Patents

Literature

204results about How to "Play a role in cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

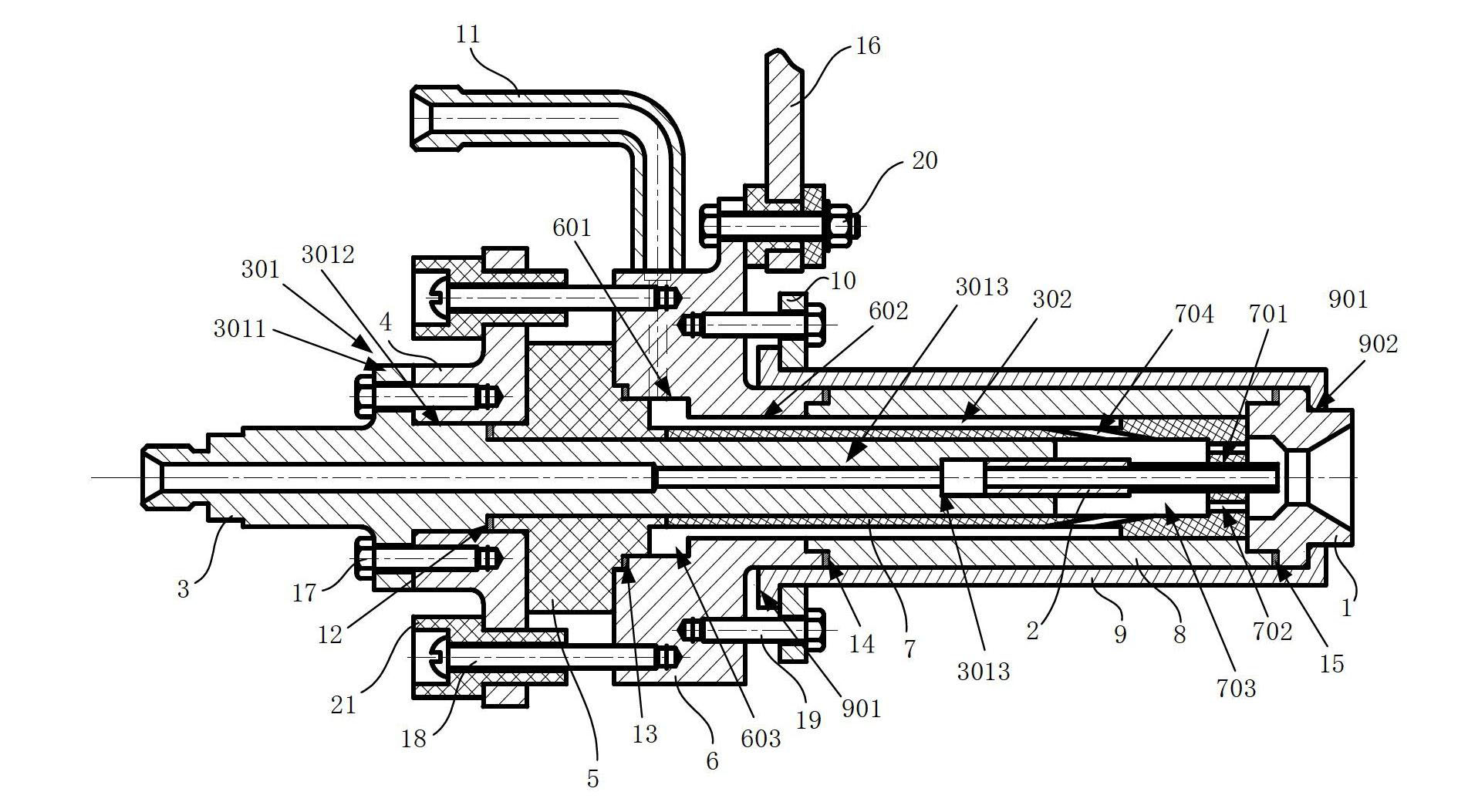

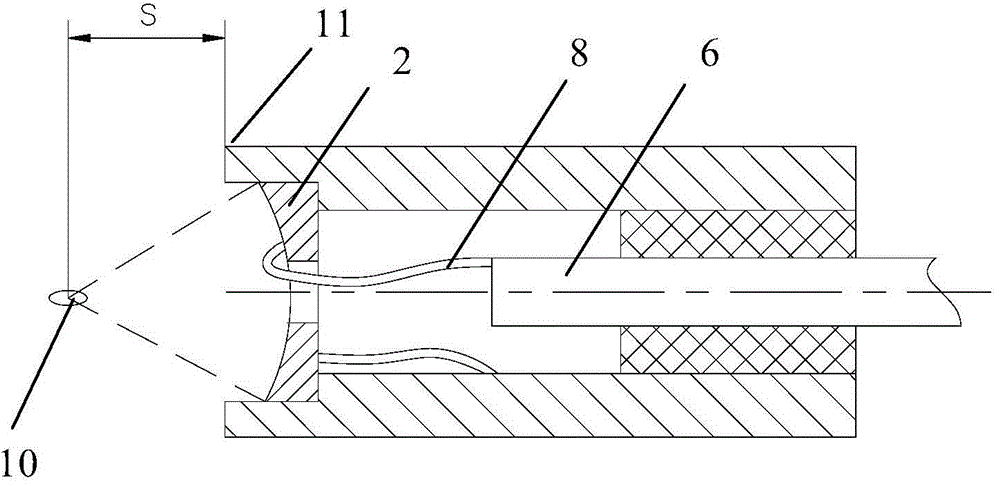

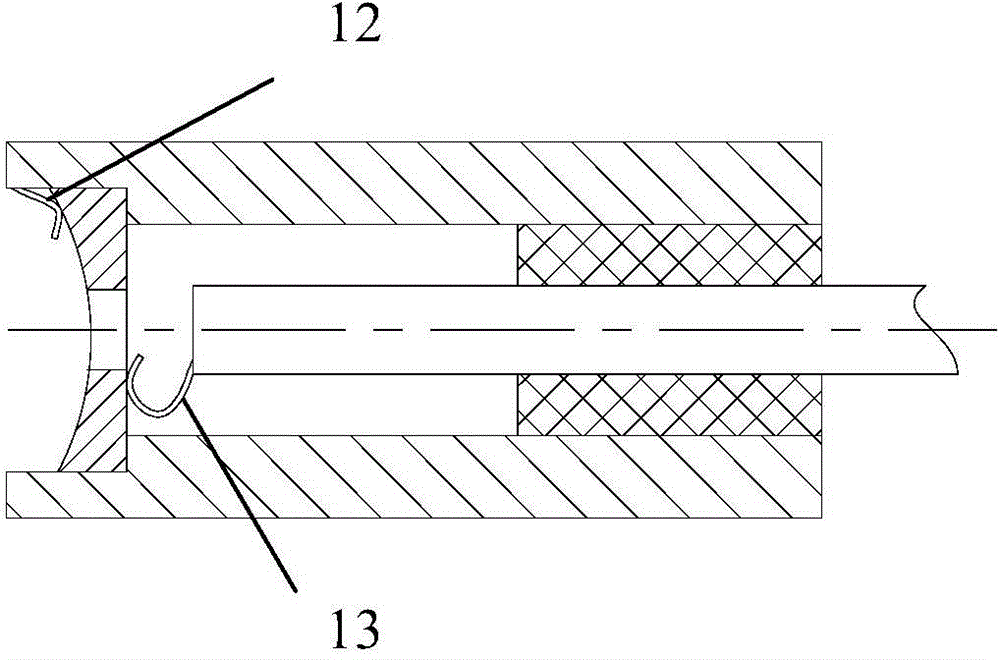

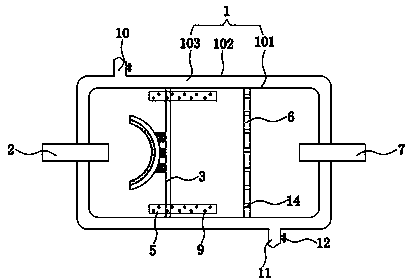

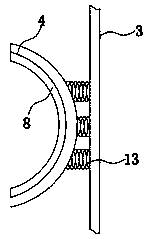

Magnetic plasma propeller

InactiveCN102678500AMeet the requirements under different experimental conditionsPlay a role in coolingMachines/enginesUsing plasmaInlet channelPropeller

The invention discloses a magnetic plasma propeller. An end cover, a supporting body and an insulation cylinder are sleeved on a cathode mounting piece from back to front; and a discharging cavity is formed between the front end face of the insulation cylinder and the front end face of the cathode mounting piece. A middle connection piece and an anode liner are sleeved on the insulation cylinder from back to front; an air inlet pipeline is communicated on the middle connection piece; air inlet channels are formed among the middle connection piece, the anode liner and the cathode mounting piece; air inlets are formed in the front end face of the insulation cylinder; and an anode is positioned with the insulation cylinder through an anode shell. A cathode is located inside the cathode mounting piece; and the front end of the cathode penetrates out of the front end face of the insulation cylinder, and is located inside the anode. Propellant is supplied by two paths; one path reaches to a position of the anode by passing through the air inlet pipeline, an air inlet cavity, the air inlet channel, a gas port, the discharging cavity and the air inlets in sequence; the other path reaches to the position of the anode by passing through the inside of the cathode mounting piece and the inside of the cathode in sequence; and the propellant in the two paths is mixed and then is subjected to discharging ionization between the cathode and the anode. The invention provides an electric propeller which uses argon as the propellant and supplies a milli-Newton level trust within a power range of 30-50 kW.

