Patents

Literature

39results about How to "Break continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

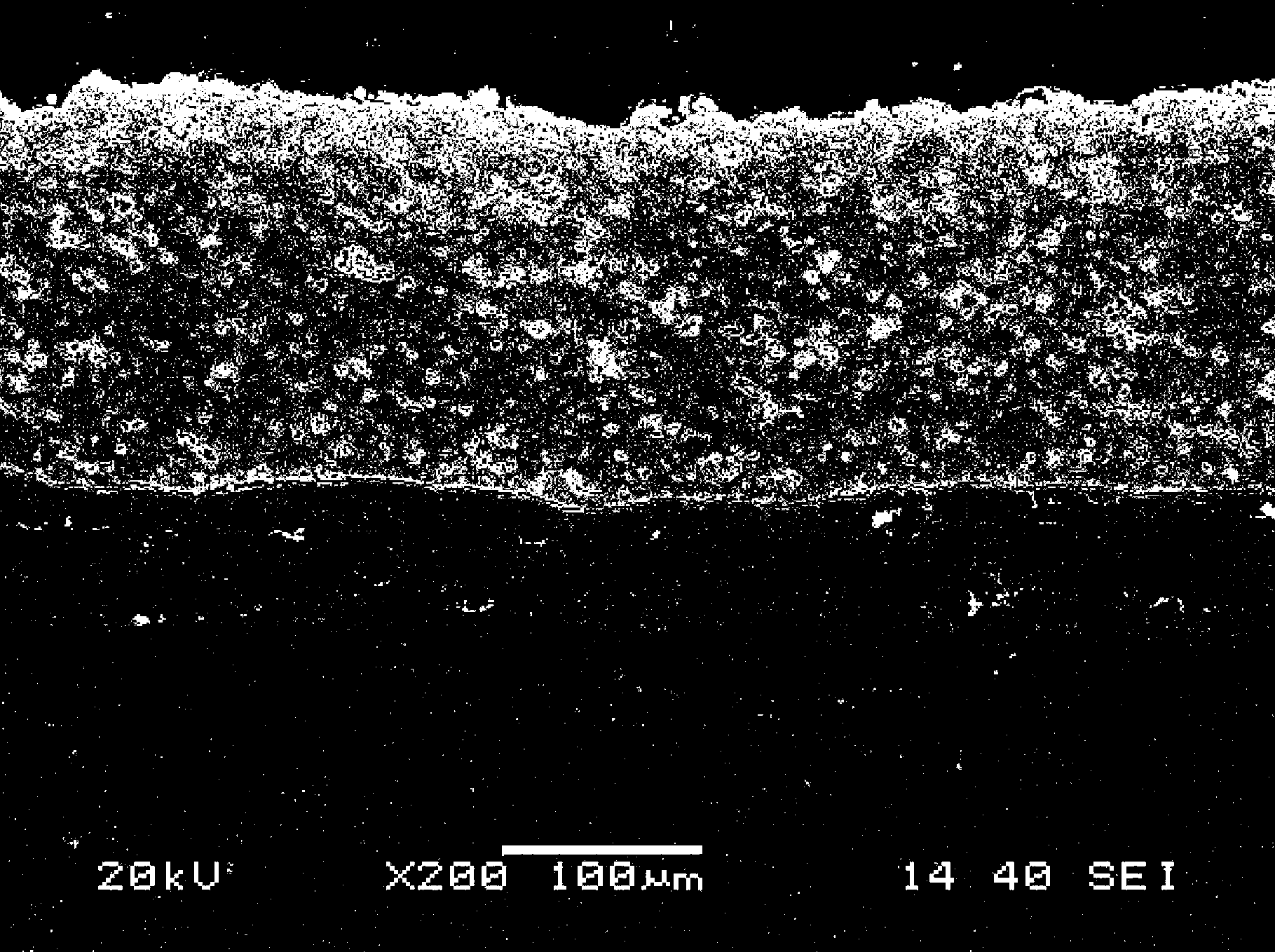

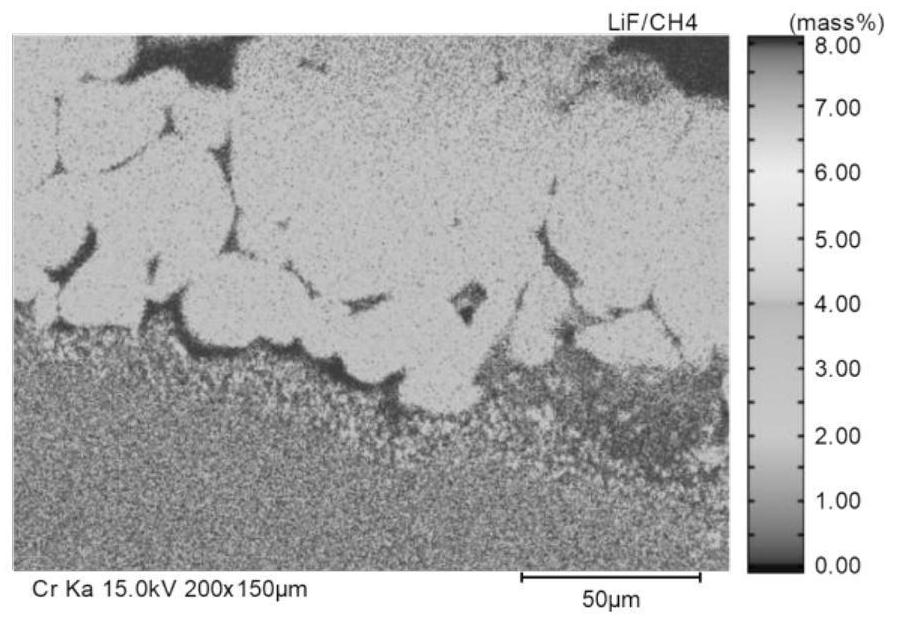

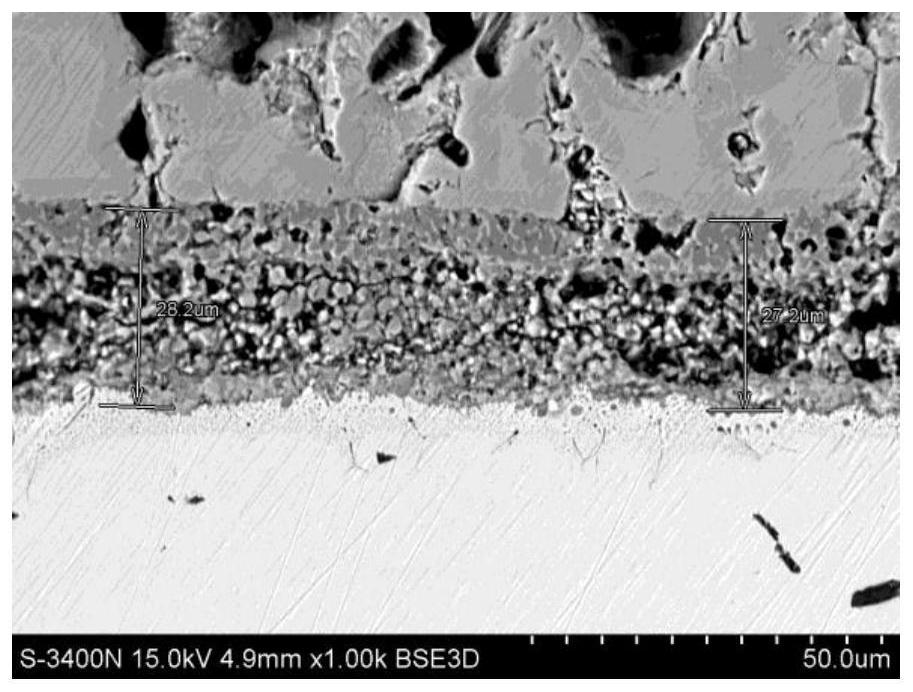

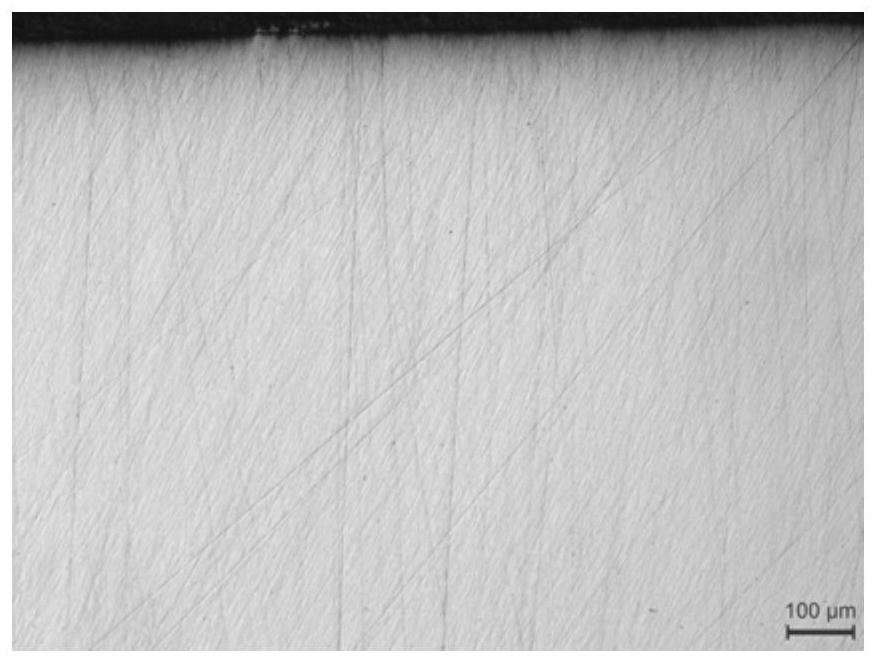

Laser surfacing modification method for thermal barrier coating

ActiveCN103266295AHigh bonding strengthImprove thermal fatigue lifeMolten spray coatingEfficient propulsion technologiesStress concentrationThermal fatigue

The invention relates to a laser surfacing modification method for a thermal barrier coating. The method comprises the following steps of: firstly, carrying out washing and sand blasting on the surface of a base body; then, preparing the thermal barrier coating in a thermal spraying state on the surface of the base body; then, designing shape, size, arrangement rule and distribution density of laser modification unit bodies in a pile nail structure to be prepared in the thermal barrier coating; then, adjusting the process parameters of a laser according to a design model; then, performing laser modification to the thermal barrier coating; and finally, performing the stress relief annealing treatment to the laser modified thermal barrier coating. With the adoption of the method for arranging discontinuous and dispersed intensifying unit bodies in the pile nail structure in the thermal barrier coating, the thermal barrier coating can not only generate characteristic of soft and hard alternate change, but also generate the 'pinning effect', thus not only relieving stress concentration at the crack tip of the coating and reducing the crack rate of the coating, but also extremely improving the bonding strength of the coatings, prolonging the thermal fatigue service life of the thermal barrier coating, improving the tissue structure of the coating and improving the compactness of the coating.

