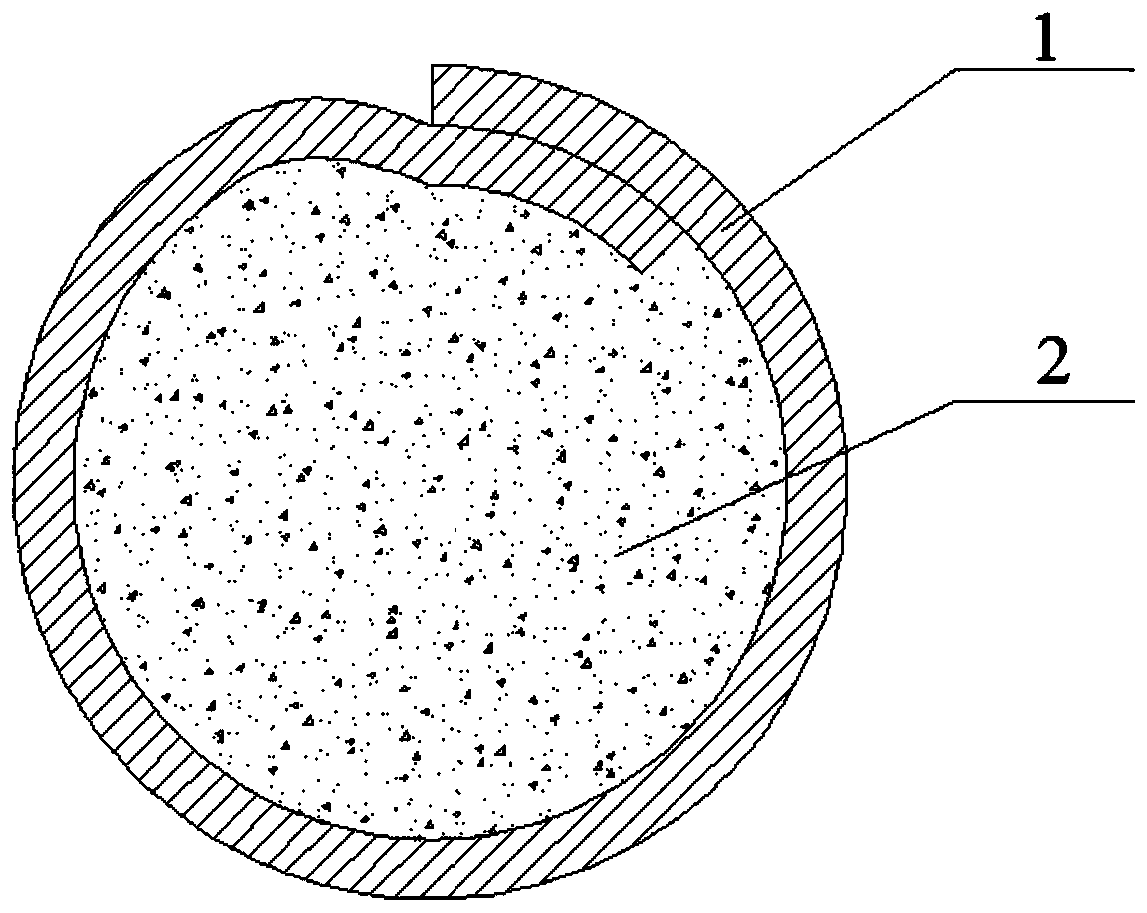

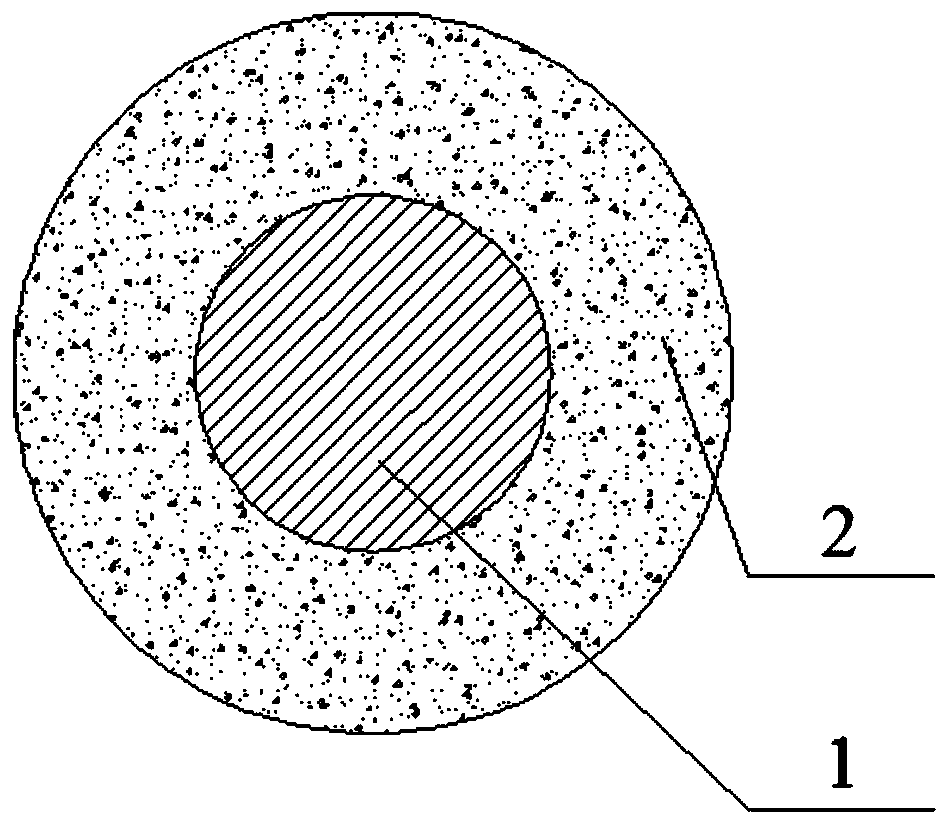

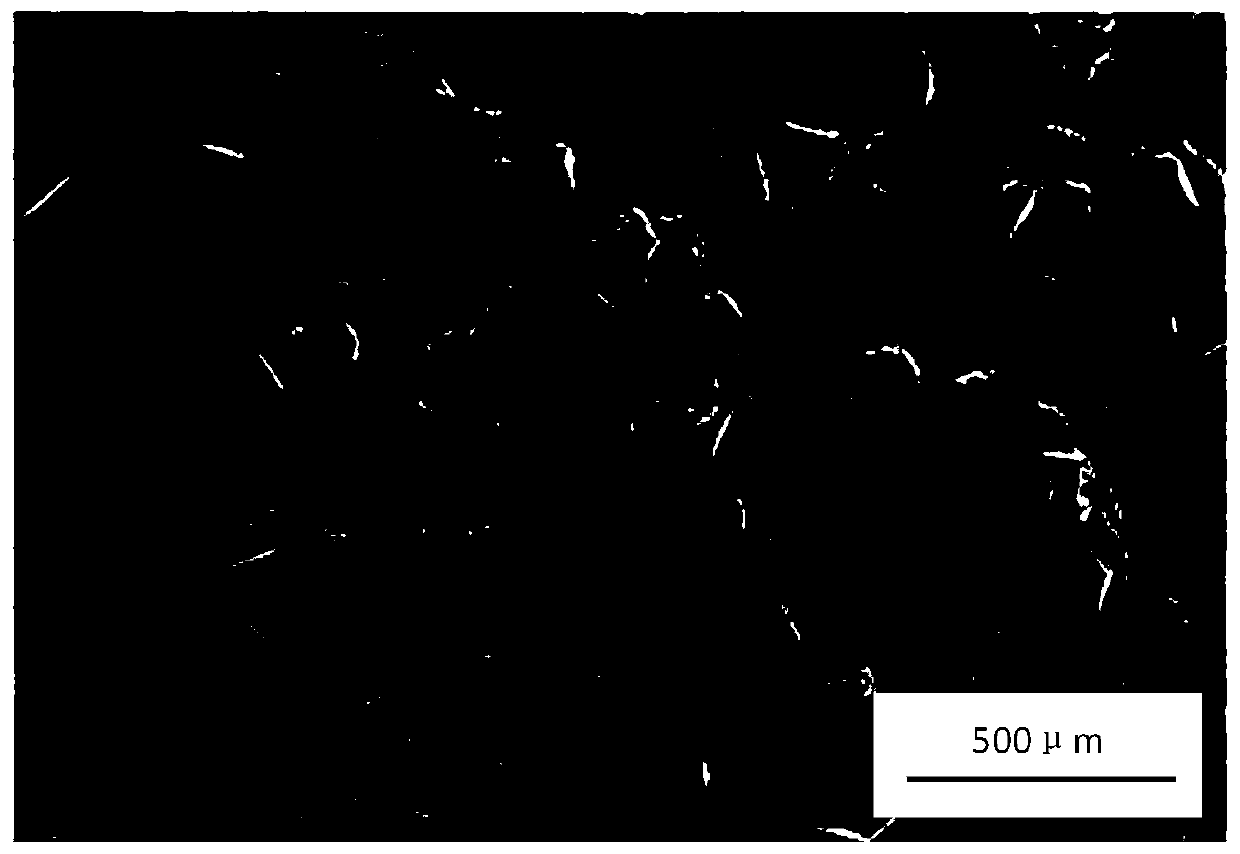

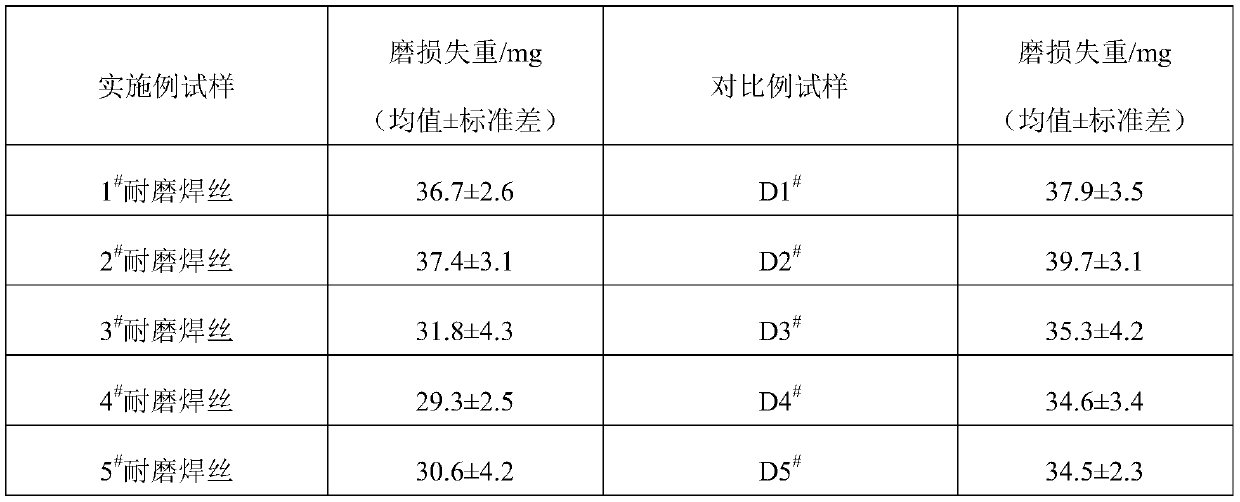

Wear-resistance medicine core composition, wear-resistance welding wire and preparation method and application thereof

ActiveCN110977248AReduce heat damageImprove brazing activityWelding/cutting media/materialsSoldering mediaLinear expansion coefficientNickel base

The invention relates to a wear-resistance medicine core composition, a wear-resistance welding wire and a preparation method and application thereof. The wear-resistance medicine core composition comprises a wear-resistance material and the balance of a filling material; the wear-resistance material is 0.6-10 wt.% of the wear-resistance medicine core composition; the wear-resistance material comprises diamond particles; the filling material comprises transition metal oxide powder and nickel base alloy powder; and the transition metal oxide powder is 12-65 wt.% of the filling material. The wear-resistance medicine core composition uses the diamond particles as wear-resistance filling materials to form wear-resistance coating layers during welding or braze coating; and transition metal oxides are used as the filling material, so that the heat loss of diamond is reduced, the brazing activity is improved, and meanwhile, the linear expansion coefficient of clad metal is reduced.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