Owner:BEIHANG UNIV

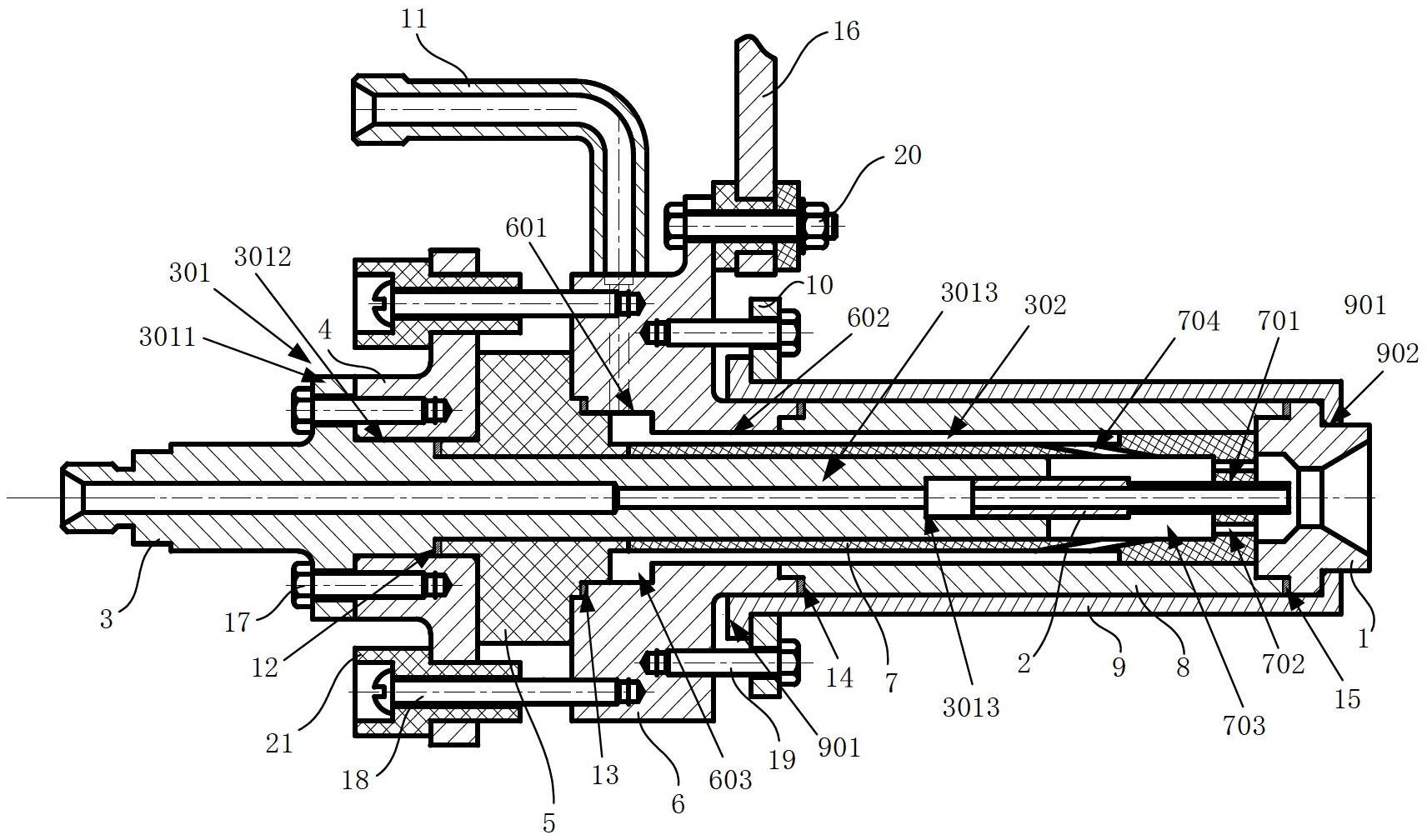

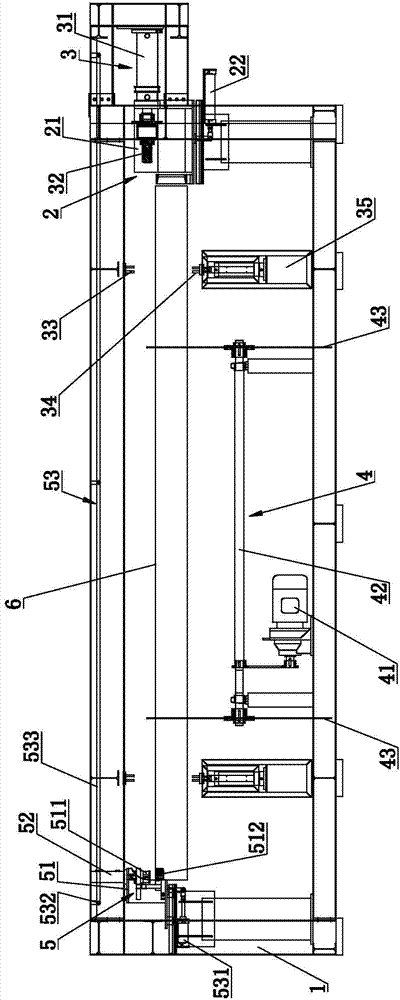

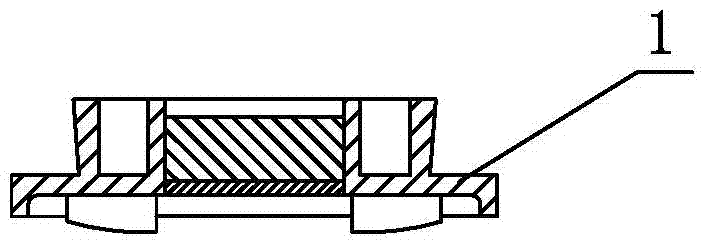

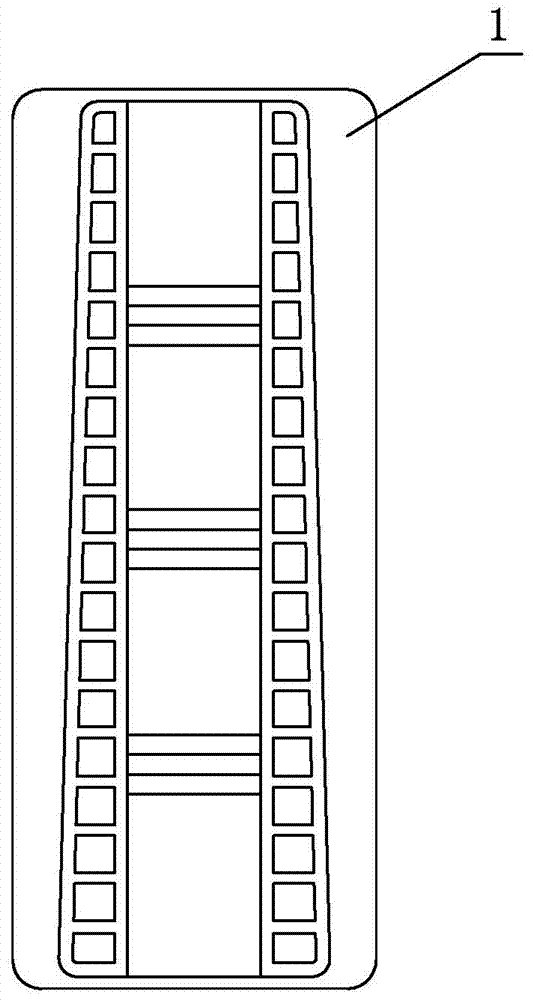

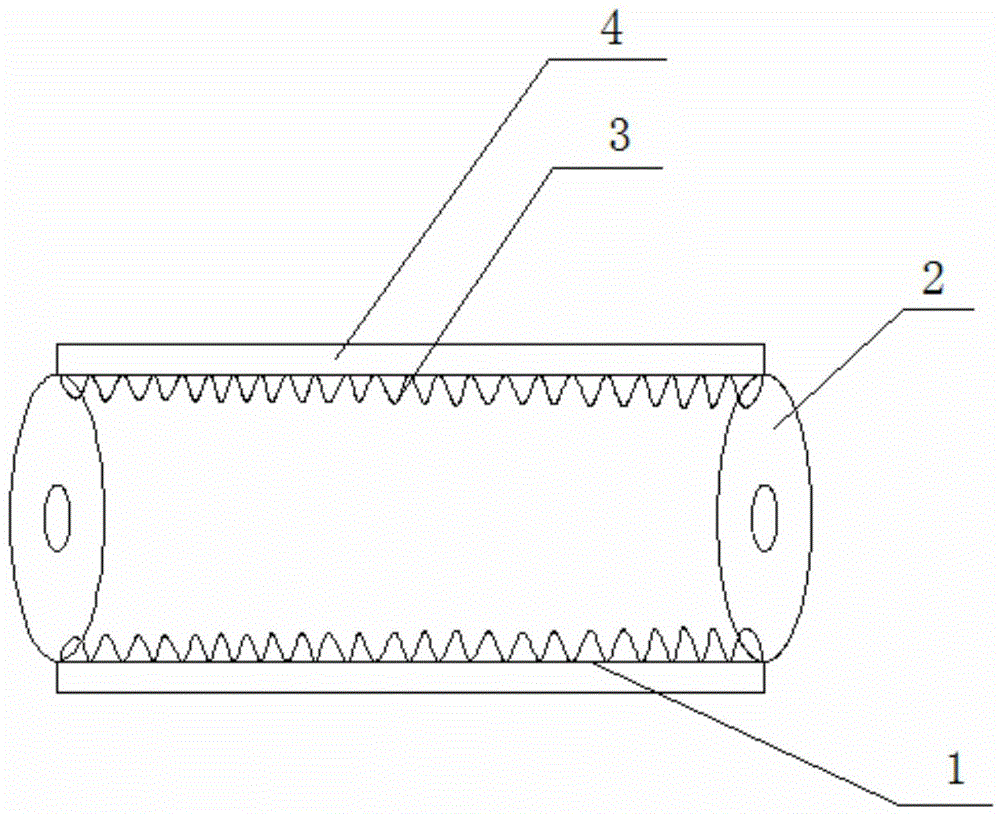

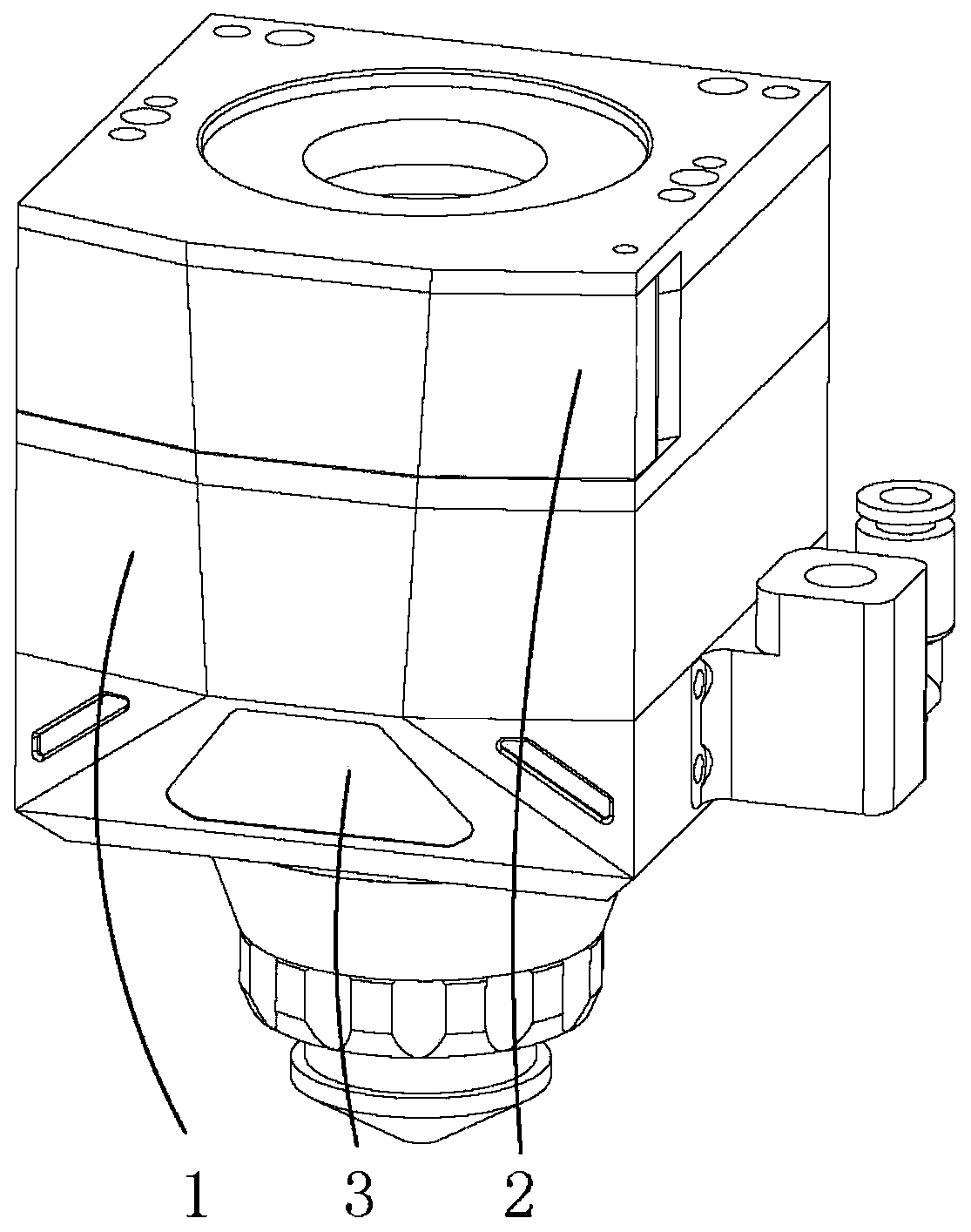

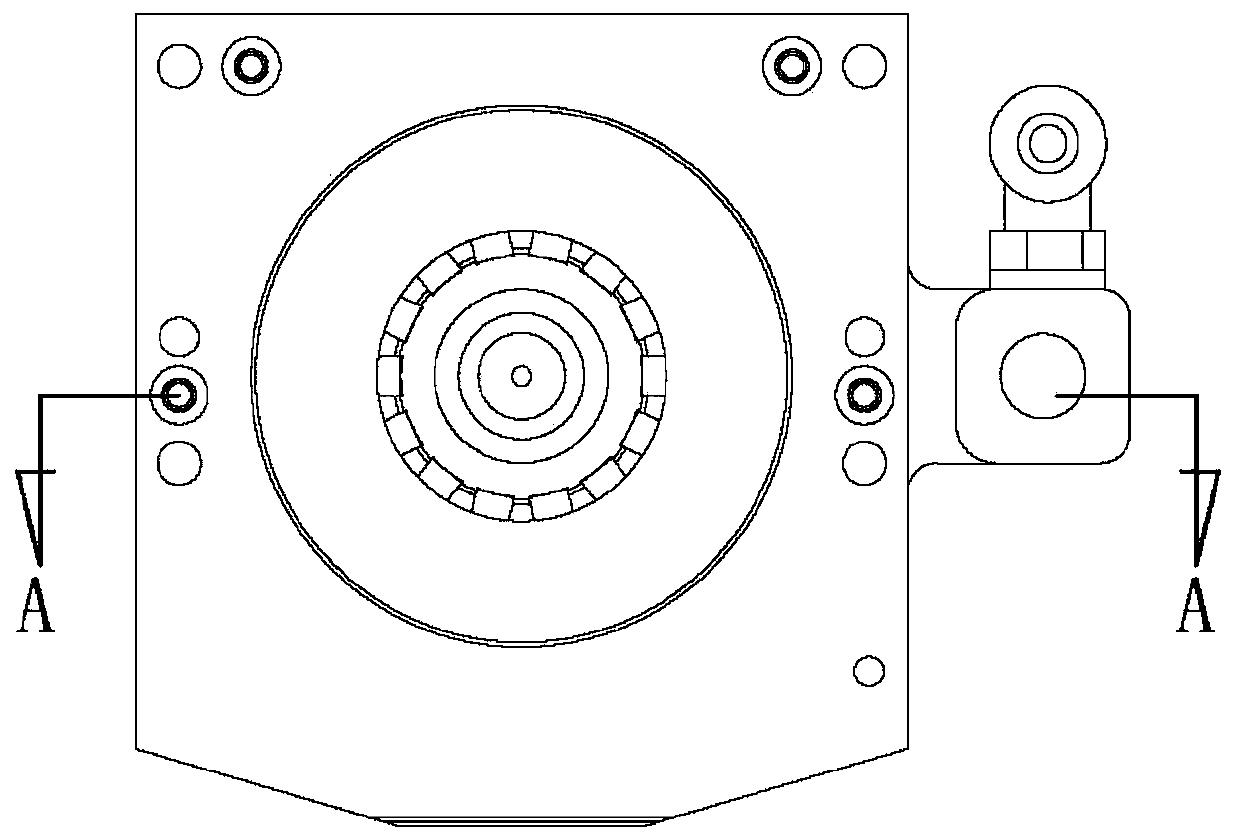

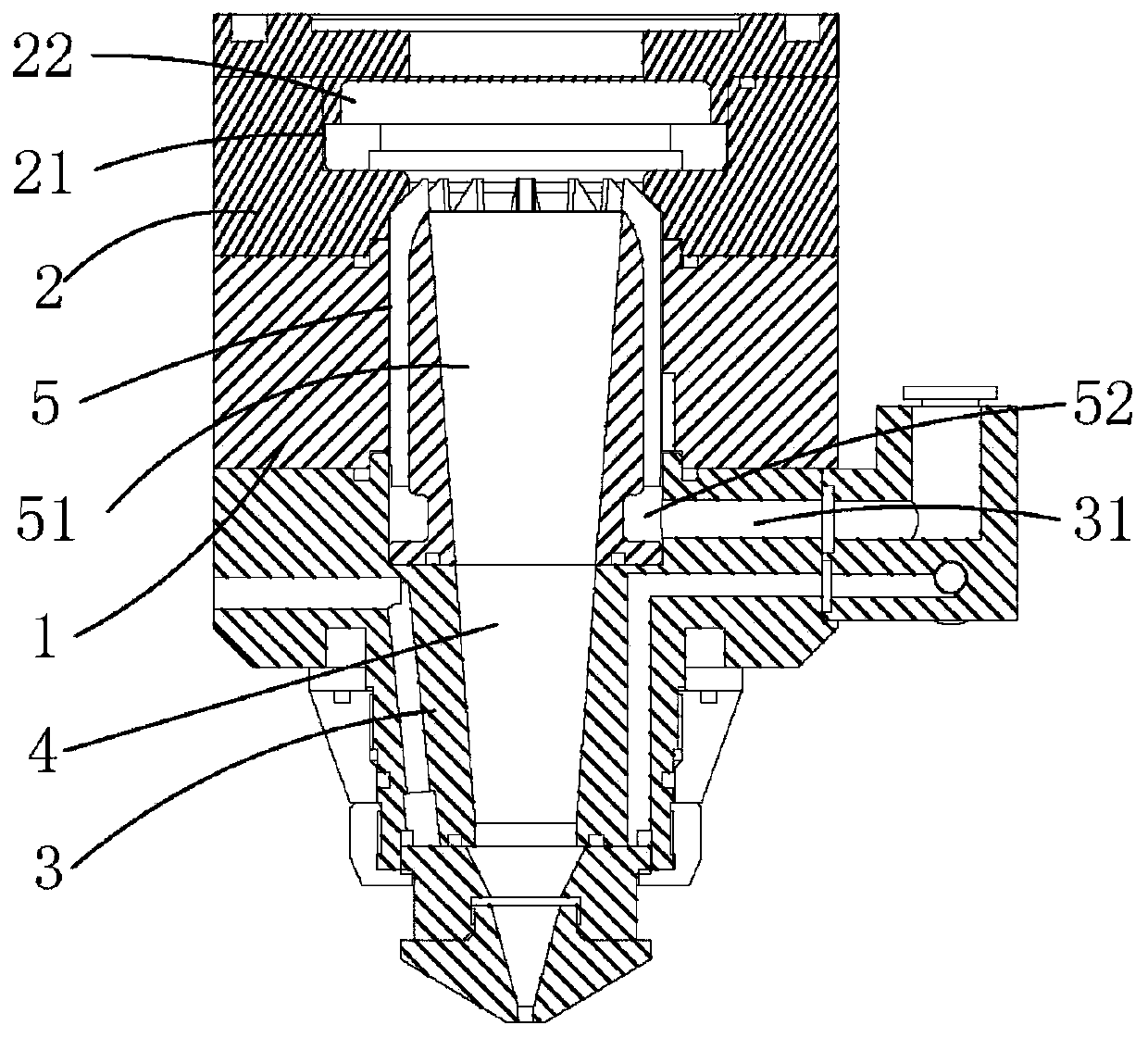

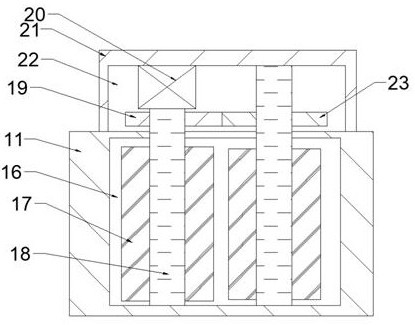

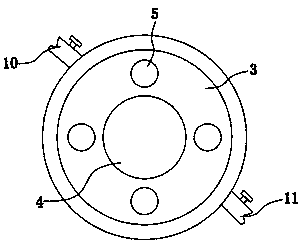

Reamer

ActiveCN104492988AIncrease productivitySave energyShaping toolsMetal-working feeding devicesReamerSmall footprint

The invention discloses a reamer. The reamer comprises a rack, wherein the rack is provided with an electromagnetic heating device and a reaming device which are arranged from front to back in sequence; the electromagnetic heating device comprises an electromagnetic heating coil; the reaming device comprises a reaming hole driven by a first power device; the rack is provided with a poking plate feeding device; the poking plate feeding device comprises a rotating shaft connected with a second power device; the rotating shaft is transversely arranged on the rack; the two ends of the rotating shaft are fixedly provided with circular poking plates; the peripheral parts of the poking plates are provided with at least three feeding fork entries for conveying metal pipes; poking plates are formed between adjacent feeding fork entries and can rotate to the positions, corresponding to the electromagnetic heating coil and a reaming head, on every two adjacent feeding fork entries respectively. The reamer has the advantages of high production efficiency, small floor area and low power consumption.