Owner:FOSHAN TAOYUAN INST OF ADVANCED MFG

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

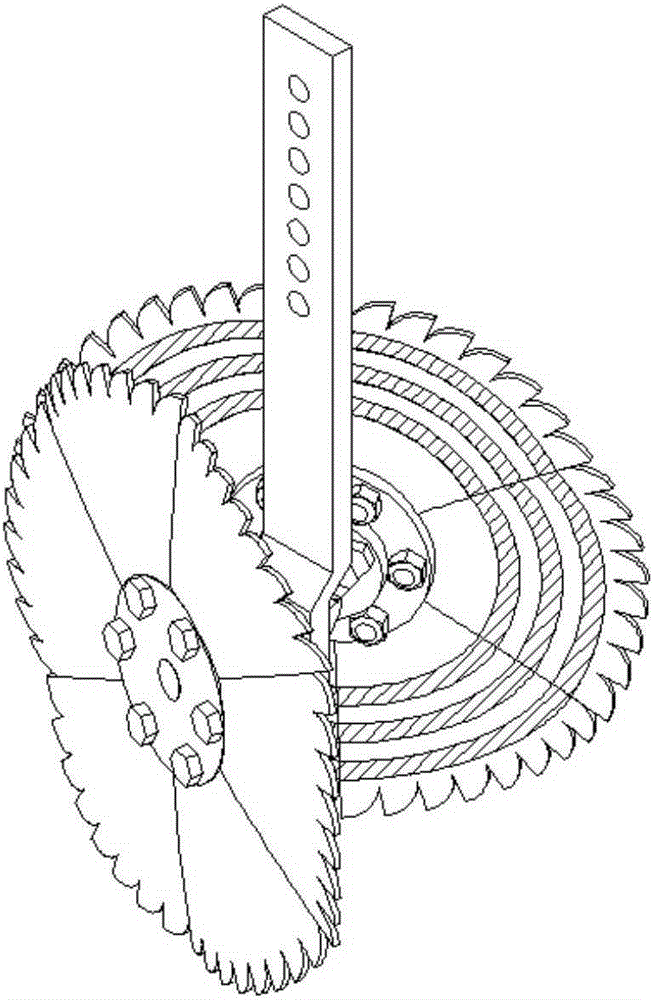

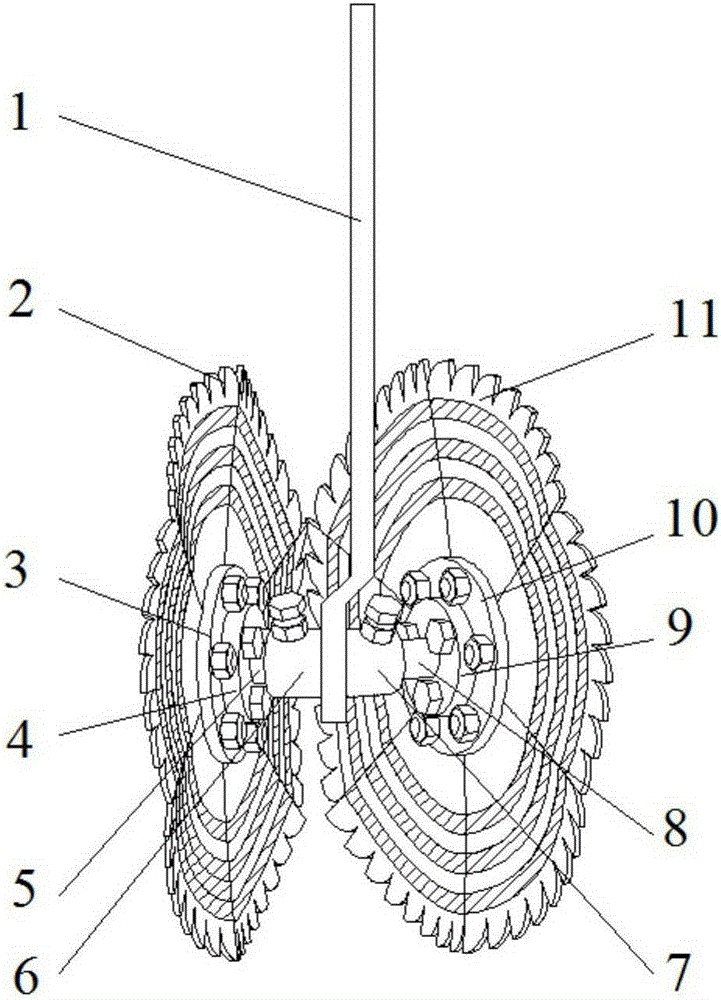

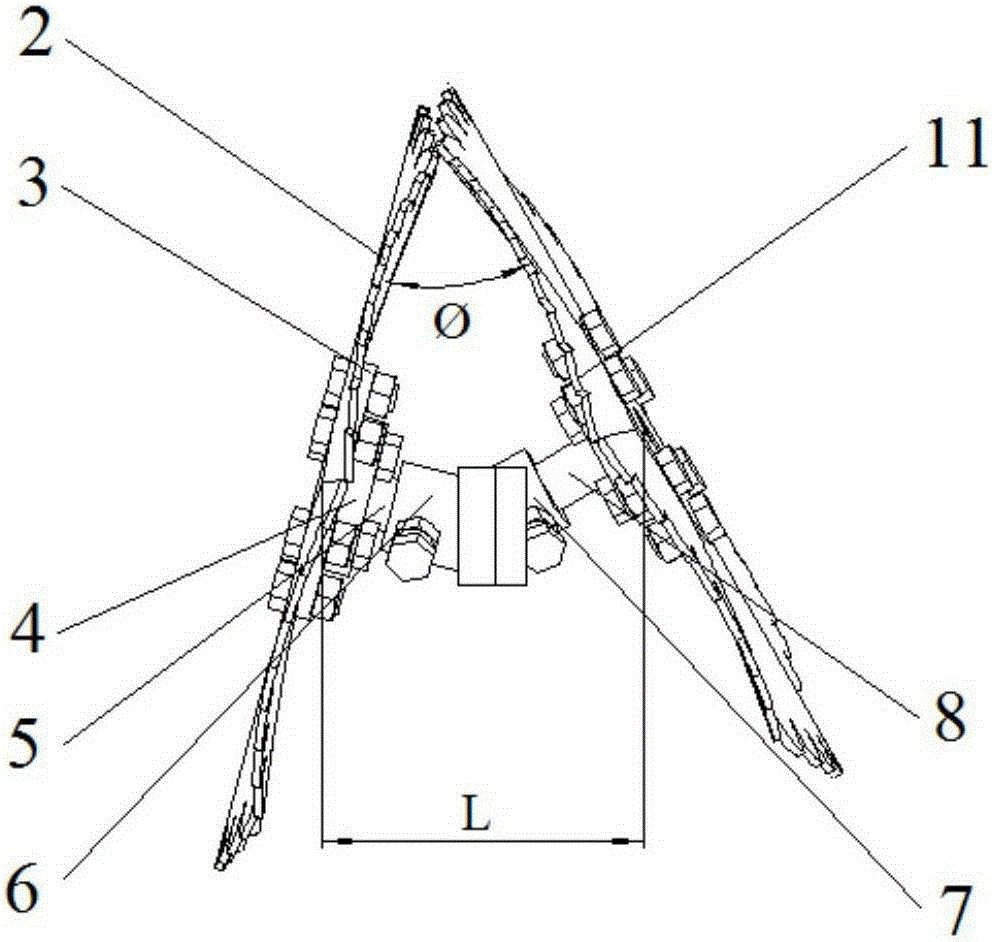

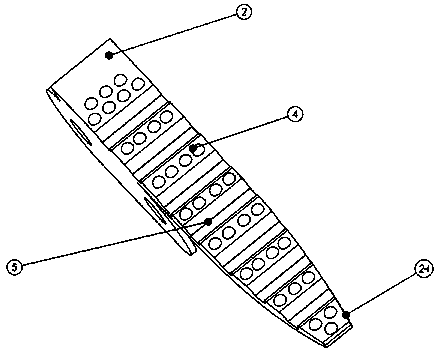

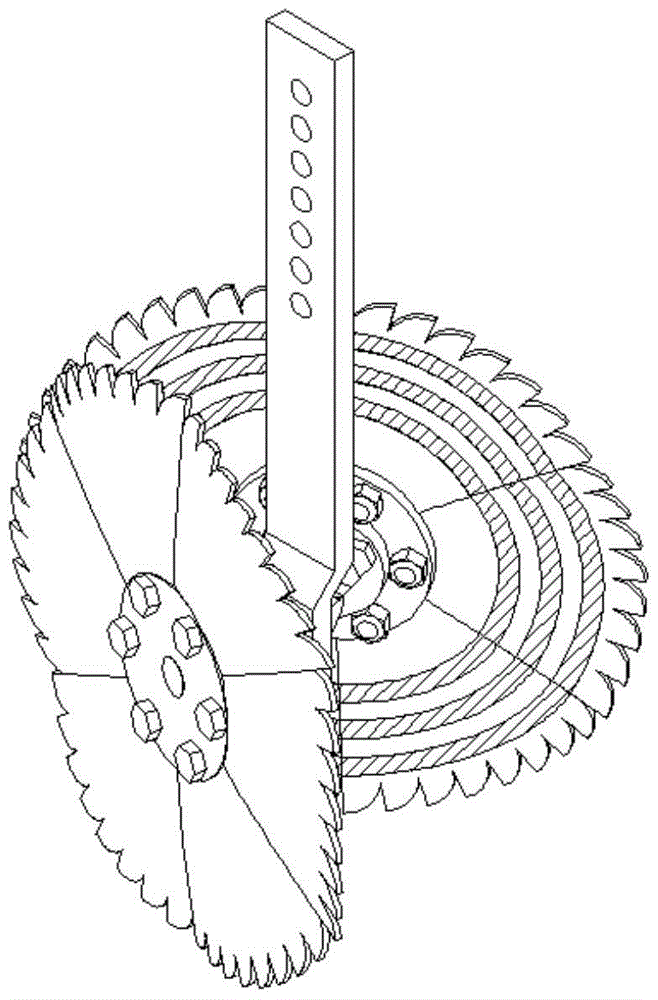

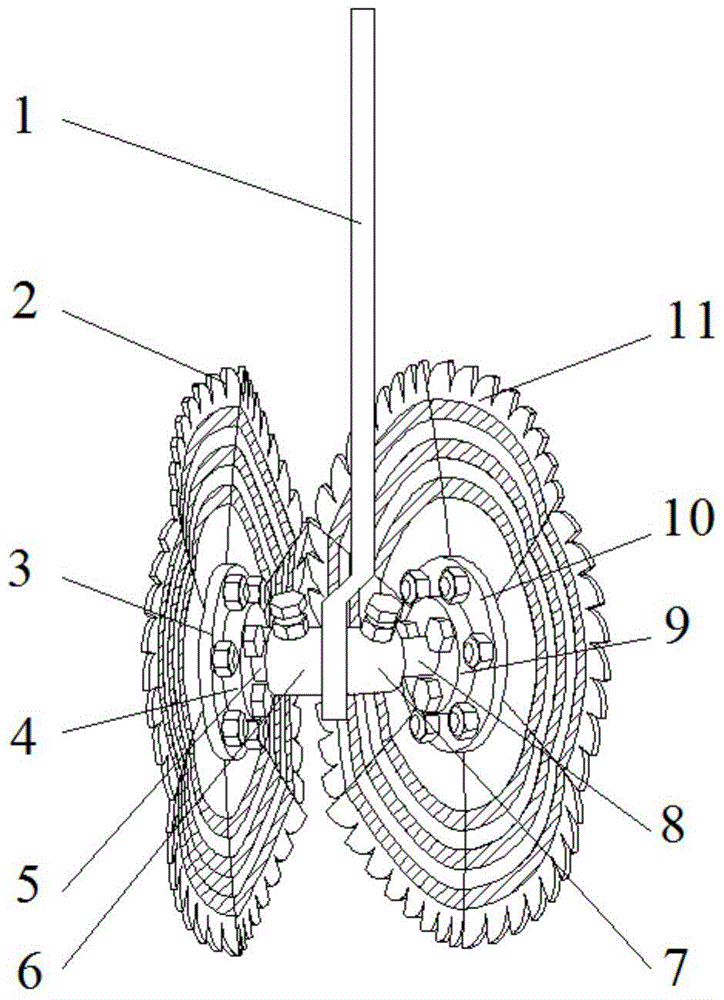

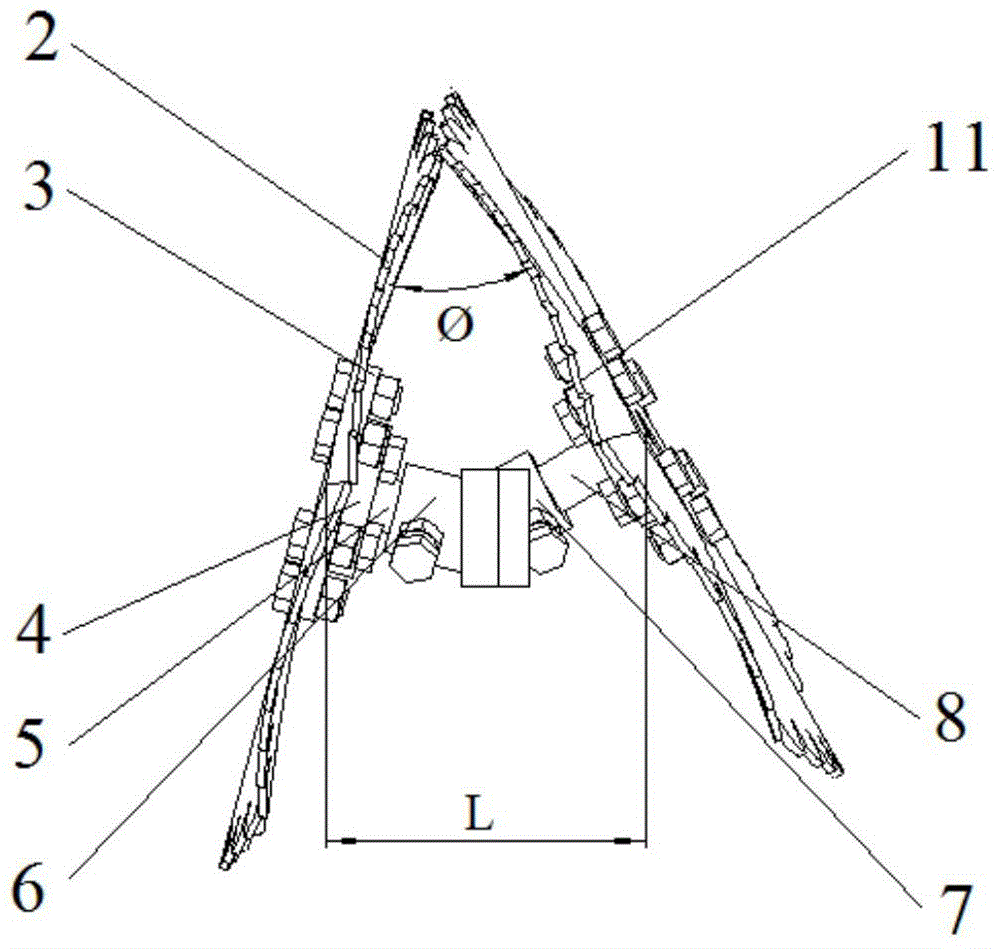

Bionic curved-surface circular disc fertilization furrow opener

InactiveCN105165187APrevent lost rotationSmall ditching resistancePlantingFurrow making/coveringCircular discEngineering

The invention discloses a bionic curved-surface circular disc fertilization furrow opener. The bionic curved-surface circular disc fertilization furrow opener comprises a mounting frame, a curved-surface circular disc I and a curved-surface circular disc II, wherein the curved-surface circular disc I and the curved-surface circular disc II are mounted at the two sides of the mounting frame by shafts; the two curved-surface circular discs are mutually inclined and are mounted in an angular staggered manner; the curved-surface circular disc I and the curved-surface circular disc II have the same structures; the curved-surface circular disc I is composed of a plurality of curve-surface sector-shaped single bodies with the same structures; the curve-surface sector-shaped single bodies are tightly connected; and the outer edge of each curve-surface sector-shaped single body is of a tooth-shaped structure. According to the bionic curved-surface circular disc fertilization furrow opener, a disc surface adopts a bionic curved-surface structure and simulates shape characteristics of animal claws and toes, so that the soil digging performance is improved, the throwing rate is reduced, and capabilities of breaking stubbles and crushing soil are enhanced; the inner part of the disc surface is filled with annular nylon, and a water film structure at which the disc surface is in contact with the soil is damaged; and furrow opener cannot adhered to the soil and the passing ability of the furrow opener is enhanced.