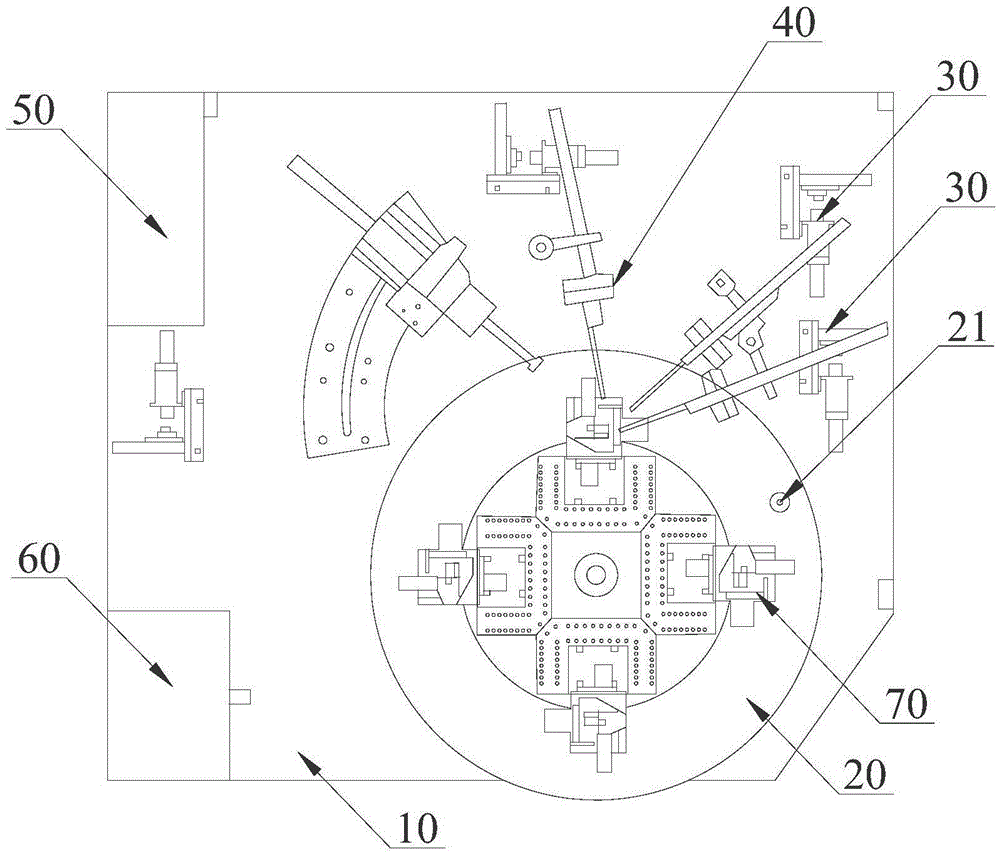

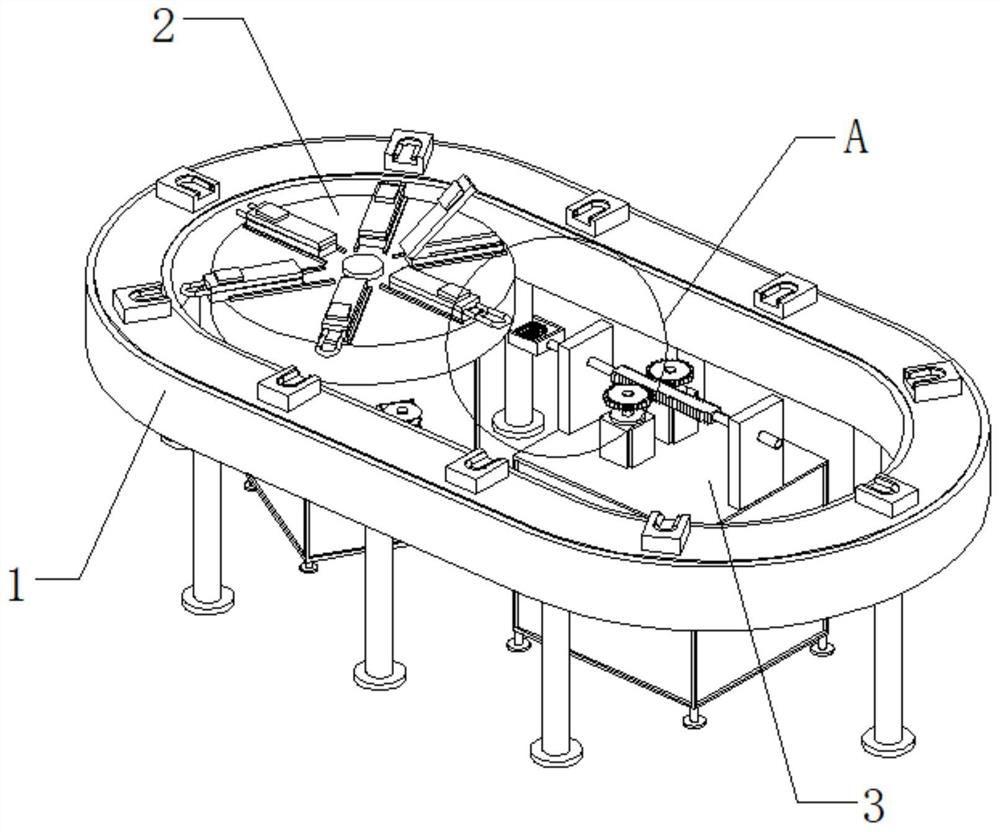

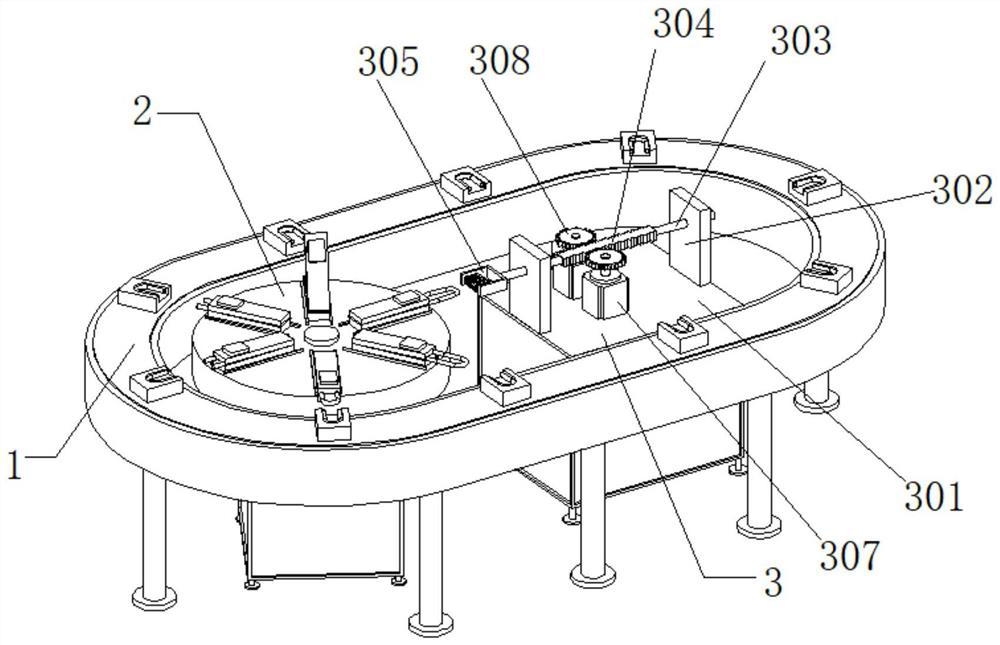

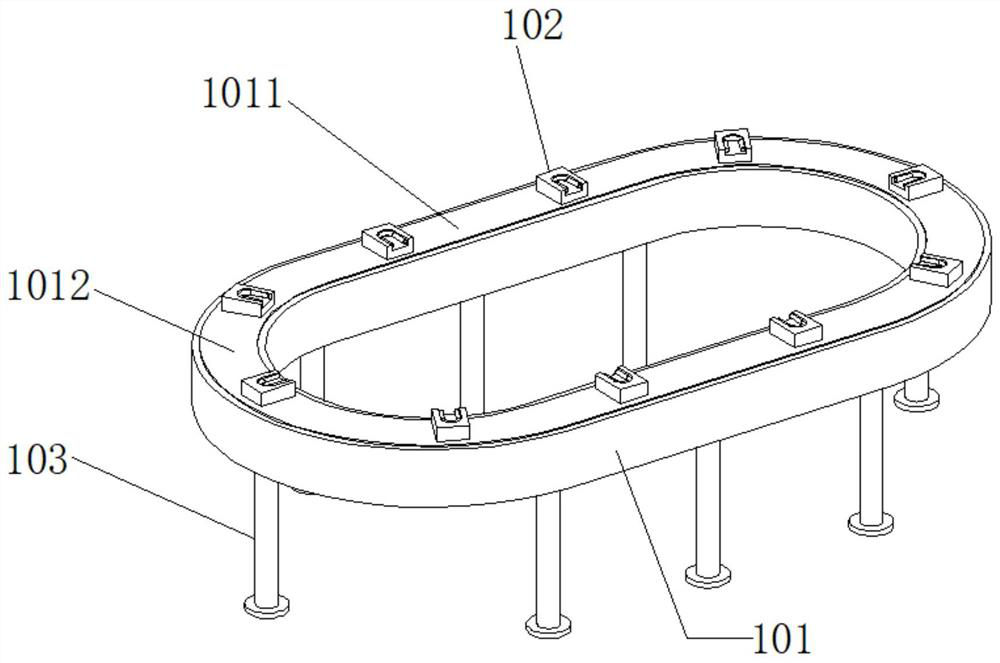

Automatic flame brazing welding machine of rotary disc type four-way valve

InactiveCN105458443ASimple structureImprove brazing efficiencyHeating appliancesMetal working apparatusFour-way valveElectrical control

The invention relates to an automatic flame brazing welding machine of a rotary disc type four-way valve. The automatic flame brazing welding machine comprises a working platform, a brazing welding fixture working table, an automatic wire feed controller, a brazing welding automatic heater, an electrical control box, an intelligent gas control box and brazing welding fixtures. The brazing welding fixture working table is installed on the working platform. A workpiece detecting sensor is arranged on the brazing welding fixture working table. The automatic feed controller and the brazing welding automatic heater are installed on the tabletop of the working platform and placed around the brazing welding fixture working table. The electrical control box and the intelligent gas control box are installed on the edge of the working platform. The brazing welding fixture working table is in a disc shape. The tabletop of the brazing welding fixture working table and the tabletop of the working platform are parallel. The brazing welding fixture working table can freely rotate around the axis. The four brazing welding fixtures are evenly distributed on the brazing welding fixture working table. The automatic wire feed controller, the brazing welding automatic heater and the workpiece detecting sensor are all electrically connected with the electrical control box. The intelligent gas control box is electrically connected with the brazing welding automatic heater.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Brazing filler metal for braze welding of titanium and titanium alloy, preparation method and braze welding method

ActiveCN102319966AReduce manufacturing costEasy to processWelding/cutting media/materialsWelding/soldering/cutting articlesManufacturing cost reductionIngot

The invention discloses a brazing filler metal for the braze welding of titanium and titanium alloy, which contains 22 to 32 percent by weight of Ni, 1 to 1.5 percent by weight of Al, 0.5 to 1.0 percent by weight of Mn, 0.3 to 0.6 percent by weight of V, 0.6 to 1.0 percent by weight of Sn, 1.5 to 2 percent by weight of Zr and the balance of Cu. The preparation method for the brazing filler metal includes the following steps: weighing the materials, casting the smelted materials to form a brazing filler metal ingot, and then extruding and rolling the brazing filler metal ingot into a braze welding foil. An argon-shielded condenser discharge resistance heating method is adopted to weld titanium with the brazing filler metal. The brazing filler metal does not contain precious metals, i.e. palladium and silver, and thereby the manufacturing cost can be greatly reduced; the processability of the brazing filler metal is good, the inter-annealing processing rate is high, a foil strip which is 0.1mm can be rolled, and the rate of finished products is 80 to 85 percent. Meanwhile, the preparation method is simple, the strength of a braze-welded titanium joint is high, the braze-welding timeis short, the metallic texture of the titanium alloy matrix cannot be changed, and in particular, the invention is suitable for the braze welding of titanium alloy parts of small specifications in large batches.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

A halogen-free pickling flux and its preparation method are disclosed

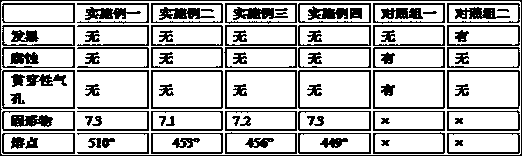

ActiveCN108890172AHigh activityLow melting pointWelding/cutting media/materialsSoldering mediaPorosityHalogen

The invention discloses a halogen-free pickling flux, which comprises the following components in parts by weight: trimethyl borate 50 60 part, methanol 30 parts 40 part, water 10 part 20 part, sodium tetraborate 1 5 part, boric acid 1 3 copies. In the halogen-free pickling flux of the invention, the addition of trimethyl borate protects the workpiece from oxidation, the trimethyl borate is hydrolyzed to generate boric acid through the addition of water, the generated boric acid and sodium tetraborate form a traditional eutectic compound combination of the flux, the melting point is further reduced by the addition of sodium tetraborate, and the activity of the flux is improved. Especially, the addition of halogen is insulated, so that the surface of the brazed workpiece will not be oxidized and blackened, and corrosion and penetrating porosity are not easy to occur, and the brazing activity is high, so that the brazing efficiency is higher.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