Owner:高密天一机械科技有限公司

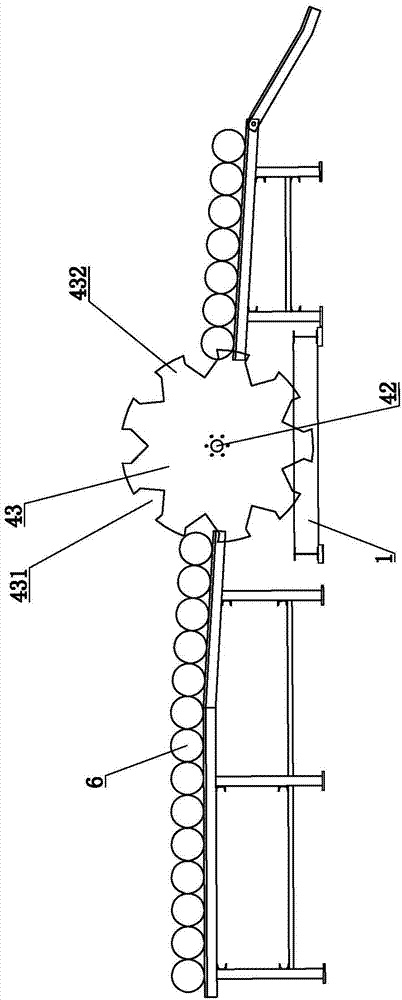

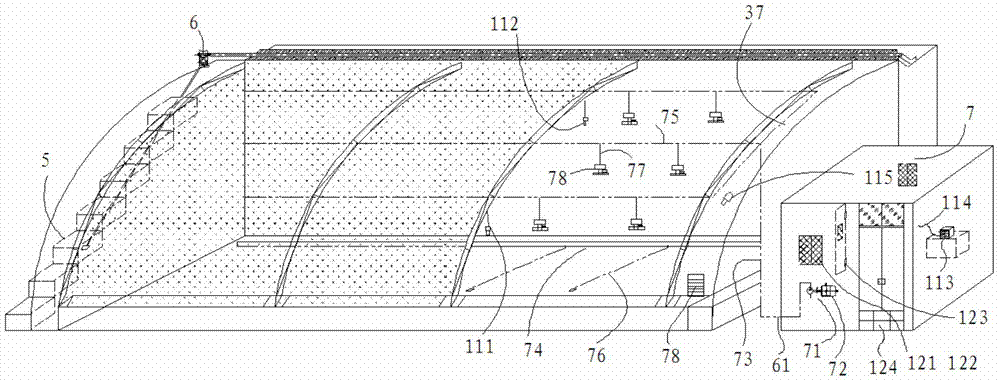

Three-dimensional pawpaw and pineapple cultivation method

ActiveCN103960105AIncrease profitImprove quality of lifeClimate change adaptationFertilising methodsInsect pestControl diseases

The invention discloses a three-dimensional pawpaw and pineapple cultivation method which comprises the following steps: 1, selecting a winter-warming type greenhouse; 2, improving the soil and adjusting the acidity, namely, deeply turning over the soil for 0.6-0.8cm before the greenhouse is built, and when the soil is deeply turned over, spreading 25m<3>+ / -5m<3> of cow dung per mu and meanwhile spreading 100kg+ / -25kg of sulfur powder per mu; 3, planting time, namely, planting in spring when the indoor temperature is more than 15 DEG C, wherein vegetatively propagated pawpaw seedlings which are planted within a period from October to November last year; 4, managing after planting, namely, fertilizing, drying, watering, managing the tree bodies and preventing and preventing and controlling diseases and insect pests; and 5, harvesting and packaging fruits. The three-dimensional cultivation mode is adopted on the basis of the height difference of pawpaw and pineapple plants and the different requirements on illumination intensity, the utilization rate of the greenhouse and the land is improved, and the economic and social benefits are high.

Owner:东平县宝岛农业科技有限公司

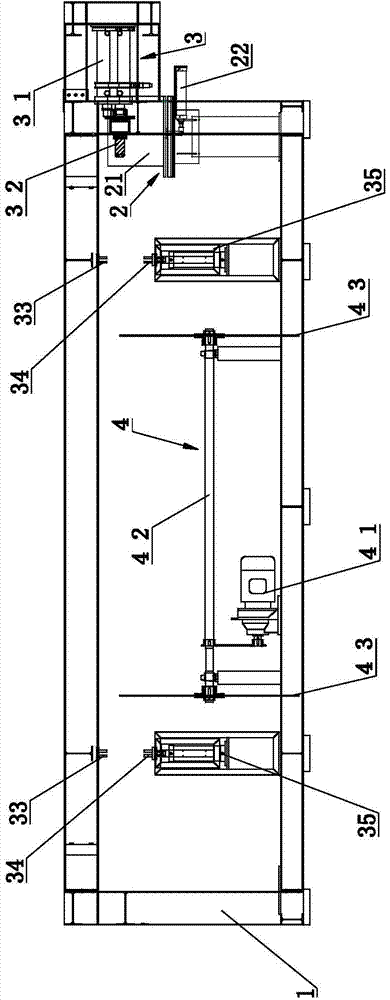

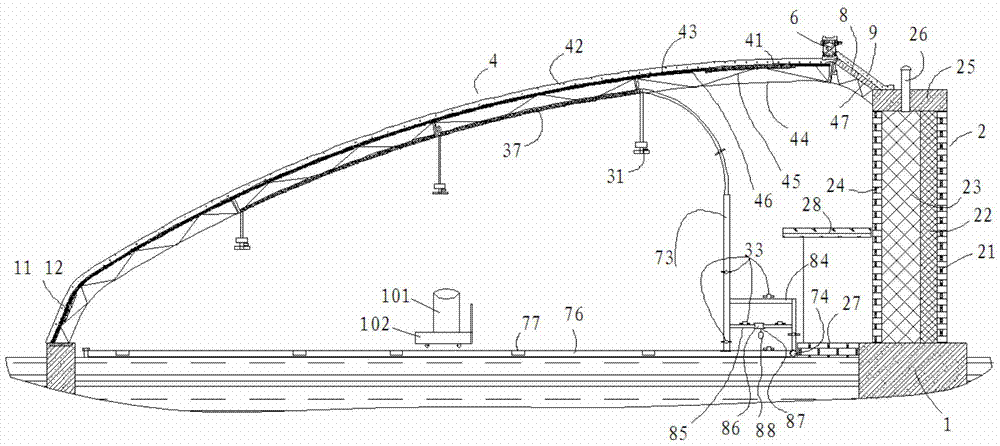

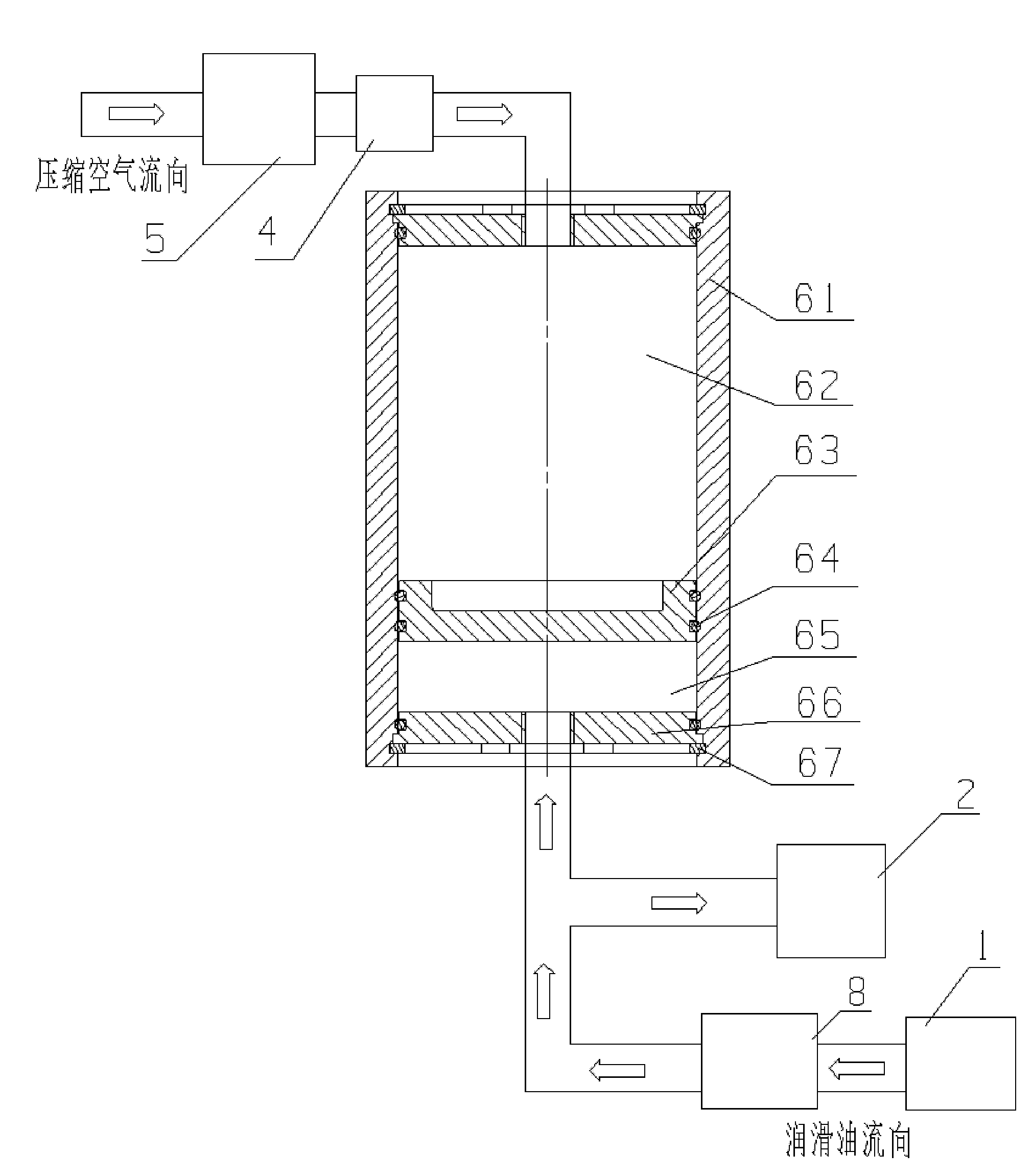

Fuel cut-off protection device for turbocharger

ActiveCN103184928AMeet frequent start and stopMeet the working conditions of unplanned downtimeMachines/enginesEngine componentsTurbochargerPetroleum engineering

The invention discloses a fuel cut-off protection device for a turbocharger. The fuel cut-off protection device comprises a three-way oil tube, wherein the first branch of the three-way oil tube is connected with the turbocharger; the second branch of the three-way oil tube is connected with a lubricating oil circuit of an engine; the third branch of the three-way oil tube is connected with the fuel cut-off protection device of the turbocharger; a one-way valve which is conducted from the engine to the three-way oil tube along a single direction is arranged in the first branch; and the fuel cut-off protection device is used for storing lubricating oil during normal running of the engine, and inputting the stored lubricating oil into the turbocharger when the engine stops running. The fuel cut-off protection device for the turbocharger can be used for storing lubricating oil during running of the engine, and can be used for inputting the stored lubricating oil into the turbocharger when the engine stops running to cool and lubricate, so that energy can be saved; and the fuel cut-off protection device for the turbocharger is suitable for the situations of frequent start and stop and halt and unexpected halt of the engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

Safety helmet with dust prevention and cooling function based on internet of things

ActiveCN108272159AReduce the temperatureAdd practical functionsHelmetsHelmet coversThe InternetEngineering

The invention relates to a safety helmet with a dust prevention and cooling function based on the internet of things. The safety helmet comprises a main body and further comprises a face mask, a cooling mechanism and a dedusting mechanism, the cooling mechanism comprises a cooling assembly and a jetting assembly, and the dedusting mechanism comprises a roller and two movable assemblies. By means of the safety helmet with the dust prevention and cooling function based on the internet of things, through the cooling mechanism, heat inside the safety helmet can be absorbed and taken away, thus thetemperature inside the safety helmet is lowered, the wearing comfort of workers is improved, the body fatigue of the workers is mitigated, cooled air is made full use of for dedusting, dust is prevented from covering the surfaces of the safety helmet and the face mask, thus the vision is not blurred, and the respiratory tract and the eyes of the workers are not influenced; through the dedusting mechanism, the surface of the face mask keeps clean, the visual effect is improved, the workers conveniently observe the surrounding environment during work, and the practicability and the functionality of the safety helmet are improved.

Owner:HUNAN KANGDEJIA FORESTRY TECH CO LTD

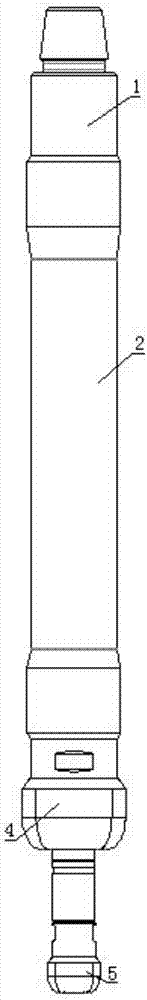

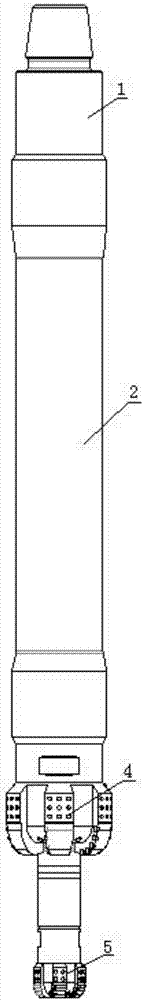

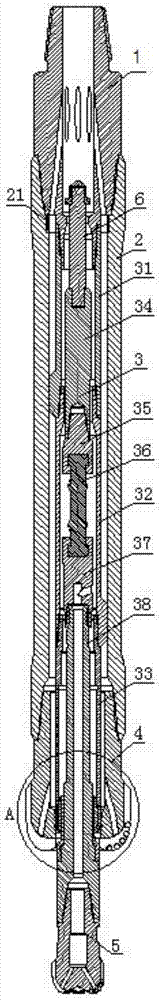

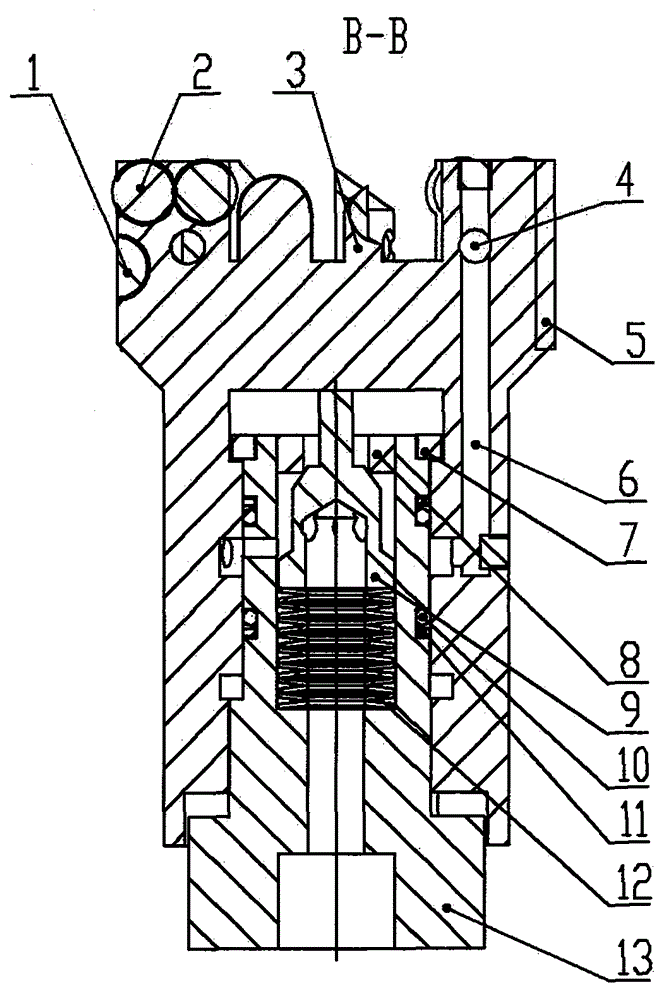

Drilling speed increasing device with composite drill bit

The invention relates to the field of petroleum and natural gas drilling equipment, in particular to a drilling speed increasing device with a composite drill bit. According to the technical scheme, the drilling speed increasing device with the composite drill bit comprises a multifunctional connector, the multifunctional connector is connected with a shell and a screw driving assembly, and the screw driving assembly is sleeved with the shell; the end, away from the multifunctional connector, of the shell is connected with a reaming drill bit body, and the end, away from the multifunctional connector, of the screw driving assembly is connected with a pilot drill bit body; water holes are formed in the reaming drill bit body and the pilot bit body; and the reaming drill bit body is a diamond drill bit or a roller bit, and the pilot bit body is a diamond drill bit or a roller bit. According to the drilling speed increasing device, the pilot bit body can achieve two-stage speed increasing, accordingly the overall drilling speed is increased, and the problems that a pilot bit of an existing two-stage drilling device is low in rotation speed and not obvious in drilling speed increasing are solved.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