Owner:JILIN UNIV

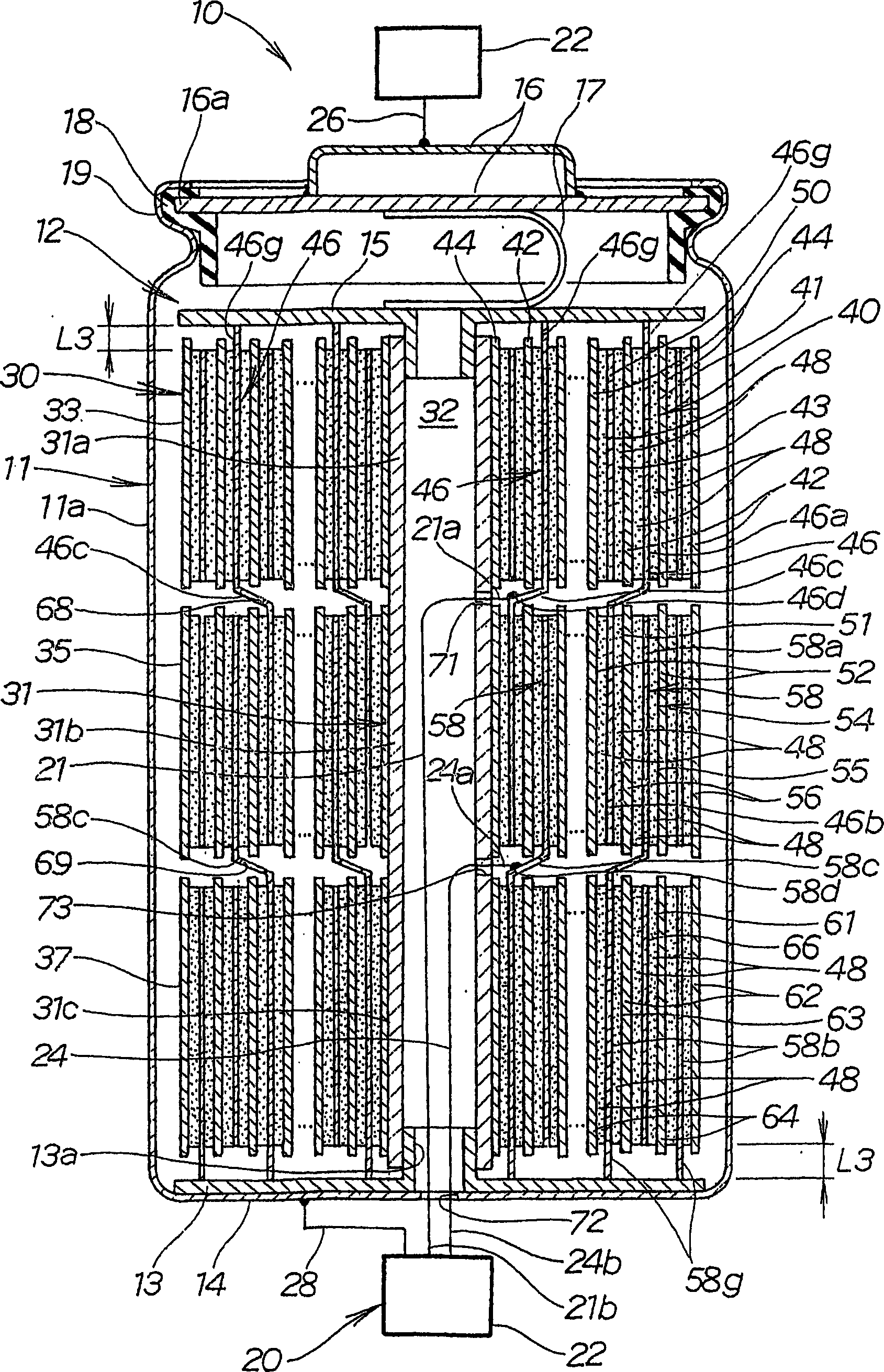

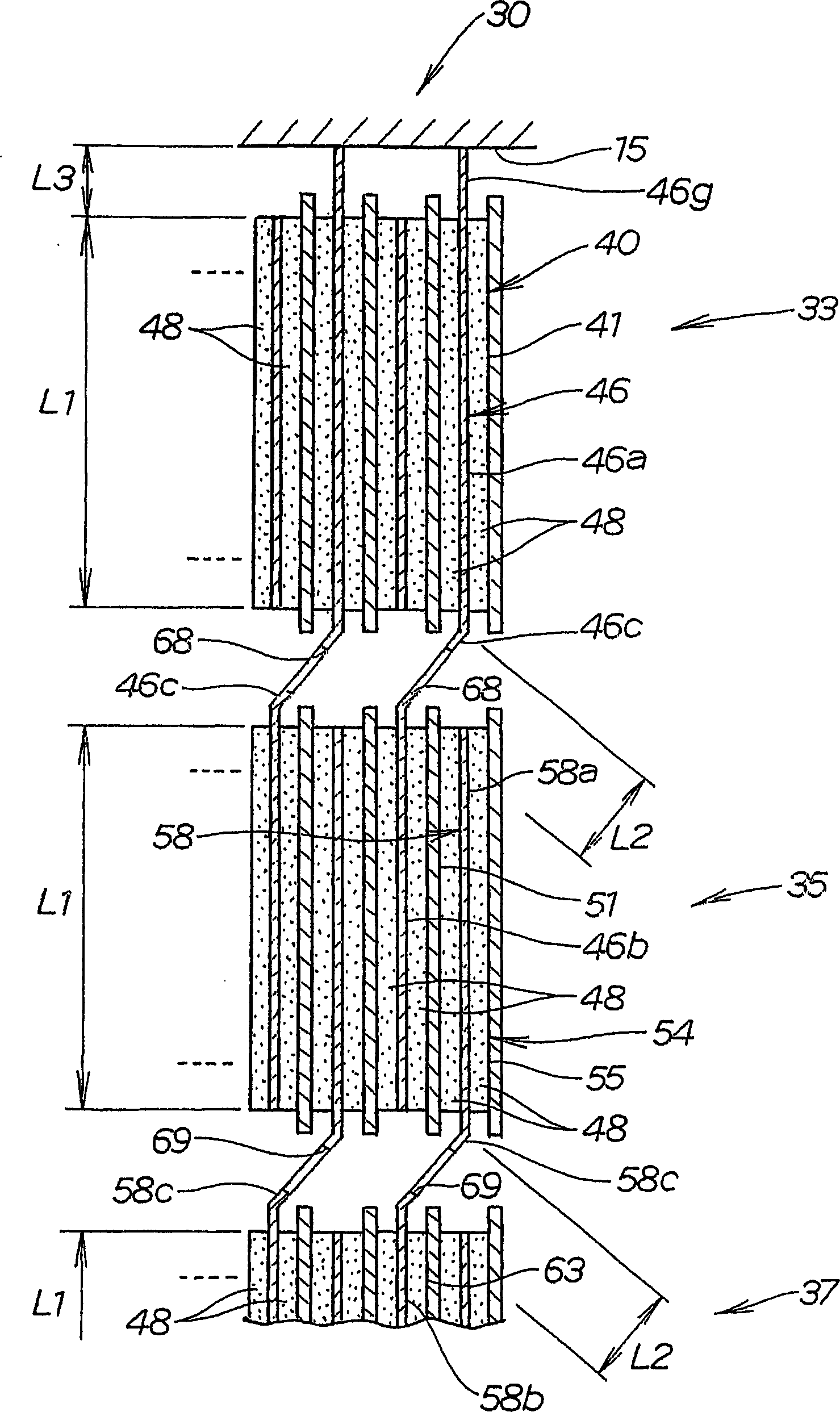

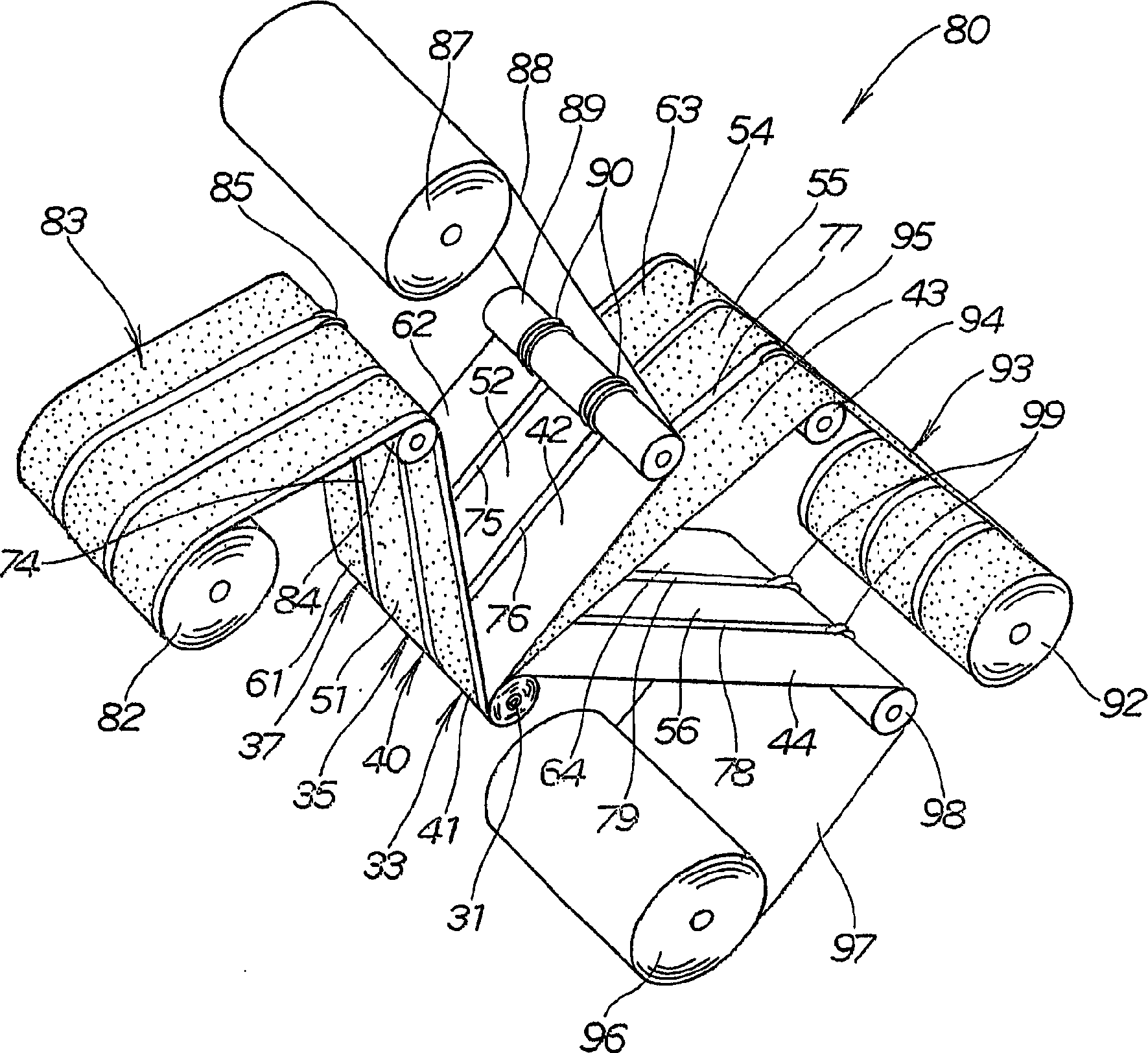

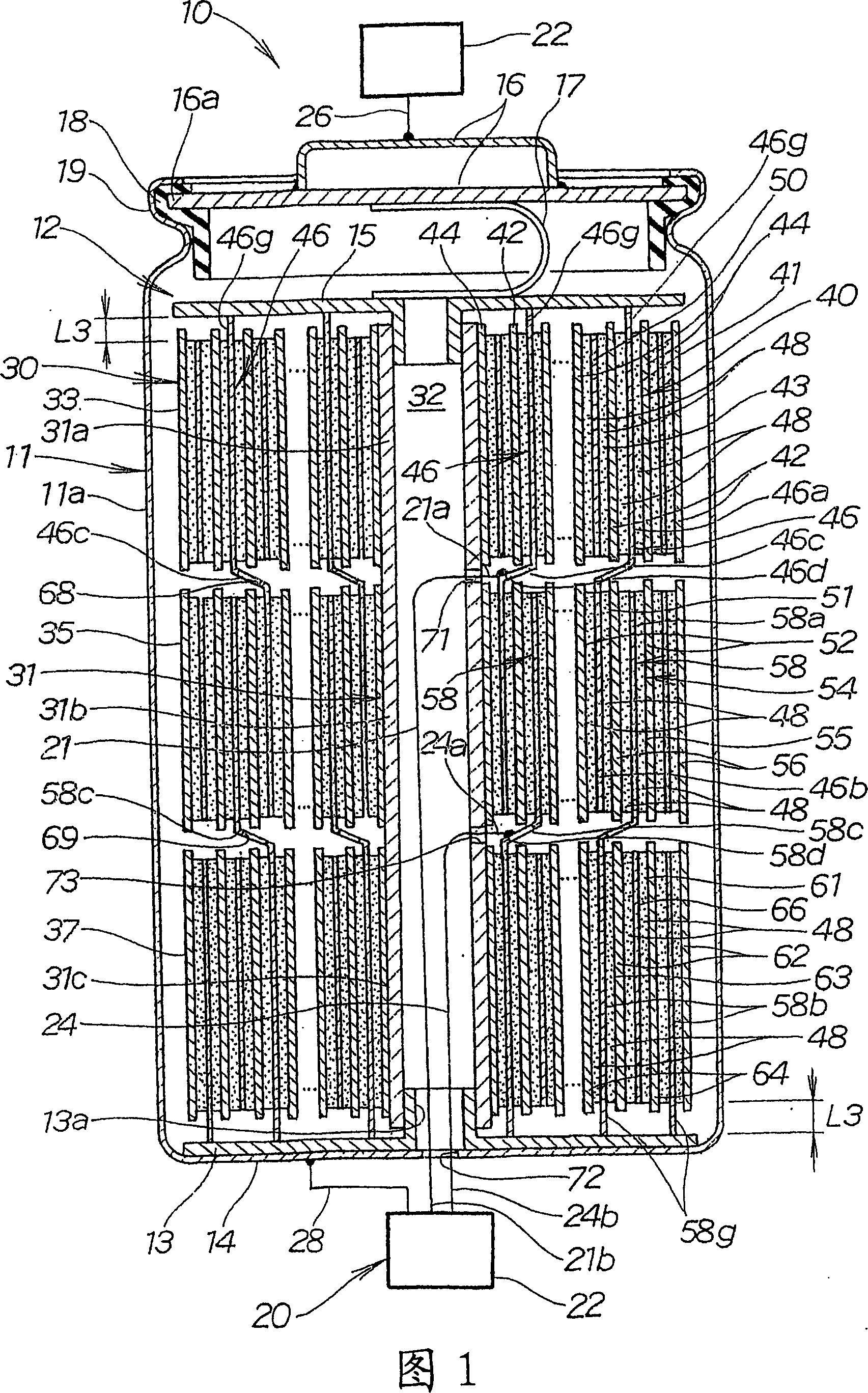

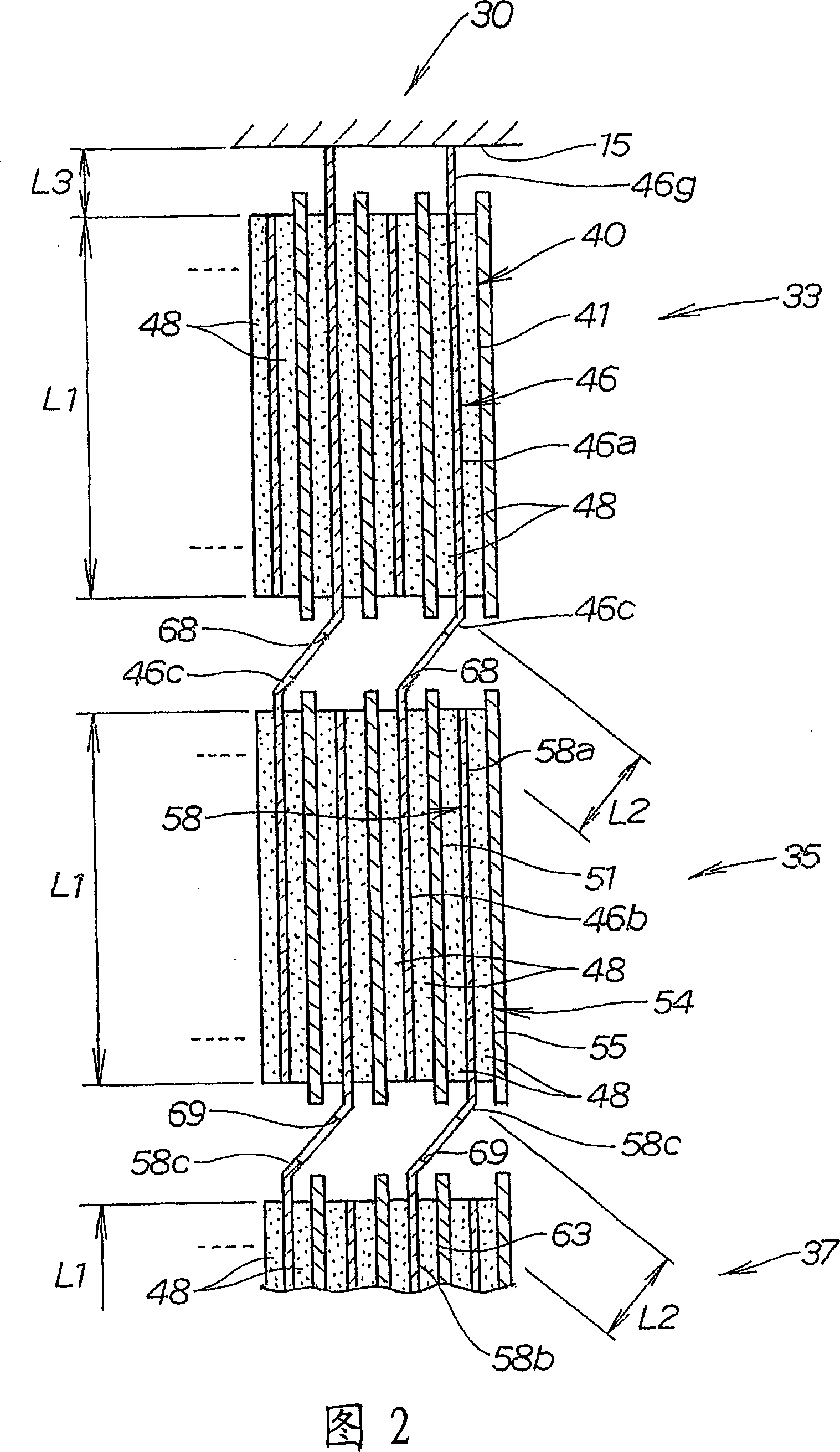

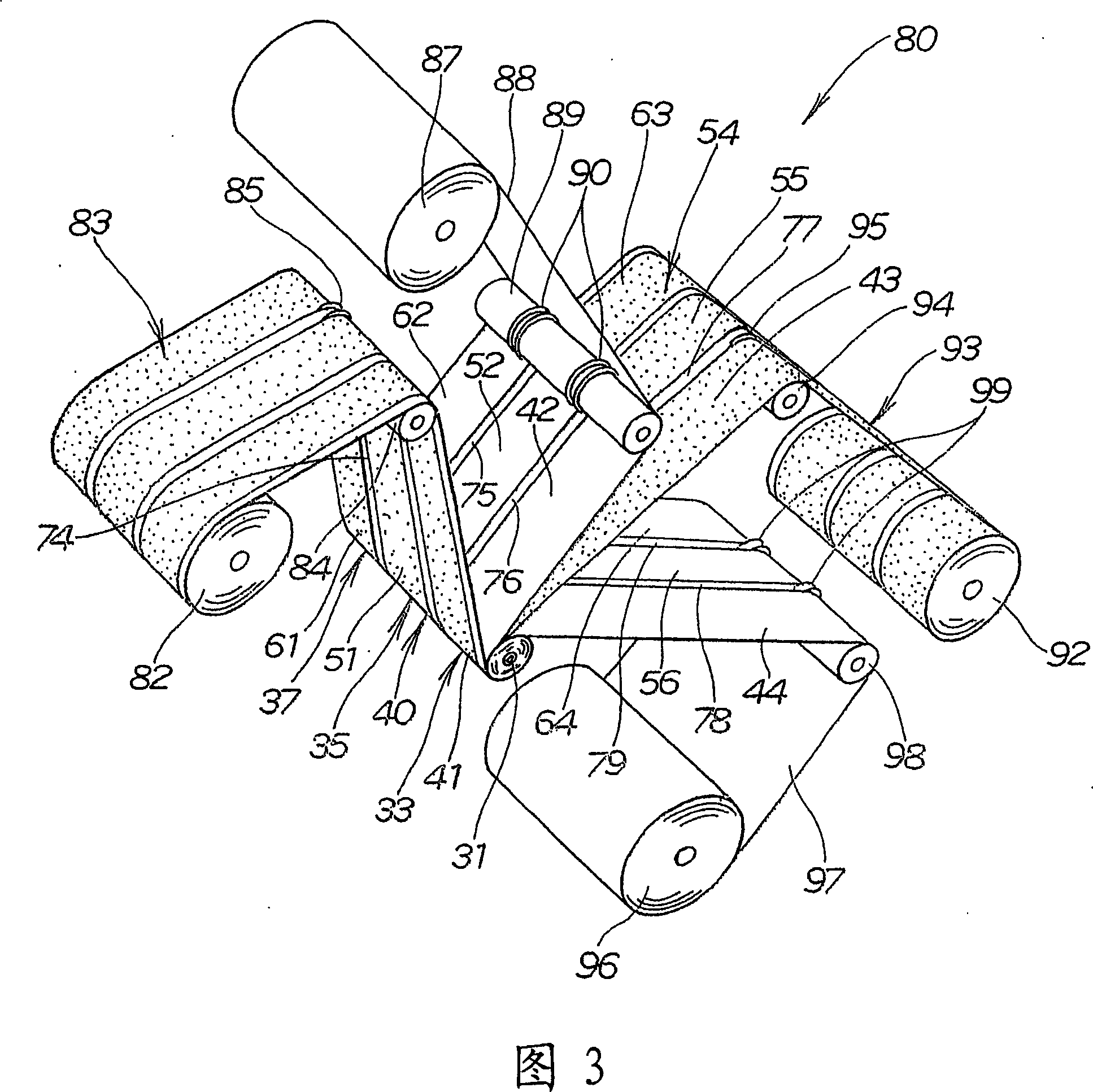

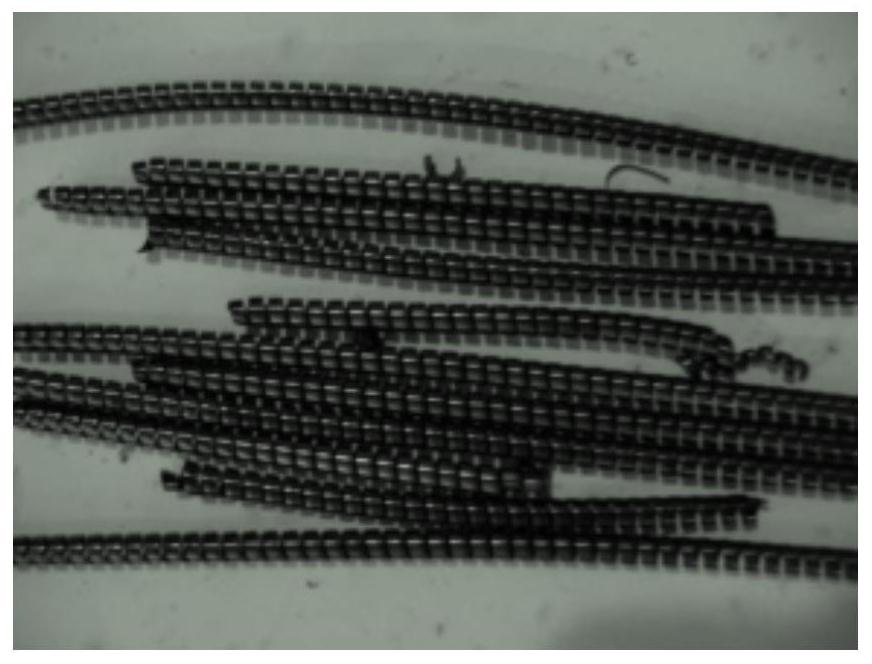

Accumulator cell assembly

InactiveCN1706059AEliminate connection impedanceIncrease currentElectrolytic capacitorsHybrid capacitor electrodesCell assemblyEngineering

PROBLEM TO BE SOLVED: To provide a serial connection structure of a storage element in which compactification is enabled by suppressing the length of a cylindrical battery and in which connection resistance can be suppressed.SOLUTION: In the serial connection structure 30 of the storage element, a positive electrode body and a negative electrode body are formed by installing a polarized electrode 48 composed of active carbon, a conductive material and a binding agent at least on one face of current collector foil, the upper storage element 33, the center storage element 35, and the lower storage element 37 are formed by winding the positive electrode body and the negative electrode body in a state of being separated by a separator, and a plurality of the storage elements 33, 35, 37 are connected in series. The serial connection structure 30 of the storage elements is constituted so that first and second enlarged current collector foils 46, 58 with at least twice the width of the polarized electrode 48 are prepared, the first and the second current collector foils 46, 58 are continuously succeeded by neighboring the storage elements, and so that the storage elements are serially connected.

Owner:HONDA MOTOR CO LTD

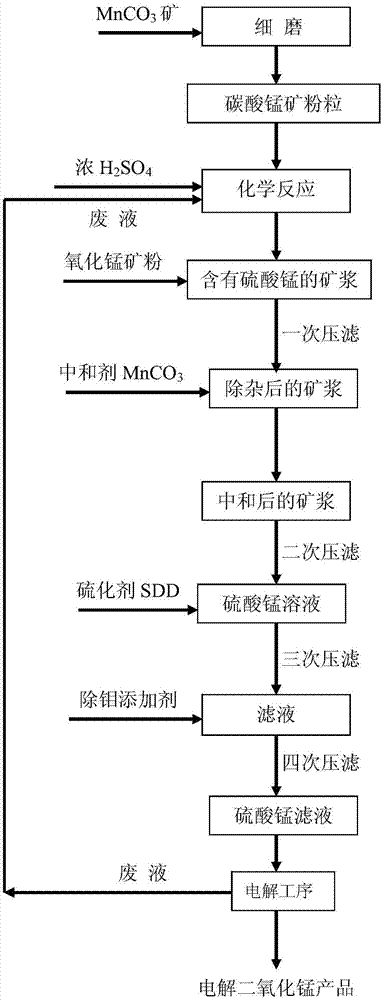

Novel neutralization process in preparation process for electrolytic manganese dioxide

ActiveCN107365915AReduce loss rateReduce volumeElectrolysis componentsProcess efficiency improvementElectrolysisSulfate

The invention discloses a novel neutralization process in a preparation process for electrolytic manganese dioxide. The novel neutralization process comprises the following steps: mixing manganese carbonate ore powder particles and concentrated sulfuric acid in a weight ratio of 1: (0.5 to 0.65), and obtaining ore pulp containing manganese sulfate and having a pH value of greater than 2 after heating, stirring and carrying out manganese leaching for 8h; then adding manganese oxide ore powder in the ore pulp containing manganese sulfate to remove impurities potassium and iron; then adding a neutralizer and carrying out secondary pressing-filtering; adding a vulcanizing agent in manganese sulfate solution to settle heavy metals, carrying out tertiary pressing-filtering, then adding a molybdenum removal additive and carrying out quartus pressing-filtering to obtain manganese sulfate filtrate; and finally carrying out static settlement and filtering on the manganese sulfate filtrate, taking the solution and carrying out electrolysis to obtain a manganese dioxide product and a waste solution. The novel neutralization process disclosed by the invention is capable of ensuring the quality of the product, greatly lowering a production cost, and increasing economic benefits, and high in market promotion value.

Owner:靖西湘潭电化科技有限公司 +1

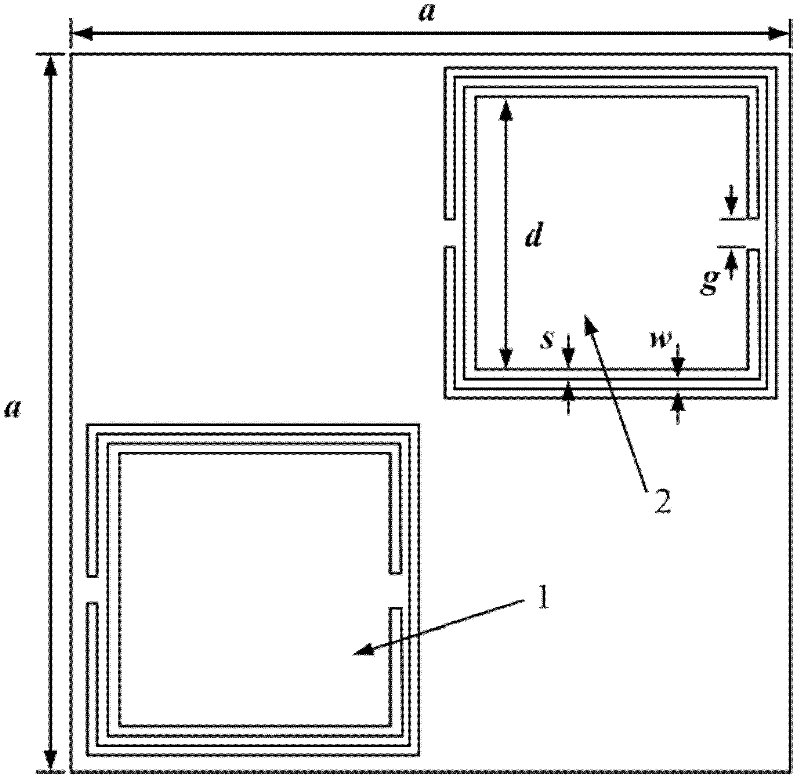

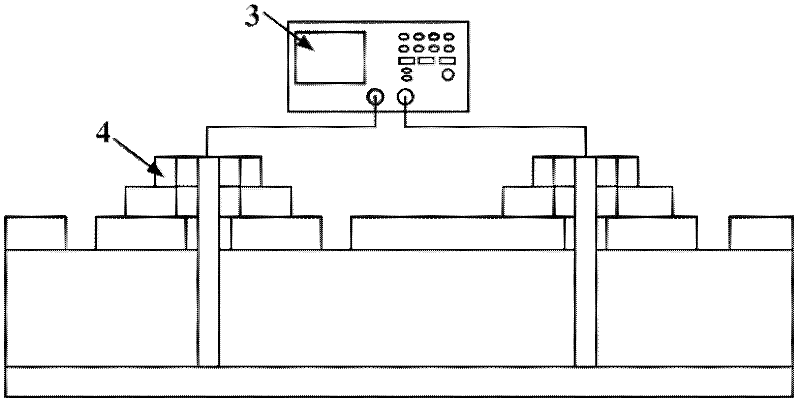

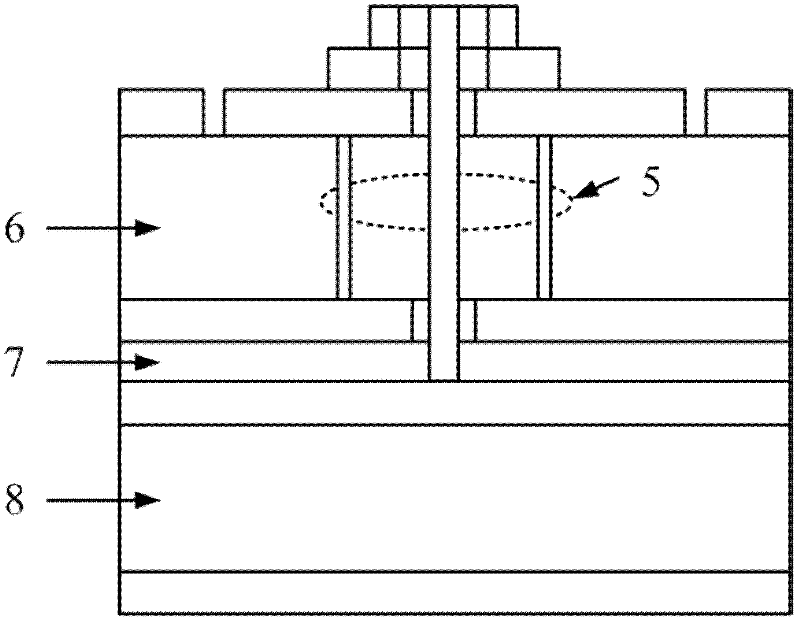

Power distribution network in high-speed circuit system

InactiveCN102522962AReduce radiation lossBreak continuityDigital technique networkCapacitanceReturn current

The invention discloses a power distribution network in a high-speed circuit system. The metal surface at one side of a buried capacitor is locally etched with a complementary split ring resonator, and the metal surface at the other side of the buried capacitor keeps complete; and simultaneously, the upper side and the lower side of the buried capacitor are respectively added with a layer of FR-4 medium, and SMA (shape memory alloy) coaxial joints are used for connecting a circuit board to a vector network analyzer to test a noise suppression transmission coefficient among ports. According to the power distribution network, the problems that the noise suppression band of a synchronous switch in the high-speed circuit system is not wide and the suppression degree is not deep are effectively solved, and simultaneously the damage for a return current path of a circuit is less. The mixed high-speed circuit system based on the power distribution network has good power integrity, and is convenient for standard technical processing of printed circuit boards.

Owner:SHANGHAI JIAO TONG UNIV

Structural steel wire and method for improving machinability of structural steel wire

The invention discloses a structural steel wire and a method for improving the machinability of the structural steel wire, and belongs to the field of steel smelting. The structural steel wire is composed of 0.42-0.48% of C, 0.15-0.35% of Si, 0.6-0.9% of Mn, 0-0.030% of P, 0.012-0.028% of S, 0.003-0.2% of Ni, 0.02-0.2% of Cr, 0.02-0.3% of Cu, 0-0.35% of Ni+Cr, 20-40% of Mn / S, class-A mingled substances with the grade 1-3, 0.010-0.035% of Als and the balance Fe and inevitable impurities. The structural steel wire has good machinability.