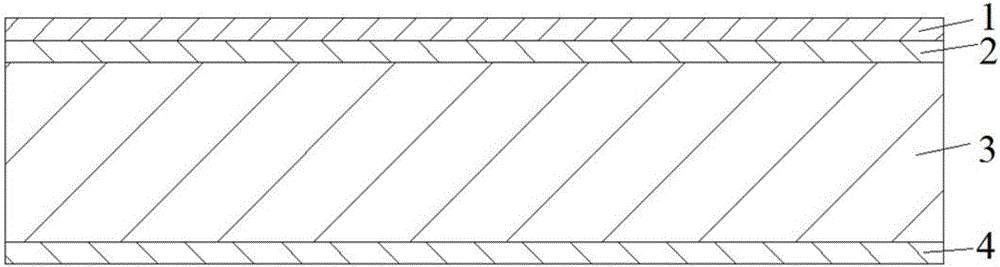

High-strength aluminum alloy composite plate for surface plate of brazing honeycomb plate, core material, wrapping layer and surface material

InactiveCN106735660AHigh strengthStop evaporationSoldering apparatusWelding/soldering/cutting articlesAluminum honeycombAlloy composite

The invention relates to a high-strength aluminum alloy composite plate for a surface plate of a brazing honeycomb plate, a core material, wrapping layers and a surface material. The high-strength aluminum alloy composite plate comprises the surface material, a first wrapping layer, the core material and a second wrapping layer, which are overlapped in sequence, wherein the thickness of the composite plate is 0.5-2.5 mm; the surface material is a 4-series aluminum alloy; the mass content of Si is 4.5-11%; the first wrapping layer and the second wrapping layer are both made of a 1050 aluminum alloy with an Si element; the mass content of Si is 0.7-0.9%; the core material is a 6-series aluminum alloy; and the solidus temperature of the core material is higher than or equal to 580 DEG C. Due to adoption of the high-strength aluminum alloy composite plate for gas carrier brazing, the core material, the wrapping layer and the surface material, the strength can be maintained when the weight of the composite plate can be reduced, in addition, the surface plate of an Mg-containing aluminum honeycomb plate can be applicable to gas carrier brazing, the production efficiency of brazing can be improved, and the production cost can be lowered.

Owner:WUXI YINBANG DEFENSE TECH CO LTD

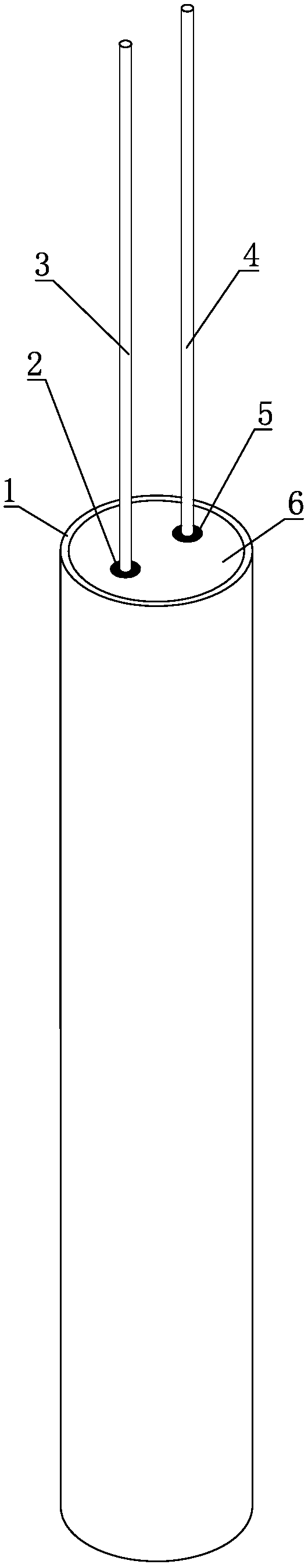

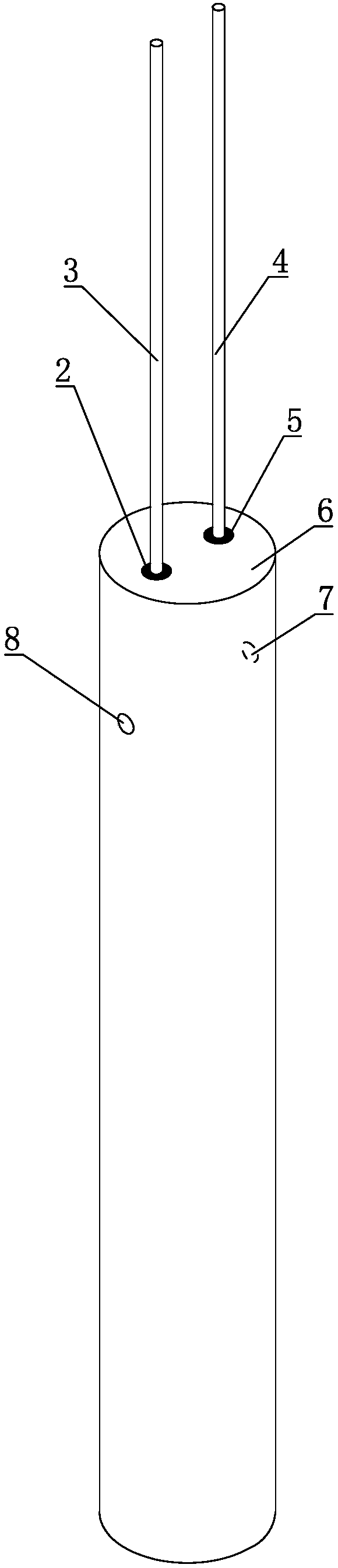

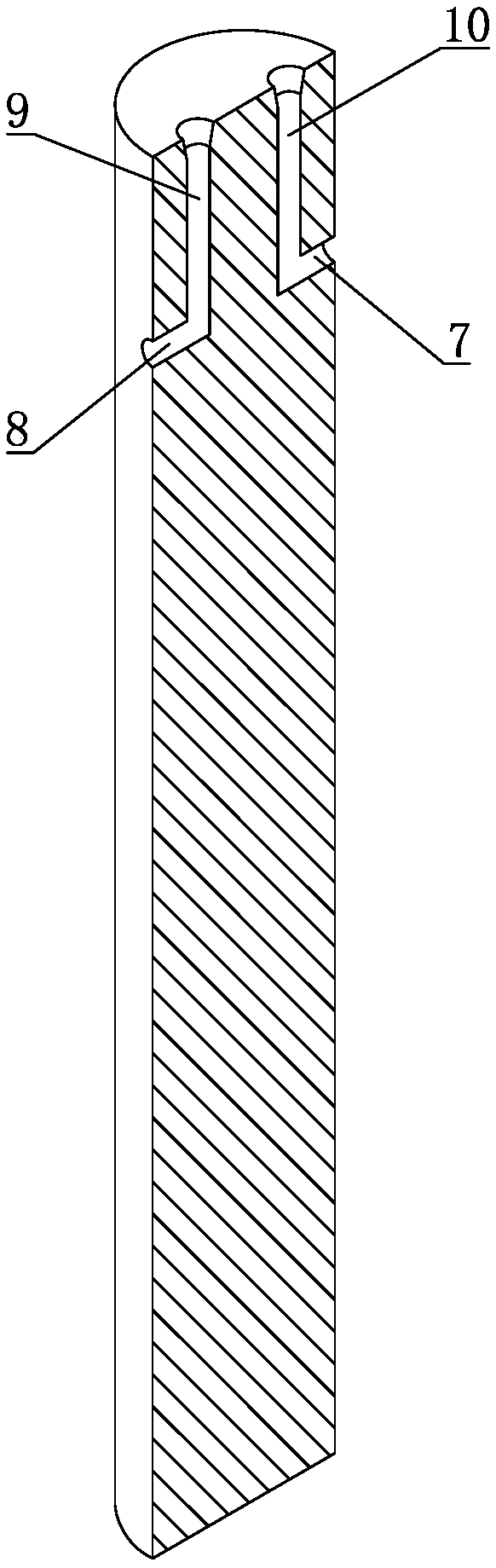

Ceramic heating rod with ceramic core and electrode leads and production method of ceramic heating rod

ActiveCN108617040AReduce areaImprove tensile propertiesOhmic-resistance electrodesHeating element shapesWarm waterWater flow

The invention relates to a ceramic heating rod with a ceramic core and electrode leads and a production method of the ceramic heating rod. The production method is applied to heating of warm water ofa smart toilet, flow of a water heater, electric soldering iron and a hair curler and production of the ceramic heating rod. The ceramic heating rod with the ceramic core and the electrode leads is characterized in that a cylindrical ceramic lining core is provided with a first electrode lead cavity and a second electrode lead cavity; the first electrode lead cavity extends inwards from the end surface of the cylindrical ceramic lining core, passes through a first electrode lead weld leg cavity and then passes outside from a first connection hole in a side wall; the second electrode lead cavity extends inwards from the end surface of the cylindrical ceramic lining core, passes through a second electrode lead weld leg cavity and then passes outside from a second connection hole in the sidewall; the inner surface of the first electrode lead weld leg cavity is provided with a first electrode lead weld leg cavity conducting material sintering layer; and the inner surface of the second electrode lead weld leg cavity is provided with a second electrode lead weld leg cavity conducting material sintering layer. The ceramic heating rod has the advantages that the purposes of a first connecting plate material sintering layer and a second connecting plate material sintering layer are changed, and the tensile property and the brazing efficiency of the electrode leads are improved.

Owner:南平市弘毅电子科技有限公司

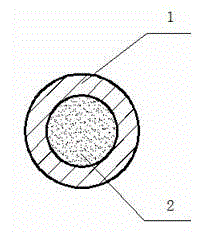

Cored copper welding wire suitable for small area brazing

ActiveCN104690448ALarge specific surface areaIncrease the heating areaWelding/cutting media/materialsSoldering mediaBoron containingOperability

The invention discloses a cored copper welding wire suitable for small area brazing, and belongs to the field of flame brazing or induction brazing of steel structures and copper pipes. The cored copper welding wire consists of an inner core brazing flux and a homogeneous alloy brazing material coating the inner core, wherein the inner core brazing flux is a mixture of boron-containing compounds and fluoride. By virtue of characteristics of high rigidity and good stiffness of a tubular material, operability of the welding wire is improved; by virtue of a characteristic of quick heat absorption of a material with a large specific surface area, the melting speed of the brazing material is increased; by virtue of a characteristic of integration of the brazing flux and the brazing material, the operating process is simplified and the brazing construction efficiency is improved; by virtue of a characteristic of less material per unit length of a hollow material, accumulation of the brazing material is reduced and the brazing material is saved; by virtue of a characteristic of attachment of the brazing flux, the flowability of the brazing material is improved, so that phenomena of loss and waste of the brazing material are reduced and the quality of a brazing joint of a small area brazing seam is ensured.

Owner:HARBIN INST OF TECH

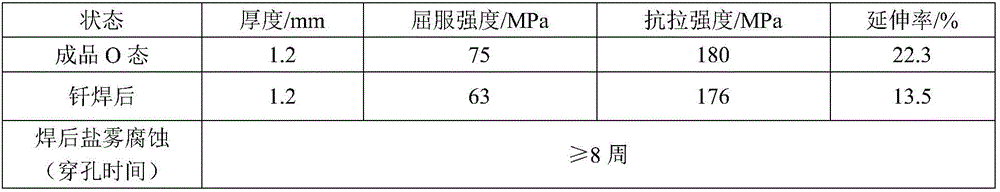

High-strength aluminum alloy composite plate for gas-carrying soldering and cladding material

InactiveCN106626601AImprove corrosion resistanceImprove internal corrosion performanceMetal layered productsAlloy compositeHigh intensity

The invention relates to a high-strength aluminum alloy composite plate for gas-carrying soldering and a cladding material. The cladding material is an aluminum alloy which contains the following components in percentage by mass: 0.8-1.2% of Zn, 0.3-0.6% of Mg, 0.1-0.6% of Mn and 0.1-0.7% of Fe. A core material of the composite plate made of the cladding material is AA3003, and the cladding material is composited on one side of the core material. According to the high-strength aluminum alloy composite plate for the gas-carrying soldering and the cladding material disclosed by the invention, on the premises that the requirements for the corrosion properties of the material are met, and the welding effect of the gas-carrying soldering is not influenced, the strength of the composite plate alloy is improved.