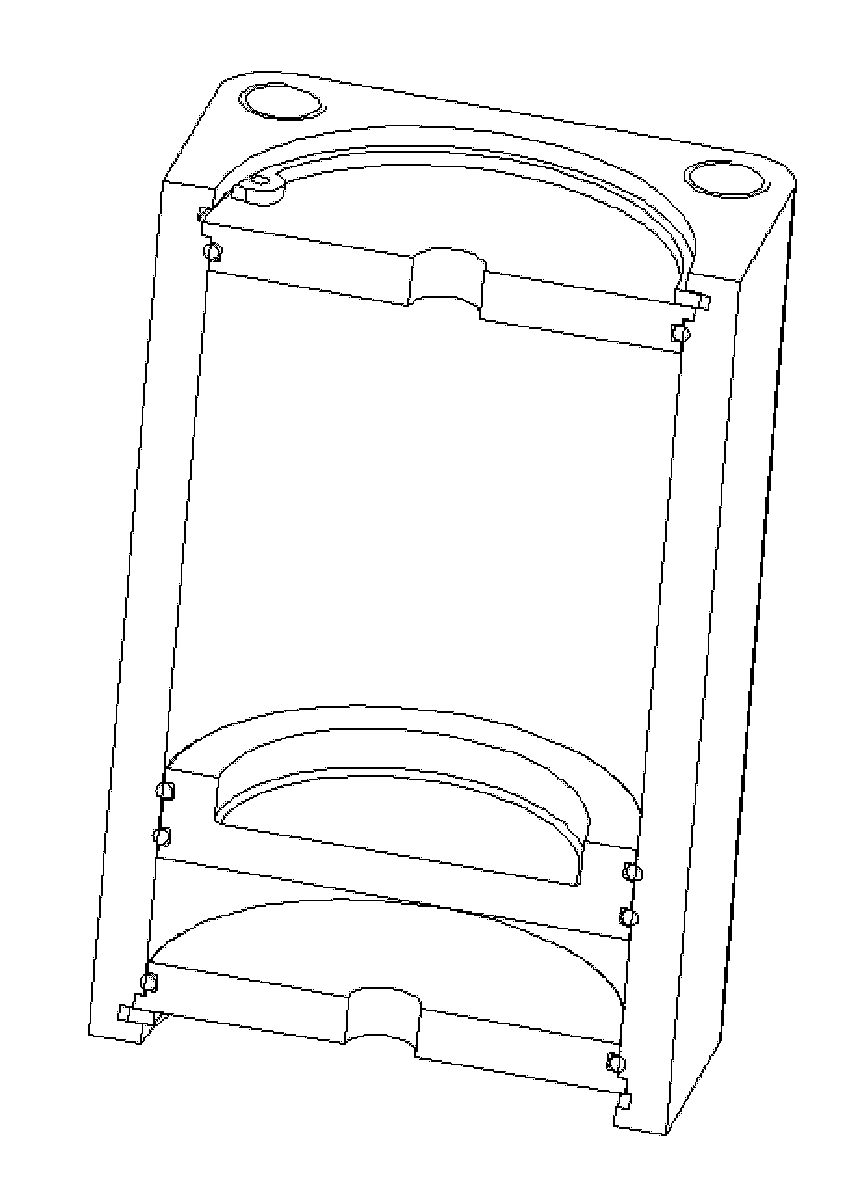

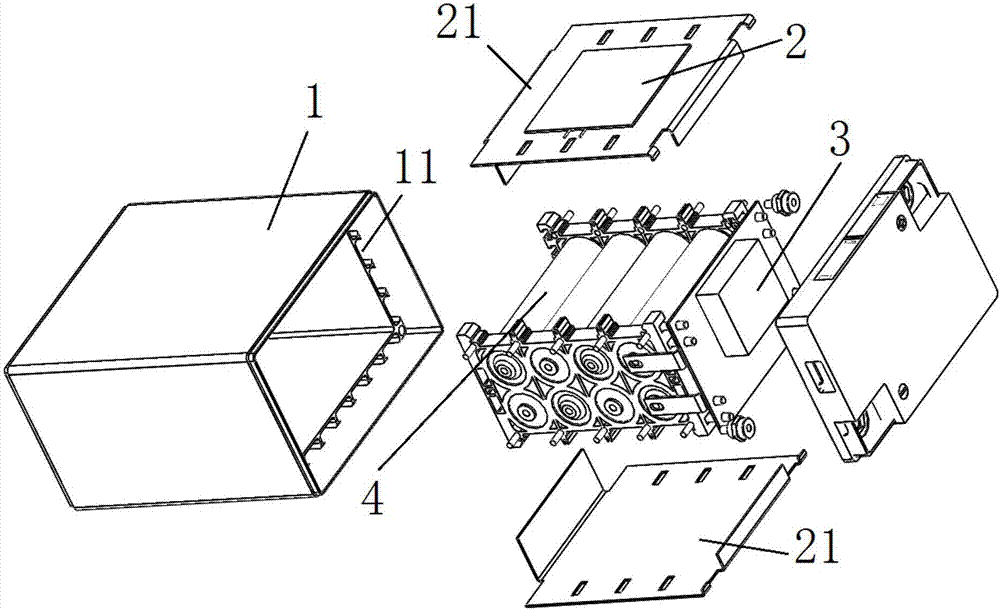

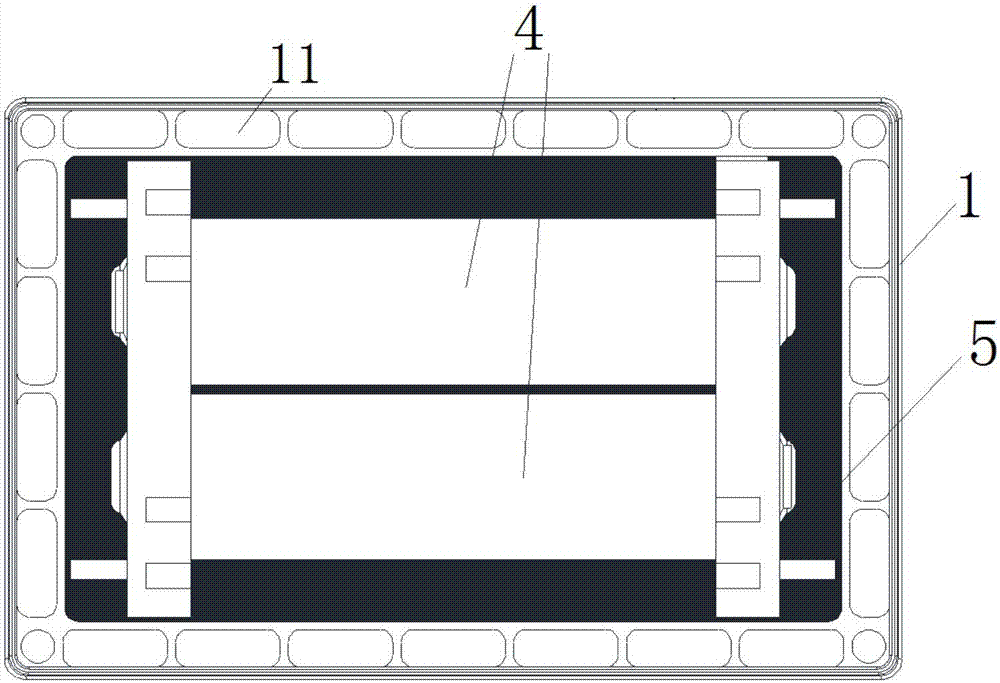

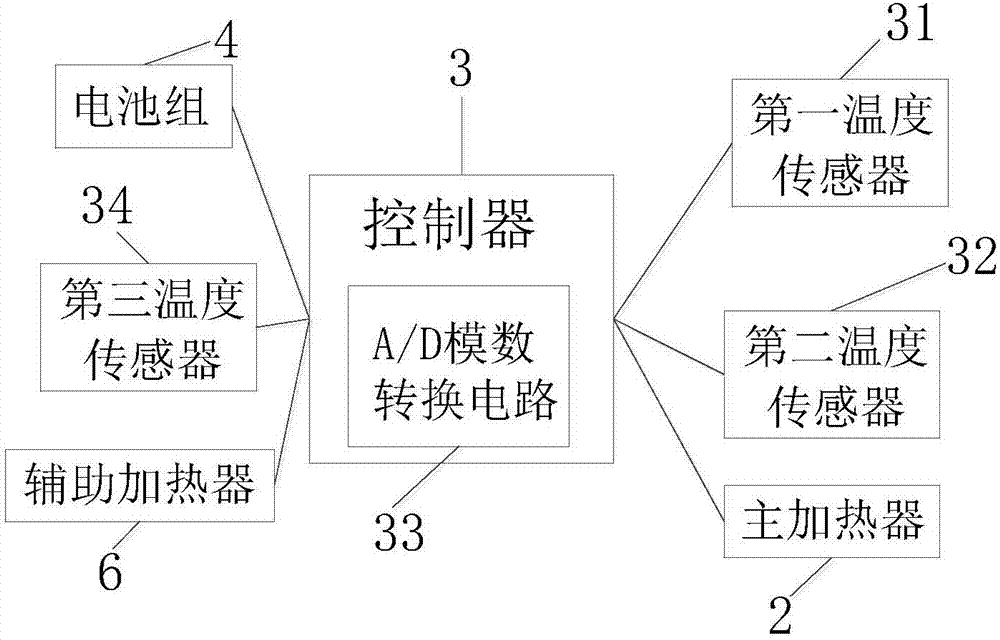

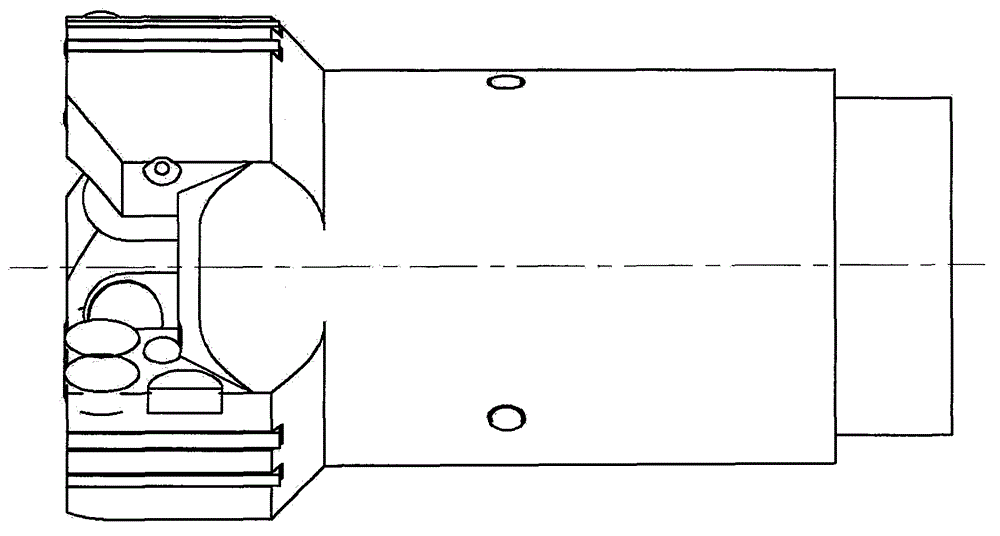

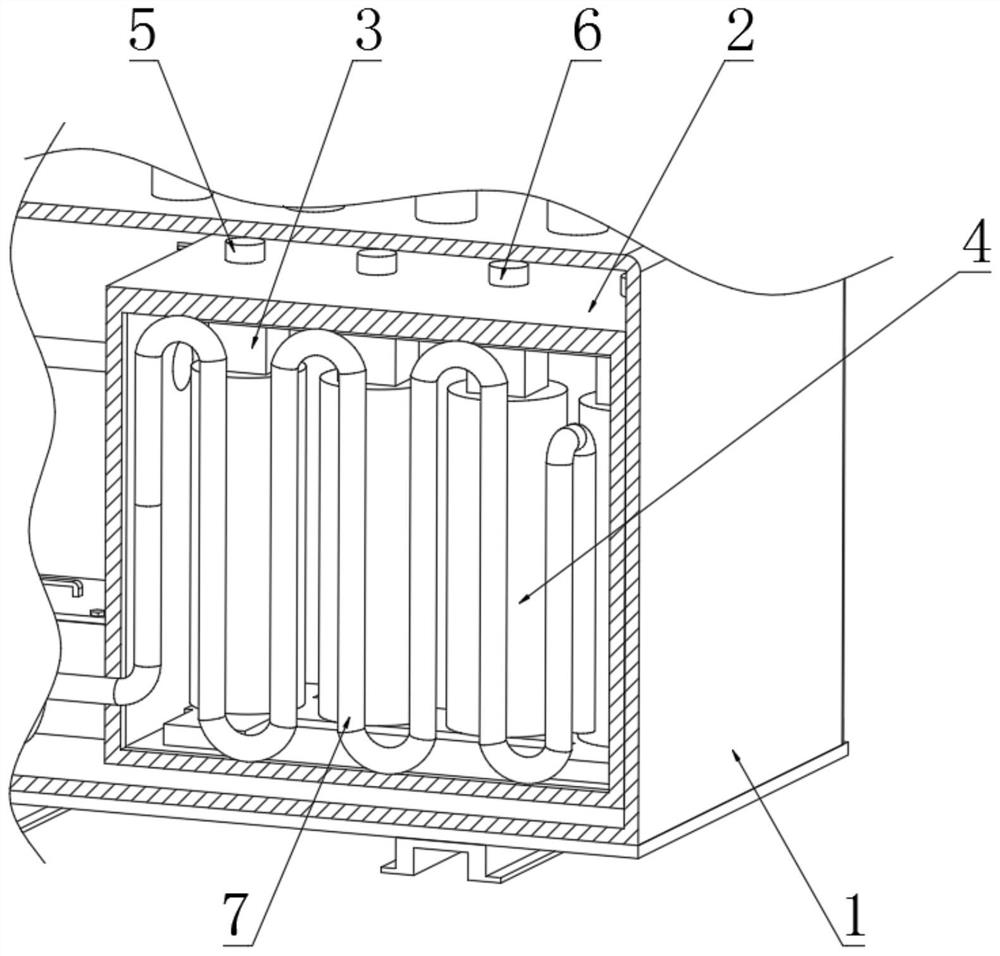

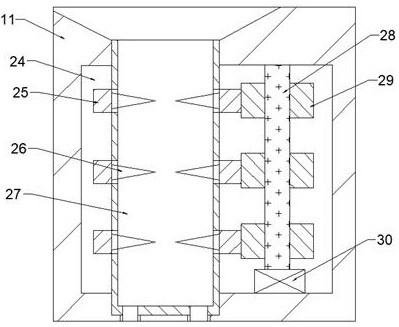

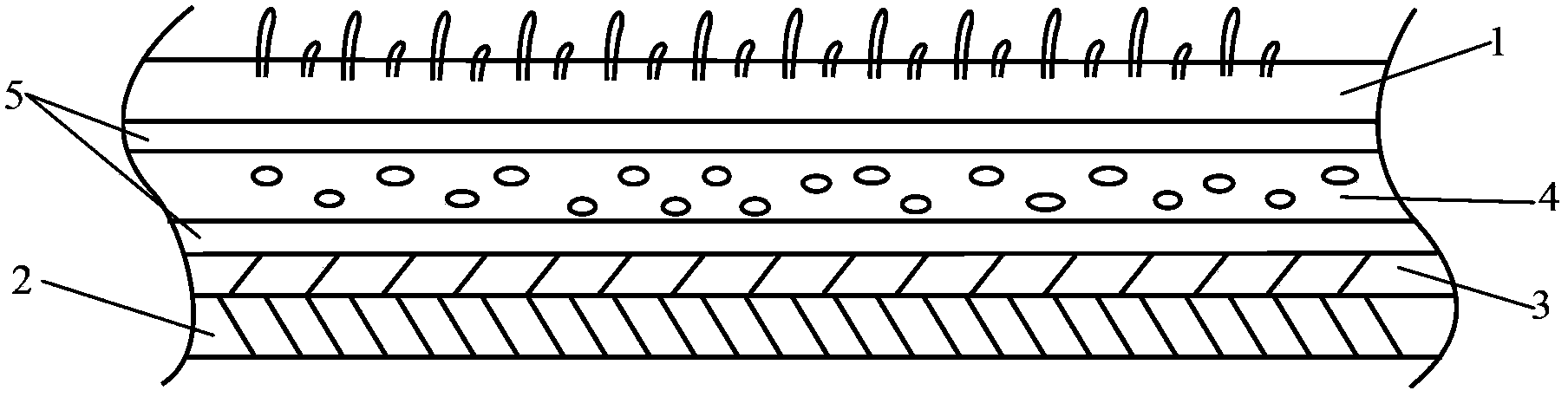

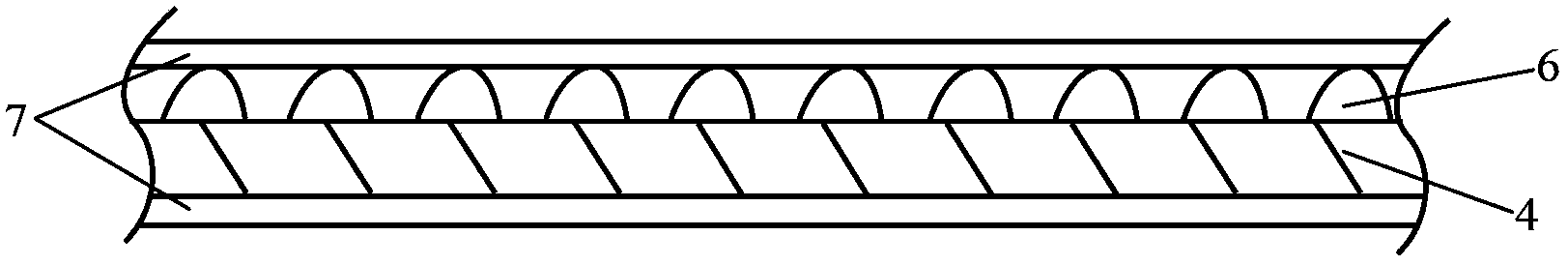

Battery box

PendingCN106876626AAvoid accessPlay a role in coolingSecondary cellsCell component detailsThermal insulationEngineering

The invention provides a battery box which comprises a shell which is internally provided with a battery pack and is a double-layer shell; a plurality of channels which are mutually communicated with one another are arranged between an inner layer and an outer layer; the shell is provided with at least two valves which are communicated with the channels; the circulation direction of at least one valve is arranged inwards; and the circulation direction of at least one valve is arranged outwards. The battery box has the beneficial effects that by arranging the channels to be connected with the valves, external air and the channels form air flow channels, redundant heat is brought away by air circulation to have the cooling action; and in a valve closing state, the action of thermal insulation is realized.

Owner:中昱博软件系统(南京)有限公司

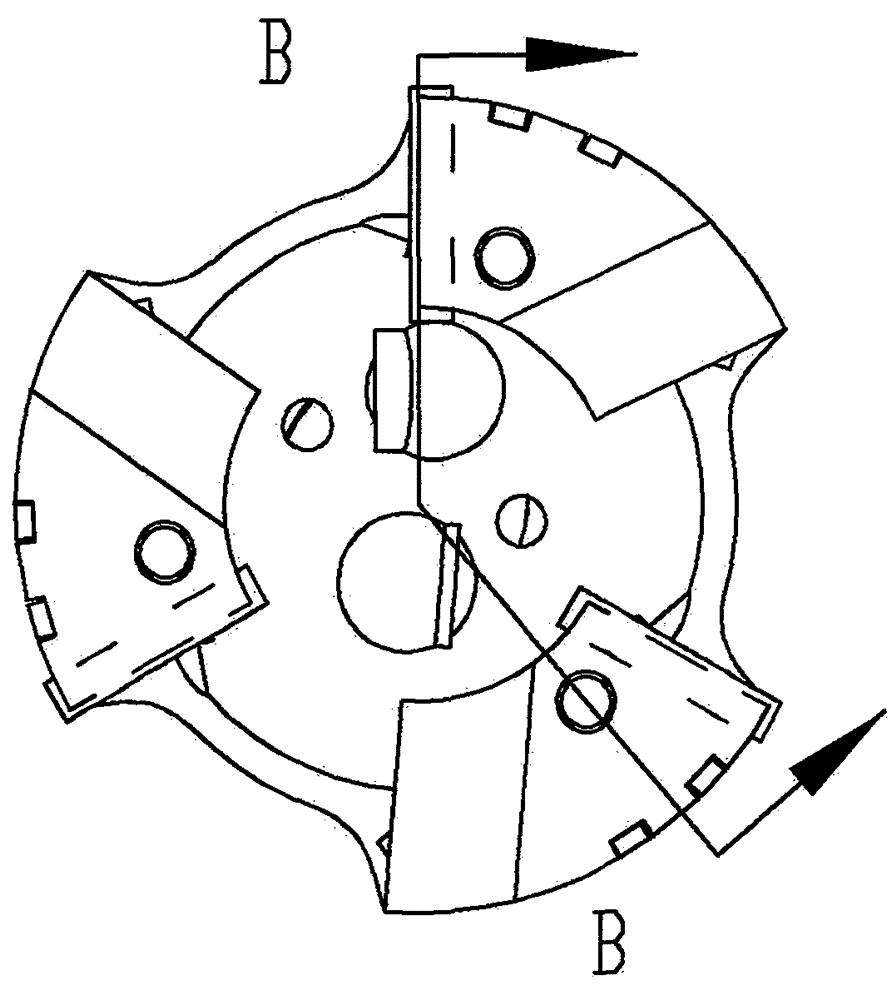

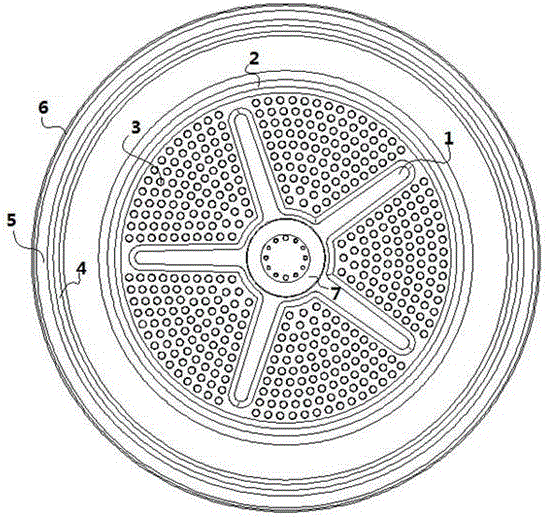

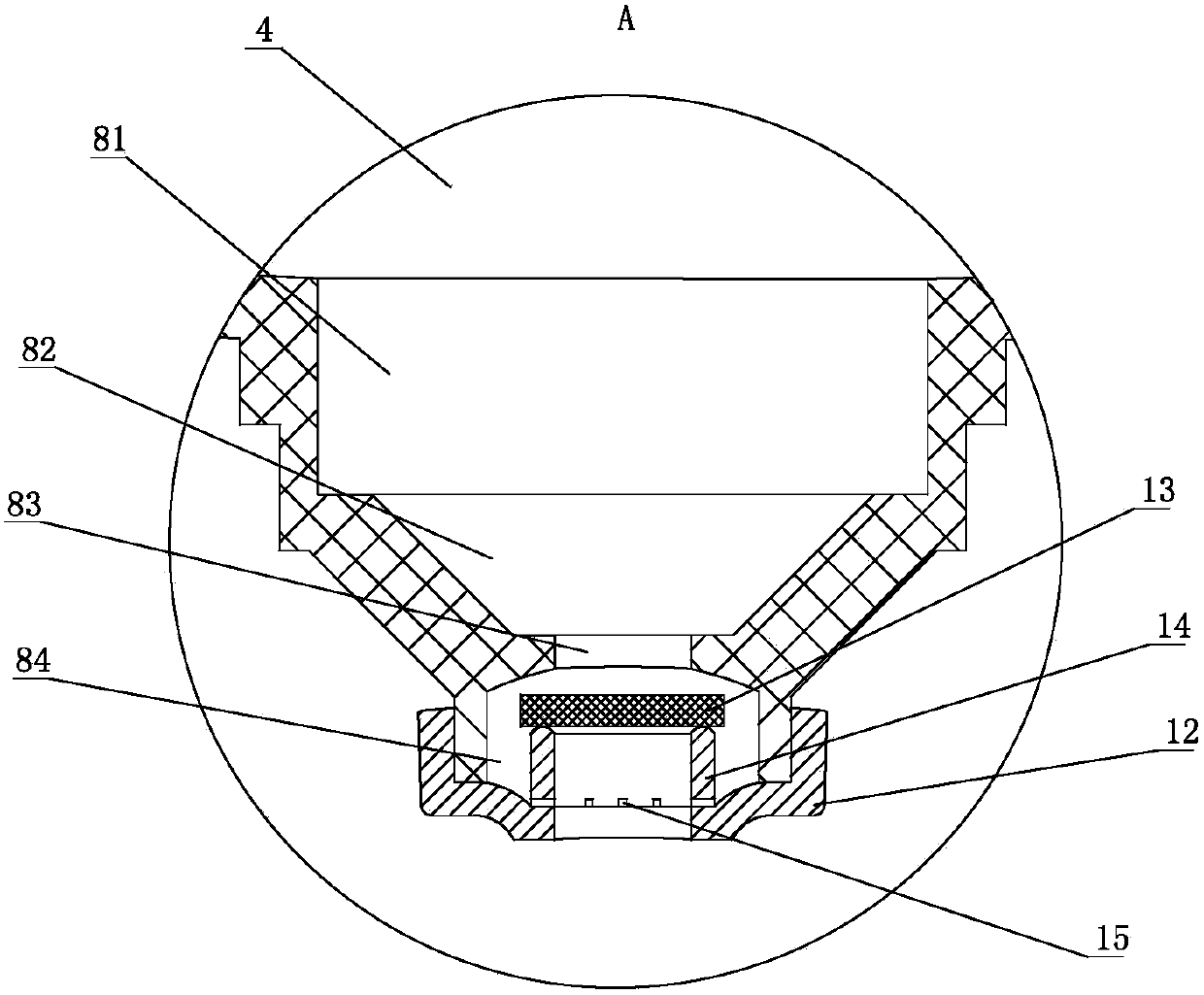

Multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit

InactiveCN104481411AImprove applicabilityImprove drilling efficiencyDrill bitsHigh pressure waterAlloy

The invention relates to a multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit, which is applicable to lubricating and cooling the drill bit and automatically drilling holes in a drilling process of a complex geological structure and has high drilling efficiency, long life and high applicability. The multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit comprises a special alloy crown part, and a diamond composite sheet is additionally arranged, so the wear degree of steel can be effectively relieved, the consistency in aperture is guaranteed, and the phenomenon of shrinkage is avoided. The high-pressure water jet of the drill bit is very