A kind of non-stoichiometric ratio tic reinforced copper matrix composite material and preparation method thereof

A copper-based composite material and composite material technology are applied in the field of non-stoichiometric TiC reinforced copper-based composite materials and their preparation, which can solve the problems of inevitable residual reaction phase, difficult to fully carry out the reaction, and difficult to form a strong interface, etc. Effects of low coefficient of friction, increased hardness and strength, good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

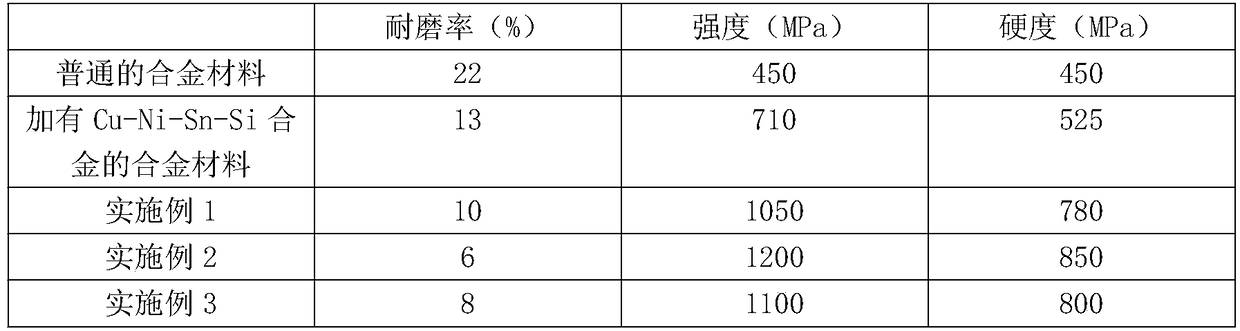

Examples

Embodiment 1

[0026] A non-stoichiometric TiC reinforced copper-based composite material, the composite material is composed of 1kg non-stoometric TiC particles and 99kg matrix copper alloy; the matrix copper alloy is Cu-Ni-Sn-Si alloy.

[0027] In this embodiment, the base copper alloy contains the following components: 7kg Sn, 0.15kg Si, 14.5kg Ni, 0.3kg Fe, 0.3kg Zn, 0.12kg Mn, 0.08kg Nb, 0.02kg Pb, impurities≤0.5 kg, the balance is Cu.

[0028] A method for preparing a non-stoichiometric TiC reinforced copper-based composite material, the specific steps are as follows:

[0029] (1) Put Ti 2 SnC and Ti 3 SiC 2 Place it in an ultrasonic cleaner filled with a cleaning solution and clean the cleaned Ti 2 SnC and Ti 3 SiC 2 After drying, ball mill and mix with Cu powder in a ball mill tank filled with argon to obtain the mixed powder;

[0030] (2) cold-pressing the mixed powder prepared in step (1) and vacuum sintering to obtain the TiC / Cu intermediate material;

[0031] (3) Put Cu i...

Embodiment 2

[0040] A non-stoichiometric TiC reinforced copper-based composite material, the composite material is composed of 3kg non-stoometric TiC particles and 97kg matrix copper alloy; the matrix copper alloy is a Cu-Ni-Sn-Si alloy.

[0041] In this embodiment, the base copper alloy contains the following components: 8kg Sn, 0.25kg Si, 15kg Ni, 0.3kg Fe, 0.3kg Zn, 0.12kg Mn, 0.08kg Nb, 0.02kg Pb, impurities≤0.5kg , the balance is Cu.

[0042] A method for preparing a non-stoichiometric TiC reinforced copper-based composite material, the specific steps are as follows:

[0043] (1) Put Ti 2 SnC and Ti 3 SiC 2 Place it in an ultrasonic cleaner filled with a cleaning solution and clean the cleaned Ti 2 SnC and Ti 3 SiC 2 After drying, ball mill and mix with Cu powder in a ball mill tank filled with argon to obtain the mixed powder;

[0044] (2) cold-pressing the mixed powder prepared in step (1) and vacuum sintering to obtain the TiC / Cu intermediate material;

[0045] (3) Put Cu i...

Embodiment 3

[0054] A non-stoichiometric TiC reinforced copper-based composite material, the composite material is composed of 5kg non-stoometric TiC particles and 95kg matrix copper alloy; the matrix copper alloy is a Cu-Ni-Sn-Si alloy.

[0055] In this embodiment, the base copper alloy contains the following components: 8.5kg Sn, 0.4kg Si, 15.5kgNi, 0.3kg Fe, 0.3kg Zn, 0.12kg Mn, 0.08kg Nb, 0.02kg Pb, impurities≤0.5 kg, the balance is Cu.

[0056] A method for preparing a non-stoichiometric TiC reinforced copper-based composite material, the specific steps are as follows:

[0057] (1) Put Ti 2 SnC and Ti 3 SiC 2 Place it in an ultrasonic cleaner filled with a cleaning solution and clean the cleaned Ti 2 SnC and Ti 3 SiC 2 After drying, ball mill and mix with Cu powder in a ball mill tank filled with argon to obtain the mixed powder;

[0058] (2) cold-pressing the mixed powder prepared in step (1) and vacuum sintering to obtain the TiC / Cu intermediate material;

[0059] (3) Put Cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com