Owner:YINBANG CLAD MATERIAL

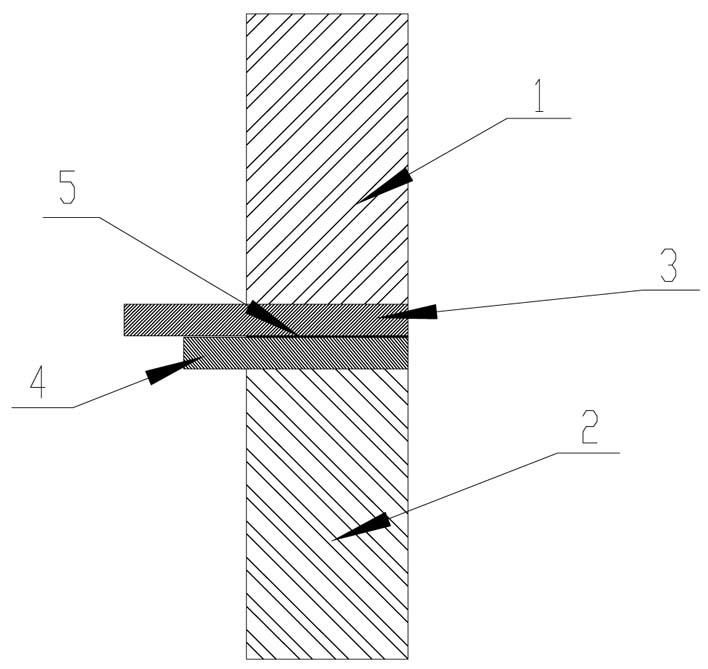

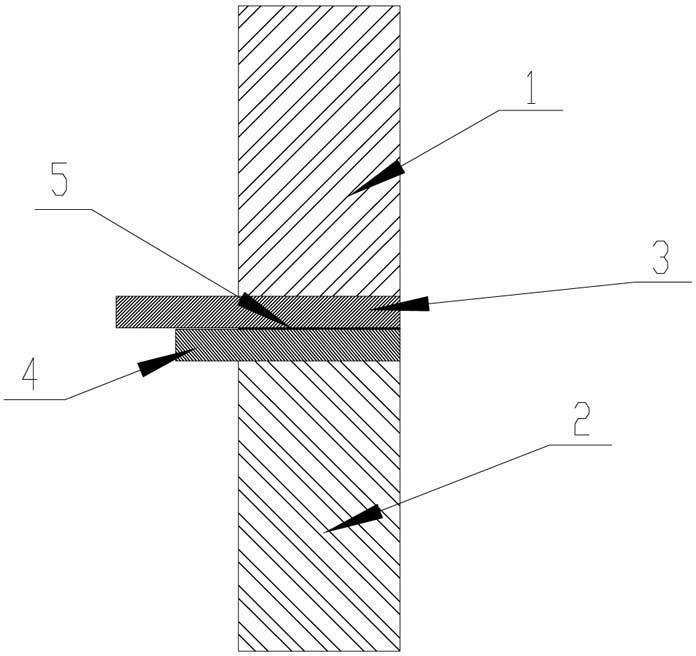

Soldering lug for CAB soldering without soldering flux

InactiveCN106695157APromote wetting and spreadingBreak continuityWelding/cutting media/materialsSoldering mediaManufacturing cost reductionSoldering

The invention discloses a soldering lug for CAB soldering without soldering flux. The soldering lug comprises a brazing filler metal layer and skin layers wrapping the two sides of the brazing filler metal layer. The soldering lug is characterized in that the brazing filler metal layer comprises 5%-15% of silicon, 0.01%-1% of magnesium and 0.05%-0.15% of bismuth, and each skin layer comprises 3%-12% of Si and less than 0.10% of magnesium. According to the soldering lug, no core layer is arranged, the soldering lug is fully molten during soldering and flows into a region to be soldered, a soldering seam is formed and attractive in appearance, the quality of products is good, no residue exists, soldering flux pollution is avoided, and the soldering efficiency of the products is high; due to the fact that a three-layer structure is adopted, the very thin soldering lug can be made, the soldering lug is applied to complex components and occasions where the soldering portions are very narrow, such as CAB soldering without the soldering flux of aluminum alloys of part extrusion, part machining and the like, and therefore the soldering lug is extremely wide in application range; and meanwhile the soldering lug is extremely simple in structure, the manufacturing process is simple, the consumption of materials can be saved, and the manufacturing cost is lowered.

Owner:ZHEJIANG YINLUN MACHINERY

A multi-element heating method for a vacuum diffusion brazing furnace

InactiveCN106392235BImprove heating efficiencyHigh heating temperatureHeating appliancesElectrical resistance and conductanceMetallurgy

The invention provides a diversified heating method for a vacuum diffusion brazing furnace and belongs to the technical field of brazing. The diversified heating method for the vacuum diffusion brazing furnace adopts ternary heating modes: resistance heating, induction heating and furnace body temperature control. In the induction heating mode, an induction coil is adopted to heat. In the furnace body temperature control mode, a heating element in the furnace body is used to heat, so that beneficial effects are obtained. By performing heating treatment by adopting the brazing furnace, the heat conductivity is high, heat is quickly diffused, the heating speed can be remarkably improved, and the heat conductive efficiency is improved. Meanwhile, after annealing / diffusing, the performance index of a heated workpiece is higher.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

High-frequency gas protection brazing furnace and work method thereof

PendingCN106925858AHeating fastImprove brazing efficiencyMetal working apparatusSoldering auxillary devicesEngineeringHeat conservation

The invention discloses a high-frequency gas protection brazing furnace and a work method thereof. The high-frequency gas protection brazing furnace comprises a furnace body, a gas protection device and a controller. The furnace body comprises a shell, a cavity, a support, a clamp, a high-frequency coil, a shielding layer and a temperature detector. The shielding layer is arranged on the inner wall of the shell, the support is arranged at the bottom of the cavity, and the clamp is arranged o the support. The high-frequency coil is wound around the surface of the cavity, and connected with the controller through a wire to form a closed loop. The gas protection device communicates with the cavity through a pipeline. The temperature detector is arranged on the surface of the clamp and connected with the controller. During work, a workpiece is firstly fixed; the controller is started, the high-frequency coil and the clamp generate electro-magnetic induction too generate heat, and the brazed workpiece is fast heated through the heat conductivity of aluminum; and then heat preservation is carried out in the furnace, then cooling is carried out, and the workpiece is taken out. The high-frequency gas protection brazing furnace has the beneficial effects of being fast in heating, saving energy, being environmentally friendly and the like.

Owner:无锡格林沃科技有限公司

Automatic brazing equipment for copper pipes and joints and its control method

ActiveCN111283289BPrecise positioningAccurateMetal working apparatusSoldering auxillary devicesEngineeringMaterials science

The invention discloses an automatic brazing equipment for copper pipes and joints and a control method thereof. Welding machine; the copper tube delivery mechanism is used to deliver the copper tube to each station; the copper tube positioning mechanism includes a positioning plate and a pressing device for positioning and pressing the copper tube; the joint feeding and assembly The mechanism is used to grab the joint and put the joint on the end of the copper pipe; the socket detection mechanism is used to detect the socket effect of the sleeve joint operation; the high-frequency brazing machine is installed on the brazing machine sliding platform The outer side of the copper tube positioning mechanism is located at the brazing station. The invention can realize a series of operation processes such as automatic feeding and positioning of copper pipes, automatic grasping of joints, detection of sockets and defective sockets, and automatic brazing after that, so as to ensure the welding of copper pipes and joints during the automatic brazing process quality and easy operation.

Owner:XIAMEN UNIV OF TECH

Wear-resistant coating composition, wear-resistant welding wire and preparation method and application thereof

ActiveCN110961830ALower oxygen partial pressureReduce heat damageWelding/cutting media/materialsCoatingsMetalPolymer

The invention relates to a wear-resistant coating composition, a wear-resistant welding wire and a preparation method and application thereof. The wear-resistant coating composition comprises a wear-resistant material, a polymer material and a filling material, wherein the wear-resistant material accounts for 0.5wt.%-5.5wt.% of the wear-resistant coating composition, and the wear-resistant material comprises diamond particles; the polymer material accounts for 5wt.-20wt.% of the wear-resistant coating composition; and the filling material comprises transition metal oxide powders and nickel-based alloy powders, wherein the transition metal oxide accounts for 10wt.%-40wt.% of the filling material. According to the wear-resistant coating composition, the diamond is used as a wear-resistant reinforcing material, the transition metal oxide is used as the filling material; when the wear-resistant coating composition is used for welding or brazing coating, the diamond forms a wear-resistant coating; and due to the existence of the filling material, the thermal damage of the diamond is reduced, the brazing activity is improved, and meanwhile, the linear expansion coefficient of cladding metal is reduced.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

High-performance green brazing material

ActiveCN106181109AAvoid serious harmRich brazing materialWelding/cutting media/materialsSoldering mediaHeavy metalsBrazing

The invention discloses a high-performance green brazing material which comprises a main material and an auxiliary material. The auxiliary material is 25-30 parts of a Sn-Ag-Cu lead-free material. The auxiliary material is prepared from 6-10 parts Zn, 4-6 parts of In, 6-8 parts of B, 2-4 parts of P, 3-9 parts of Ni, 5-7 parts of Mn and 7-9 parts of Co. The high-performance green brazing material completely avoids heavy metal carcinogenic elements of lead and cadmium, the brazing material is environment-friendly, and human bodies are prevented from being severely hurt; the brazing material is rich in ingredient, and the brazing performance is improved; the Zn, the In and the P are added in the formula, and therefore the effect of increasing the mobility of the brazing material in a molten state is achieved, and the brazing efficiency is high; the Co and the Ni are added in the formula, and therefore the effect of reinforcing the high strength and toughness of the brazing material is achieved; and the Mn is added in the formula, and therefore the effect of reducing the melting temperature space is achieved.

