Straw deep-burying bionic spiral ditching device

A bionic spiral and spiral technology, applied in the direction of excavation/covering of trenches, planting methods, agricultural gas emission reduction, etc., can solve the problems of large trenching resistance, insufficient trenching depth, and difficulty in deep burial of straw, and reduce stickiness. Adhesion, simple and compact overall structure, good performance in soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

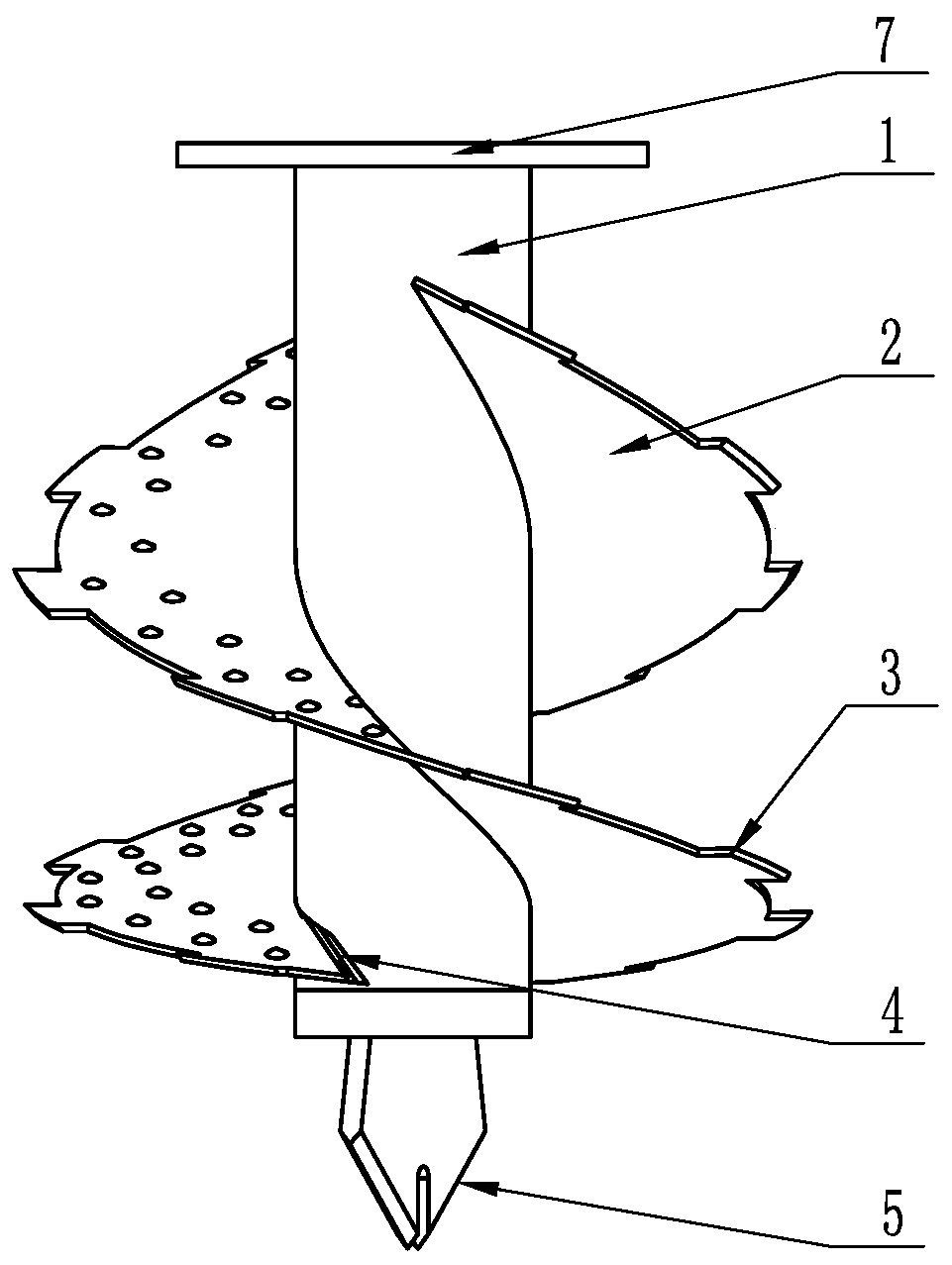

[0033] Embodiment 1: as figure 1 As shown, a bionic spiral ditching device for straw deep burial in the present invention includes a cutter shaft 1, a bionic spiral blade 2, a bottom soil cutting blade 4 and a knife tip 5, and the bionic spiral blade 2 is symmetrically arranged on the cutter shaft by a double helix 1, the force is balanced, the lead is increased, and the problems of soil blockage and poor linearity are solved; the bottom cutting blade 4 is set at the bottom of the bionic spiral blade 2, and the knife tip 5 is set at the ground end of the knife shaft 1 .

[0034] The flange connected to the cutter shaft 1 is connected with the reduction box to obtain power. The bionic helical blade 2 is welded to the cutter shaft 1 so as to rotate at a high speed to complete the upward conveying of the soil.