beneficial for assisting in the drilling efficiency; the drilling diameter of the water jet is larger than the drilling diameter of the conventional mechanical rotary cut drilling, and the aperture of a soft coal seam at a local area can be increased by 20-30 times. The drill bit can be used for performing other drilling construction processes in combination with product characteristics when water circulates through a region drilled to meet the requirement of the process in a cut joint outside a fracturing breakage region, a hole collapse region, a hole blockage region, a gas accumulation region and a region with coal blast and spray holes, and the construction is integrally performed to save time and labor.

Owner:XUZHOU BOAN TECH DEV

Latent curing epoxy resin binder diamond grinding tool and preparation method thereof

ActiveCN104493734AImprove liquidityLow viscosityAbrasion apparatusGrinding devicesEpoxyHeat resistance

The invention provides a latent curing epoxy resin binder diamond grinding tool and a preparation method thereof. The latent curing epoxy resin binder diamond grinding tool is characterized in that a working layer is mainly prepared from the following materials in parts by weight: 100 parts of an epoxy resin binder, 2-20 parts of a diamond abrasive material, 70-100 parts of a curing agent, 0.5-3 parts of an accelerant, 5-30 parts of a water-soluble pore-forming agent and 5-7 parts of a filler. The preparation method comprises the following steps: first mixing part of the materials to prepare the latent curing epoxy resin binder; then mixing all of the materials; finally casting the mixed materials into a mould to cure the material to obtain the latent curing epoxy resin binder diamond grinding tool. Compared with similar hot-press molded products, the latent curing epoxy resin binder diamond grinding tool adopting a casting process has the following advantages: the operational time is long, the process is simple, the cost and the energy consumption is low, the production efficiency is high, and the heat resistance, the abrasion resistance and the compactness are good; the water-soluble pore-forming agent generates pores in a water milling process so as to achieve the functions of removing chips, cooling and improving the self-sharpening property.