Owner:ZHENJIANG SIDA ALLOY MATERIALS

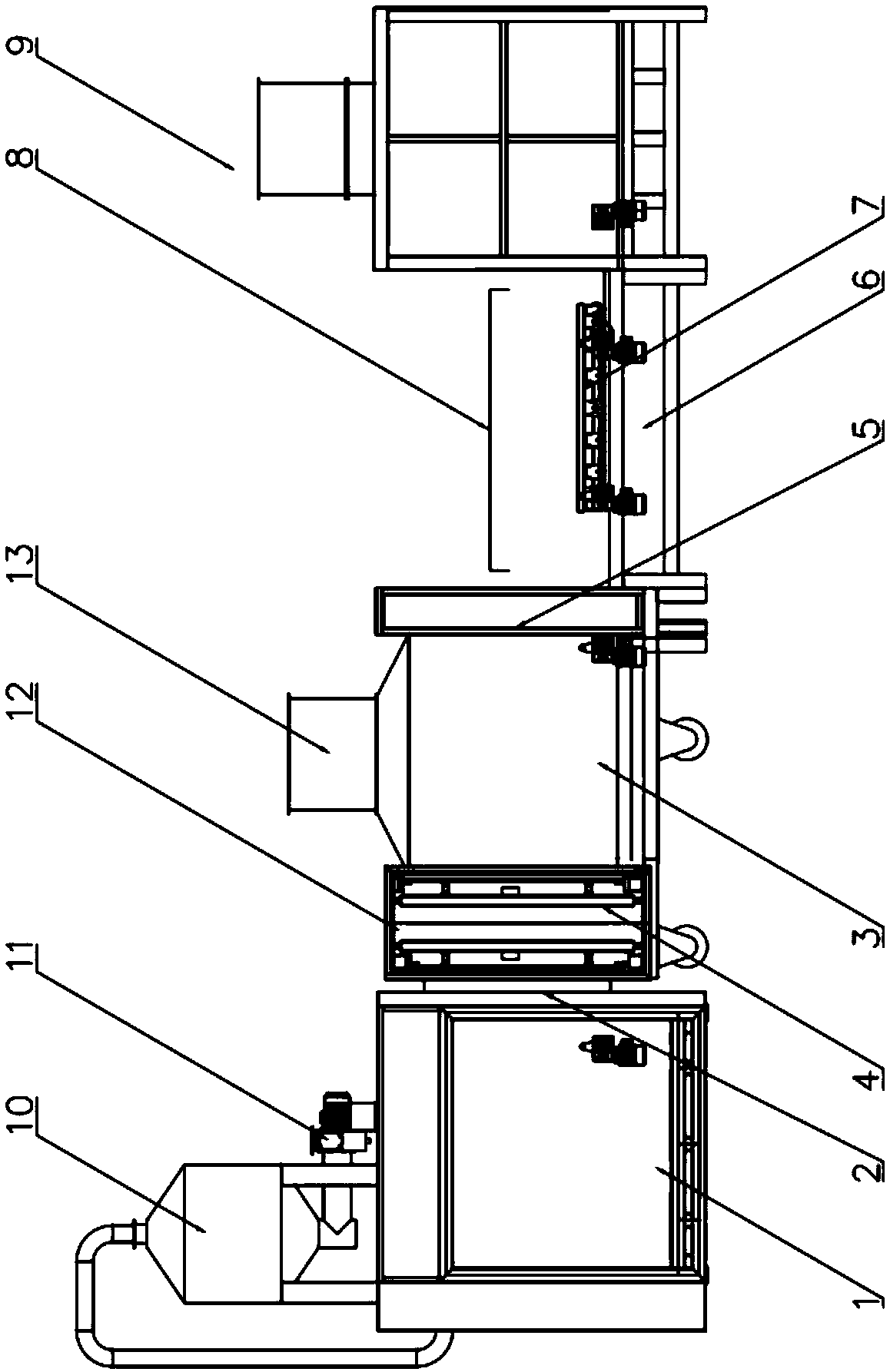

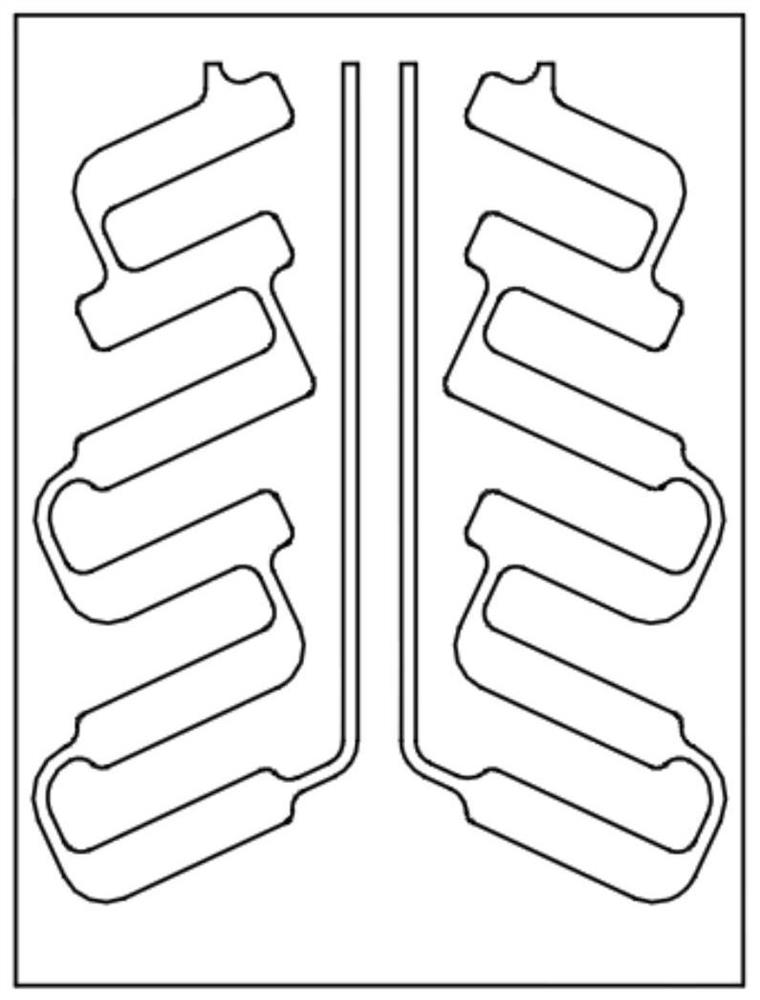

Production line of air conditioner piping assembly and brazing process

ActiveCN113664315AFast solderingFast brazingHeating appliancesSoldering auxillary devicesProduction lineProcess engineering

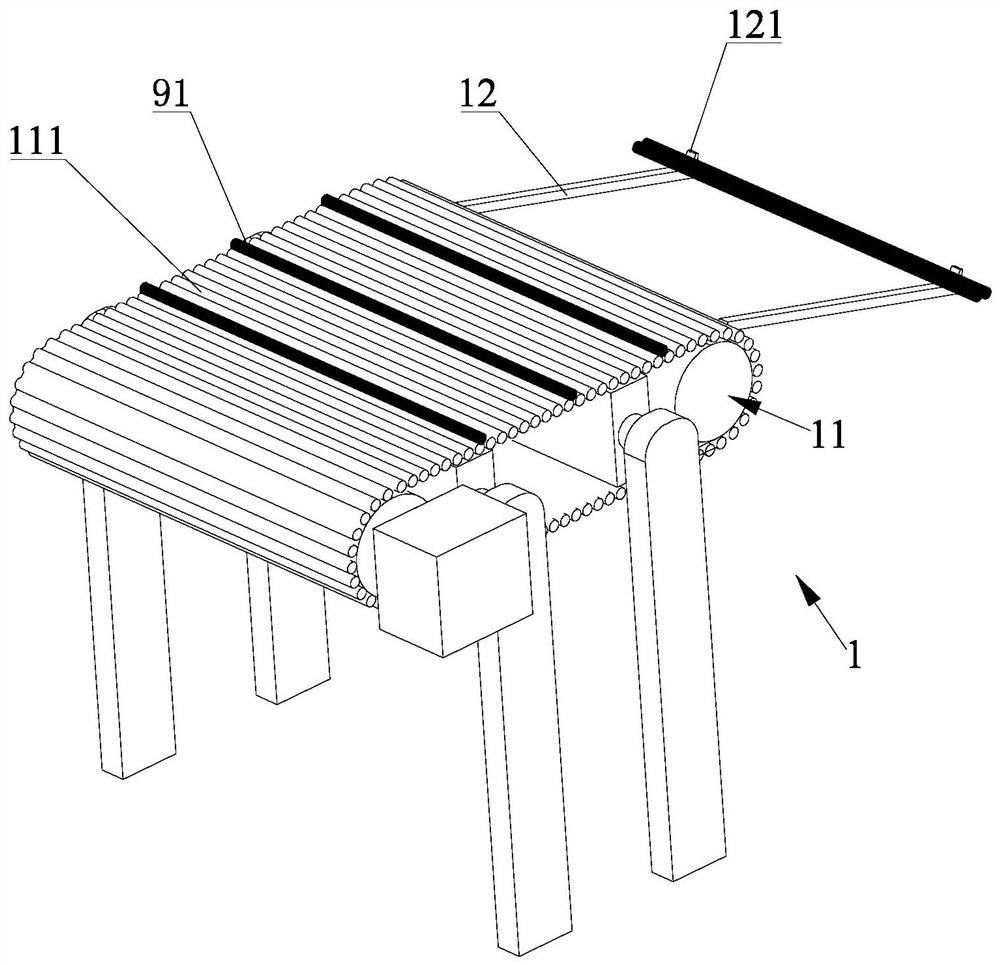

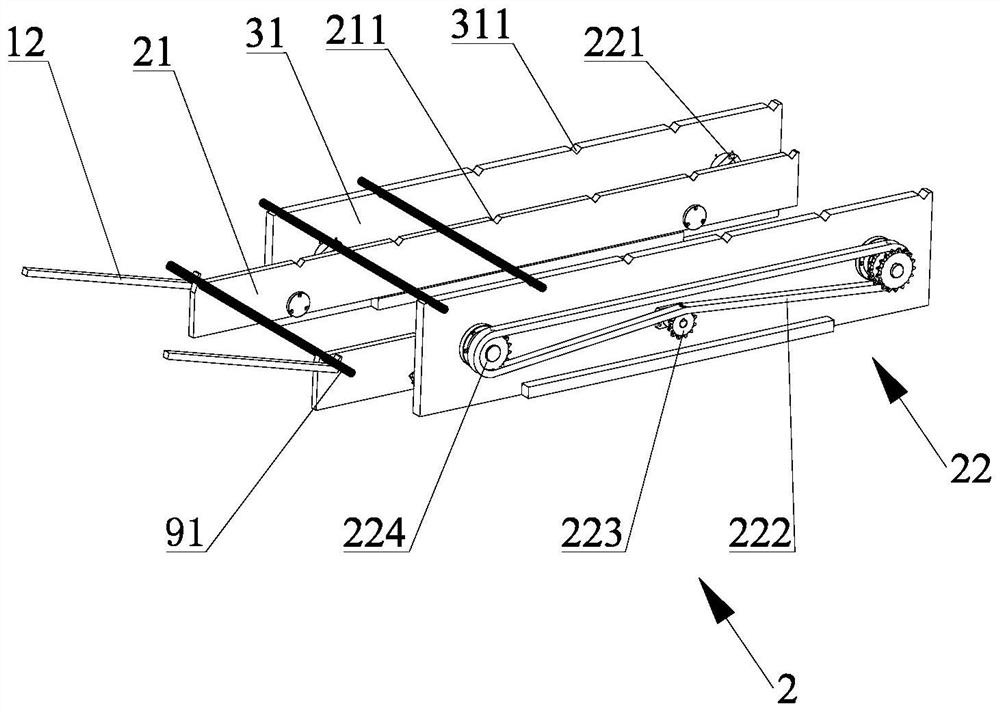

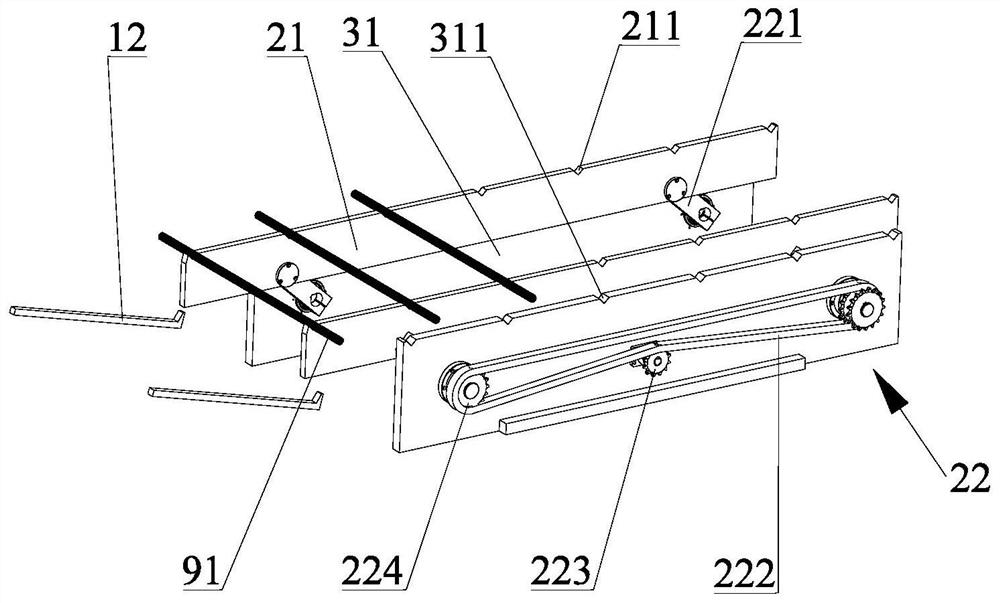

The invention relates to the technical field of air conditioner machining equipment, and particularly discloses a production line of an air conditioner piping assembly and a brazing process. The production line involves a U-shaped pipe head feeding machine, a side pipe feeding machine and a welding device, wherein the U-shaped pipe head feeding machine comprises a closed-loop conveyor, a plurality of fixing blocks are fixedly connected to the upper surface of the closed-loop conveyor at intervals, a U-shaped groove used for placing a U-shaped pipe head is formed in the upper surface of each fixing block, the side pipe feeder is arranged in an inner ring at one end of the closed-loop conveyor, and the welding device is arranged in an inner ring at the other end of the closed-loop conveyor. According to the production line of air conditioner piping assembly and the brazing process, rapid brazing of the air conditioner piping assembly is achieved in an assembly line mode, manual feeding, discharging and welding do not need in the whole process, the automation degree of the production line is high, the brazing efficiency is high, the fixing blocks and side pipe fixing clamps can be directly replaced, the production line is suitable for air conditioner piping assemblies of different specifications, and the applicability of the production line is wider.

Owner:沈督

Rhythmic vacuum purification nitrogen protection brazing furnace

InactiveCN109454306AImprove brazing qualityImprove brazing efficiencyMetal working apparatusSoldering auxillary devicesNitrogenThermostat

The invention provides a rhythmic vacuum purification nitrogen protection brazing furnace which comprises a brazing chamber, a guide rail and a control panel. A thermostat is arranged in the brazing chamber; an access port is formed in the side surface of the brazing chamber; a vacuum purification chamber is connected to the access port of the brazing chamber; openings are formed in two sides of the vacuum purification chamber; a first furnace door is arranged between the opening close to the brazing chamber and the access port; a second furnace door is arranged on the opening far away from the brazing chamber; a nitrogen filling pipeline is further arranged in the vacuum purification chamber; the guide rail is used for connecting the brazing chamber and the vacuum purification chamber; aconveying vehicle for conveying a product is slidably connected onto the guide rail and is connected with a drive device; the guide rail extends out of the second furnace door and forms a feeding andblanking area; an air cooling device is further arranged beside the feeding and blanking area; and the control panel is used for controlling the devices. The rhythmic vacuum purification nitrogen protection brazing furnace provided by the invention has the advantages of high brazing quality and the like.

