Binder for improving the hardening strength of molding sand

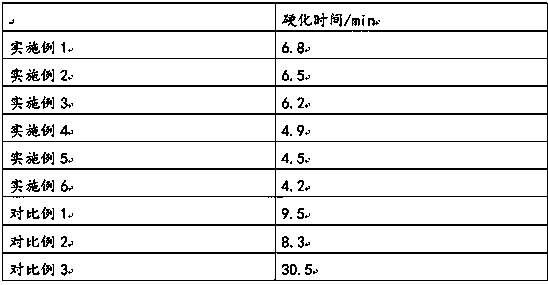

A technology of hardening strength and binder, applied in the directions of casting molds, cores, casting molding equipment, etc., can solve the problems that the casting mold cannot be reused, the sand mold collapse is poor, and the casting cost is reduced, so as to shorten the hardening time, improve the Collapse performance and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

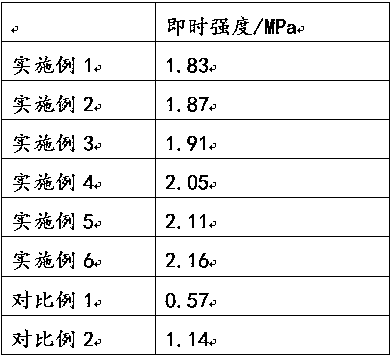

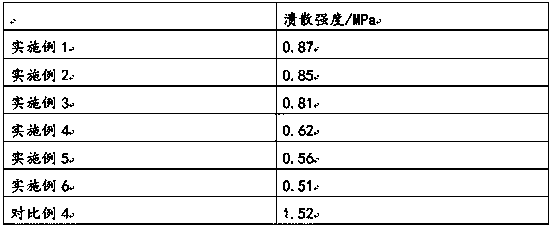

Examples

Embodiment 1

[0057] A binder for improving the hardening strength of molding sand. Phosphoric acid and maleic acid are mixed and then heated to obtain a mixed acid; the mixed acid is added to water to prepare a mixed acid solution; the mixed acid solution is added Add aluminum hydroxide and sodium carbonate, perform ultrasonic treatment for 3 minutes to obtain a reaction solution, and then stir at 500r / min and 1500r / min for 1 hour respectively to obtain a transparent liquid. The mixed mass ratio of phosphoric acid and maleic acid is 10:1. The mass fraction of phosphoric acid in the mixed acid solution is 32%. The molar ratio of aluminum hydroxide to phosphoric acid is 2:1, and the molar ratio of sodium carbonate to maleic acid is 1:1. The ultrasonic treatment frequency is 35kHz, and the power is 600W.

Embodiment 2

[0059]A binder for improving the hardening strength of molding sand. Phosphoric acid and maleic acid are mixed and then heated to obtain a mixed acid; the mixed acid is added to water to prepare a mixed acid solution; the mixed acid solution is added Add aluminum hydroxide and sodium carbonate, perform ultrasonic treatment for 5 minutes to obtain a reaction solution, and then stir at 500r / min and 1500r / min for 1.5 hours respectively to obtain a transparent liquid. The mixing mass ratio of phosphoric acid and maleic acid is 10:1.5. The mass fraction of phosphoric acid in the mixed acid solution is 35%. The molar ratio of aluminum hydroxide to phosphoric acid is 2:1, and the molar ratio of sodium carbonate to maleic acid is 1:1. The ultrasonic treatment frequency is 40kHz, and the power is 600W.

Embodiment 3

[0061] A binder for improving the hardening strength of molding sand. Phosphoric acid and maleic acid are mixed and then heated to obtain a mixed acid; the mixed acid is added to water to prepare a mixed acid solution; the mixed acid solution is added Add aluminum hydroxide and sodium carbonate, perform ultrasonic treatment for 4 minutes to obtain a reaction solution, and then stir at 500r / min and 1500r / min for 1.2 hours respectively to obtain a transparent liquid. The mixing mass ratio of phosphoric acid and maleic acid is 10:1.3. The mass fraction of phosphoric acid in the mixed acid solution is 32-35%. The molar ratio of aluminum hydroxide to phosphoric acid is 2:1, and the molar ratio of sodium carbonate to maleic acid is 1:1. The ultrasonic treatment frequency is 38kHz, and the power is 600W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com