Ultrathin heat insulation film

A thermal insulation film, ultra-thin technology, applied in the direction of coatings, layered products, synthetic resin layered products, etc., can solve the problems of low porosity, insufficient flexibility, thickness of thermal insulation film, etc., to reduce thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

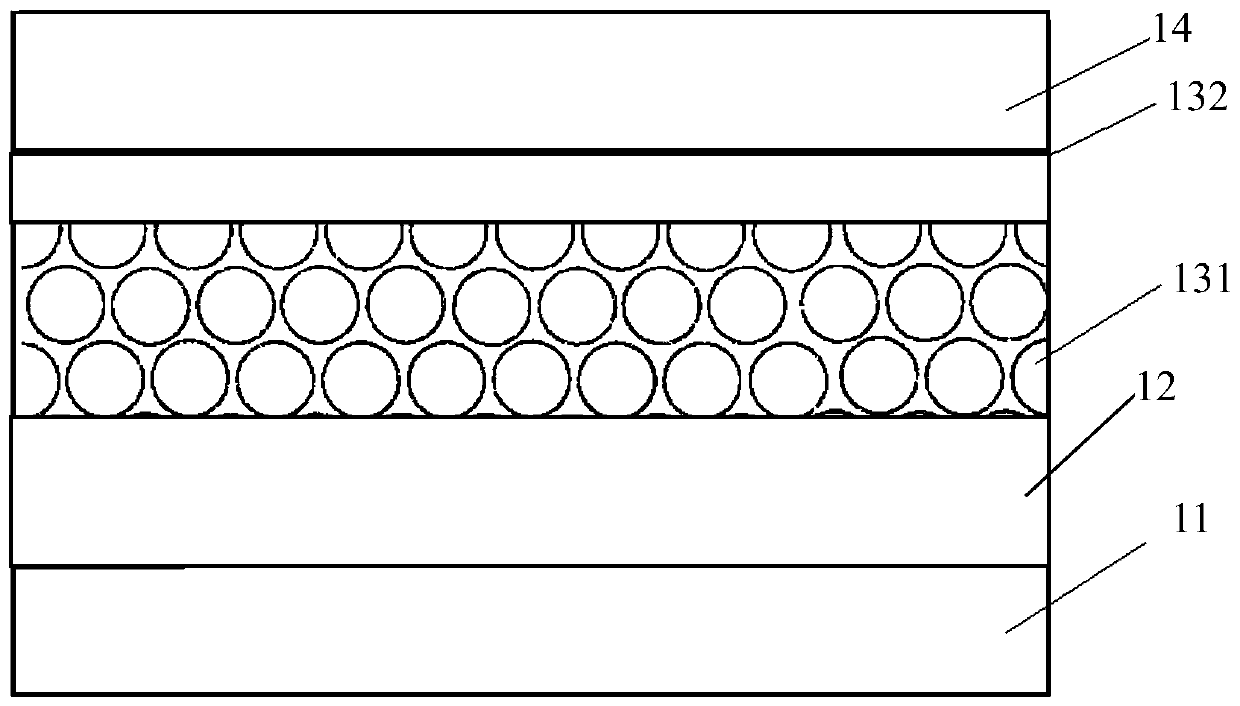

[0036] like figure 1 As shown, the present invention provides an ultra-thin heat insulation film 100, which includes a substrate layer 11, an adhesive layer 12, a heat insulation layer 13 and a protection layer 14 in sequence from bottom to top.

[0037] Wherein the substrate layer 11 is a PET film with a thickness of 40 μm, a visible light transmittance ≥ 89%, and a haze ≤ 1.5.

[0038] The adhesive layer 12 is polyurethane hot melt adhesive with a thickness of about 1.5 μm.

[0039] The heat insulating layer 13 includes an airgel layer 131 and a metal oxide layer 132 . The airgel layer 131 is adhered to the surface of the substrate layer 11 through the adhesive layer 12 , and the metal oxide layer 132 is coated on the surface of the airgel layer 131 by coating. The total thickness of the heat insulating layer 13 is 1.05 μm. The airgel layer 131 has a thickness of 1 μm, and the metal oxide layer 132 has a thickness of 50 nm.

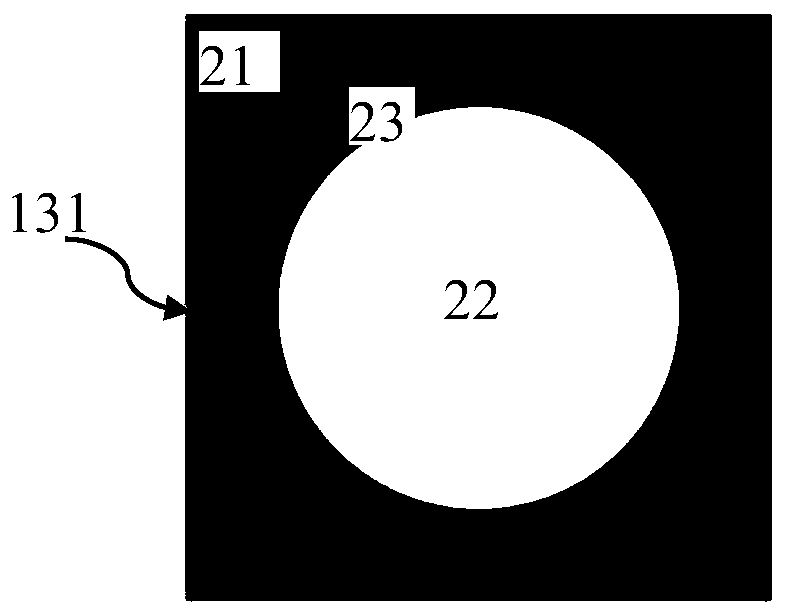

[0040] combine figure 2 As shown, the airgel ...

Embodiment 2

[0045] In this embodiment, the substrate layer 11 is an ETFE film with a thickness of 40 μm, a visible light transmittance ≥ 89%, and a haze ≤ 1.5. The adhesive layer 12 is a temperature-resistant epoxy adhesive with a thickness of about 1.2 μm.

[0046] The total thickness of the heat insulating layer 13 is 2.05 μm. The airgel layer 131 has a thickness of 2 μm, and the metal oxide layer 132 has a thickness of 40 nm. The airgel layer 131 is a doped silica airgel with a porosity of 75%. Titanium dioxide can be doped with titanium ions by co-precipitation method of complexing agent when preparing silica sol, and then the aerogel doped with titanium dioxide can be obtained through gelation, solvent replacement, supercritical carbon dioxide drying method and high temperature treatment. In this embodiment, the doping amount of titanium dioxide is 0.02%. The pores 21 and the isolated cavities 22 inside the silica airgel are filled with CO 2 Gas, the diameter of the cavity 22 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com