Owner:广东奔朗新材料股份有限公司

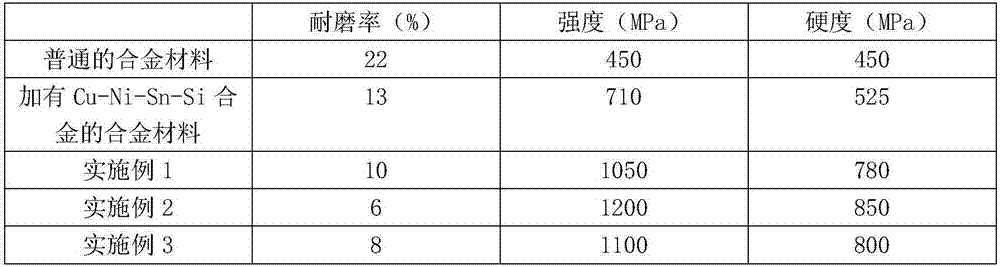

Non-stoichiometric ratio TiC reinforced copper-based composite and preparation method thereof

ActiveCN107119207AFacilitate deintercalation diffusionImprove collapseWear resistanceUltimate tensile strength

The invention discloses a non-stoichiometric ratio TiC reinforced copper-based composite and a preparation method thereof and belongs to the technical field of metallurgical composites. The composite is composed of, by mass percentage, 1-5% of non-stoichiometric ratio TiC particles and the balance a base body copper alloy. The base body copper alloy is a Cu-Ni-Sn-Si alloy. The preparation method comprises the following steps of 1, conducting vacuum in-situ reactive sintering on Ti2SnC, Ti3SiC2 and Cu powder to prepare a non-stoichiometric ratio TiC / Cu intermediate material; 2, placing Cu into a vacuum induction smelting furnace, after the Cu is fully molten, sequentially adding Ni, the TiC / Cu intermediate material, Sn and Si into the vacuum induction smelting furnace for smelting, so that a non-stoichiometric ratio TiC / Cu-Ni-Sn-Si powder material is obtained, and then conducting gas atomization treatment on the TiC / Cu-Ni-Sn-Si powder material, so that prealloy powder is obtained; and 3, conducting ball milling, cold pressing for blank production, vacuum sintering, extrusion and heat treatment on the prealloy powder, so that the TiC / Cu-based composite is obtained. The non-stoichiometric ratio TiC reinforced copper-based composite has the beneficial effects of being good in strength, low in friction coefficient, high in abrasion resistance and the like.

Owner:JIANGXI UNIV OF SCI & TECH

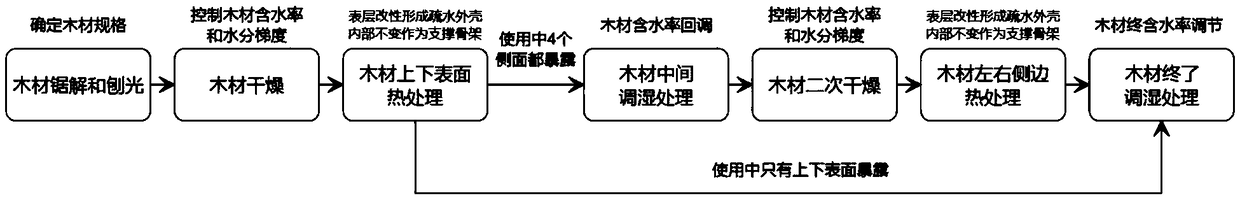

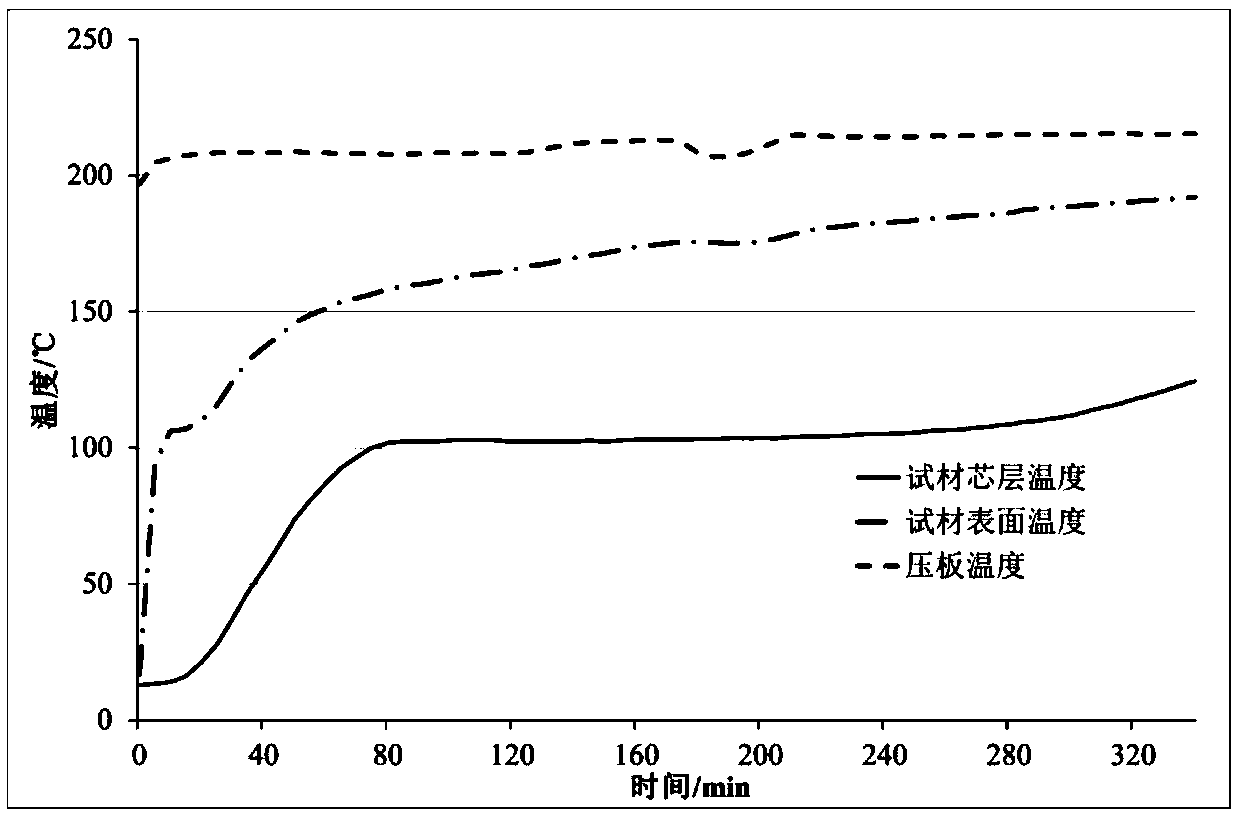

Novel wooden structural material with stable durability and preparation method of novel wooden structural material

ActiveCN108638277AOvercome the disadvantage of significant decrease in strengthImprove stabilityPlywood pressesWood compressionSurface layerUltimate tensile strength

The invention discloses a novel wooden structural material with stable durability and a preparation method of the novel wooden structural material and belongs to the technical field of wood protectionand modification. The novel wooden structural material with the stable durability comprises a protective outer shell formed through surface layer heat modification and a core layer. The core layer isa supporting skeleton with a temperature stagnant zone formed through process controlling in the preparing process. The preparation method of the novel wooden structural material with the stable durability comprises the steps that firstly, a wood is sawed and planed, then, the wood is dried, the moisture content of the wood is controlled, by means of a process method, a moisture gradient is formed between the wood surface layer and the core layer, a plate type hot press is used for carrying out heating treatment on the wood surface, the temperature of the core layer is controlled in the heating process, and finally, wet-conditioning treatment is carried out on the wood. The novel wooden structural material with the stable durability and the preparation method of the novel wooden structural material have the main beneficial effects that by means of scientific control over the initial moisture content level and the internal moisture content gradient of the wood and by adjusting the temperature rising rate of the wood surface layer and the core layer, the temperature stagnation area not formed through a conventional process is formed on the core layer, and the mechanical strength ofthe novel wooden structural material is not affected while the size stability of the wood is improved.

Owner:NANJING FORESTRY UNIV

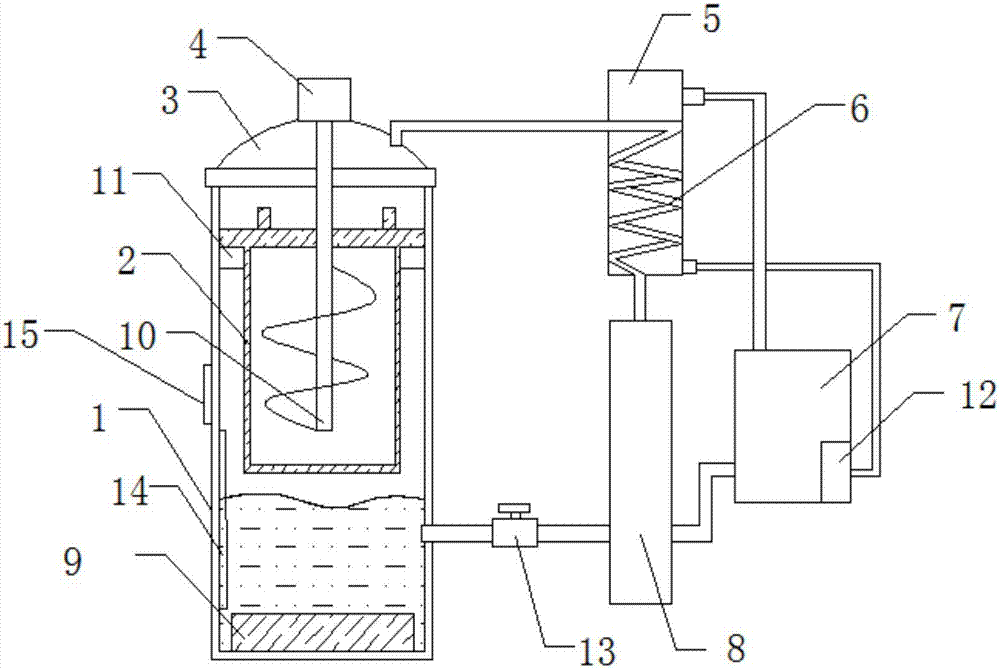

Raw material extraction device for industrial production

InactiveCN107325889AEasy accessEasy to understandEssential-oils/perfumesNatural resourceDistillation

The invention discloses a raw material extraction device for industrial production, which includes a distillation tank, a condenser, an oil-water separator and a water storage tank. A resistance heater is fixedly installed at the bottom of the inner cavity of the distillation tank. A distillation net cylinder is placed directly above the resistance heater, a top cover is installed on the top of the distillation tank, a stirring motor is fixedly installed on the upper surface of the top cover, and a stirring rod is connected to the stirring motor. A liquid level gauge is fixedly installed in the inner cavity, and a condensing pipe is arranged inside the condenser, and the top cover communicates with the air inlet of the condensing pipe in the condenser through an air guide pipe, and the air outlet of the condensing pipe is connected with the oil-water The liquid inlet of the separator is communicated, a circulating water pump is fixedly installed inside the water storage tank, and a control panel is installed on the side wall of the distillation tank. The invention has ingenious conception, reasonable design and fully utilizes natural resources.

Owner:LIANGXI HAOXING IND DESIGN OFFICE

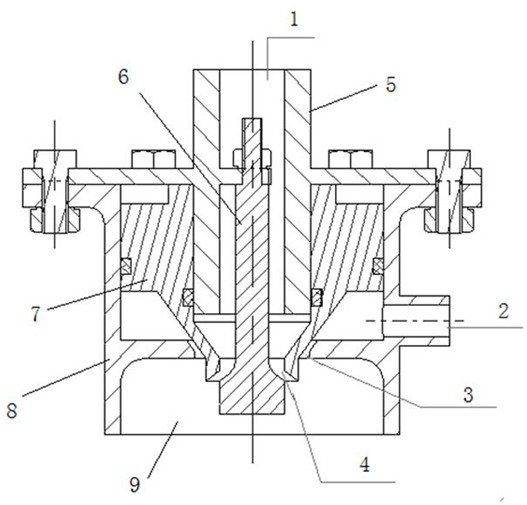

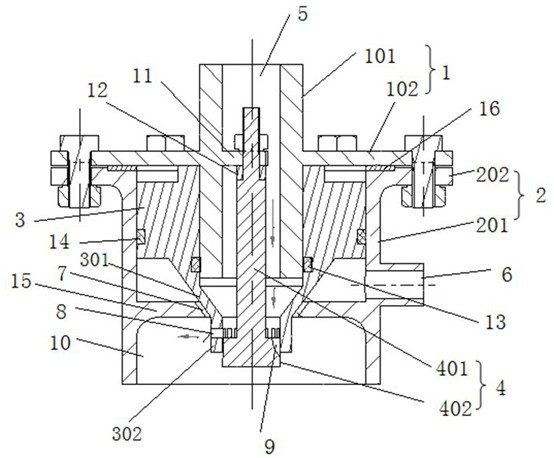

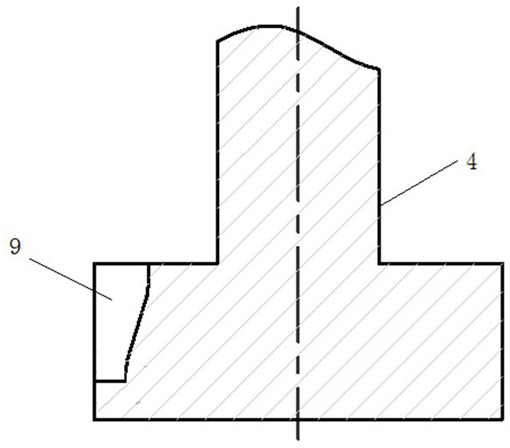

Needle valve injector for variable thrust rocket engine

ActiveCN113653572AIncrease the effective strokeReduce difficultyRocket engine plantsInjectorNeedle valve

The invention belongs to a needle valve injector for a rocket engine, and provides a needle valve injector for a variable thrust rocket engine in order to solve the technical problem of low combustion efficiency caused by poor mixing of propellants in an inner ring and propellants in an outer ring in an existing needle valve injector. The outer wall of the upper section of a needle valve cooperates with the inner wall of a shell so that the needle valve can linearly move relative to the shell, the lower section of the needle valve comprises a conical section and a column section, the small end of the conical section is connected with the column section, a gap is reserved between the outer wall of the tail end of the small end of the conical section and the shell to form an annular oxidant outlet channel, and a fuel outlet channel is formed in the side wall of the column section. A center rod comprises a connecting rod and a flow control boss, the connecting rod is connected with an upper cover, the outer wall of the flow control boss cooperates with the inner wall of the column section so that the needle valve can linearly move relative to the flow control boss, a cooling groove is formed in the side wall of the flow control boss, and the oxidant outlet channel, the fuel outlet channel and the cooling groove all communicate with a combustion chamber.

Owner:西安空天引擎科技有限公司 +1

Method and device for reducing metal dust in electric wire and cable drawing process

The invention relates to a method and a device for reducing metal dust in the electric wire and cable drawing process. A heating tube is mounted in front of a wire inlet of drawing equipment, two ends of the heating tube are sealed with sealing pads made of high-temperature-resistant materials, in-out ports matched with the diameter of a metal pole required to be drawn in size are reserved in the sealing pads at two ends, and the metal pole required to be drawn directly enters a first die of the drawing equipment after heated in the heating tube. The temperature in the heating tube is set to range from 300 DEG C to 350 DEG C if the metal pole is made of copper and set to range from 300 DEG C to 320 DEG C if the metal pole is made of an aluminum and aluminum alloy. With the adoption of the method and device, production of the metal dust is avoided essentially, the safety performance is improved, harm of the metal dust to the body health of a worker and serious accidents are avoided, the work efficiency is improved, the production cost is saved, the product quality is guaranteed, and the method and the device have great usage value.

Owner:SINOSTAR CABLE CO LTD

Inner-barrel back cover for dry washers and manufacturing method of inner-barrel back cover

InactiveCN106702670AMeet the needs of useNo loss of lightOther washing machinesTextiles and paperPunchingMachining

The invention discloses an inner-barrel back cover for dry washers and a manufacturing method of the inner-barrel back cover and belongs to the technical field of inner-barrel back cover machining. The inner-barrel back cover is manufactured by steps of material cutting, blanking, stretching, punching, flanging, riveting, packaging and the like. Quality of the product is strictly controlled, so that machining qualification rate of the inner-barrel back covers is high, and surface quality is good.