Owner:江苏韦斯泰科技有限公司

A frame-type cold plate and its processing method

ActiveCN109341372BReduce temperature gradientIncrease the heat exchange areaSoldering apparatusStationary conduit assembliesAnodizingFriction welding

Owner:贵州永红换热冷却技术有限公司

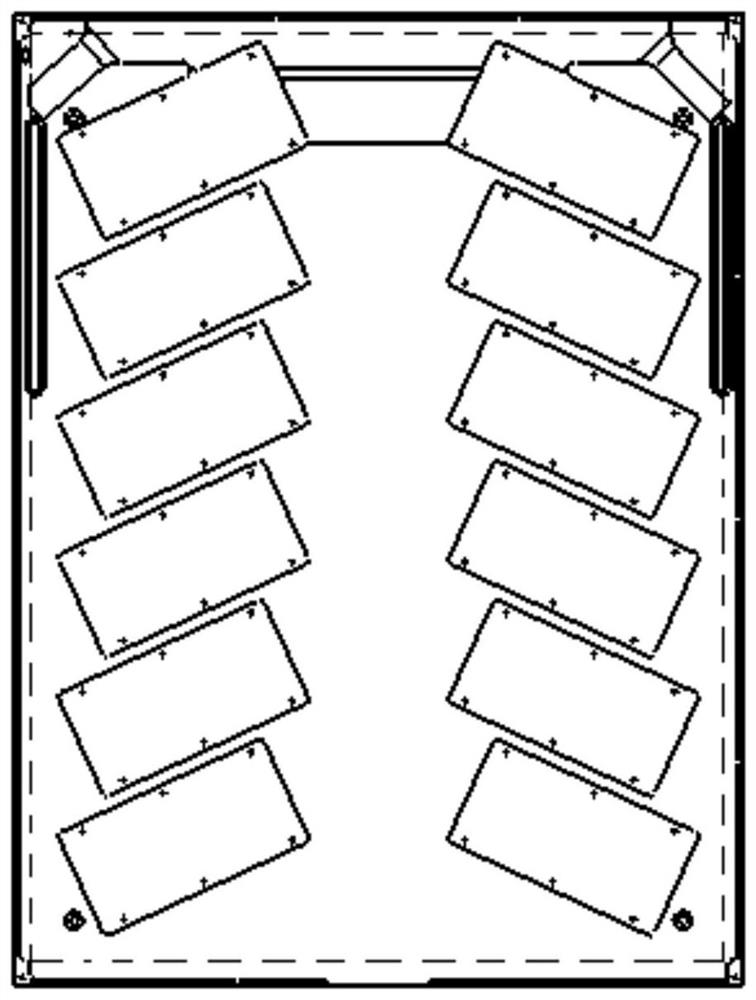

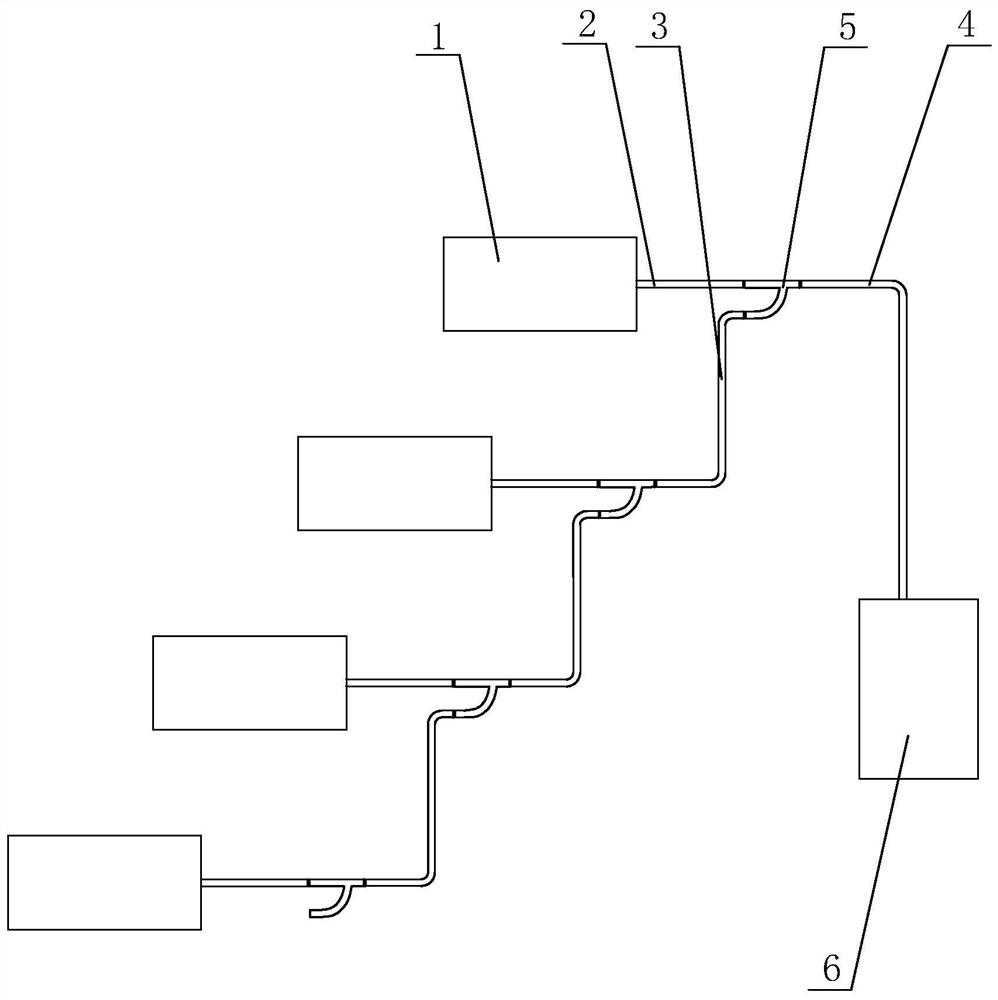

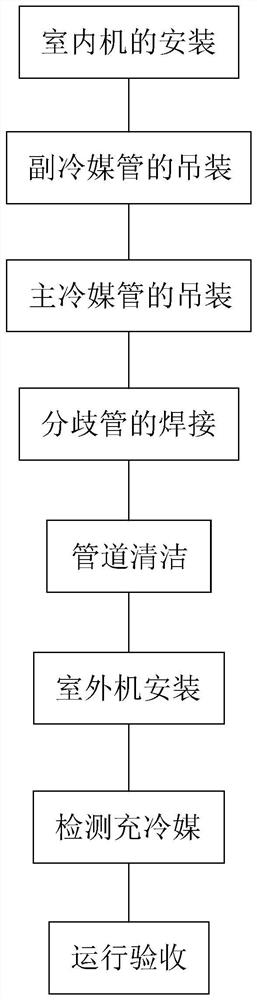

A method for installing a multi-connected air-conditioning system

ActiveCN109899956BReduce entryImprove brazing efficiencyDucting arrangementsMechanical apparatusGas cylinderEngineering

Owner:湖北亚运景建设科技有限公司

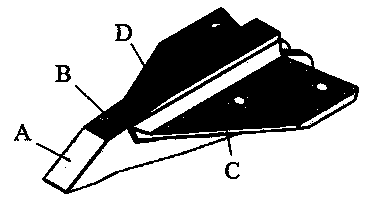

Brazing method of wear-resistant sheet

InactiveCN111014866AImprove brazing efficiencyQuality improvementHeating appliancesMetal working apparatusMetallurgyHeat conservation

The invention discloses a brazing method of a wear-resistant sheet. The method adopts high-frequency induction heating and comprises the following steps that (1) cleaning is conducted on the brazed surface; (2) the brazed surface is placed horizontally, the solder and flux are spread, and then the wear-resistant sheet is placed; (3) two parallel induction tubes, corresponding to the brazed surface, on an induction ring are used for induction heating and located 5-15 mm above the brazed surface, the induction current is 20-30 A, the voltage is 400-600 V, and the frequency is 100-400 KHz; (4) when the solder and flux are melted, the high frequency induction current is adjusted, heat preservation is conducted, and the pressure is applied on the wear-resistant sheet with a pressing bar; and (5) after the heat preservation for 10-15 s, the power is cut off, and the pressure is maintained for 5-10 s until the solder is solidified. The method is suitable for brazing of the wear-resistant sheet with a complex shape matrix, the brazing efficiency of the wear-resistant sheet is high, quality is high, no pollution is achieved, and the double-performance ideal composite of the matrix and the wear-resistant sheet is obtained.

Owner:HANDAN HUIQIAO COMPOSITE MATERIAL TECH CO LTD

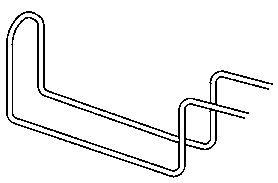

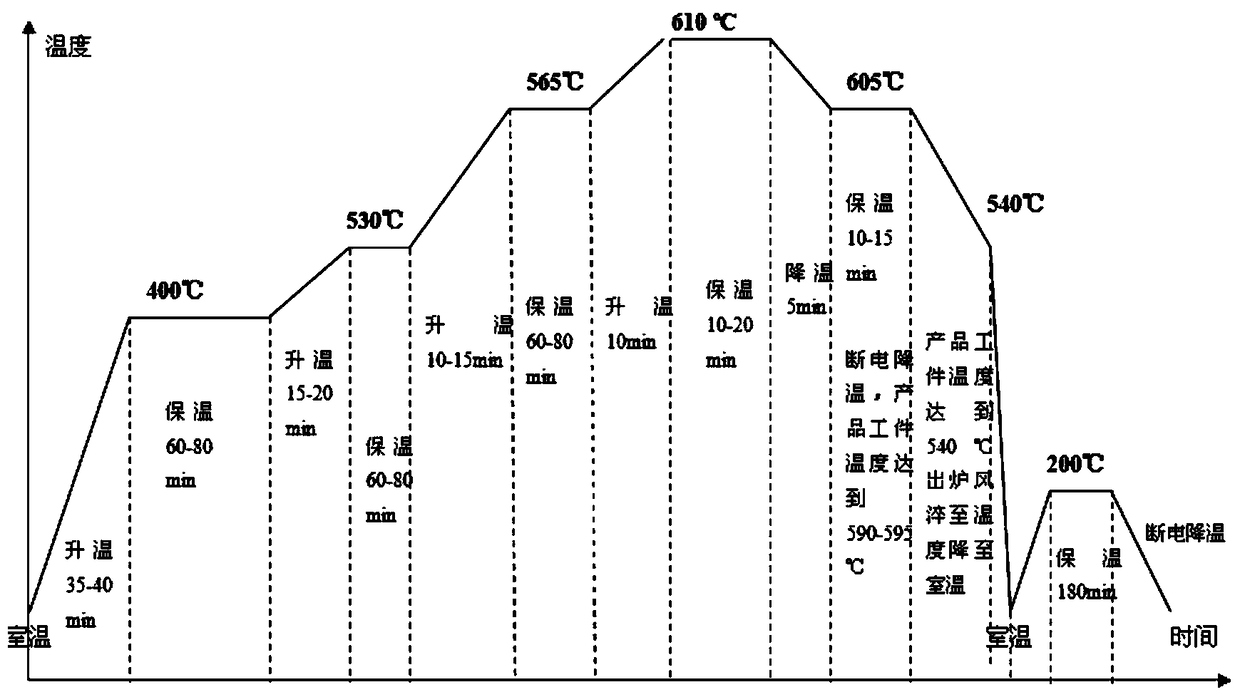

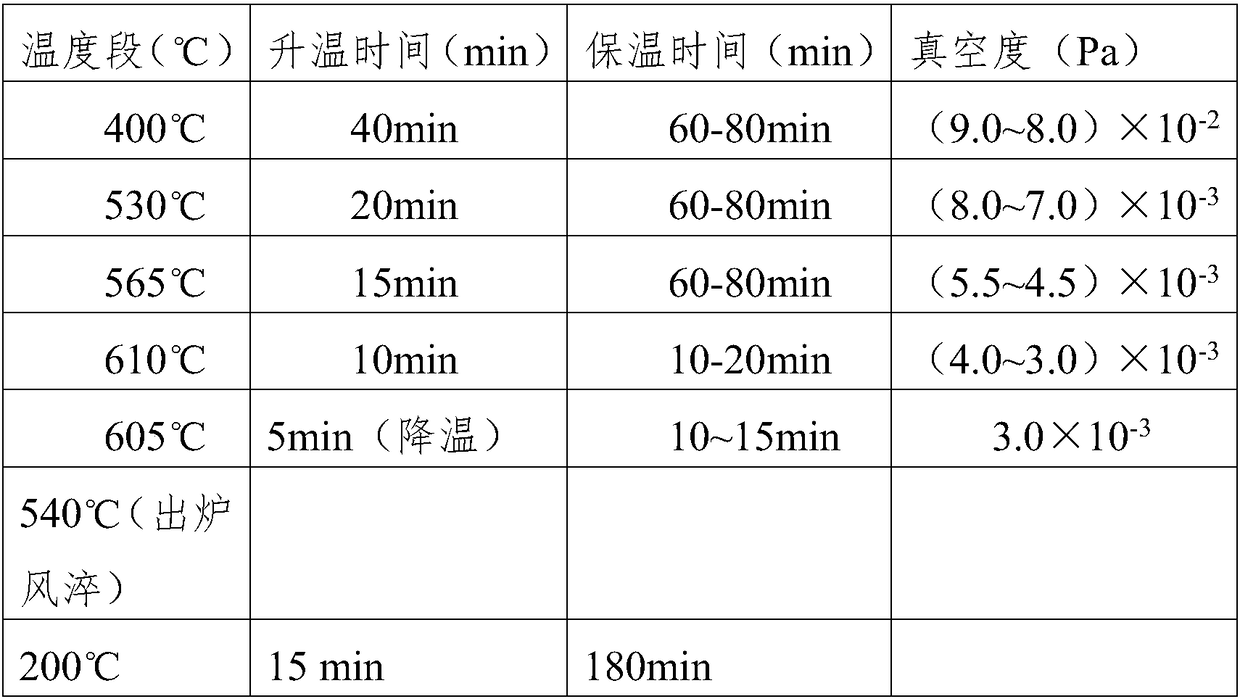

Integrated process of vacuum brazing and heat treatment for aluminum alloy gas circuit board

