High and medium-temperature heat treatment deformation preventing device for large turbine blades

A technology of thermal treatment and water turbine, which is applied to the anti-deformation device of medium-temperature heat treatment, and the high field of large-scale water turbine blades. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

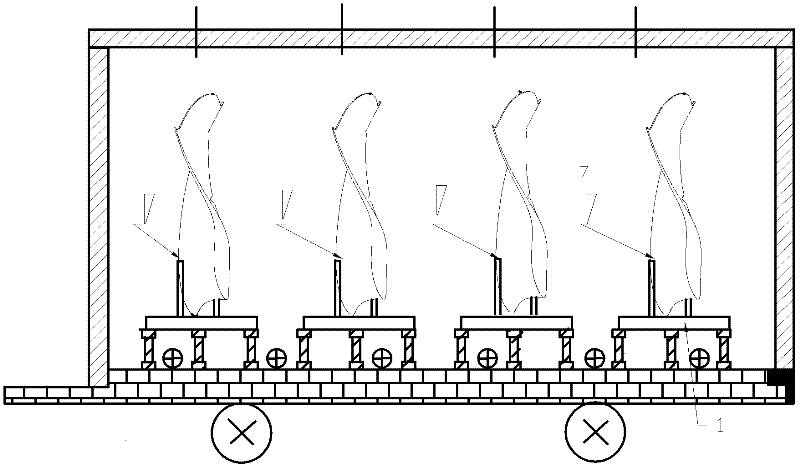

[0021] An anti-deformation device for high and medium temperature heat treatment of blades of large water turbines, such as figure 1 Shown: the device is assembled by a cast support frame 1 and a heat-resistant wedge iron 7 supporting it.

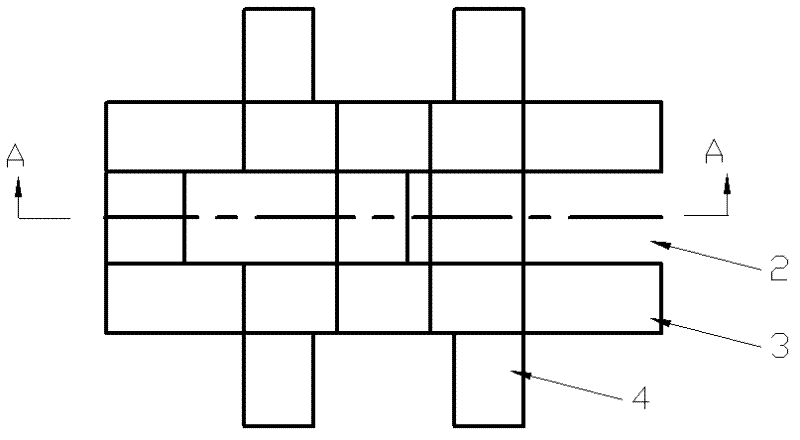

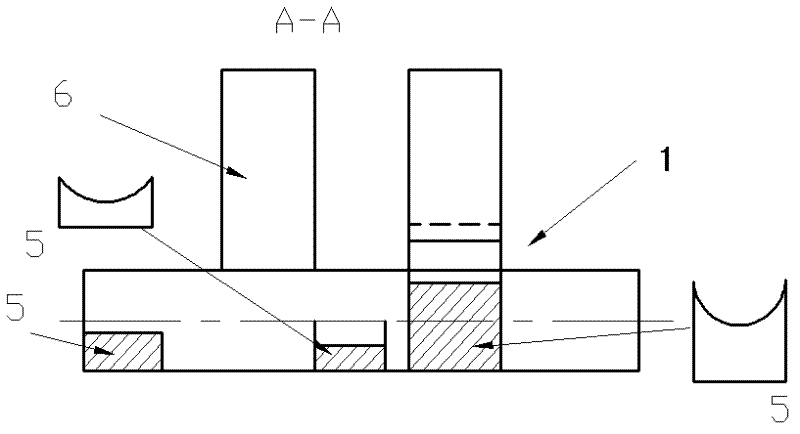

[0022] like figure 2 and 3 As shown: the casting support frame 1 is assembled from the U-shaped groove 2 in the middle, the groove walls 3 on both sides of the U-shaped groove 2, and the triangular side supports 4 fixed at both ends of the outer sides of each groove wall 3. Three crossbeams 5 with different heights with arc-shaped tops are fixed at intervals in the groove 2 , and two groove columns 6 are fixed on each side of the above-mentioned U-shaped groove 2 .

[0023] The arcs of the tops of the three beams 5 are similar to the arcs of the supported blades, and their heights correspond to the height of the supported blades.

[0024] The heat-resistant wedge iron 7 is located between the casting support frame 1 and the blade.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com