Owner:SGIS SONGSHAN CO LTD

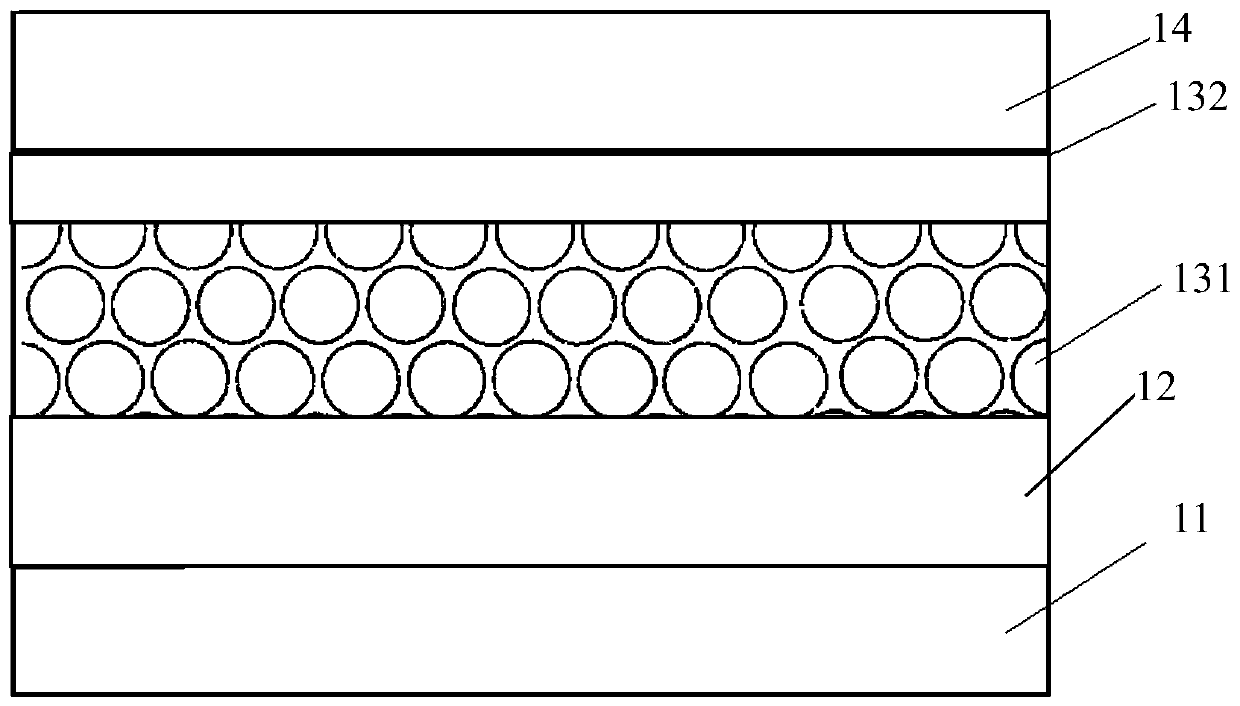

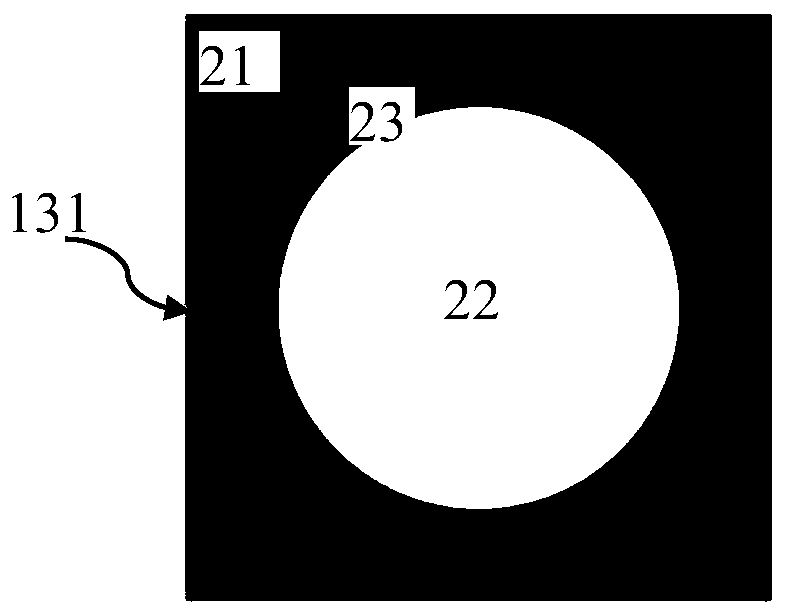

Ultrathin heat insulation film

PendingCN109693422ALow thermal conductivityGood weather resistanceSynthetic resin layered productsCoatingsTotal thicknessThermal conductivity

The present invention relates to an ultrathin heat insulation film. The ultrathin heat insulation film comprises a substrate layer, an adhesive layer, a heat insulation layer and a protective layer which are arranged from bottom to top; the substrate layer is a flexible polymer film having a thickness of 15-40 [mu]m; the adhesive layer is a high temperature-resistant adhesive; the heat insulationlayer comprises an aerogel layer and a metal oxide layer, and the aerogel layer is bonded to the surface of the substrate layer by the adhesive layer; the metal oxide layer is a high-refractive indexmetal oxide, and the metal oxide layer covers the surface of the aerogel layer; the total thickness of the heat insulation layer is less than 3 [mu]m; and the protective layer covers the surface of the metal oxide layer, and has a thickness of 10-30 nm. The overall thickness of the heat insulation film is only 50 [mu]m or less, the heat conductivity is very low, and the ultrathin heat insulation film can be attached to the surface of a complicated shape object or applied to occasions having strict thickness limit on the heat insulation film, and can be used to produce window films, vacuum cupsheat insulation lunch boxes, outdoor sleeping bags and other products.

Owner:深圳德宝天成科技有限公司

Soldering lug for CAB soldering without soldering flux

InactiveCN106695157APromote wetting and spreadingBreak continuityWelding/cutting media/materialsSoldering mediaManufacturing cost reductionSoldering

The invention discloses a soldering lug for CAB soldering without soldering flux. The soldering lug comprises a brazing filler metal layer and skin layers wrapping the two sides of the brazing filler metal layer. The soldering lug is characterized in that the brazing filler metal layer comprises 5%-15% of silicon, 0.01%-1% of magnesium and 0.05%-0.15% of bismuth, and each skin layer comprises 3%-12% of Si and less than 0.10% of magnesium. According to the soldering lug, no core layer is arranged, the soldering lug is fully molten during soldering and flows into a region to be soldered, a soldering seam is formed and attractive in appearance, the quality of products is good, no residue exists, soldering flux pollution is avoided, and the soldering efficiency of the products is high; due to the fact that a three-layer structure is adopted, the very thin soldering lug can be made, the soldering lug is applied to complex components and occasions where the soldering portions are very narrow, such as CAB soldering without the soldering flux of aluminum alloys of part extrusion, part machining and the like, and therefore the soldering lug is extremely wide in application range; and meanwhile the soldering lug is extremely simple in structure, the manufacturing process is simple, the consumption of materials can be saved, and the manufacturing cost is lowered.

Owner:ZHEJIANG YINLUN MACHINERY

Preparation method of sanitation product with incompletely-degreased pure cotton non-woven fabric

InactiveCN110396764APromote wettingFeel goodBiochemical treatment with enzymes/microorganismsNon-woven fabricsLacquerHigh pressure water

The invention relates to the field of sanitation products and provides a preparation method of a sanitation product with an incompletely-degreased pure cotton non-woven fabric. The defects are overcome that a preparation technology of a pure cotton non-woven fabric in the prior art is complex, energy consumption is high, and only complete degreasing can be conducted. The sanitation product with the incompletely-degreased pure cotton non-woven fabric is prepared in the mode that a fluid-permeability surface layer, an absorber and a non-fluid-permeability bottom layer are prepared and integrallycompounded. A method for preparing the fluid-permeability surface layer comprises the specific steps of 1) opening and impurity removal for raw cotton; 2) combing; 3) incomplete degreasing; 4) whiteness improvement; 5) laccase treatment; 6) washing with water, drying and secondary impurity removal, wherein during secondary impurity removal, impurities with the diameters of 0.5 millimeter or beloware removed through a foreign fiber sorting machine; 8) net formation through carding; 9) spunlace, wherein the high-pressure water flow is adopted for snarling a cotton net obtained through treatment in step 8); 10) drying, wherein a next treatment working process is executed.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Accumulator cell assembly

InactiveCN100340019CBreak continuityAvoid intersectionElectrolytic capacitorsHybrid capacitor electrodesConductive materialsEngineering

PROBLEM TO BE SOLVED: To provide a serial connection structure of a storage element in which compactification is enabled by suppressing the length of a cylindrical battery and in which connection resistance can be suppressed.SOLUTION: In the serial connection structure 30 of the storage element, a positive electrode body and a negative electrode body are formed by installing a polarized electrode 48 composed of active carbon, a conductive material and a binding agent at least on one face of current collector foil, the upper storage element 33, the center storage element 35, and the lower storage element 37 are formed by winding the positive electrode body and the negative electrode body in a state of being separated by a separator, and a plurality of the storage elements 33, 35, 37 are connected in series. The serial connection structure 30 of the storage elements is constituted so that first and second enlarged current collector foils 46, 58 with at least twice the width of the polarized electrode 48 are prepared, the first and the second current collector foils 46, 58 are continuously succeeded by neighboring the storage elements, and so that the storage elements are serially connected.

Owner:HONDA MOTOR CO LTD

Free-cutting and corrosion-resisting non-magnetic high manganese steel balance block for compressor

A free-cutting and corrosion-resisting non-magnetic high manganese steel balance block for a compressor belongs to the technical field of metallurgy, and is characterized by comprising the following components in percentage by weight: 10-19 percent of Mn, 5-12 percent of Cr, not more than 0.8 percent of Cr, not more than 1.5 percent of Cu, not more than 0.3 percent of S, not more than 1.0 percent of Si, and Fe in balancing amount. The free-cutting and corrosion-resisting non-magnetic high manganese steel balance block disclosed by the invention has the advantages of reasonable formula, low cost of materials, freeness of lead for realizing environment friendliness, free-cutting processing, stable cold-processing magnetism and favorable corrosion resistance. Inclusions such as manganese sulfide and copper in a free state are respectively formed by adding S and Cu elements; the tissue continuousness of an alloy steel substrate is interrupted and the cutting difficulty is reduced; meanwhile, the residue of carbide is reduced by properly reducing the component of C element; the corrosion-resisting capability of the non-magnetic high manganese steel is improved by adding Cr element; and meanwhile, the stability of a non-magnetic high manganese steel austenite is ensured by reasonably adjusting the proportions of the C element, the Mn element and the Cr element, i.e., the magnetic stability during cold processing is improved.

Owner:FUYANG HUANTONG ELECTRIC POWER EQUIP

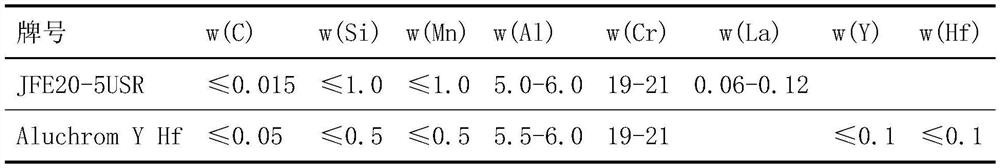

Production method of barium cleaning iron-chromium-aluminum alloy

The invention provides a production method of a barium cleaning iron-chromium-aluminum alloy. The method comprises the following steps: S1, an alloy containing Si, Mn and Cr is proportioned, and the alloy as a smelting raw material is added into a smelting furnace for smelting; S2, vacuum decarburization is conducted in an AOD furnace or a VOD furnace, C is smaller than or equal to 0.05 wt%, and silicon iron is added for pre-deoxidation; S3, smelting is continued to enable Si, Mn and Cr to reach a preset range; S4, an aluminum ingot is added for final deoxidation, sufficient soft blowing is conducted, the content of Al is adjusted in the refining furnace, and the content of Al is controlled to be 5-8.5 wt%; S5, barium alloy is weighed and added into the refining furnace, the weight percentage of Ba is 0.010%-0.5%, and sufficient stirring is conducted; S6, high-calcium refining slag is adopted to adsorb and remove impurities; S7, La is added into the refining furnace for rare earth alloying, and the weight percentage of La is 0.03%-0.15%; and S8, continuous casting, hot continuous rolling, annealing, acid pickling, coping, cold rolling, intermediate annealing, cold rolling, longitudinal shearing, withdrawal and straightening and finished product packaging are conducted, and the product is obtained.

Owner:国研(淮安)新材科技有限公司

Stainless-steel-colored aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, in particular to a stainless-steel-colored aluminum alloy and a preparation method thereof. The stainless-steel-colored aluminum alloyis prepared from the following components in percentage by weight: 0.38-0.41% of silicon, less than 0.15% of iron, less than 0.1% of copper, less than 0.1% of manganese, 0.48-0.51% of magnesium, lessthan 0.1% of chrome, less than 0.1% of zinc, less than 0.1% of titanium and the balance of aluminum and impurities, wherein the single impurity is less than 0.05%, and the total amount of the impurities is less than 0.15%. The stainless-steel-colored aluminum alloy has the color and gloss of an existing stainless steel profile, has a mirror effect of stainless steel, has the smaller density and lower cost than those of the stainless steel profile, and can replace the existing stainless steel profile to be applied to building decoration.

Owner:东莞市润华铝业有限公司

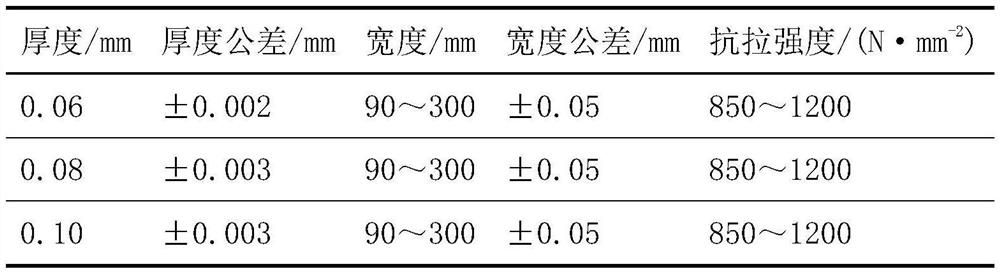

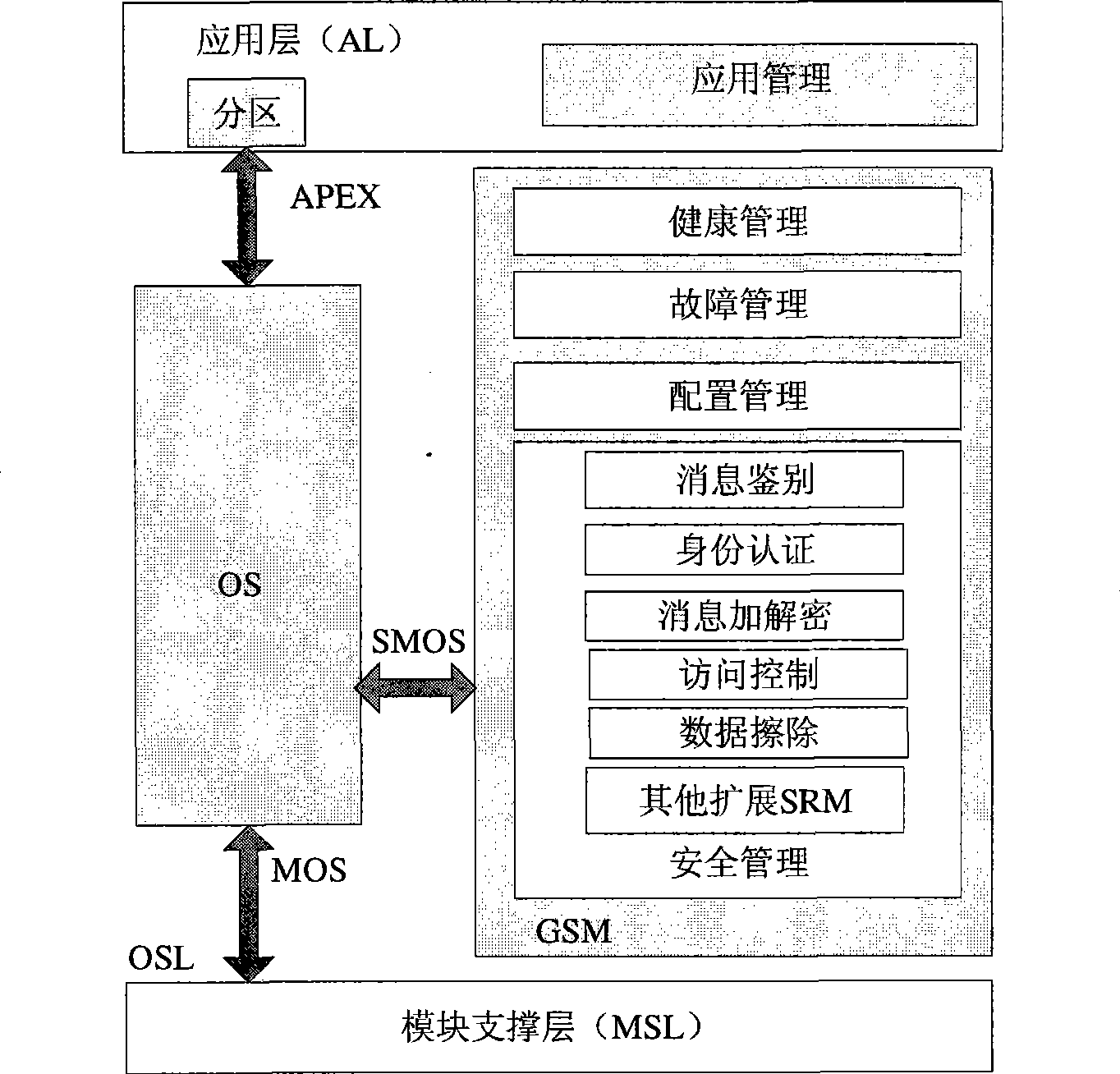

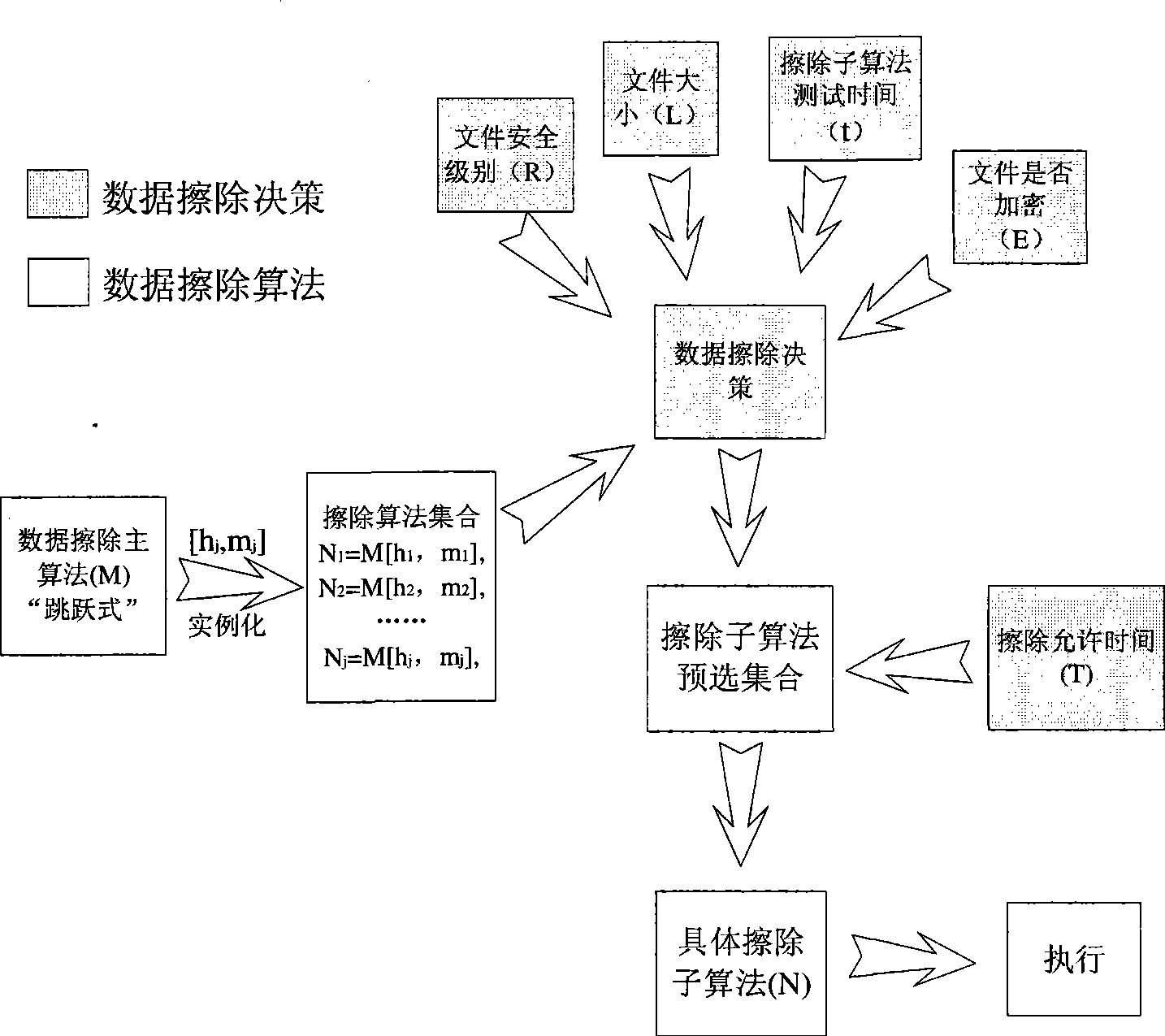

Time termination high-performance grading data erasing method for synthetic aviation electronic system

ActiveCN101364228AErasure implementationAchieve different coverageSpecial data processing applicationsDiffusion methodsAviation

The invention discloses a time-limited efficient method for erasing ranked data in an integrated avionics system, and provides a layered architecture to erase the data of the integrated avionics system, wherein the upper layer thereof is the ranked data erasing decision, which decides a sub-algorithm for erasing data in a file by adopting a 'mean correspondence diffusion method' and combining the file properties, such as security level, size, encryption, etc., as well as the system allowable erasing time. The lower layer is the ranked data erasing algorithm, which comprises a main erasing algorithm and an erasing algorithm set composed of erasing sub-algorithms, wherein, the main erasing algorithm is used for balancing the security and the timeliness of the file erasing by designing a 'skipping' method; the erasing sub-algorithms in the erasing algorithm set are generated and configured according to different parameters by the main erasing algorithm, and used for being called by the erasing decision, so as to erase the files at different security levels. The method for erasing the ranked data has the characteristics of limited time, high efficiency, safety and flexibility. Therefore, the method is suitable for the integrated airborne avionics system of the next-generation.

