Shell material used for pump valve type precision castings, and preparation process and application thereof

A precision casting and shell material technology, applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of cost increase, difficulty in shelling, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

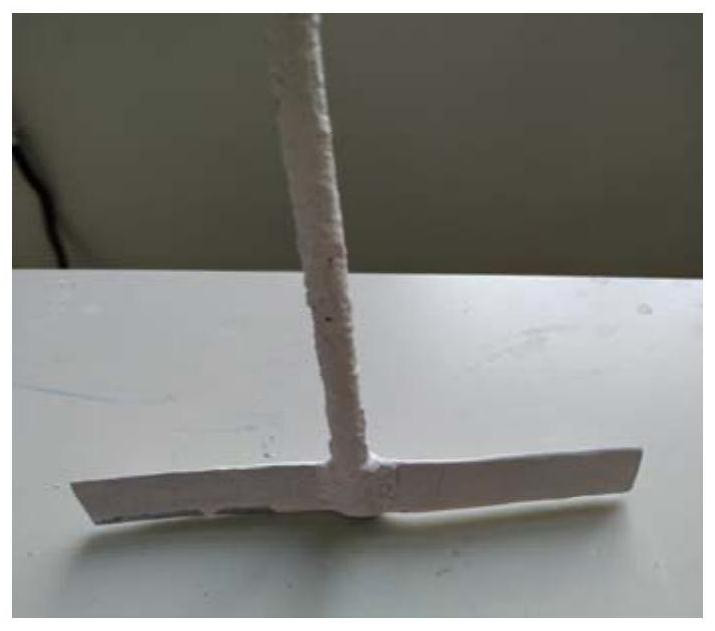

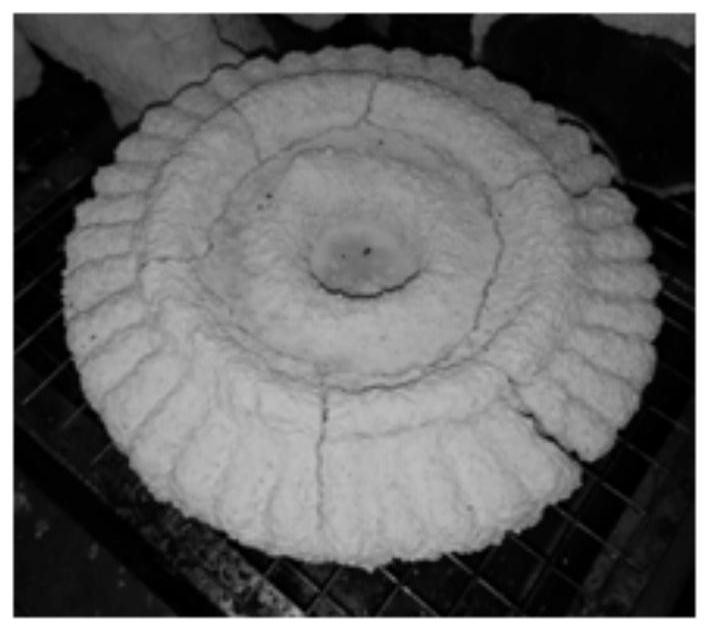

[0028] In this embodiment, it is carried out according to the method described in the technical solution of the present invention. First, mix the fused silica powder and ethyl silicate in a weight ratio of 10:3 and stir evenly. The particle size of the fused silica powder is 53 μm. Stir with a T-type mixer at a speed of 120 rpm for 50 hours to make a slurry. Then adjust the viscosity of the slurry with deionized water, measure the viscosity with a No. 5 flow cup, and adjust the viscosity value to 8.8s. Apply the slurry evenly on the shell back layer with a thickness of 0.85mm. Sprinkle white corundum powder evenly into the slurry on the back layer of the shell with a rain shower sander. The white corundum powder accounts for 30% by weight of the slurry, the particle size is 220 μm, the sanding speed is 3m / s, and the time is 9 seconds. , forming a layer of quartz material. Coat one layer of quartz material with a thickness of 1.2mm on the shell, and dry it for 8 hours in an ...

Embodiment 2

[0031] In this embodiment, it is carried out according to the method described in the technical solution of the present invention. First, mix the fused silica powder and ethyl silicate in a weight ratio of 10:5 and stir evenly. The particle size of the fused silica powder is 108 μm. Stir with a T-type mixer at a speed of 110 rpm for 72 hours to make a slurry. Then adjust the viscosity of the slurry with deionized water, measure the viscosity with a No. 5 flow cup, and adjust the viscosity value to 16.8s. Apply the slurry evenly on the shell back layer with a thickness of 1.05mm. Sprinkle white corundum powder evenly into the slurry of the back layer of the shell with a rain shower sander, the white corundum powder accounts for 23% by weight of the slurry, the particle size is 120μm, the sanding speed is 4m / s, and the time is 8 seconds , forming a layer of quartz material. Coat three layers of quartz material with a thickness of 3.9mm on the shell, and dry for 6 hours in an ...

Embodiment 3

[0034] In this embodiment, it is carried out according to the method described in the technical solution of the present invention. First, mix the fused silica powder and ethyl silicate in a weight ratio of 10:4 and stir evenly. The particle size of the fused silica powder is 189 μm. Stir with a T-type mixer at a speed of 175 rpm for 83 hours to make a slurry. Then adjust the viscosity of the slurry with deionized water, measure the viscosity with a No. 5 flow cup, and adjust the viscosity value to 12.8s. Apply the slurry evenly on the shell back layer with a thickness of 1.11 mm. Sprinkle white corundum powder evenly into the slurry of the back layer of the shell with a rain shower sanding machine. The white corundum powder accounts for 15% by weight of the slurry, the particle size is 160 μm, the sanding speed is 6m / s, and the time is 8 seconds. , forming a layer of quartz material. Coat the shell with 3 layers of quartz material with a thickness of 4.3mm, and dry it for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com