Owner:WUHU XIECHENG METAL PROD

Nozzle air guide device for laser cutting head

The invention provides a nozzle air guide device for a laser cutting head. The nozzle air guide device comprises a hollow shell, a lower protective glass seat, a nozzle and a hollow guide cylinder, wherein the lower protective glass seat is arranged at the end, close to optical fiber, of the shell, and the nozzle is arranged at the end, far away from the optical fiber, of the shell; the shell is fixedly connected with the lower protective glass seat and the nozzle respectively, and the inner parts of the shell, the lower protective glass seat and the nozzle successively communicates to form athrough-going laser passage; a through-going air inlet pipe is arranged on the nozzle, an air source communicates with the laser passage through the air inlet pipe, and the air inlet pipe is used forconveying cutting gas; the guide cylinder is arranged in the laser passage and is fixedly connected with the inner surfaces of the shell, the lower protective glass seat and the nozzle respectively; and the guide cylinder communicates with the air inlet pipe and the laser passage respectively. The nozzle air guide device uses the guide cylinder to adjust the direction and the flow speed of airflow, so that the airflow is more stable. An air storage tank is combined with a flow guide tank, so that an effect of redistributing the airflow can be achieved.

Owner:武汉奥森迪科智能科技股份有限公司

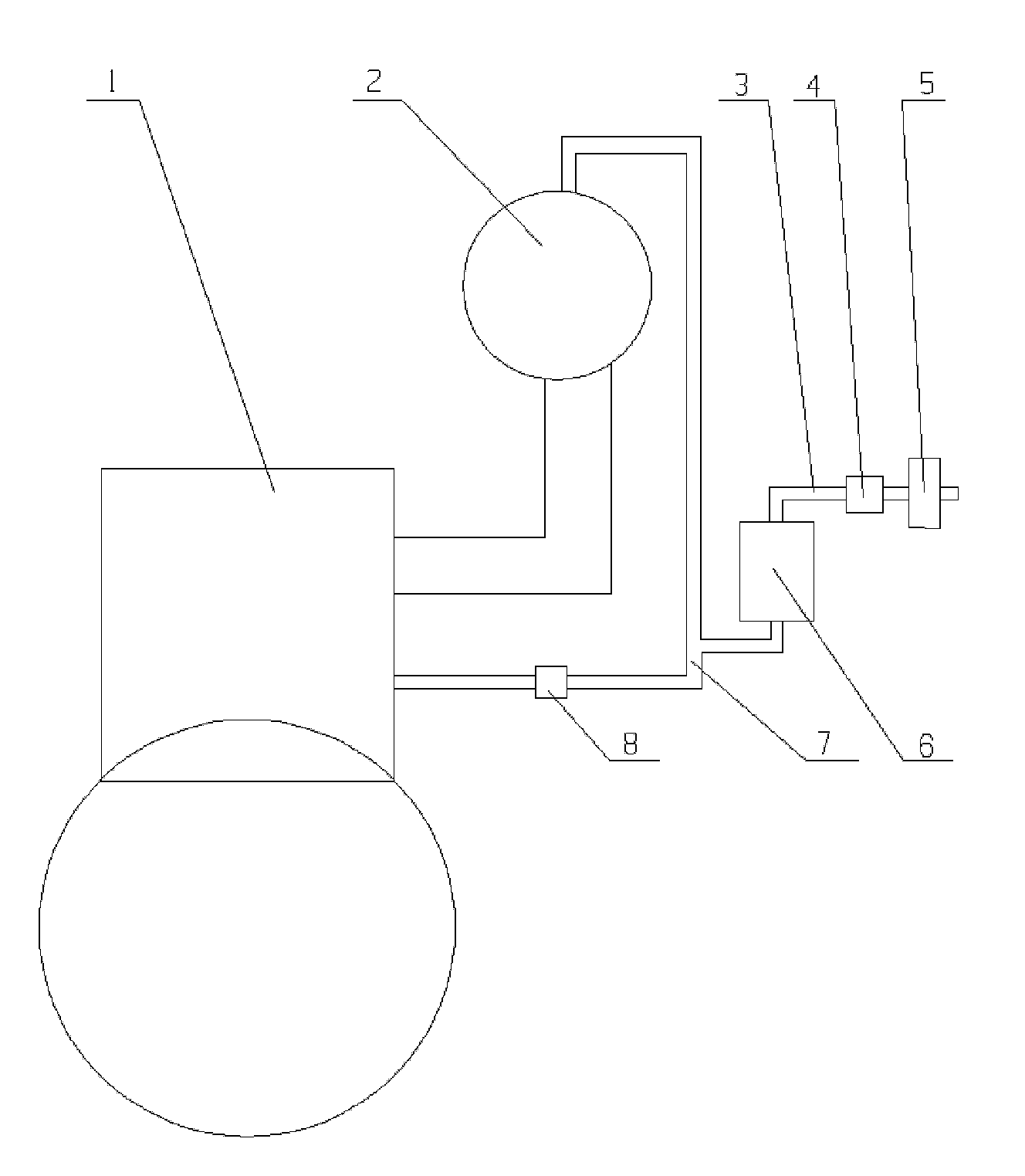

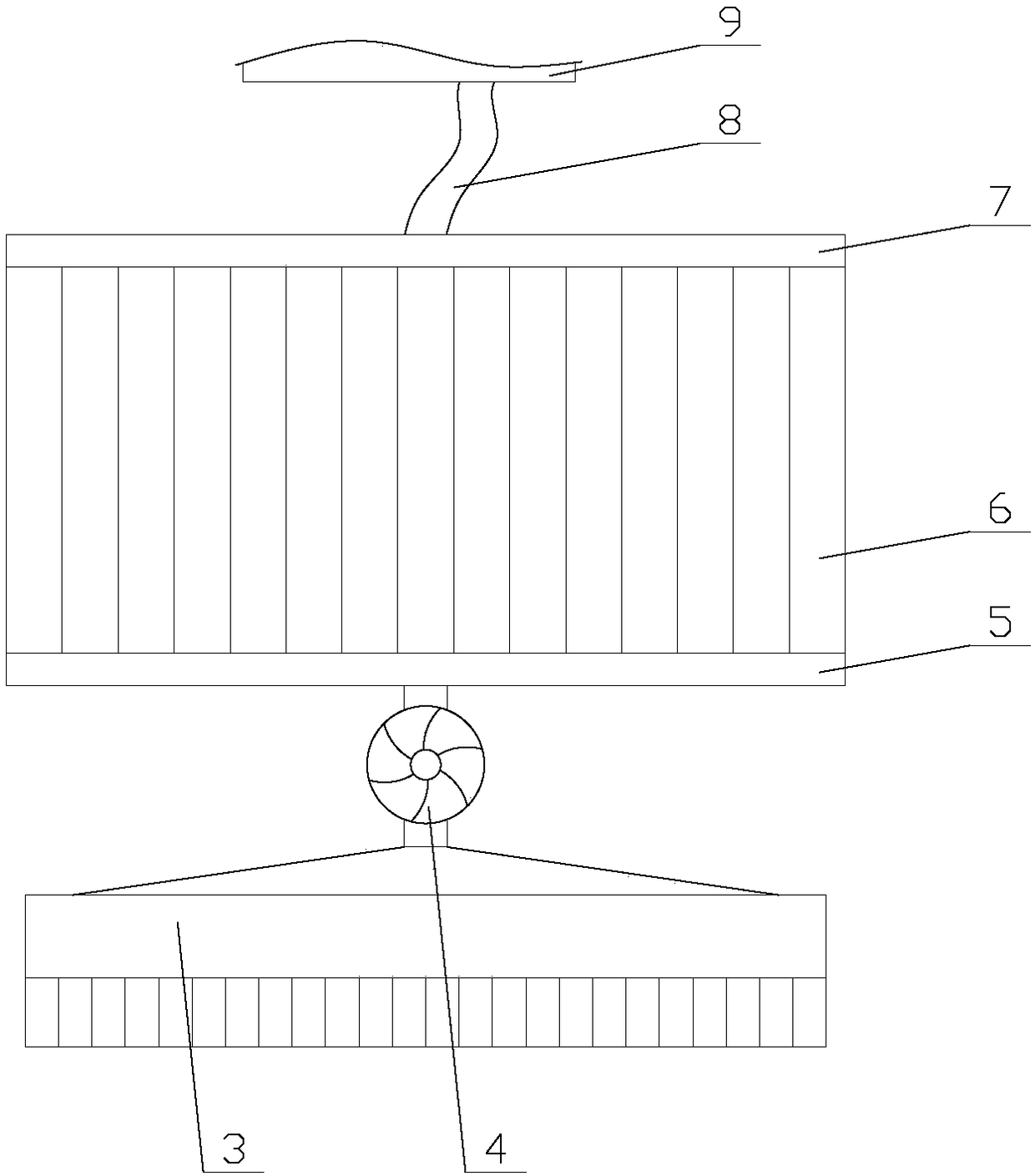

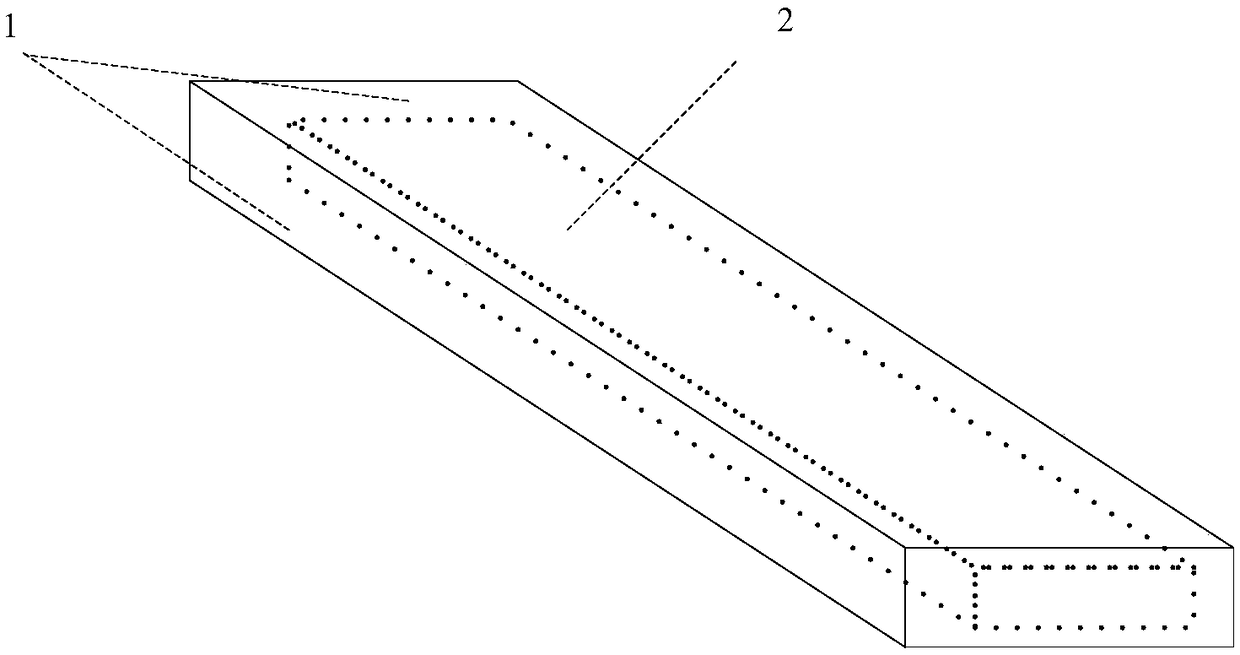

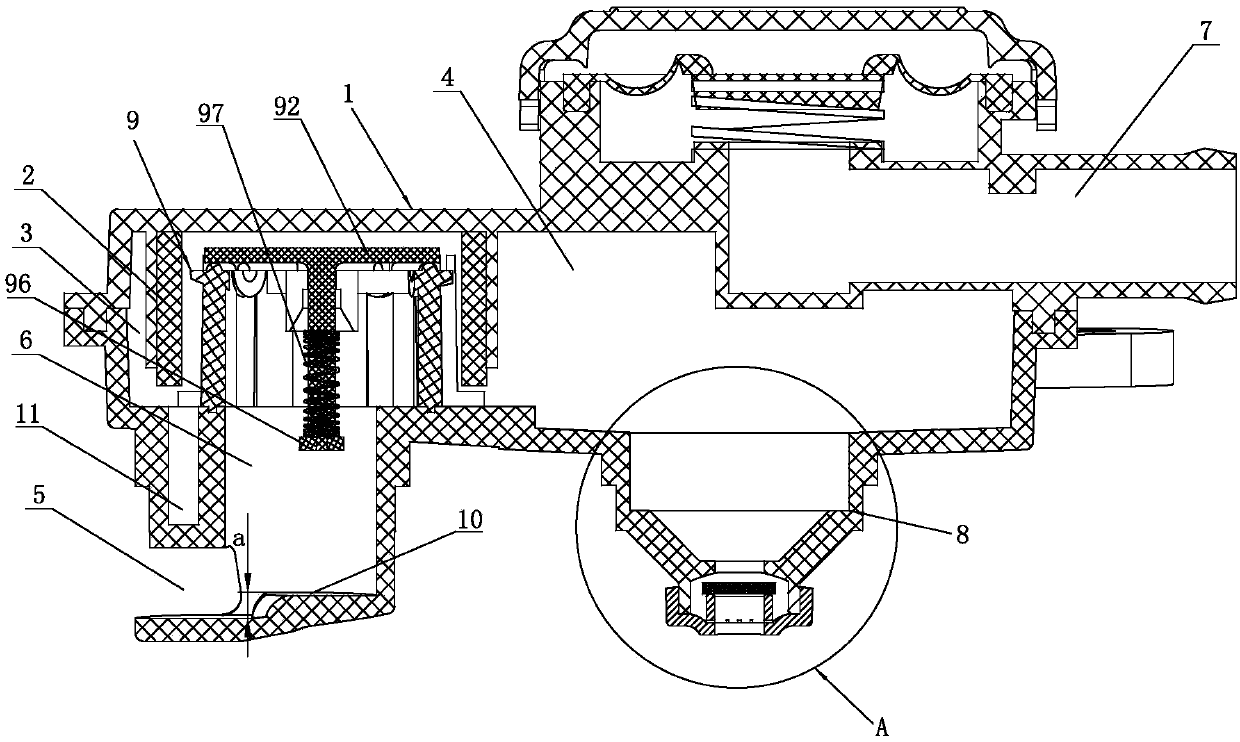

Horizontal type oil-gas separator for diesel engine

PendingCN107829800AControl speedImprove filtering effectMachines/enginesCrankcase ventillationControl valvesDiesel engine

The invention discloses a horizontal type oil-gas separator for a diesel engine. The horizontal type oil-gas separator comprises a shell (1) and a filter element (2). The shell (1) is internally provided with a filter cavity (3) and a buffer cavity (4). The filter cavity (3) is formed in the transverse side of the buffer cavity (4) and communicates with the buffer cavity (4). A gas inlet (5) is formed in the position, below the filter cavity (3), of the shell, wherein the gas inlet (5) allows mixed gas to enter therein. The gas inlet (5) communicates with the filter cavity (3) through a gas inlet channel (6). A gas outlet (7) is formed in the position, above the buffer cavity (4), of the shell (1), and an oil returning opening (8) is formed in the position, below the buffer cavity (4), ofthe shell (1). The filter element (2) is located in the filter cavity (3) and is of an annular structure. An adjustment valve (9) is arranged at the position, above the gas inlet channel (6), inside the filter cavity (3). The outer diameter of the adjustment valve (9) is less than the inner diameter of the filter element (2) but greater than the inner diameter of the gas inlet channel (6). The adjustment valve (9) is eccentrically arranged relative to the gas inlet channel (6). Compared with the prior art, the horizontal type oil-gas separator has the beneficial effects of being high in oil-gas separation efficiency and good in application stability.