ActiveCN104002005BReduce total brazing high temperature section timeReduce temperature gradientWelding/cutting auxillary devicesAuxillary welding devicesThermal insulationRoom temperature

The invention relates to a vacuum brazing and heat treatment integrated process of aluminium alloy gas circuit board. The specific process parameters are that the aluminium alloy gas circuit board is heated to 400 DEG C, heating is conducted for 35-40 min, thermal insulation is conducted for 60-80 min, and the vacuum degree is larger than 8.0*10-2 Pa; the aluminium alloy gas circuit board is heated to 530 DEG C, heating is conducted for 15-20 min, thermal insulation is conducted for 60-80 min, and the vacuum degree is larger than 8.0*10-3 Pa; the aluminium alloy gas circuit board is heated to 565 DEG C, heating is conducted for 10-15 min, thermal insulation is conducted for 60-80 min, and the vacuum degree is larger than 4.5*10-3 Pa; the aluminium alloy gas circuit is heated to 610 DEG C, heating is conducted for 10 min, thermal insulation is conducted for 10-20 min, and the vacuum degree is larger than 3.0*10-3 Pa; the aluminium alloy gas circuit board is cooled to 605 DEG C, cooling is conducted for 5 min, thermal insulation is conducted for 10-15 min, outage and cooling are contacted until the temperature is 540 DEG C, and the aluminium alloy gas circuit board is put out of a furnace and is subjected to wind quenching to be cooled to be at the room temperature. The vacuum brazing and heat treatment integrated process of the aluminium alloy gas circuit board has the advantages that the production process is simple, the cycle is short, the consumed energy is little, the production percent of pass is high, and the production cost is low. The percent of pass of the welding joint of the aluminium alloy gas circuit part is improved to 90% from the original 40%, and a good effect is achieved.

Owner:GUIZHOU YONGHONG AVIATION MACHINERY

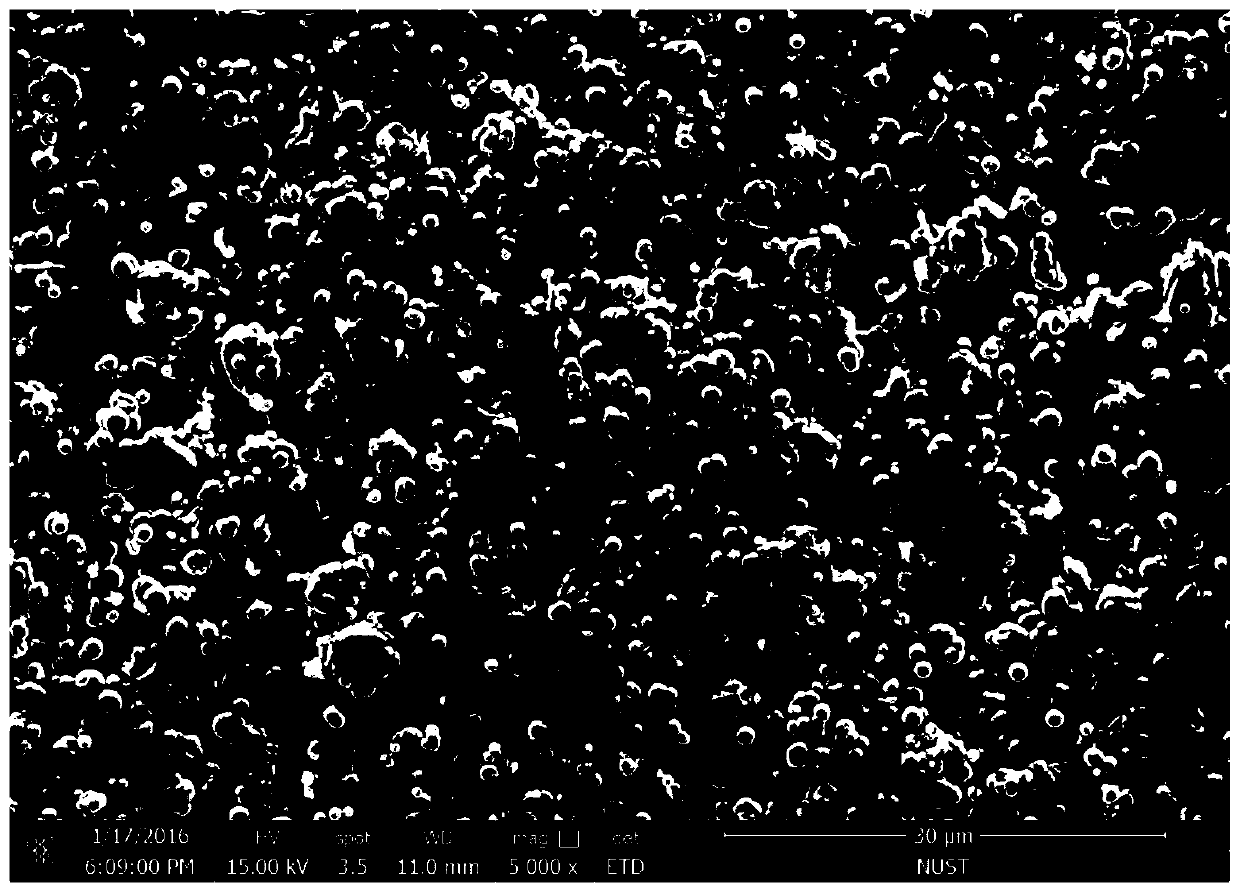

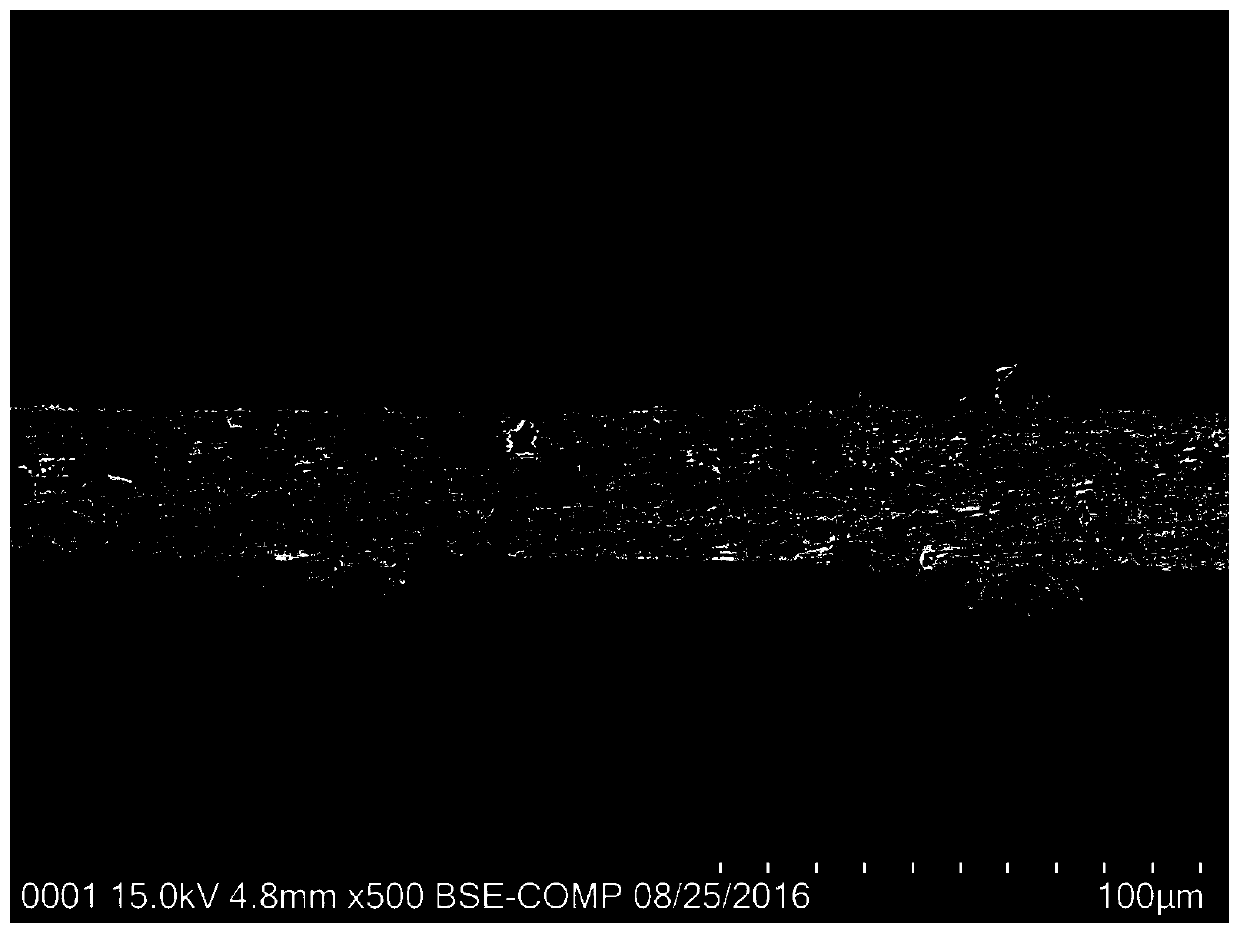

A kind of surface metallization and brazing method for electronic packaging composite material

ActiveCN107008984BImprove bindingSmall difference in coefficient of thermal expansionSoldering apparatusLiquid/solution decomposition chemical coatingThermal dilatationBraze alloy

The invention belongs to the technical field of welding, and relates to a surface metallizing and brazing method of a high-volume-fraction SiCp / Al composite. Through a reasonable process, a Ni-P-SiC composite coating is obtained, by adding SiC particles into the coating, the thermal expansion coefficient difference between a substrate and the coating can be effectively reduced, the binding force of the coating can be properly improved, and in addition, compared with the mode that nickel plating is only conducted on the upper surface of the SiCp / Al composite for welding, the brazing strength can be improved to a certain degree by adding the SiC particles into the coating. Low-melting glass brazing alloy (namely SnO-ZnO-P2O5 glass brazing alloy) and SiC ceramic have good wettability, the requirement for oxygen partial pressure of the welding condition is low when glass is used as brazing alloy, the brazing efficiency can be effectively improved, the cost is reduced, and thus, by combing surface metallizing with the brazing process, good brazing joints can be obtained and can meet the requirement for application in the electronic packaging field.

Owner:江苏虹普电子材料科技有限公司

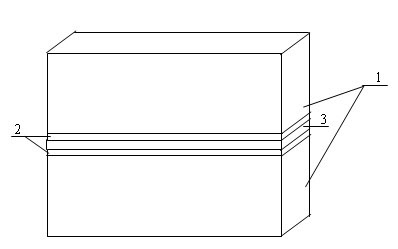

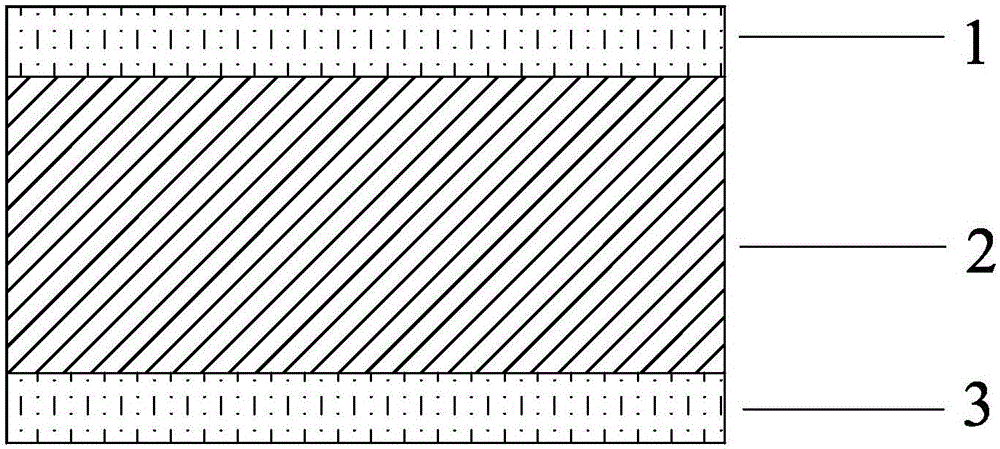

Diffusion bonding agent for brazing of aluminum alloy honeycomb plate and diffusion brazing method

