Forming method and device for male coupling part of universal joint

A technology of universal joints and forming methods, applied in forming tools, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, waste of resources, and rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

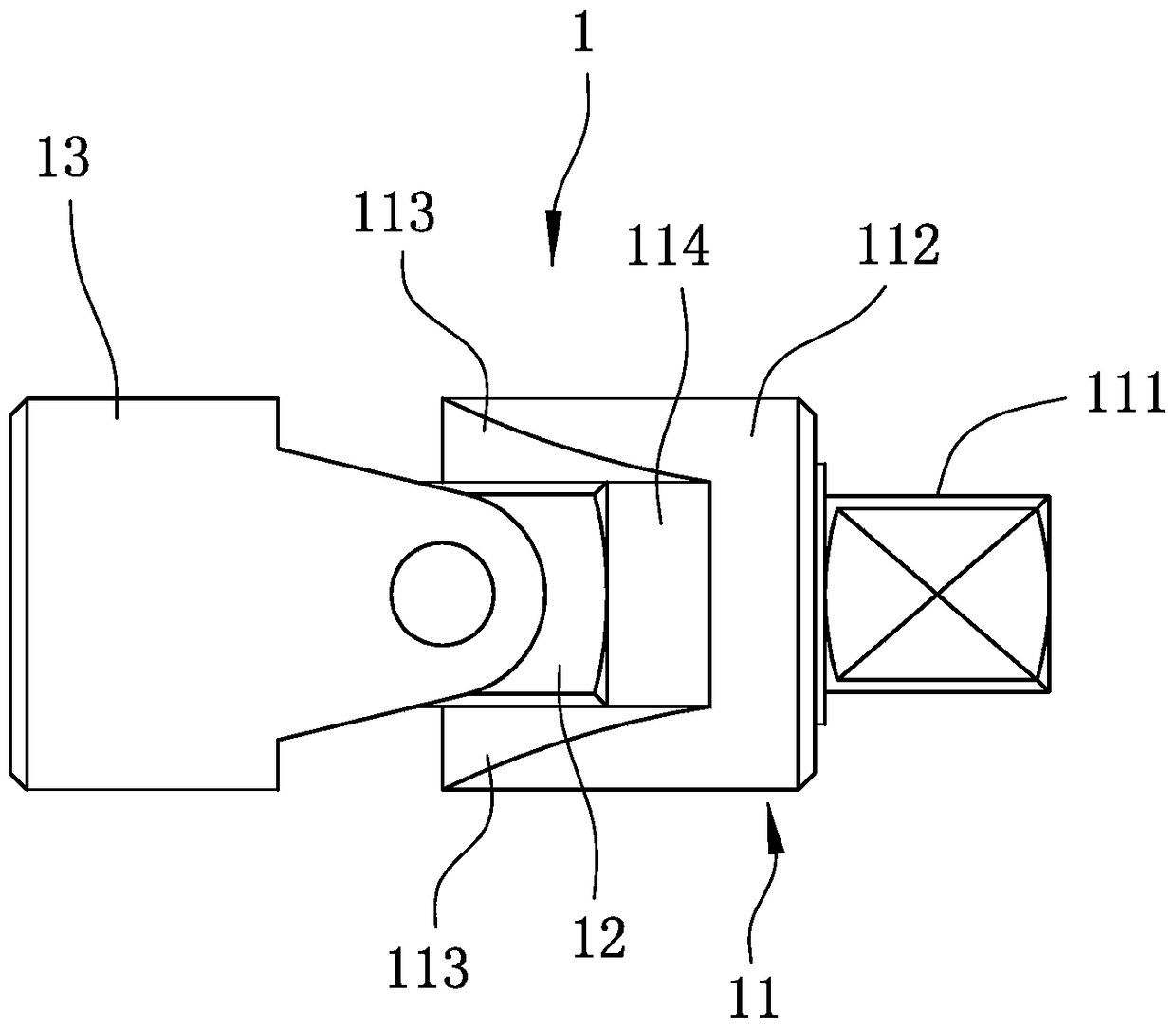

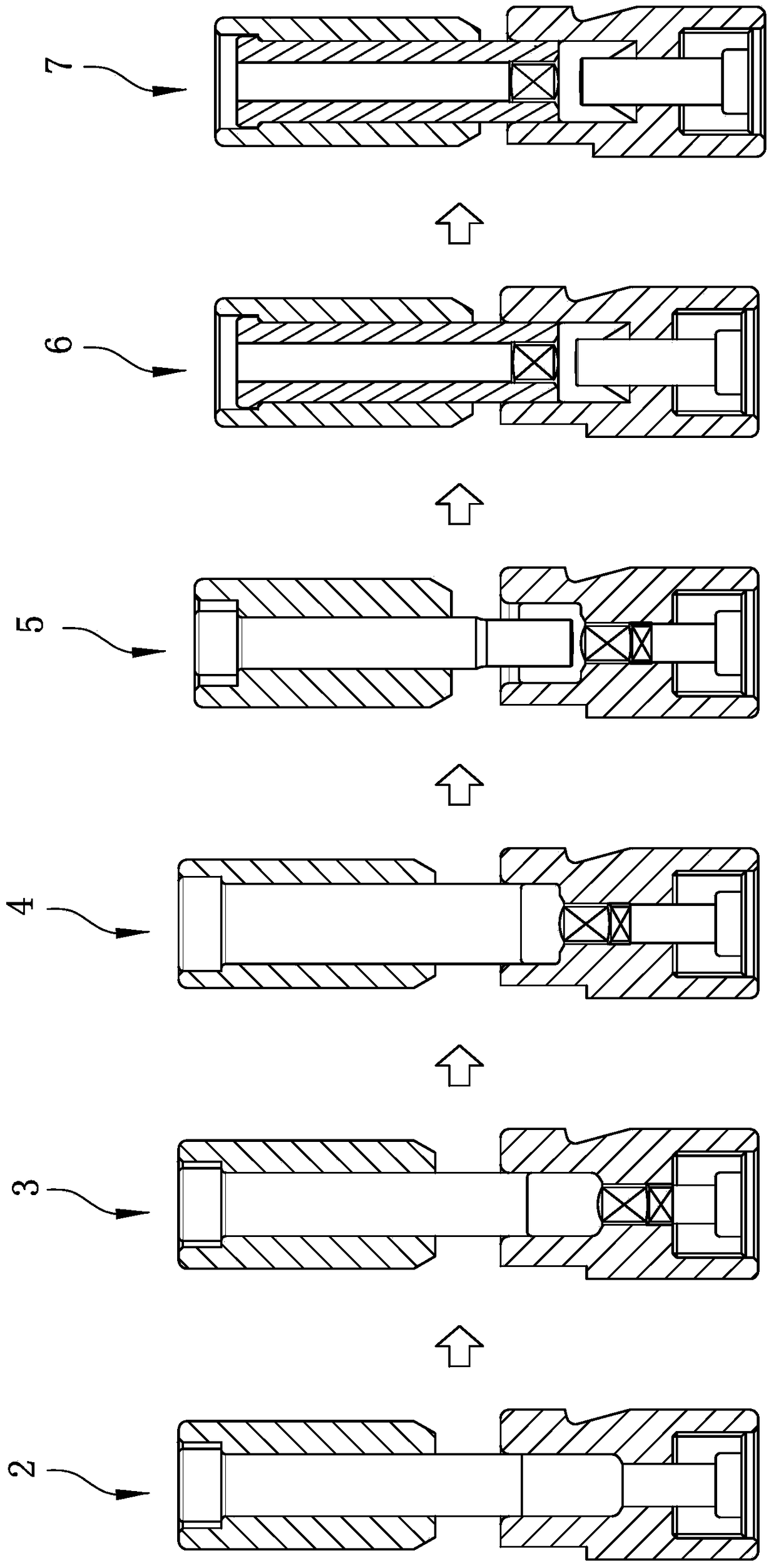

[0029] refer to figure 2 One embodiment of the forming device of the male joint of the universal joint of the present invention includes a pre-forging die 2, a bump forming die 3, an extrusion die 4, a lug forming die 5, and an oblique forging die 6, And a bevel forming die 7.