Owner:XIDIAN UNIV

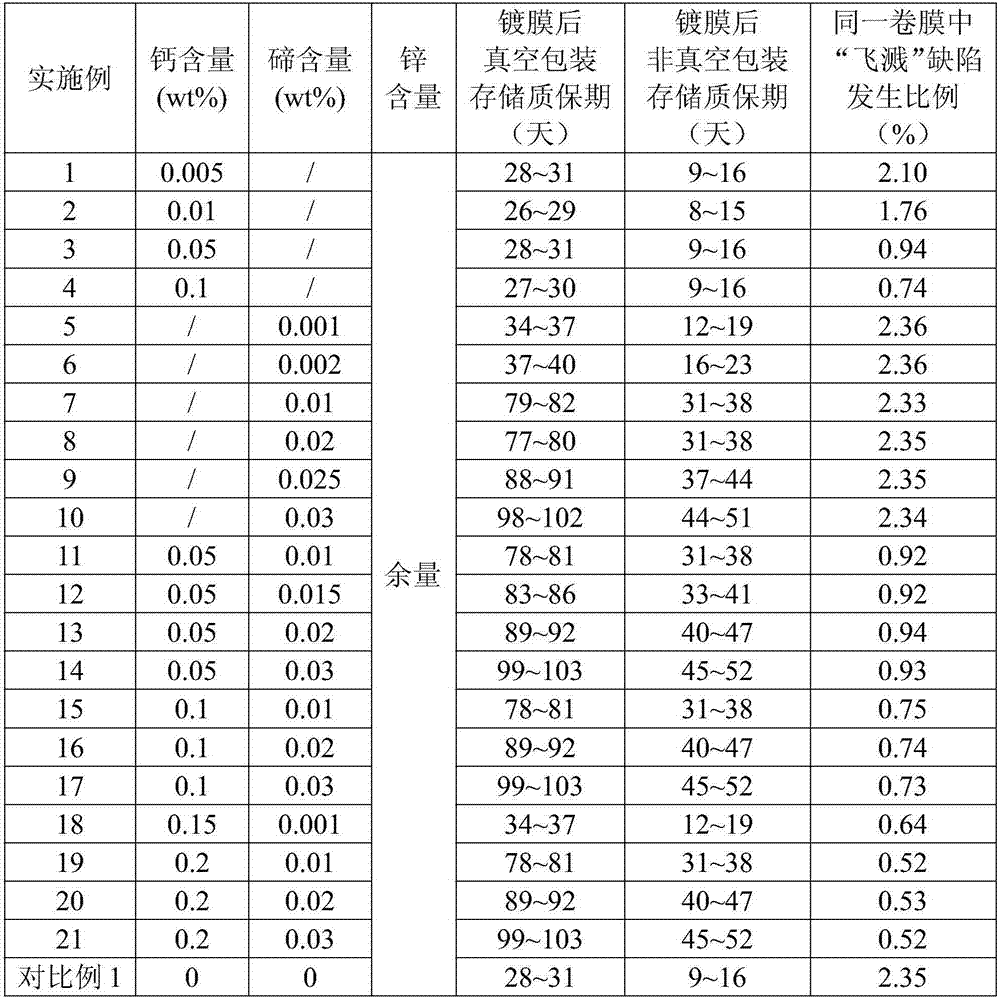

Heat sink zinc-based microalloy

InactiveCN107354345AImprove protectionExtended storage periodThin/thick film capacitorFixed capacitor electrodesTe elementZinc alloys

The invention discloses a heat sink zinc-based microalloy which takes zinc as a matrix and is added with trace calcium and / or tellurium. The heat sink zinc-based microalloy is prepared from the following components in percentage by weight: 0.005 to 0.2 percent of calcium, 0.001 to 0.03 percent of tellurium, less than or equal to 0.02 percent of impurities, and the balance of zinc, wherein the total weight percentage of all the components is 100 percent. When the zinc alloy disclosed by the invention is used for vacuum evaporation coating of a metal thin film, the occurrence rate of the "splashing" defect is low, and the yield is high; and furthermore, the storage time of the evaporation-coated thin film subjected to is longer than that of a conventional pure zinc evaporation-coated thin film.

Owner:绍兴市天龙锡材有限公司

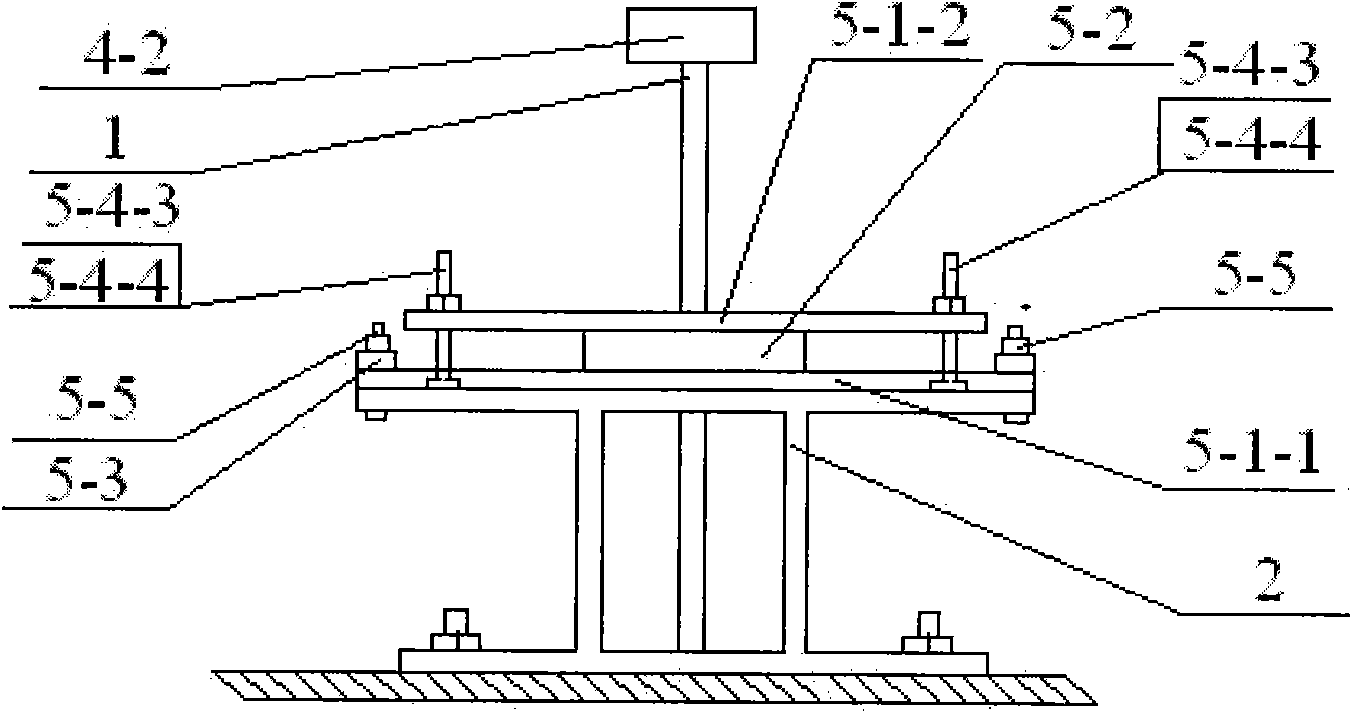

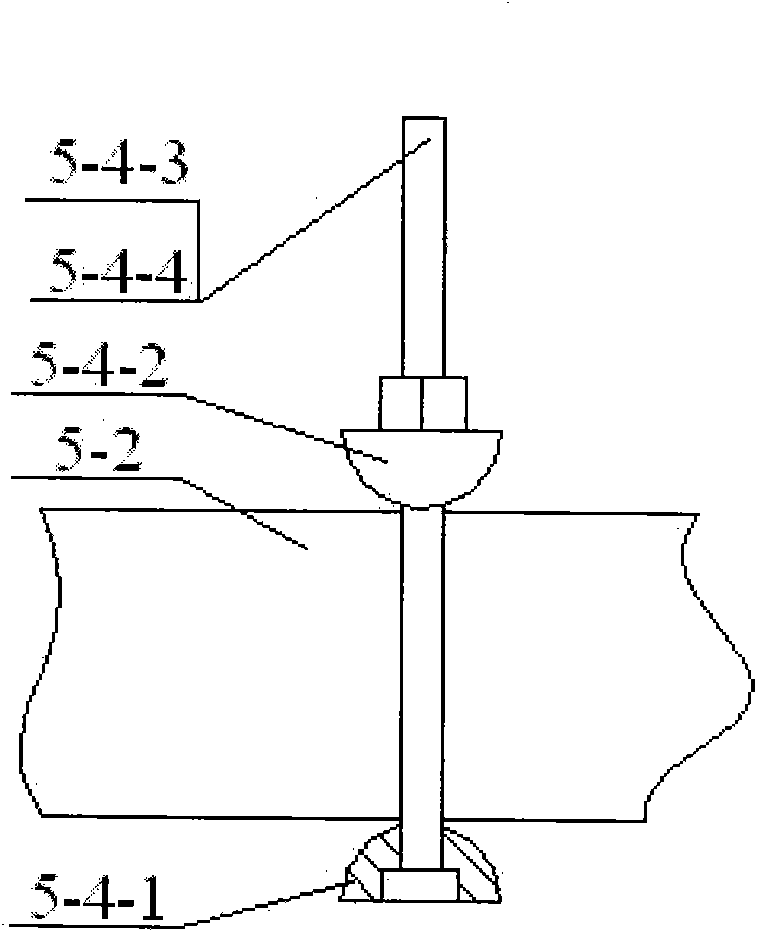

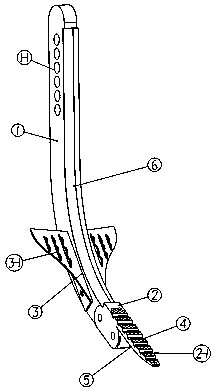

Bionic sub-soiling shovel

InactiveCN111034390AEasy to exportReduce resistanceSpadesShovelsAgricultural engineeringStructural engineering

The invention relates to a sub-soiling shovel. The sub-soiling shovel consists of a shovel handle, a shovel tip fixed at the bottom of the shovel handle and a pair of wing shovels symmetrically arranged on the left and right sides of the shovel tip; the front end face of the shovel handle is designed with a farming drag reduction structure which is a soil guiding plate fixed on the front end faceof the shovel handle, and the two sides on the front end face of the soil guiding plate are inclined; the upper surfaces of the wing shovels are also designed with the farming drag reduction structures, the drag reduction structures are six wavy strips that are different in length, are fixed on the surfaces of the wing shovels and are equidistantly distributed along the length directions of the wing shovels, and the tops of the wavy strips are in arc shapes; the surface of the shovel tip is designed with the farming drag reduction structure as well, the farming drag reduction structure imitates the body surface geometrical features of soil cave animals and aquatic scallops and is designed as ribs equidistantly distributed on the surface of the shovel tip, and bumps are uniformly distributed on the surfaces of the ribs so as to further play the role of crushing and removing soil to achieve drag reduction effects; the edges of the wing shovels are in S shapes; and the bottom surface of the shovel tip is an arc-shaped curved surface, so that high-to-low smooth transition from the front end to the rear end of the shovel tip can be realized. The related sub-soiling shovel is small in cultivation resistance, so that soil can be easily loosened and broken, and the sub-soiling quality of the soil can be enhanced.