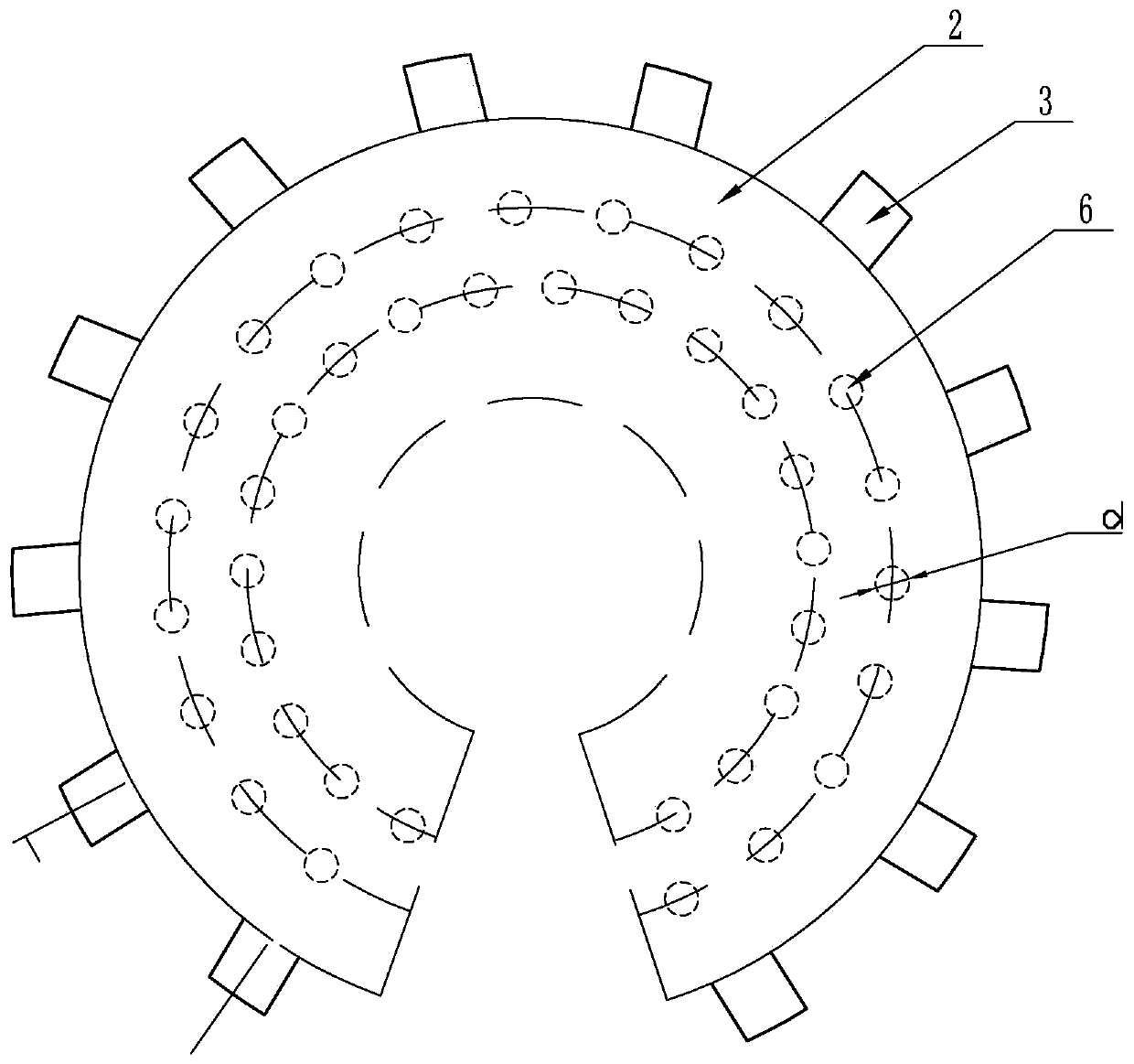

[0035] Such as figure 1 , figure 2 As shown, the surface of the bionic helical blade 2 in this example is provided with a plurality of spherical crowned protrusions ...

Embodiment 2

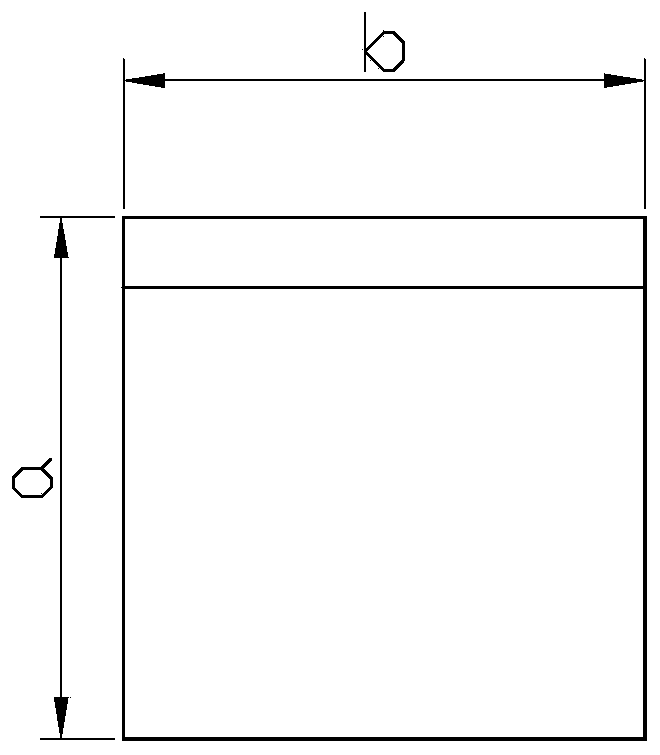

[0054] Embodiment 2: The difference between this example and Embodiment 1 is: in this example, the distance from the center of the outermost protrusion along the bionic spiral blade 2 to the edge of the blade is 20; this example sets 3 rows of protrusions, and the distance between two adjacent rows of protrusions 25mm; the external diameter d of the protrusion 6 of the spherical crown is 10mm, and the height is 5mm. The pitch P is 115mm; the blade angle λ of the blade tip is 25°, the maximum section outer diameter W of the blade is greater than the outer diameter D of the blade at the installation end, the maximum rotation diameter W of the blade is 100mm, and the height is 0.9W.

Embodiment 3

[0055] Embodiment 3: The difference between this example and Embodiment 1 is: in this example, the center of the outermost protrusion along the bionic spiral blade 2 is 40mm away from the edge of the blade; this example is provided with two rows of protrusions with a distance of 35mm; the spherical crown The external diameter d of the protrusion 6 is 16mm, and the height is 8mm. The pitch P is 250mm; the blade angle λ of the blade tip is 45°, the maximum section outer diameter W of the blade is greater than the outer diameter D of the blade at the installation end, the maximum rotation diameter W of the blade is 160mm, and the height is 1.2W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com