Method for adjusting three-roll mill roll gap controller

An adjustment method and technology of three-roll mill, applied in the direction of rolling force/roll gap control, control/adjustment system, self-adaptive control, etc., can solve the problem that the precision of the finished product frame has a great influence, the fluctuation of the compensation value will be very large, and the steel pipe The wall thickness fluctuates greatly and other problems, so as to solve the problem of uneven force, increase the yield and uniform wall thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

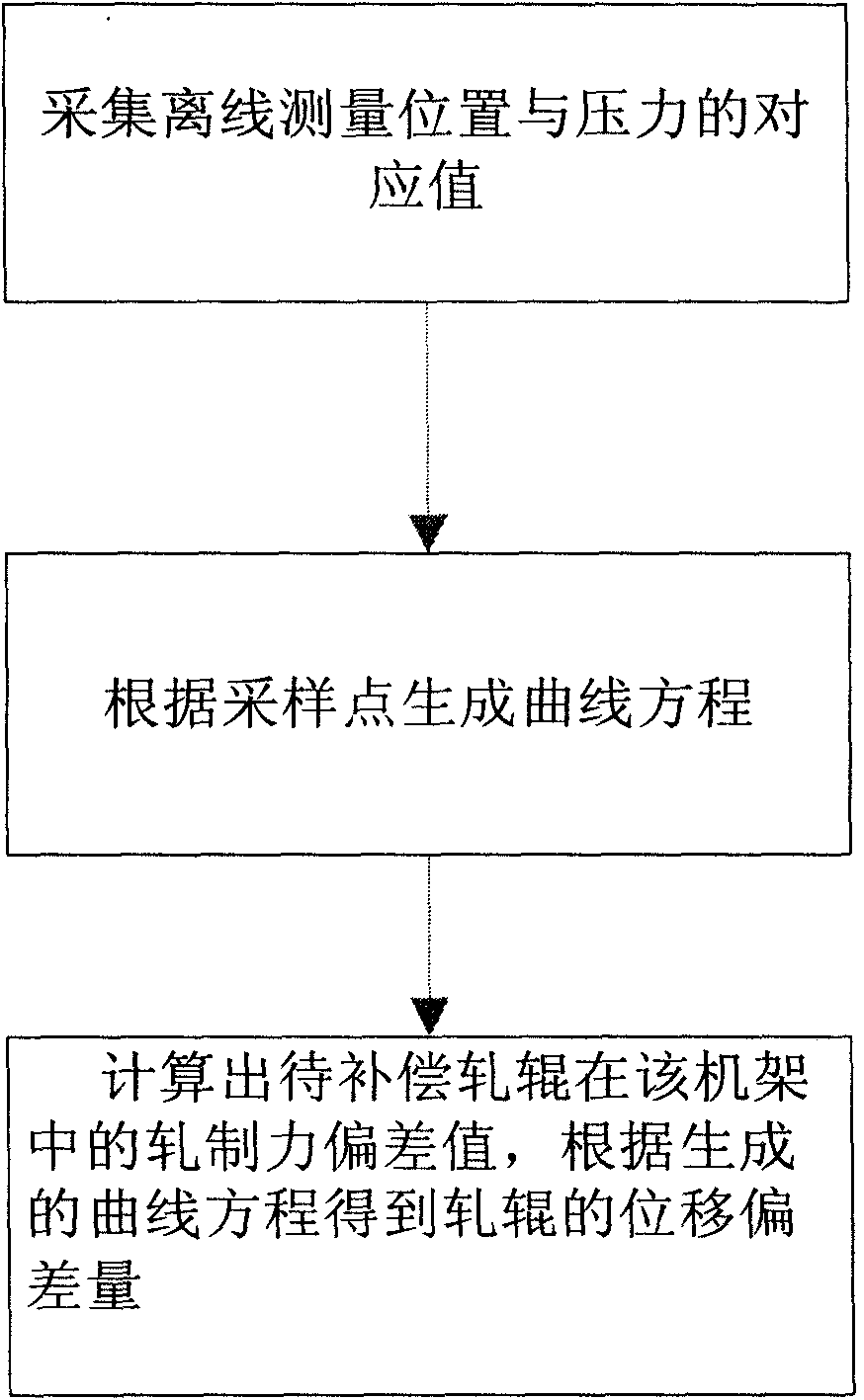

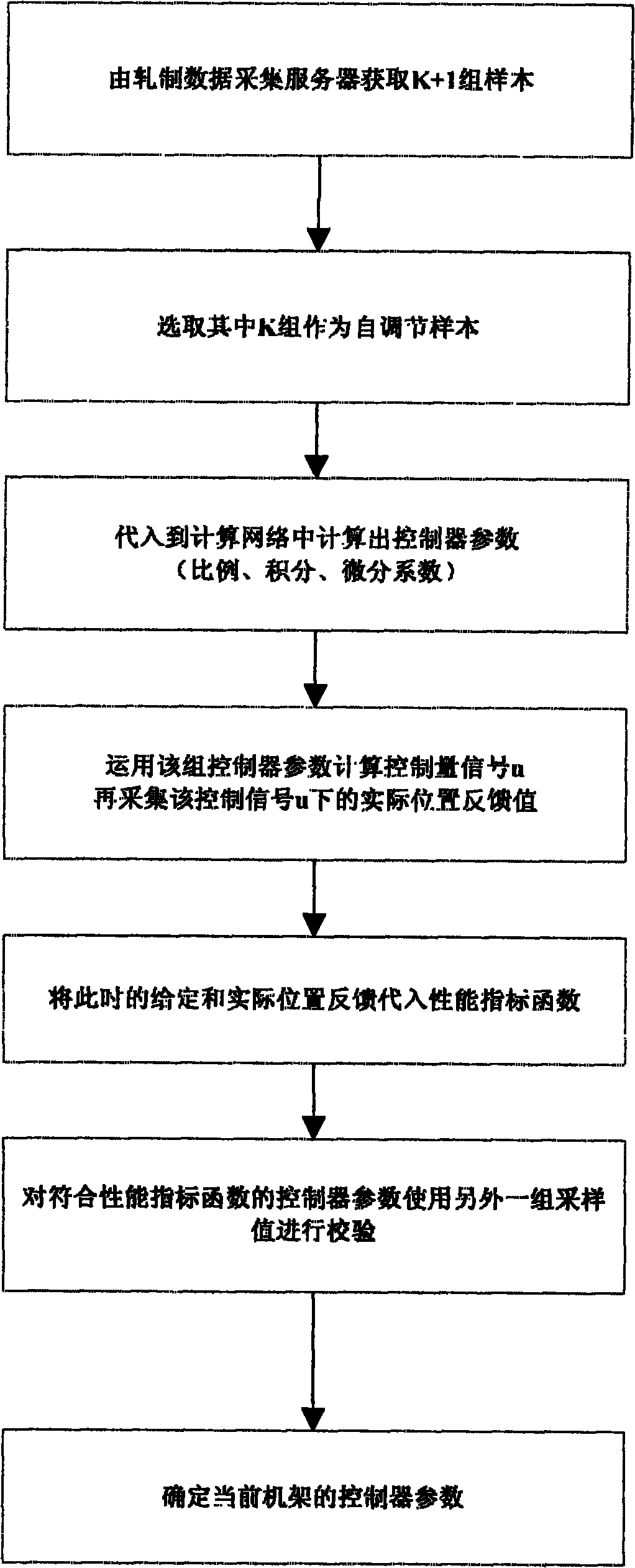

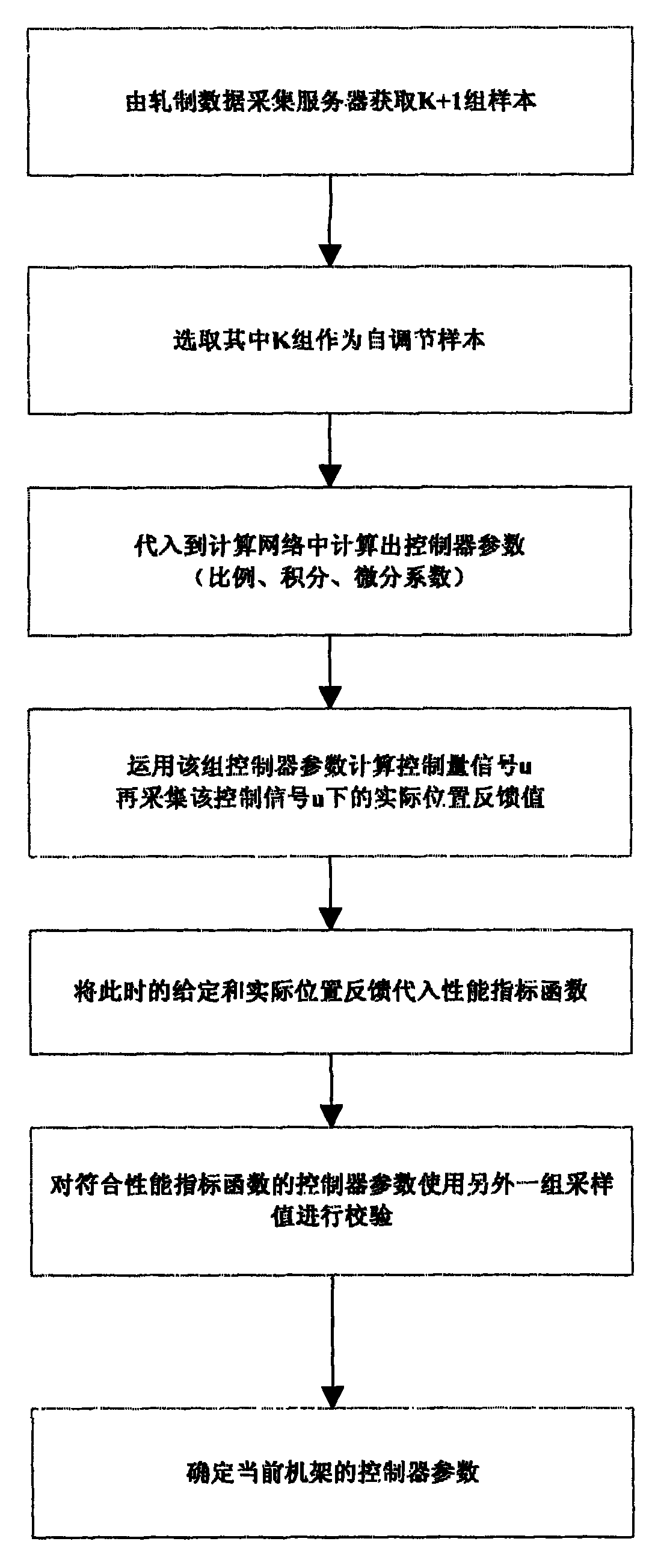

[0038] Such as figure 1 , figure 2 Shown:

[0039] The present invention adopts a dual insurance implementation mode of deriving controller parameters with the idea of neural network, and then applying incremental control equations to the controller. PID (Proportion Integration Differentiation) control to achieve a better control effect, it is necessary to adjust the three control functions of proportional kp, integral ki and differential kd to form a relationship of mutual cooperation and mutual restraint in the control quantity. It must be a simple "linear combination", and the best relationship can be found from the infinitely changing nonlinear combination. The arbitrary nonlinear expression ability of neural network can realize the PID control with the best combination through the learning of system performance. By adopting BP (Back Propagation) neur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com