Owner:NORTHWEST A & F UNIV

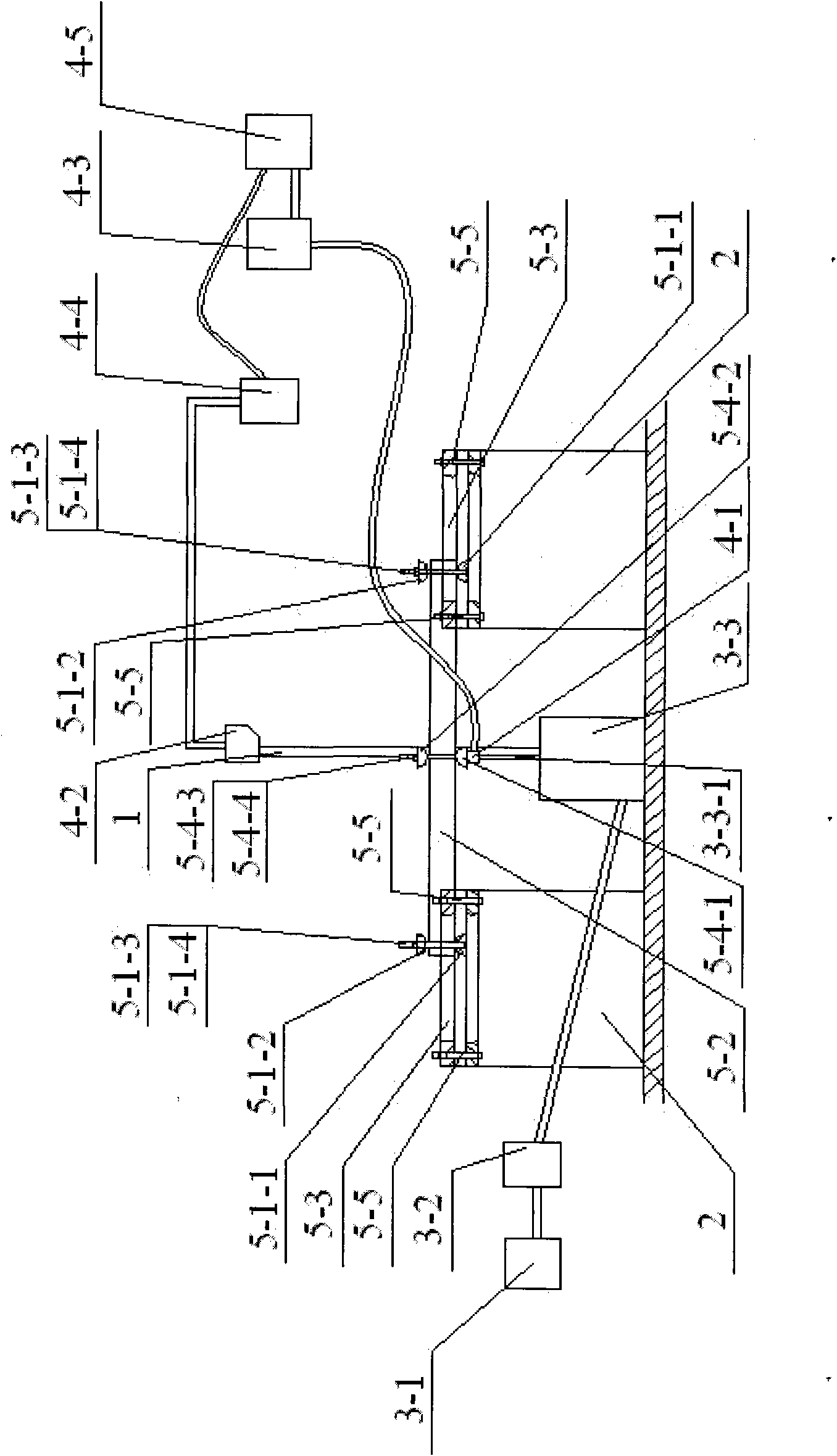

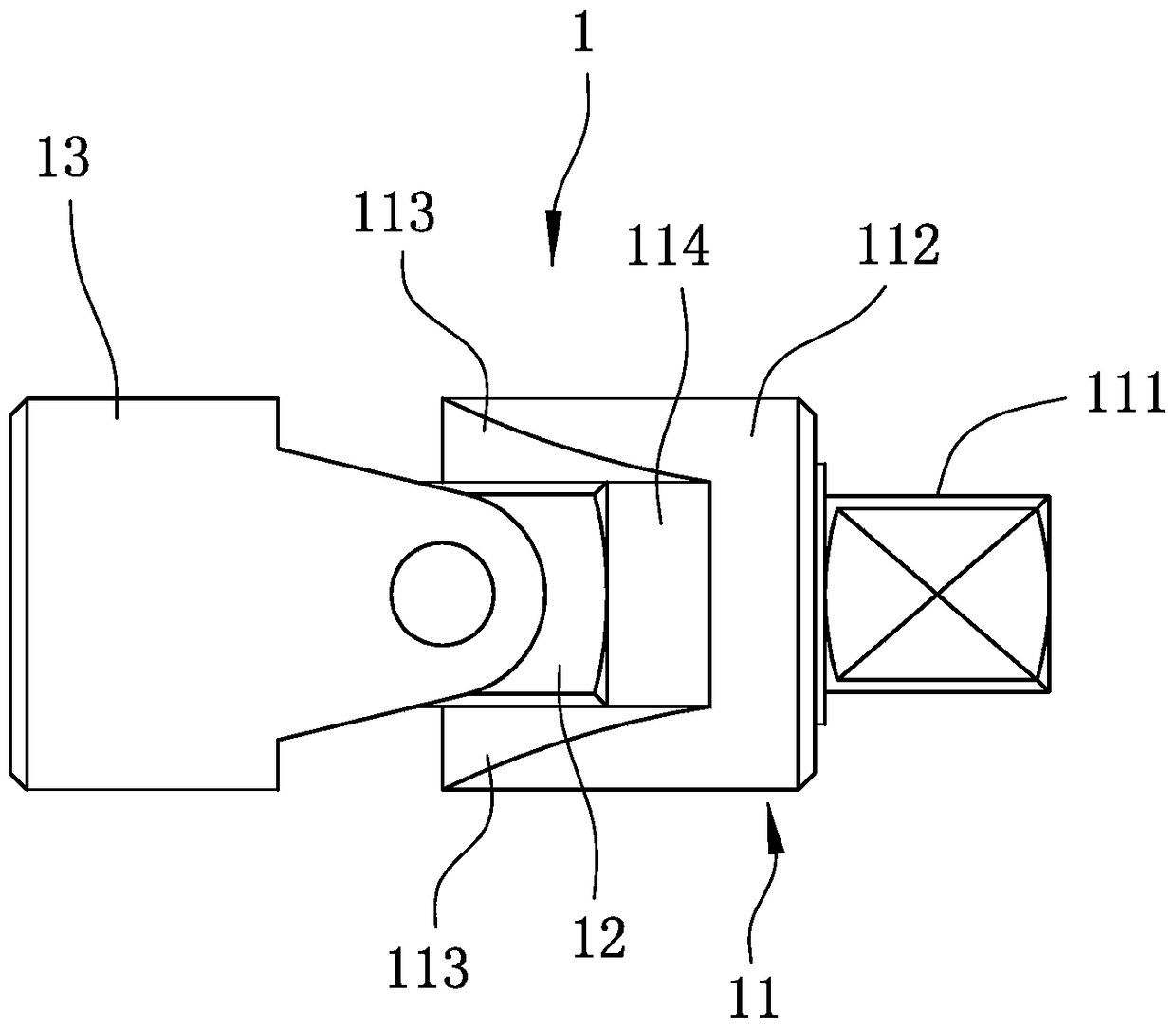

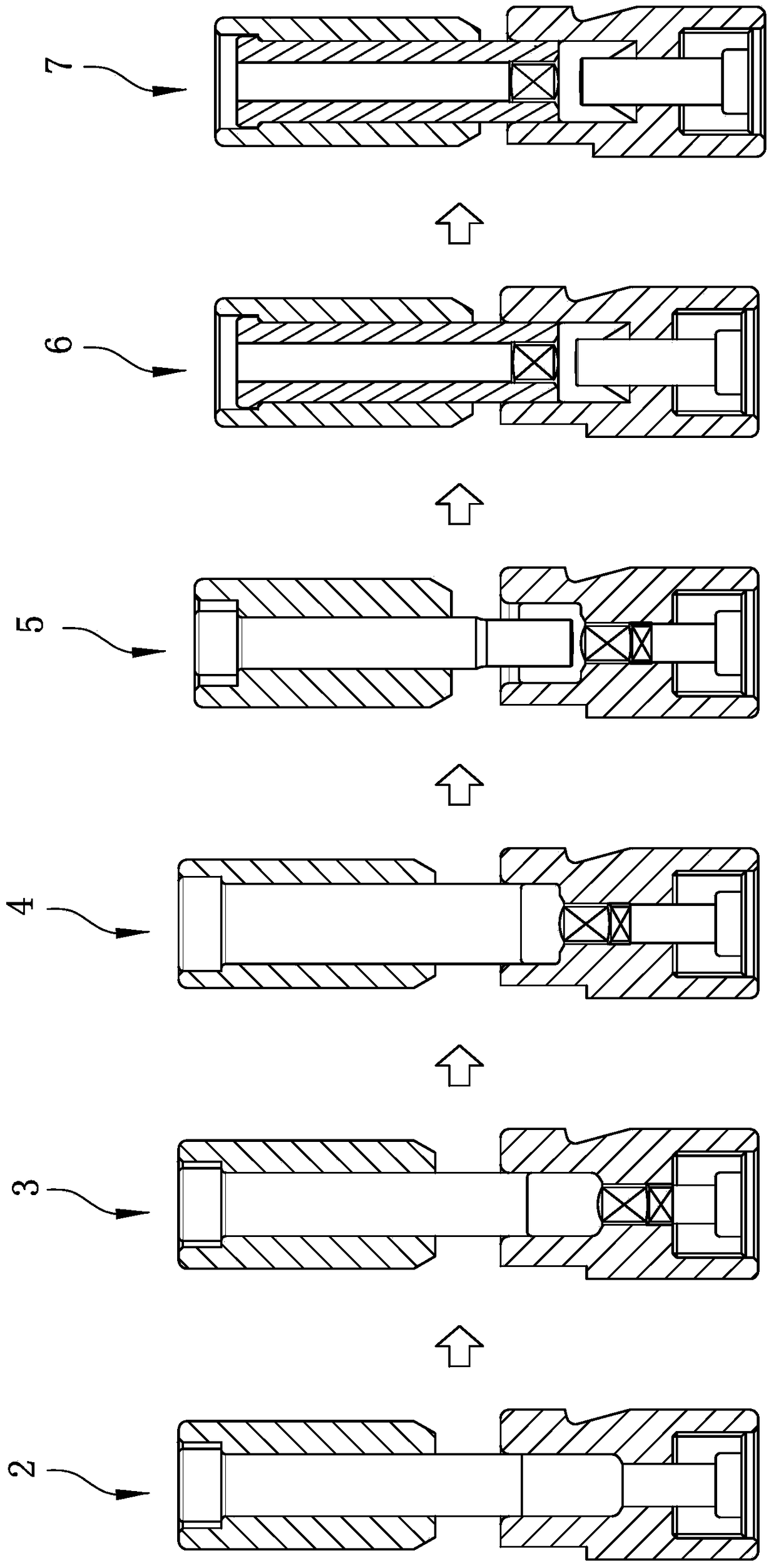

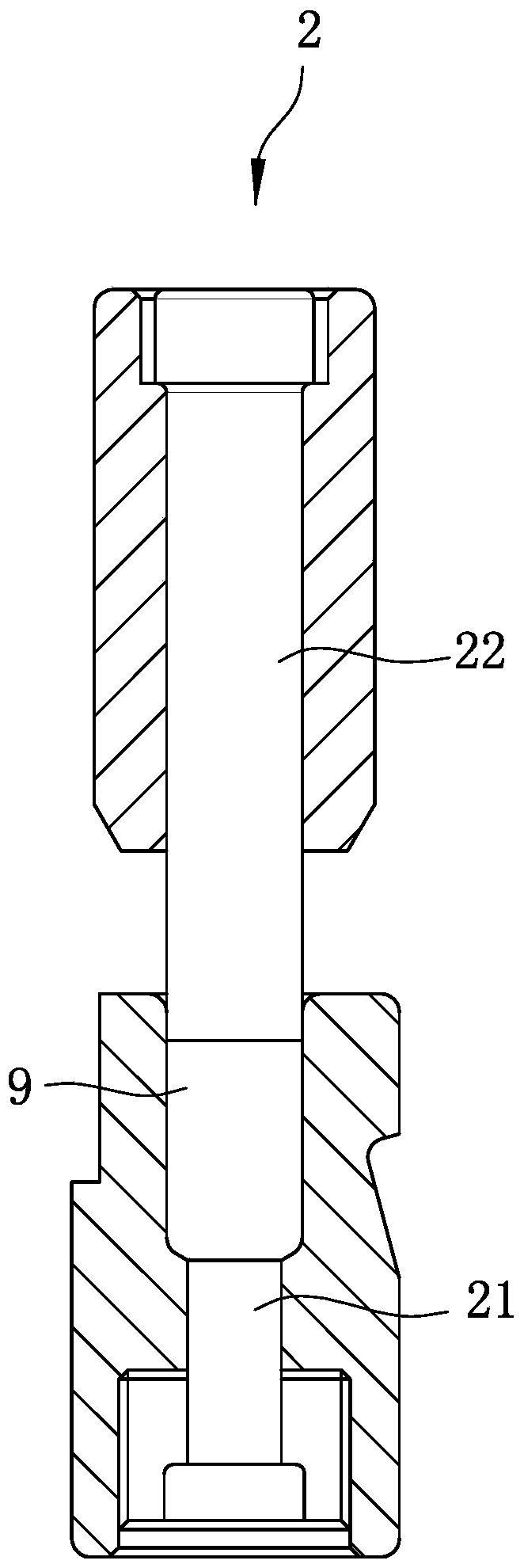

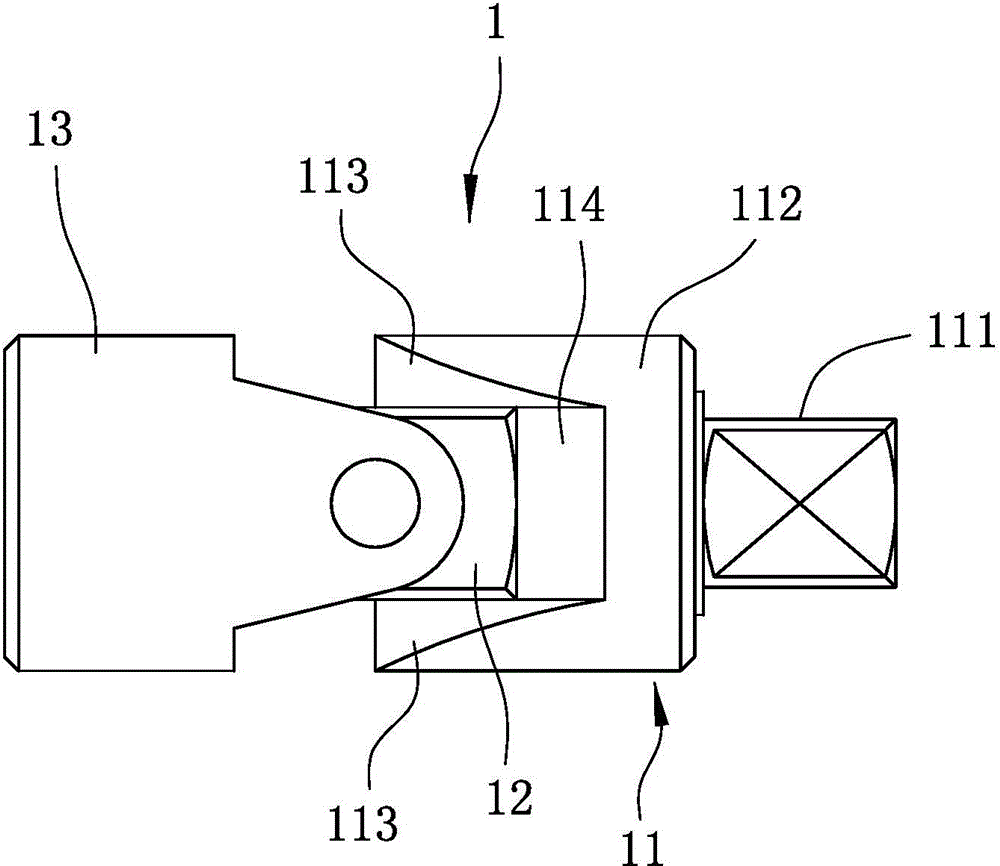

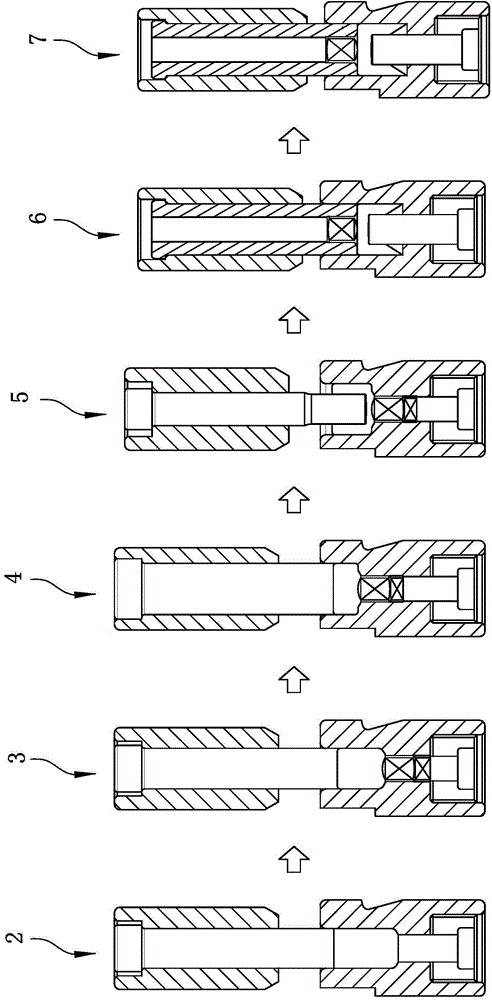

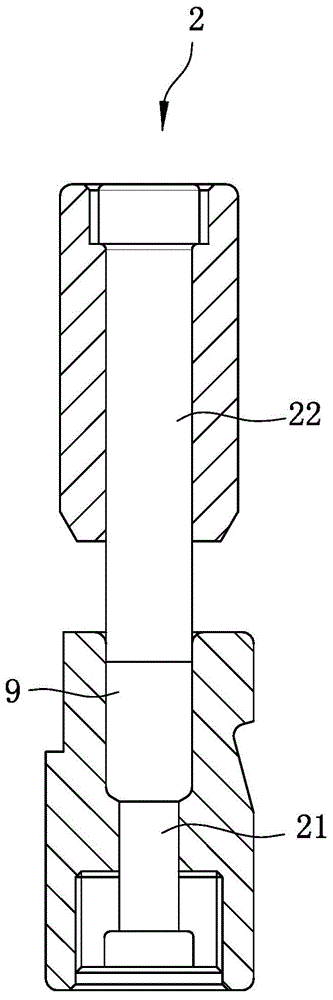

Forming method and device for male coupling part of universal joint

InactiveCN106141068BIncrease profitBreak continuityShaping toolsExtrusion diesUniversal jointEngineering

The invention discloses a forming method and a device for a male connector of a universal joint. The forming method comprises the following steps: (A) preparing a columnar blank with a set length; (B) placing the columnar blank into a pre-forging die to make the columnar blank formed into a pre-forged piece; (C) placing the pre-forged piece into a convex block forming die to form a convex block part at one end of the pre-forged piece, the outer diameter of the convex block part being less than that of the other end of the pre-forged piece; and (D) placing the pre-forged piece into a convex lug forming die to make the pre-forged piece form a seat body part connected with the convex block part, and two convex lug parts formed at one end, away from the convex block part, of the seat body part in a spacing manner, the seat body part being cooperated with the convex lug parts to define a movable slot. The male connector can be formed according to the steps, and a cutting procedure is not needed, so that the use rate of materials can be increased.

Owner:赖传荣

Preparation process of blending modified polyurethane adhesive

PendingCN114836161ABreak continuityDestroy compactnessPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolymer sciencePolyurethane adhesive

The invention discloses a preparation process of a blending modified polyurethane adhesive, and belongs to the technical field of improved materials. The preparation process of the blending modified polyurethane adhesive comprises but is not limited to the following steps: preparing polyethersulfone, and mixing the polyethersulfone with dichloromethane until a milk white solution is obtained; then, 4, 4 '-diphenylmethane diisocyanate and polyurethane are mixed, and a mixture is obtained; mixing the milky white solution with the mixture, and evaporating dichloromethane by adopting an oil bath until the dichloromethane is fully volatilized to obtain a secondary mixture; and transferring the secondary mixture to a double-screw extruder for treatment to obtain a product. According to the preparation process of the blending modified polyurethane adhesive, the raw material components are simple, processing operation is facilitated, and various properties are good.

Owner:郑春华

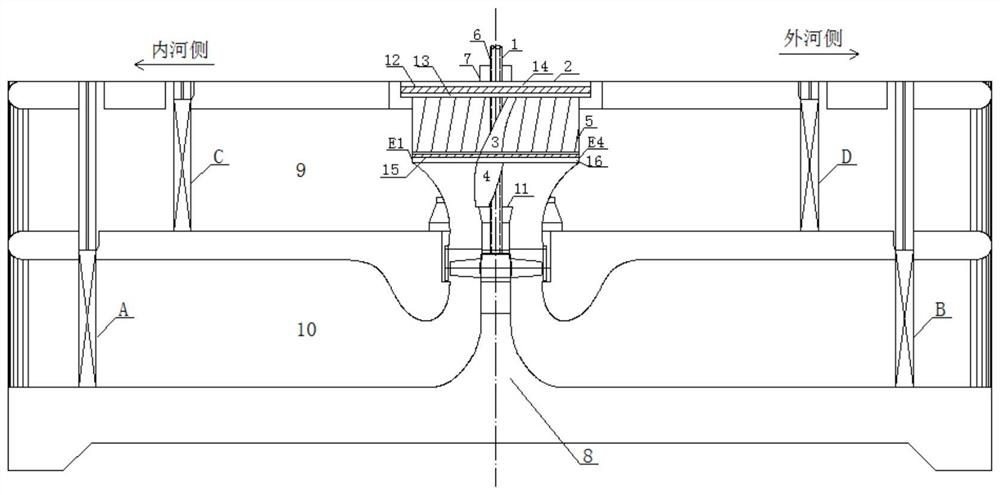

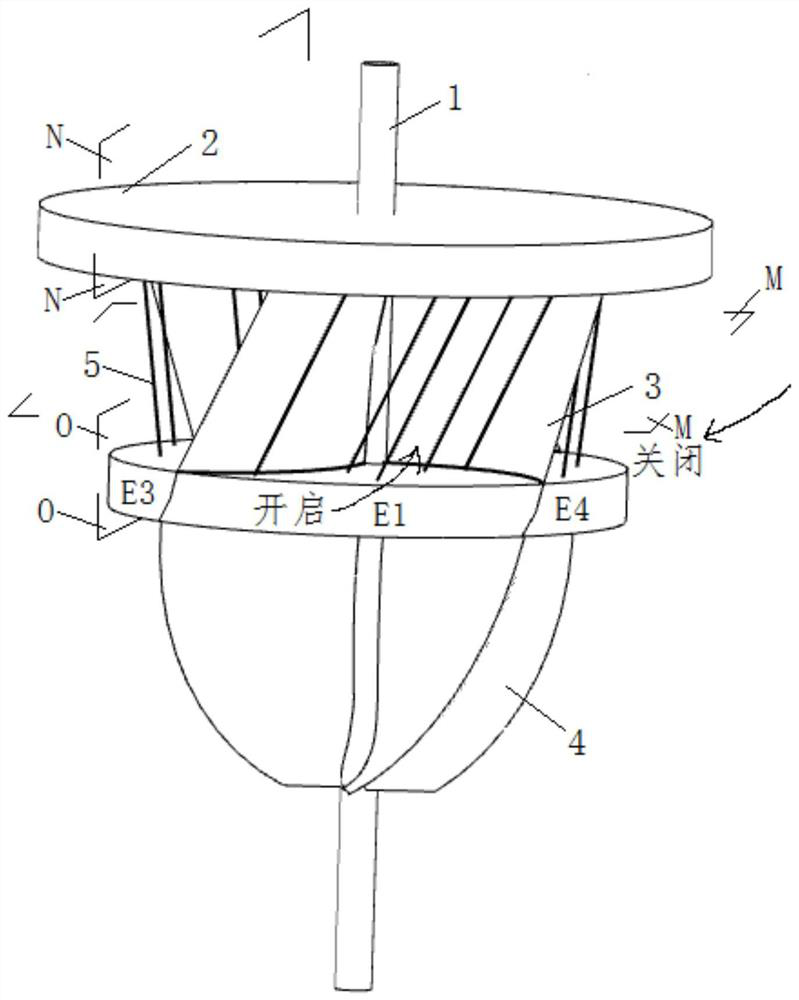

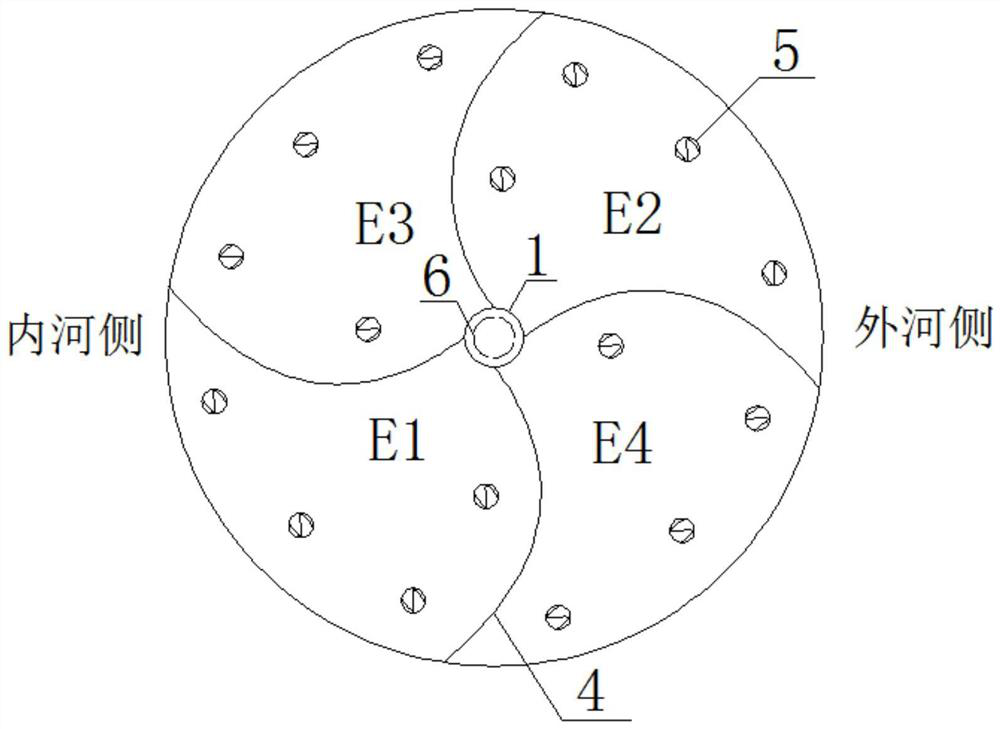

A new double-stage flexible flapper device and its operation method for bidirectional pumping stations

ActiveCN112253488BSimple structureWorking principle is clearPump componentsPump controlPull forceWater flow

A novel double-stage flexible flapper device suitable for a bidirectional pumping station and its operating method, comprising a central shaft, a deflector, a double-stage flapper, a large spring, a magnetic plate and a water pump top cover. The two-stage flexible flapper device is a detachable structure. Each flapper is composed of two separate flappers. The outer side of a single flapper adopts a 1 / 4 circular surface shape and is set directly above the water outlet bell mouth. It is connected to the central axis and can move spirally around the central axis, and the weight of the second-stage flap door is greater than that of the first-stage flap door. There are magnetic plates in the single flap door and the top cover of the water pump, and the single flap door and the top cover of the flap door Large springs are arranged obliquely between them. The whole device realizes graded outflow and graded cutoff through the balance relationship between the flapper's own weight, spring force (pull force), magnetic plate attraction and water pressure. The invention has a simple structure and a novel concept, and can ensure that the flap door can be opened smoothly and in time when the machine is turned on and the water flow can maintain a good flow state, and the flap door can be closed in time by gravity when the machine is turned off.