ActiveCN111250857AAchieve Diffusion BrazingDiffusion brazing is suitable forWelding/cutting media/materialsSoldering mediaLiquid alloyAluminium alloy

The invention relates to a diffusion bonding agent for brazing of an aluminum alloy honeycomb plate and a diffusion brazing method. The diffusion bonding agent comprises the following components of, by mass, 80%-90% of Ga-In eutectic liquid alloy and 10%-20% of Si powder. The diffusion brazing method comprises the steps of coating the diffusion bonding agent on the to-be-welded surface of a honeycomb core strip and the to-be-welded surfaces of an upper panel and a lower panel, and placing the honeycomb core strip, the upper panel and the lower panel in a mesh belt type continuous brazing furnace for heating after assembling to obtain the aluminum alloy honeycomb plate. By means of the active bonding agent, high-reliability, high-compactness, brazing-filler-free and brazing-flux-free connection between the aluminum alloy honeycomb plates can be achieved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

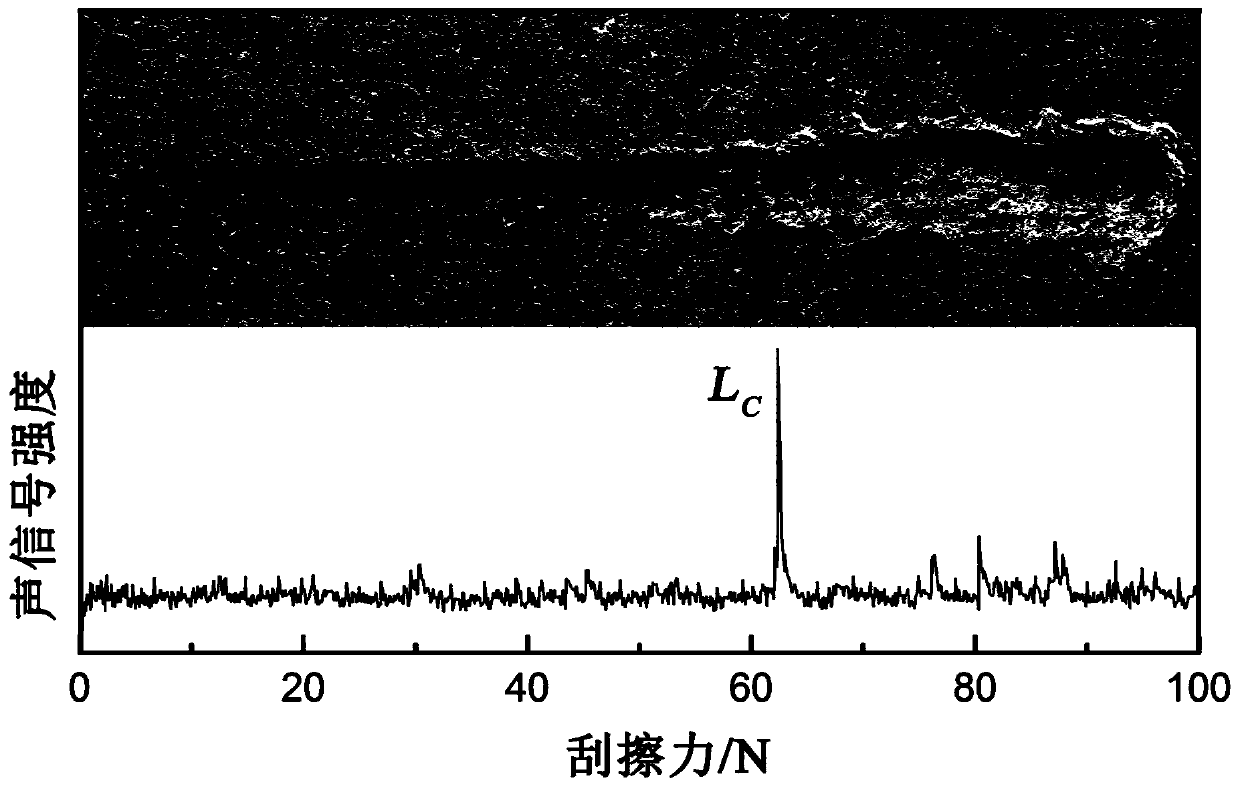

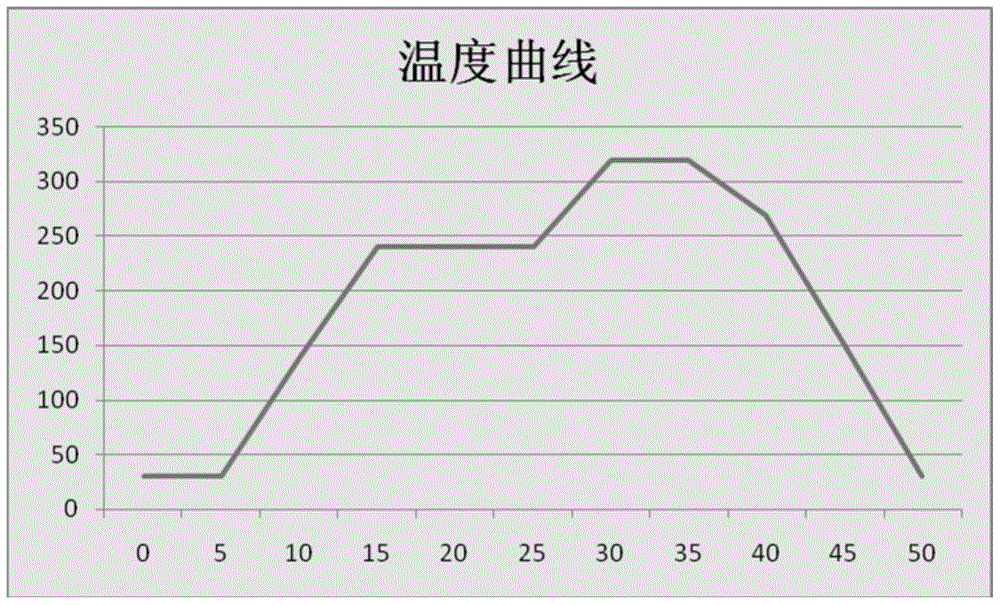

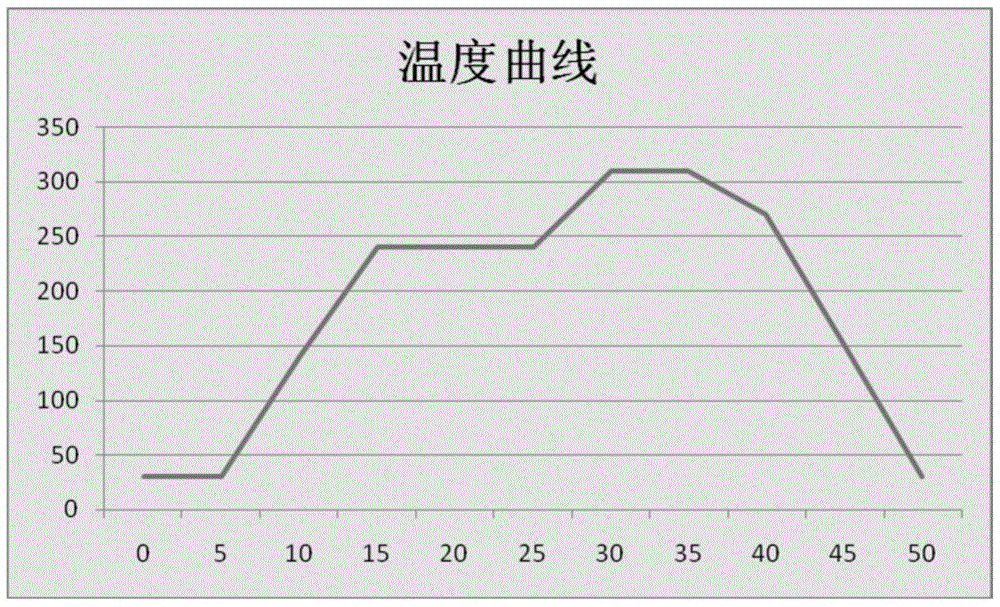

A vacuum brazing chip mounting process method without load and low void ratio

The invention relates to a low-voidage vacuum brazing chip mounting technique free of loads. The technique comprises the following steps that (1), a sputtering Au technology is adopted in the back face of a chip to be brazed, and the back face is metallized; (2), the chip to be brazed is arranged on a to-be-brazed gold plating chip mounting area of an integrated circuit packaging shell, and brazing materials are placed between the chip to be brazed and the to-be-brazed gold plating chip mounting area; (3), a test sample to be brazed is placed in brazing equipment to be brazed according to technological conditions specially designed. In the brazing process, temperature curve optimization is combined with vacuum degree control, the air pressure difference is used for replacing the pressing block loads, optimization design is carried out on the temperature interval, the heating rate, the heat preservation time and the vacuum degree, the optimal technological conditions are determined, the problem that the chip is damaged due to adopted loads in the traditional method is solved, the brazing voidage is lowered, and the brazing yield and brazing quality are obviously improved.

Owner:BEIJING MXTRONICS CORP +1

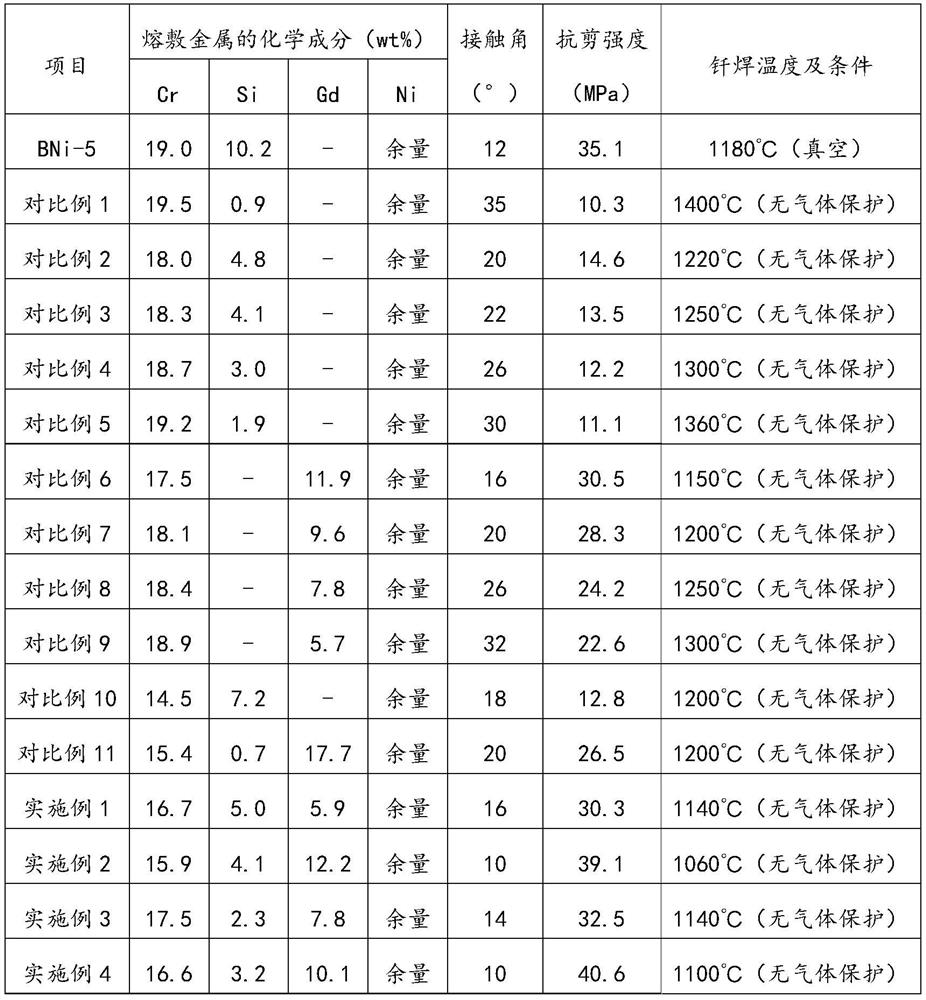

A kind of nickel base flux core solder, preparation method and application

ActiveCN112621020BImprove thermal stabilityAccelerated corrosionWelding/cutting media/materialsSoldering mediaNickel chromium alloyNichrome

The invention discloses a nickel-based flux-cored solder, which comprises a flux core and a nickel-based alloy wrapping the flux core; the nickel-based alloy is a nickel-chromium alloy; and the flux core accounts for 30% of the total mass of the nickel-based flux-cored solder to 40%, the drug core comprises in terms of mass fraction: 13% to 24% NiSi 2 Powder, 19% to 33% GdF 3 powder, brazing flux powder is the balance; the invention also discloses the preparation method of the nickel-based cored solder and the brazing applied to ceramics and superalloys in the atmospheric environment; the invention has its own flux, which can be realized during brazing The automatic and synergistic addition of the brazing flux is achieved. In addition, the invention has good processing performance, reduces the brazing temperature during the application process, and improves the strength of the brazing joint.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com