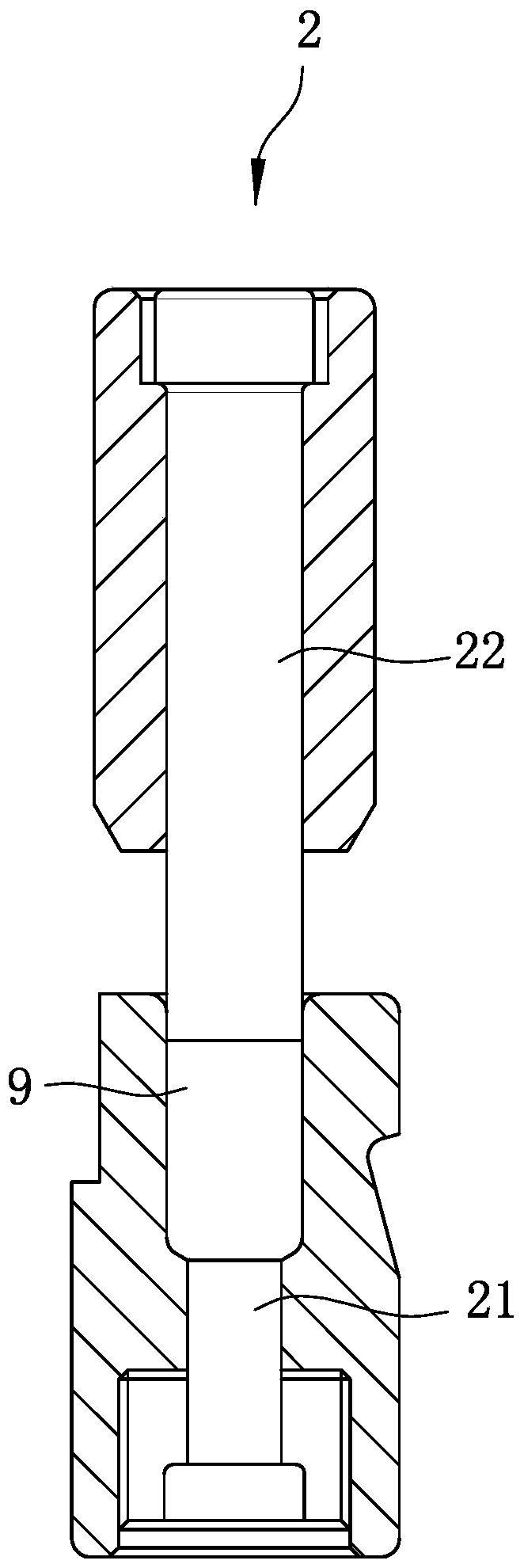

[0030] refer to image 3 , the pre-forging die 2 includes a pre-forging female die 21, and a pre-forging male die 22 that can reciprocate relative to the pre-forging female die 21. refer to Figure 4 , the bump forming die 3 includes a bump forming female die 31 and a bump forming male die 32 that can reciprocate relative to the bump forming female die 31 . The bump forming master mold 31 has a forming space 311 . The forming space 311 has a bump area 312 away from the bump forming male die 32 , and a main body area 313 connected to the bump forming area 312 and extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com