Owner:YANGZHOU UNIV

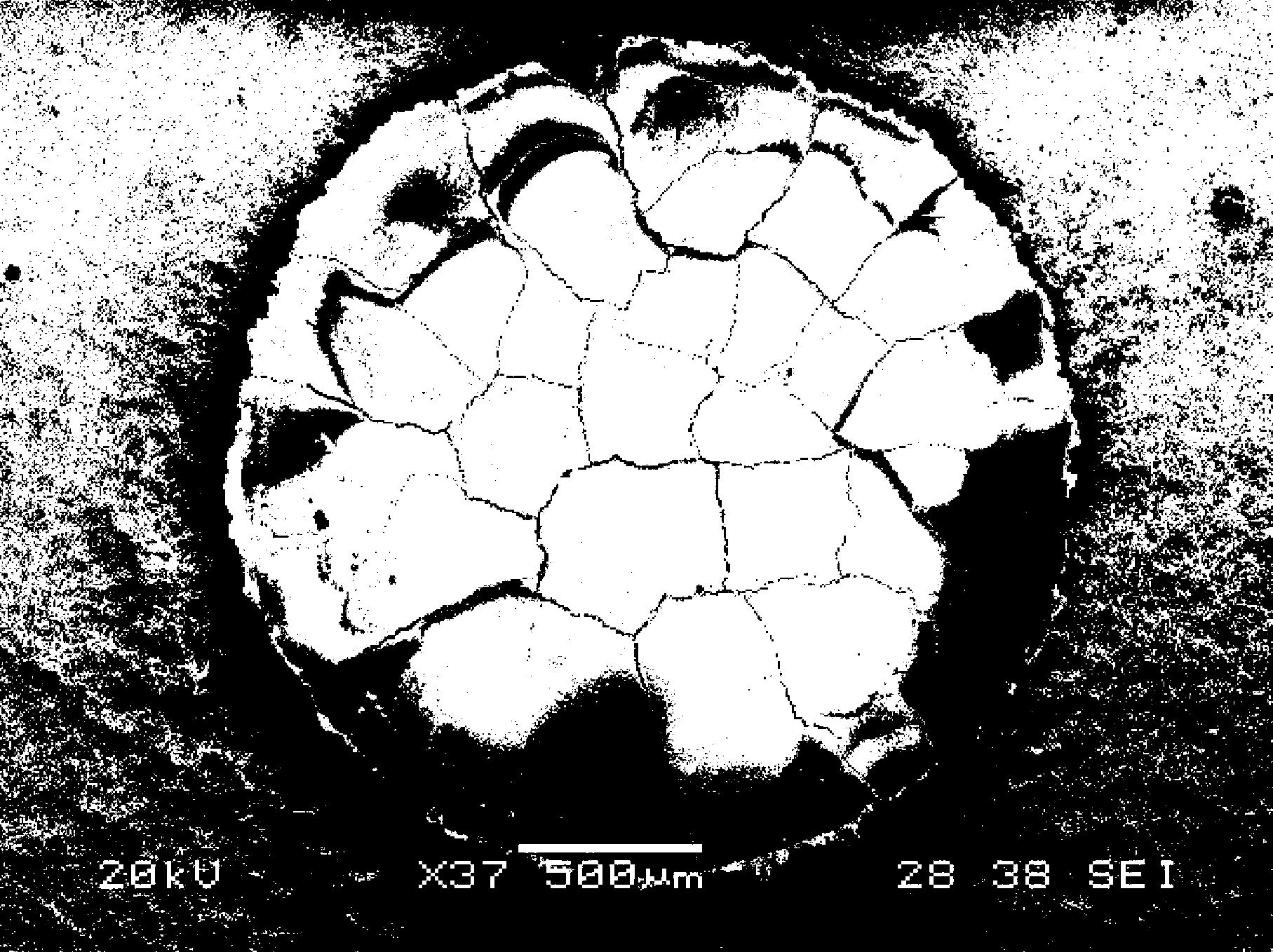

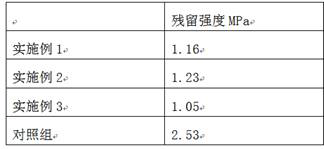

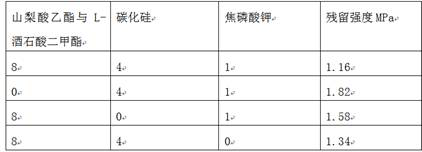

A method for preparing foundry sand with good collapsibility

InactiveCN110666096BHigh strengthGood collapsibilityFoundry mouldsFoundry coresInorganic potassium compoundsCrazing

The invention discloses a method for preparing casting molding sand with good collapsibility, and relates to the technical field of casting. The method comprises the following steps that a collapse modifier is prepared, the collapse modifier is composed of organic grease, carbide micro powder and inorganic potassium compound; and roughing sand, water glass, water, clay and the collapse modifier are mixed to form the casting molding sand with good collapsibility. According to the method, the normal-temperature strength and the residual strength of the molding sand can be effectively improved, pores and cracks can be generated in a bonding film in the molding sand after high-temperature by adding the collapse modifier prepared in the method, so that the continuity of the bonding film generated in the molding sand can be effectively destroyed, and then the residual strength is reduced, so that the collapsibility is remarkably improved, and better recycling is facilitated.

Owner:含山县能华铸造有限公司

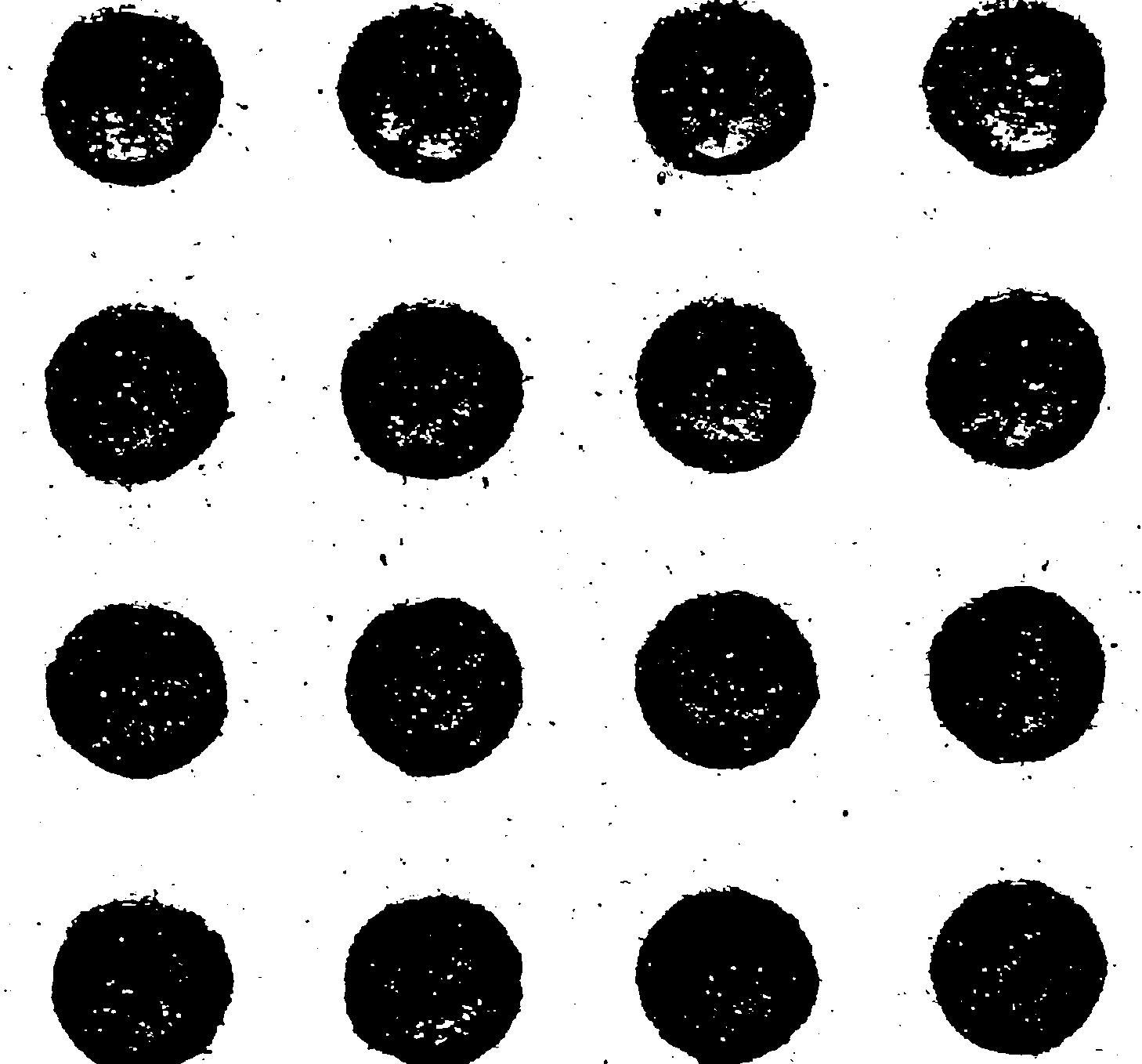

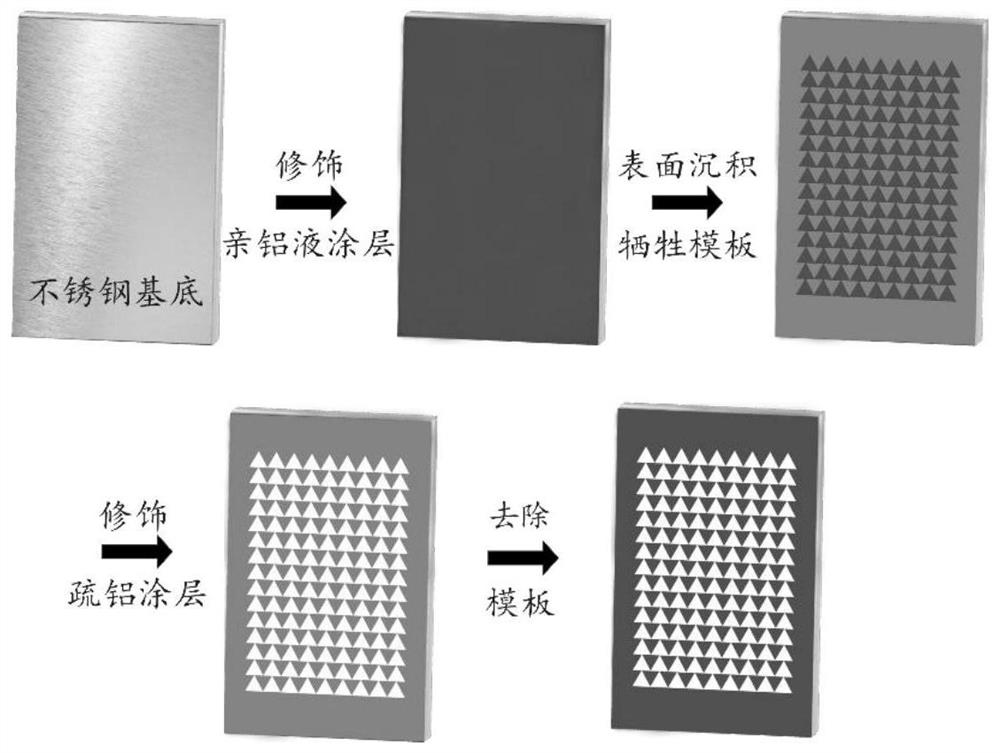

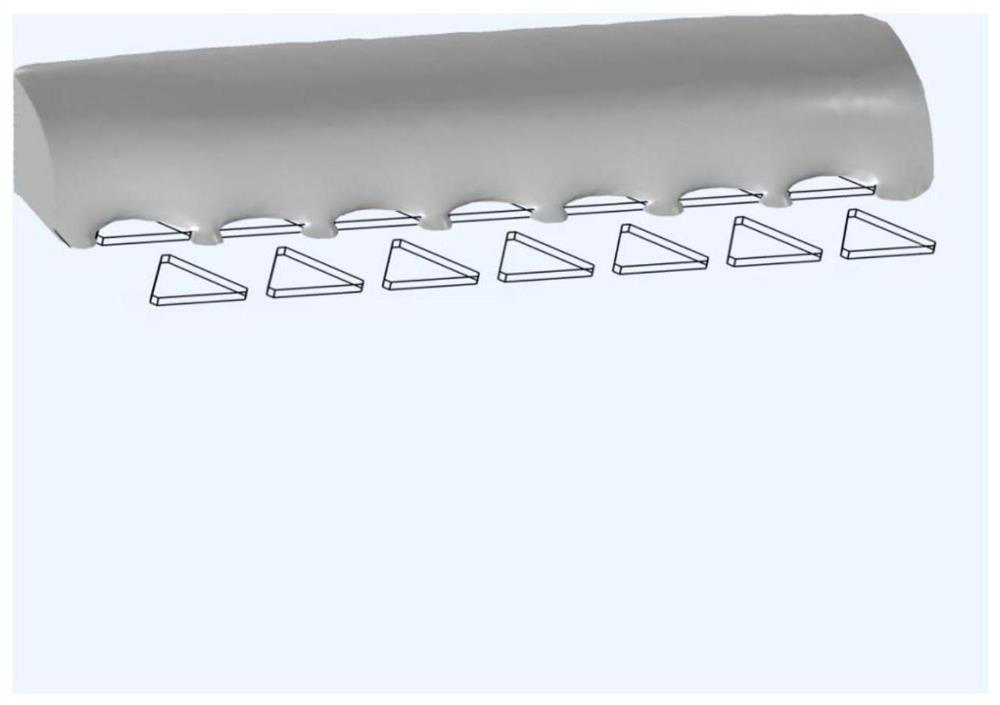

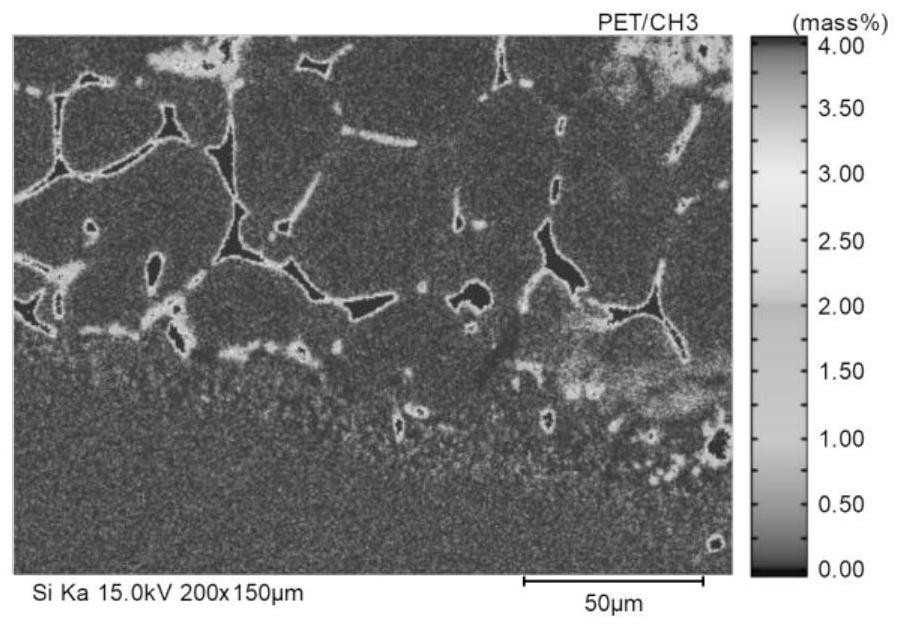

Hydrophilic dual-effect array coating capable of promoting aluminum melt spreading and preparation method thereof

ActiveCN113235088BEasy to spreadBreak continuityMolten spray coatingSuperimposed coating processPhysical chemistryMetallic materials

The invention discloses a hydrophilic-phobic dual-effect array coating capable of promoting aluminum melt spreading and a preparation method thereof, and relates to the technical field of metal material processing. The preparation method includes the following steps: providing a substrate; modifying aluminophilic liquid coating on the substrate; depositing a sacrificial template on the aluminophilic liquid coating; modifying the aluminophobic liquid coating on the sacrificial template; The aluminum-repellent liquid coating is composed of aluminophobic coating units arranged in an array; after etching the sacrificial template, a part of the aluminum-philic liquid coating on the upper layer of the substrate is exposed, that is, the dual-effect array is obtained on the substrate. coating. The invention destroys the continuity of the solid-liquid three-phase contact line, reduces the hysteresis of the contact angle, promotes the spreading of the aluminum melt, and improves the film forming rate by constructing a hydrophilic and phobic interphase structure on the heat exchange wall surface.

Owner:DALIAN JIAOTONG UNIVERSITY

Method for eliminating micro-cracks on surface of galvanized sheet

ActiveCN112872036AAvoid microcracksAvoid Microcrack DefectsWork cooling devicesMetal rolling arrangementsLaminar coolingStrip steel

The invention provides a method for eliminating micro-cracks on the surface of a galvanized sheet. The method comprises the following steps that a plate blank is obtained; after the plate blank is heated to the temperature of 1250-1270 DEG C, rough rolling and finish rolling are carried out, meanwhile, the finish rolling starting temperature is controlled to be 1100-120 DEG C, and finish rolling strip steel is obtained; the finish rolling strip steel is subjected to laminar cooling and coiling, and hot rolling strip steel is obtained; the laminar cooling ending temperature ranges from 630 DEG C to 670 DEG C; the hot-rolled strip steel is subjected to cold rolling, and cold-rolled strip steel is obtained; and the cold-rolled strip steel is galvanized, and a galvanized sheet with good surface quality is obtained. The galvanized sheet produced through the method has no microcracks; and in addition, the method does not increase alloy and equipment cost, only process and equipment parameters are adjusted, and the method is simple, high in applicability and remarkable in effect.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

A Casting Process for Improving the Casting Defects of Gear Gear Housing of Reducer

Owner:ANHUI HANSHAN COUNTY ANHUI PROVINCE IN THE SLOWDOWN MACHINERY

Forming method and device for male connector of universal joint

InactiveCN106141068AIncrease profitBreak continuityShaping toolsExtrusion diesUniversal jointEngineering

The invention discloses a forming method and a device for a male connector of a universal joint. The forming method comprises the following steps: (A) preparing a columnar blank with a set length; (B) placing the columnar blank into a pre-forging die to make the columnar blank formed into a pre-forged piece; (C) placing the pre-forged piece into a convex block forming die to form a convex block part at one end of the pre-forged piece, the outer diameter of the convex block part being less than that of the other end of the pre-forged piece; and (D) placing the pre-forged piece into a convex lug forming die to make the pre-forged piece form a seat body part connected with the convex block part, and two convex lug parts formed at one end, away from the convex block part, of the seat body part in a spacing manner, the seat body part being cooperated with the convex lug parts to define a movable slot. The male connector can be formed according to the steps, and a cutting procedure is not needed, so that the use rate of materials can be increased.

