Production method of barium cleaning iron-chromium-aluminum alloy

An iron-chromium-aluminum alloy and production method technology, applied in the field of alloy manufacturing, can solve the problems of poor quality of FeCrAl alloy products and difficulty in continuous production, and achieve the effects of improving high-temperature oxidation resistance and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for producing barium-purified iron-chromium-aluminum alloys, the steps comprising:

[0026] S1. Weigh the ingredients of pure iron, medium-carbon ferrochrome and silicon-manganese alloy to make the carbon content reach 0.5%, and add them as smelting raw materials into the smelting furnace for smelting;

[0027] S2. Carry out vacuum decarburization in an AOD furnace, make the C in the smelted alloy ≤0.05% by weight percentage, and add ferrosilicon for pre-deoxidation. This step can also be carried out in a VOD furnace;

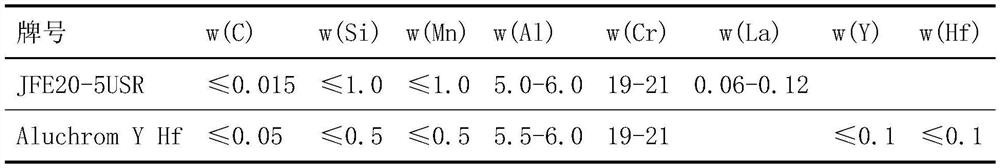

[0028] S3. Continue smelting to make Si, Mn and Cr all reach the preset range, wherein Si≤1.0%, Mn≤1.0%, and Cr are 17%~25% by weight percentage;

[0029] S4, adding aluminum ingots for final deoxidation, performing sufficient soft blowing, and adjusting the content of Al in the refining furnace, so that the weight percentage of Al is controlled between 5% and 8.5%;

[0030] S5. Weigh the barium alloy and add it to the refining furnace so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com