Bionic sub-soiling shovel

A technology of subsoiling shovel and shovel tip, applied in the field of bionic subsoiling shovel, can solve the problems of strong soil breaking ability, small tillage resistance, large tillage resistance, etc., so as to increase soil removal ability, reduce tillage resistance, and reduce tillage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

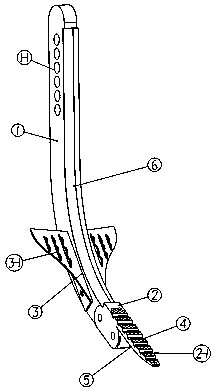

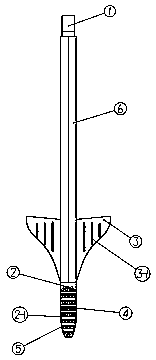

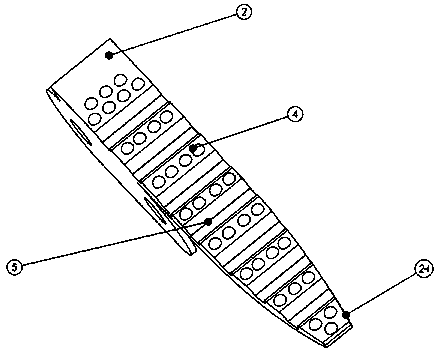

[0018] Depend on Figure 1-4 It can be known from the shown embodiment that this embodiment consists of a shovel handle 1 , a shovel tip 2 fixed at the bottom of the shovel handle 1 , and symmetrical wing shovels 3 on both sides of the lower end of the shovel handle 1 near the shovel tip 2 . The front end face of the shovel handle 1 is provided with a tillage drag reduction structure, which is a soil guide plate 6 fixed on the front end face of the shovel handle 1, and both sides of the front end face of the soil guide plate 6 are inclined planes, which can move the soil to both sides. Derived; the upper surface of the wing shovel 3 is also provided with a farming drag reduction structure, the drag reduction structure is six corrugated strips 3-1 of different lengths fixed on the surface of the wing shovel 3, along the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com