Owner:赖传荣

Structural steel wire rod, method for improving cutting performance of structural steel wire rod

The invention discloses a structural steel wire and a method for improving the machinability of the structural steel wire, and belongs to the field of steel smelting. The structural steel wire is composed of 0.42-0.48% of C, 0.15-0.35% of Si, 0.6-0.9% of Mn, 0-0.030% of P, 0.012-0.028% of S, 0.003-0.2% of Ni, 0.02-0.2% of Cr, 0.02-0.3% of Cu, 0-0.35% of Ni+Cr, 20-40% of Mn / S, class-A mingled substances with the grade 1-3, 0.010-0.035% of Als and the balance Fe and inevitable impurities. The structural steel wire has good machinability.

Owner:SGIS SONGSHAN CO LTD

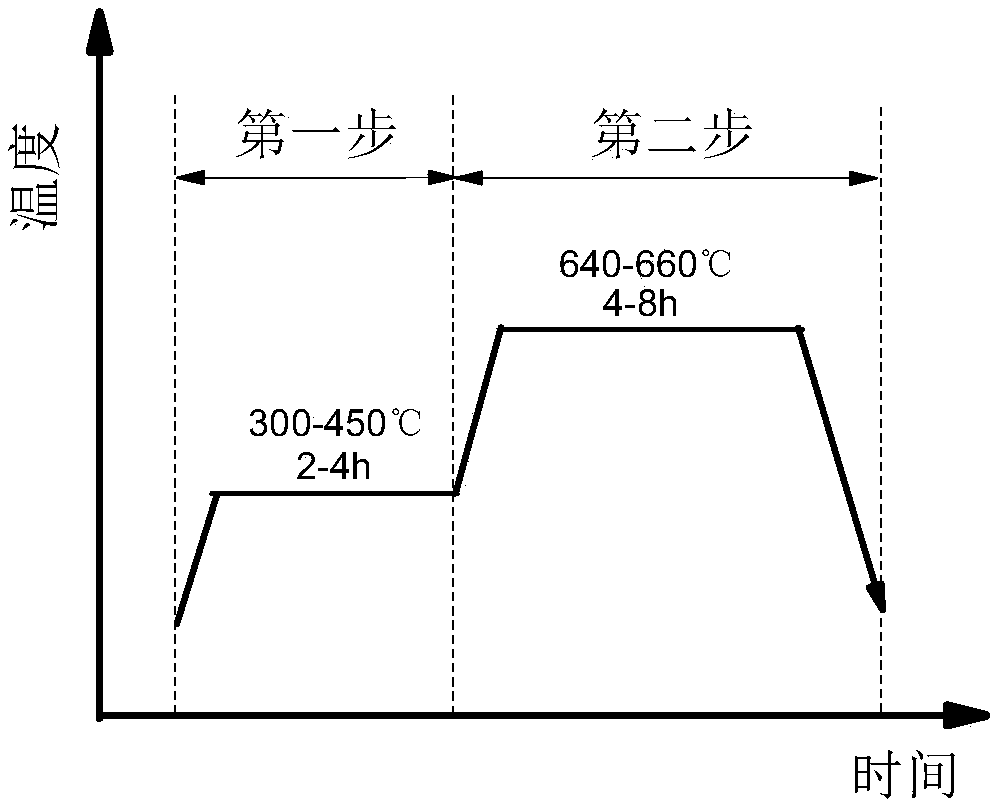

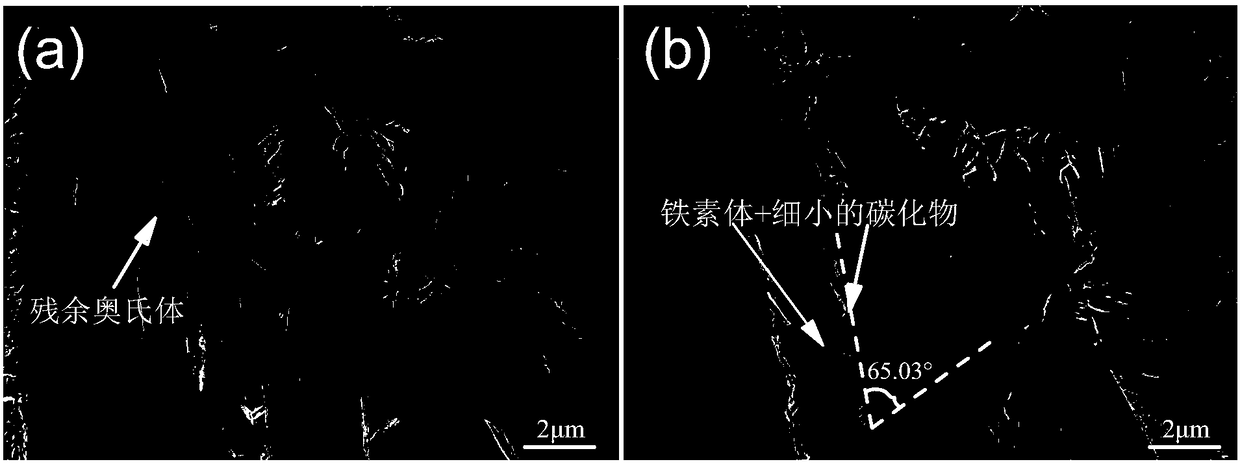

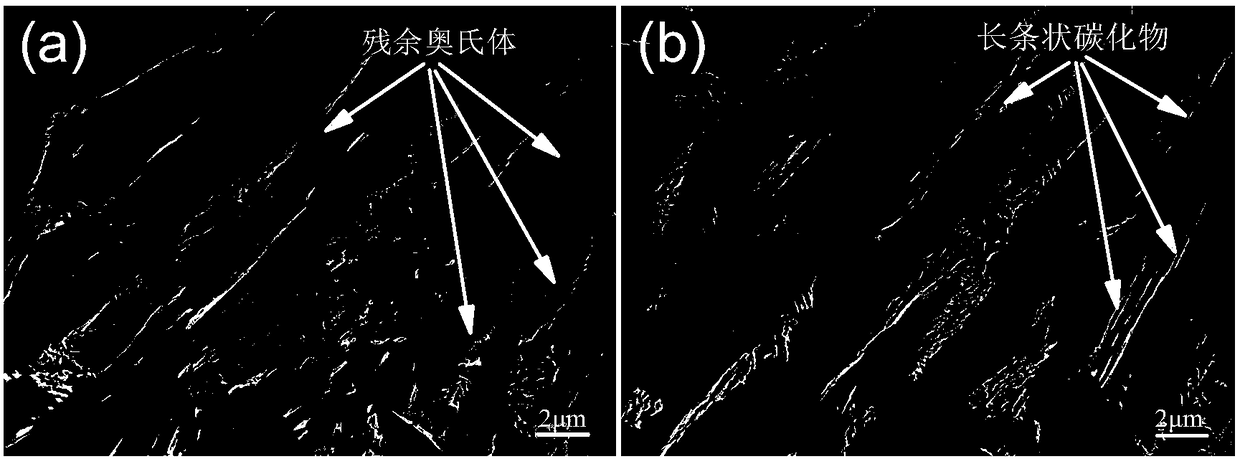

A two-step tempering process for improving the impact toughness of large nuclear power forgings

ActiveCN106191389BBreak continuityQuenching stress reliefFurnace typesHeat treatment furnacesNuclear powerAbsorbed energy

The invention relates to a two-step method tempering process for improving impact toughness of a nuclear power large forging. The process includes the following steps that (1) the quenched nuclear power large forging is heated to 300-450 DEG C for heat preservation; and (2) the forging is heated to 600-660 DEG C continuously for heat preservation, then the forging is cooled in a furnace, and the process is completed. Compared with the prior art, the impact absorbing energy average value of steel treated by the two-step method tempering process can reach about 100J. The impact toughness is obviously improved compared with the nuclear power large forging treated by a traditional tempering process. Moreover, the process is simple, easy to operate and implement and the like.

Owner:SHANGHAI JIAO TONG UNIV

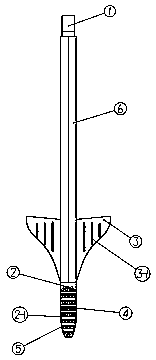

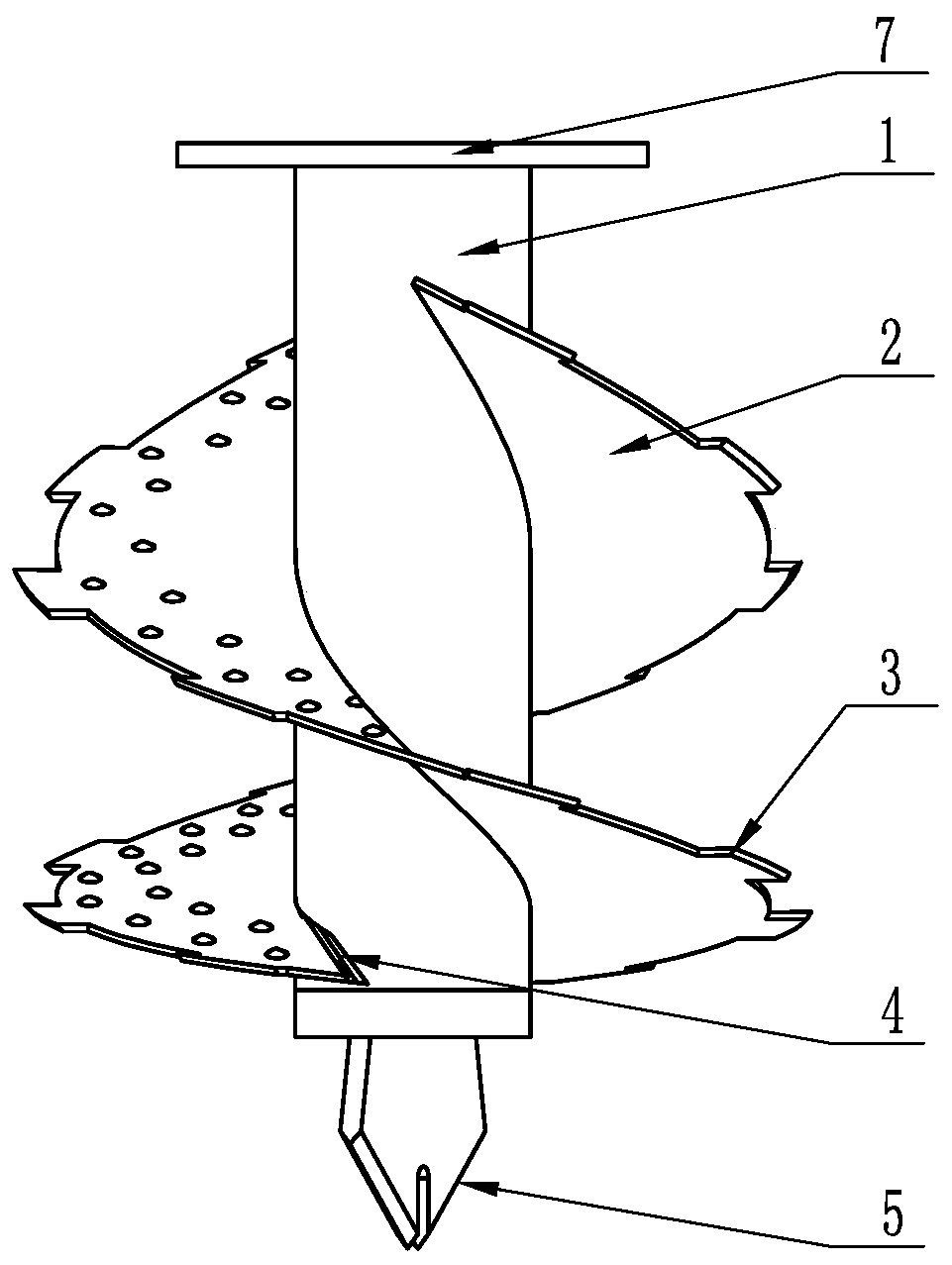

Straw deep-burying bionic spiral ditching device

InactiveCN110999598AAvoid uneven forceImprove linearityPlantingAgriculture gas emission reductionSoil scienceSpiral blade

The invention discloses a straw deep-burying bionic spiral ditching device, and belongs to the technical field of agricultural machinery. The straw deep-burying bionic spiral ditching device comprisesa cutter shaft, bionic spiral blades, bottom soil cutting blades and a cutter point, wherein the bionic spiral blades are symmetrically arranged on the cutter shaft in a double-spiral manner; the bottom soil cutting blades are arranged at the bottom ends of the bionic double-spiral blades; and the cutter point is arranged at the grounding end of the cutter shaft. According to the straw deep-burying bionic spiral ditching device, the double-spiral blades are symmetrically arranged, so that the problem of non-uniform stress of a ditcher is solved, and meanwhile, the problem of poor linearity oftravelling of a machine tool is solved; the bottom soil cutting blades are arranged at the bottoms of the double-spiral blades, and the cutter point is arranged at the grounding end of the cutter shaft, so that the straw deep-burying bionic spiral ditching device is high in soil burying performance, low in resistance and simple and compact in overall structure; and large soil blocks are not formed in a ditching process, and an effect of deeply loosening soil can be achieved. The straw deep-burying bionic spiral ditching device is an initiative in agricultural machinery.

Owner:SHENYANG AGRI UNIV

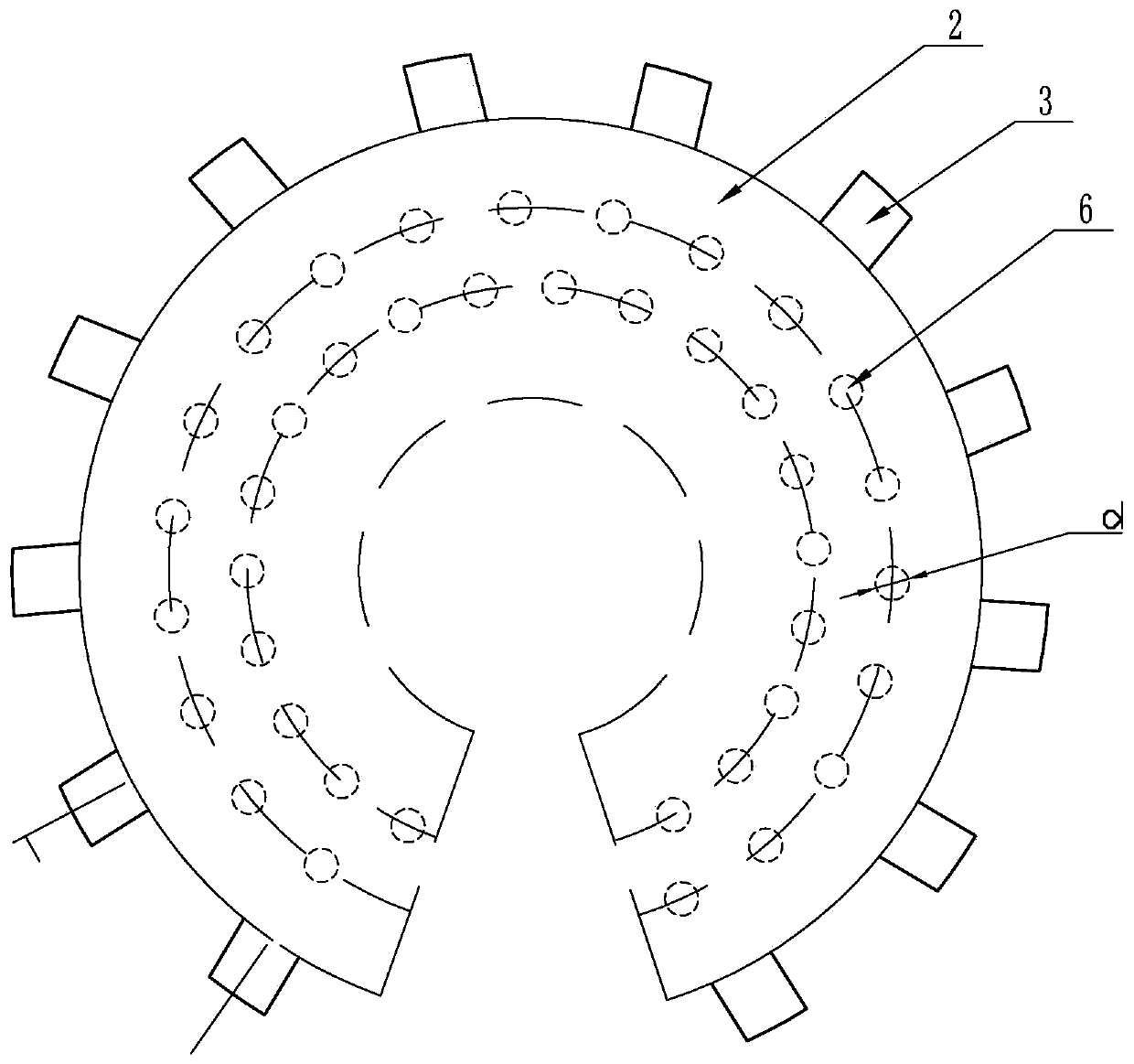

Bionic surface disc fertilization opener

InactiveCN105165187BPrevent lost rotationSmall ditching resistancePlantingFurrow making/coveringCircular discEngineering

The invention discloses a bionic curved-surface circular disc fertilization furrow opener. The bionic curved-surface circular disc fertilization furrow opener comprises a mounting frame, a curved-surface circular disc I and a curved-surface circular disc II, wherein the curved-surface circular disc I and the curved-surface circular disc II are mounted at the two sides of the mounting frame by shafts; the two curved-surface circular discs are mutually inclined and are mounted in an angular staggered manner; the curved-surface circular disc I and the curved-surface circular disc II have the same structures; the curved-surface circular disc I is composed of a plurality of curve-surface sector-shaped single bodies with the same structures; the curve-surface sector-shaped single bodies are tightly connected; and the outer edge of each curve-surface sector-shaped single body is of a tooth-shaped structure. According to the bionic curved-surface circular disc fertilization furrow opener, a disc surface adopts a bionic curved-surface structure and simulates shape characteristics of animal claws and toes, so that the soil digging performance is improved, the throwing rate is reduced, and capabilities of breaking stubbles and crushing soil are enhanced; the inner part of the disc surface is filled with annular nylon, and a water film structure at which the disc surface is in contact with the soil is damaged; and furrow opener cannot adhered to the soil and the passing ability of the furrow opener is enhanced.

Owner:JILIN UNIV

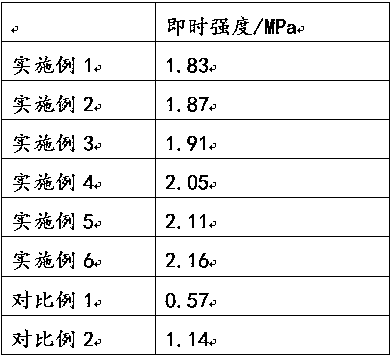

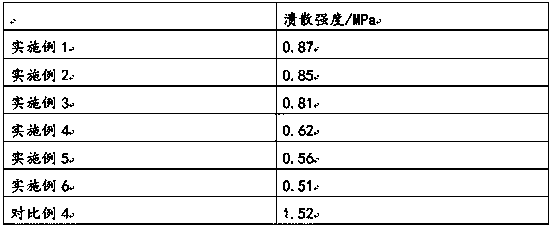

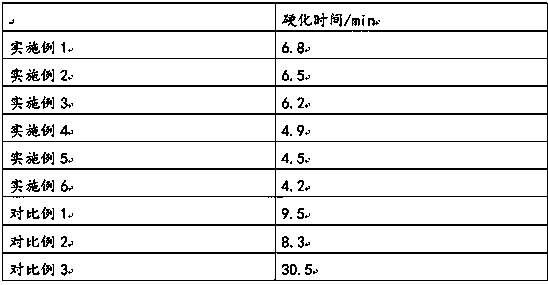

Binder for improving the hardening strength of molding sand

InactiveCN111482553AImprove collapseGood collapsibilityFoundry mouldsFoundry coresO-Phosphoric AcidAluminium hydroxide

The invention discloses a binder for improving the hardening strength of molding sand, and relates to the technical field of casting. Phosphoric acid and maleic acid are mixed and then heat treatmentis carried out to obtain mixed acid; the mixed acid is added to water to prepare a mixed acid solution; and aluminum hydroxide and sodium carbonate are added to the mixed acid solution, ultrasonic treatment is performed for 3 to 5 minutes to obtain a reaction solution, and then the reaction solution is stirred at the rotating speed of 500r / min and 1500r / min respectively for 1 to 1.5 hours to obtain transparent liquid, that is the binder is obtained. The invention provides the binder for improving the hardening strength of the molding sand; the binder prepared by the invention is applied to a sand mold; under the promotion of microwaves, the hardening time can be shortened greatly, the production efficiency is improved, meanwhile, the instant strength can be greatly improved, and the binderhas more excellent collapsibility, low retained strength and is more conducive to recycling.

Owner:HANSHAN RONGSHENG MACHINERY CASTING

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com