Owner:宁海县雄达模塑有限公司

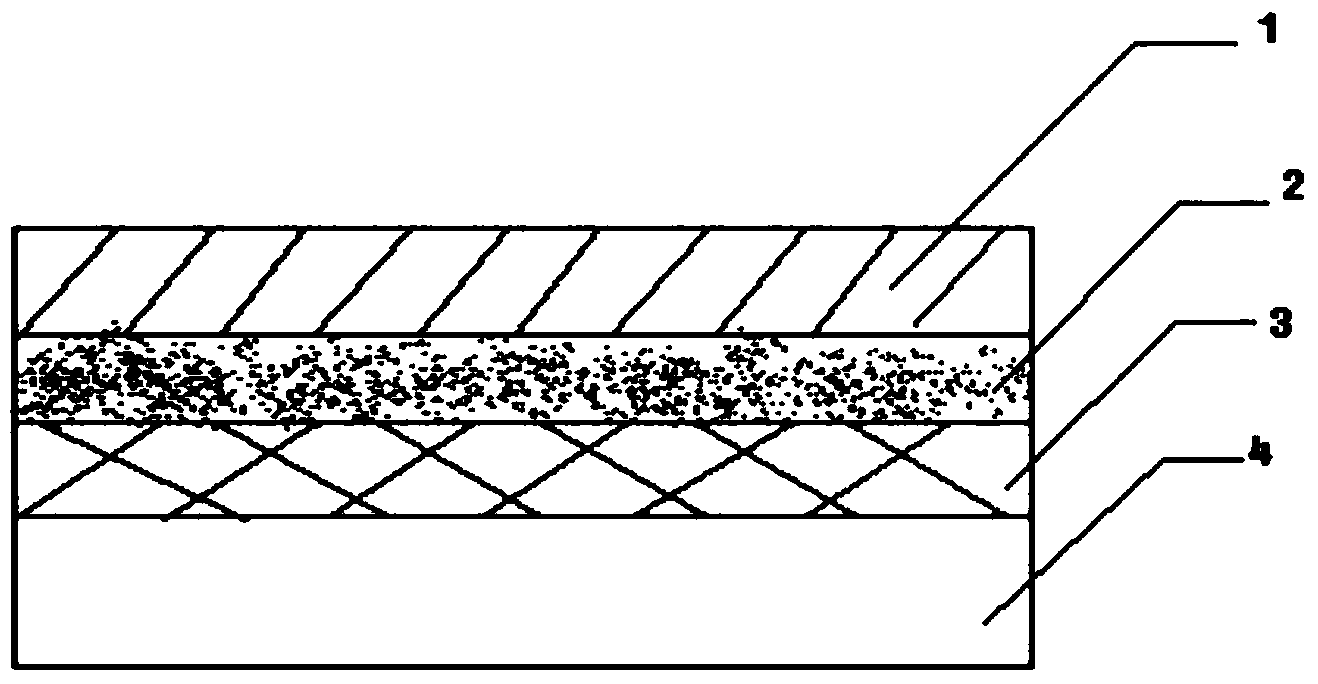

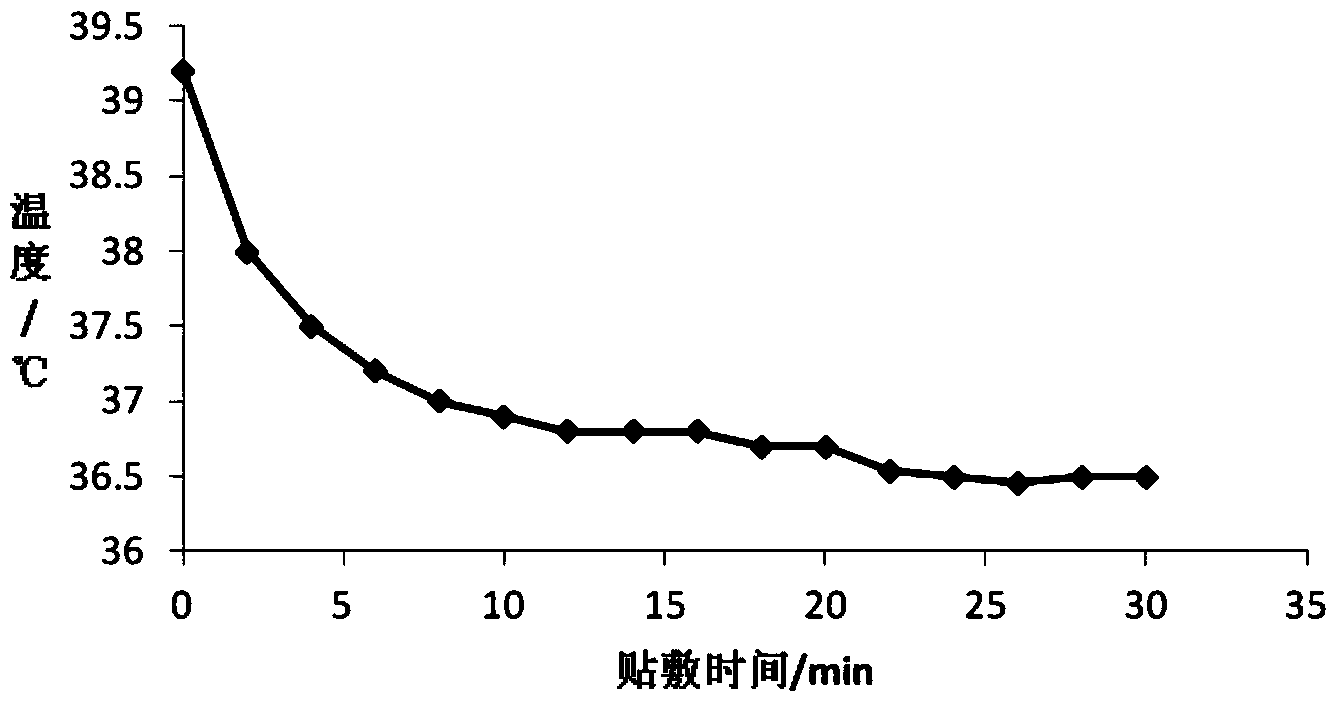

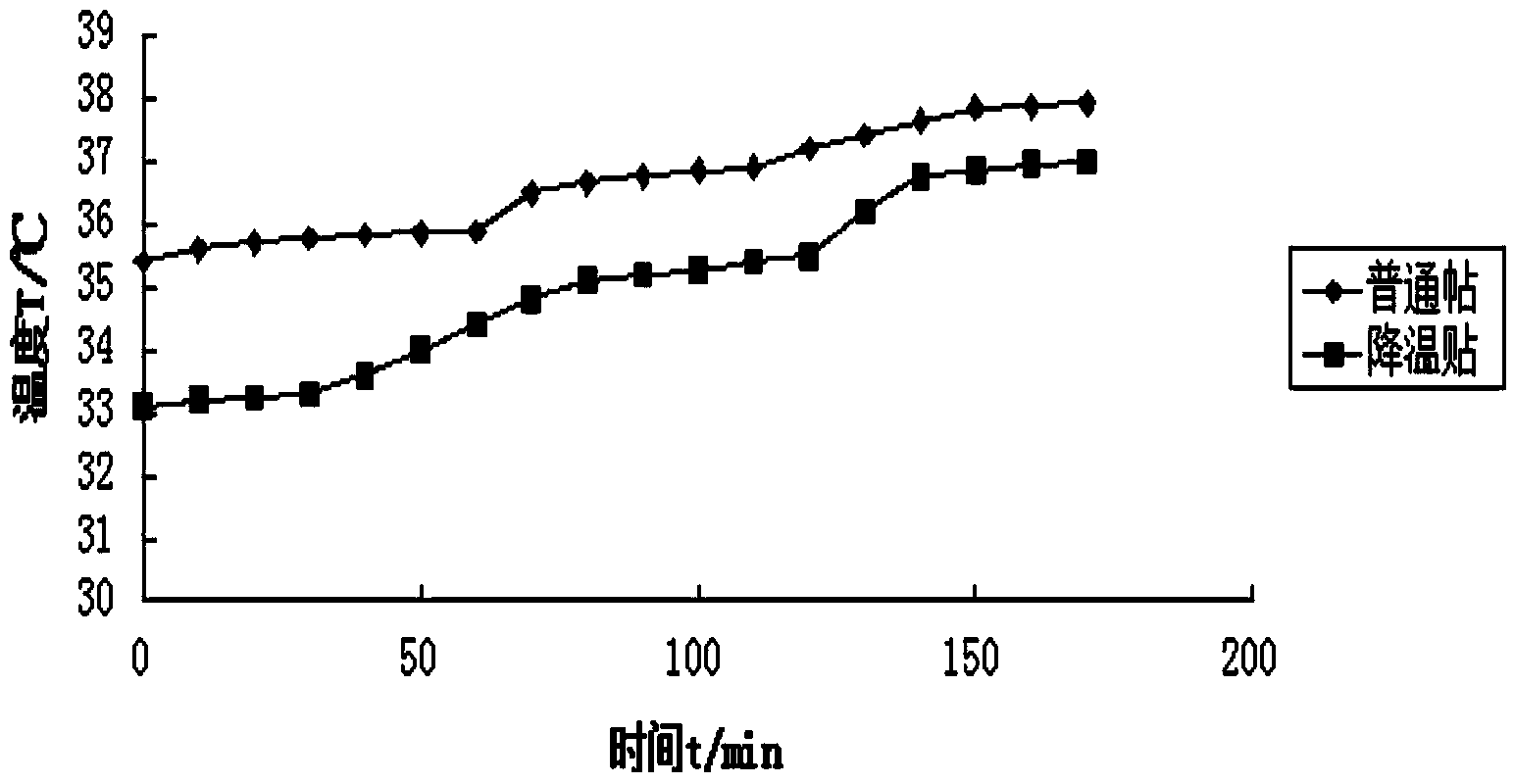

Ammonium chloride cooling patch and preparation method thereof

The invention discloses an ammonium chloride cooling patch. The ammonium chloride cooling patch is adhered and connected with a back lining layer, a gel layer, a viscose layer and an anti-adhesion layer from outside to inside in sequence, wherein the gel layer consists of the following components in percentage by weight: 3%-6% of polyvinyl alcohol, 10%-15% of methacrylic acid, 10%-15% of pressure-sensitive adhesive, 10%-15% of glycerol, 3%-6% of polylactic acid, 0.3%-1% of pregelatinized starch, 9%-18% of ammonium chloride, and the balance of water. The invention further discloses a preparation method of the ammonium chloride cooling patch, wherein the preparation method is as follows: mixing the components to prepare gel, coating the gel prepared by mixing the components on the back lining layer as the gel layer, then, coating the viscose layer on the gel layer, and finally coating the anti-adhesion layer on the viscose layer to obtain the ammonium chloride cooling patch. The ammonium chloride cooling patch disclosed by the invention is obvious in cooling effect, firstly takes away local heat of a human body by gasification of moisture in the gel to achieve a partial cooling effect, and secondly takes away much heat by dissolution heat absorption of the ammonium chloride to achieve a dual-cooling effect.

Owner:广东达成弘业生物科技有限公司

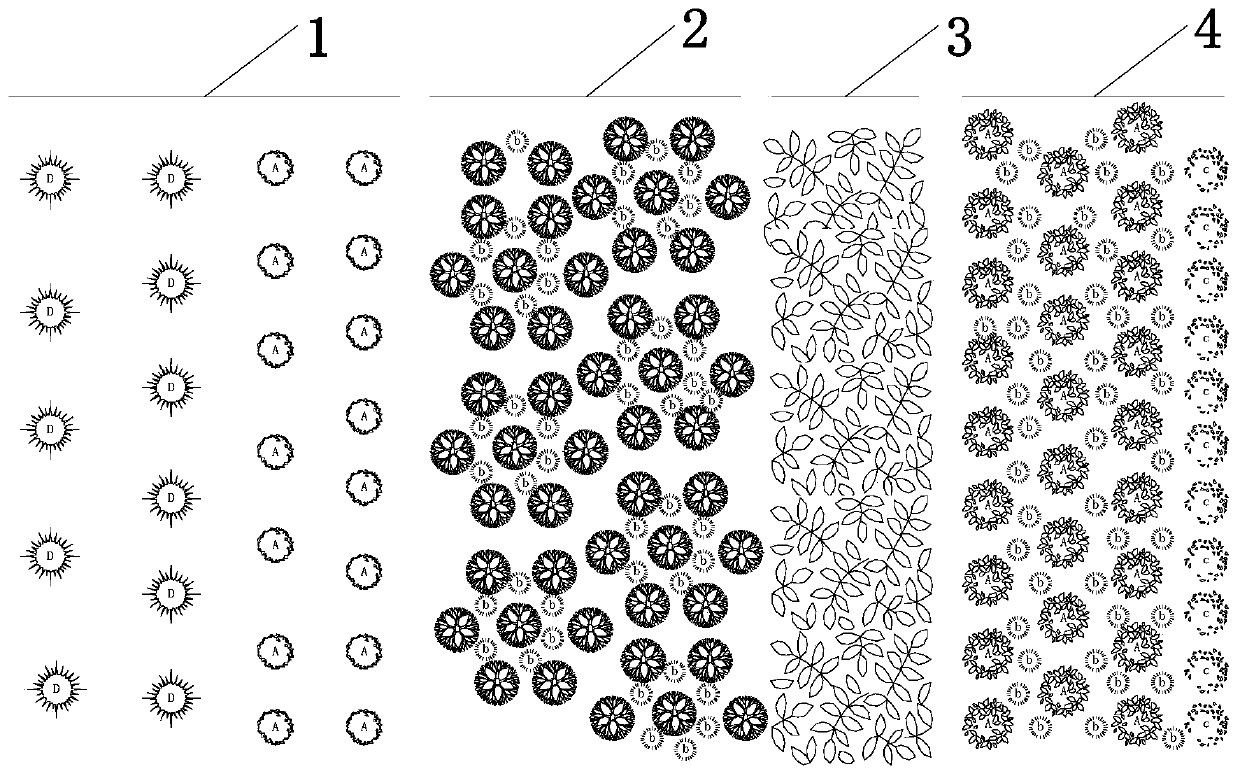

Ecological protective forest belt structure on periphery of urban agglomeration

PendingCN110268906AMitigate the heat island effectReduce wind speedPlant cultivationCultivating equipmentsRural areaEngineering

The invention relates to an ecological protective forest belt structure on the periphery of an urban agglomeration. The structure comprises protective forest belts arranged on the periphery of a beltway or at the junctions between cities and countryside, wherein the protective forest belts between the adjacent cities are connected; each protective forest belt comprises a deceleration diversion forest belt, a vortex purification forest belt and a dense protective landscape forest belt which are sequentially arranged in the wind direction; a shrub and grass interval area is arranged between each vortex purification forest belt and the corresponding dense protective landscape forest belt, and each deceleration diversion forest belt is a pure arbor forest belt. Each vortex purification forest belt comprises arbor planted along rings, large-crown-breadth arbor planted in the centers of the rings, shrubs and herbaceous ground cover plants, and each dense protective landscape forest belt comprises shrubs, herbaceous ground cover plants and rows of arbor, wherein every two adjacent rows of arbor are planted triangularly. According to the structure, by arranging the forest belts with different functions and structures, incoming wind gradually and orderly passes through all the functional forest belts, and the effects of guiding the wind direction, reducing the wind speed and removing remaining dust are finally achieved.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

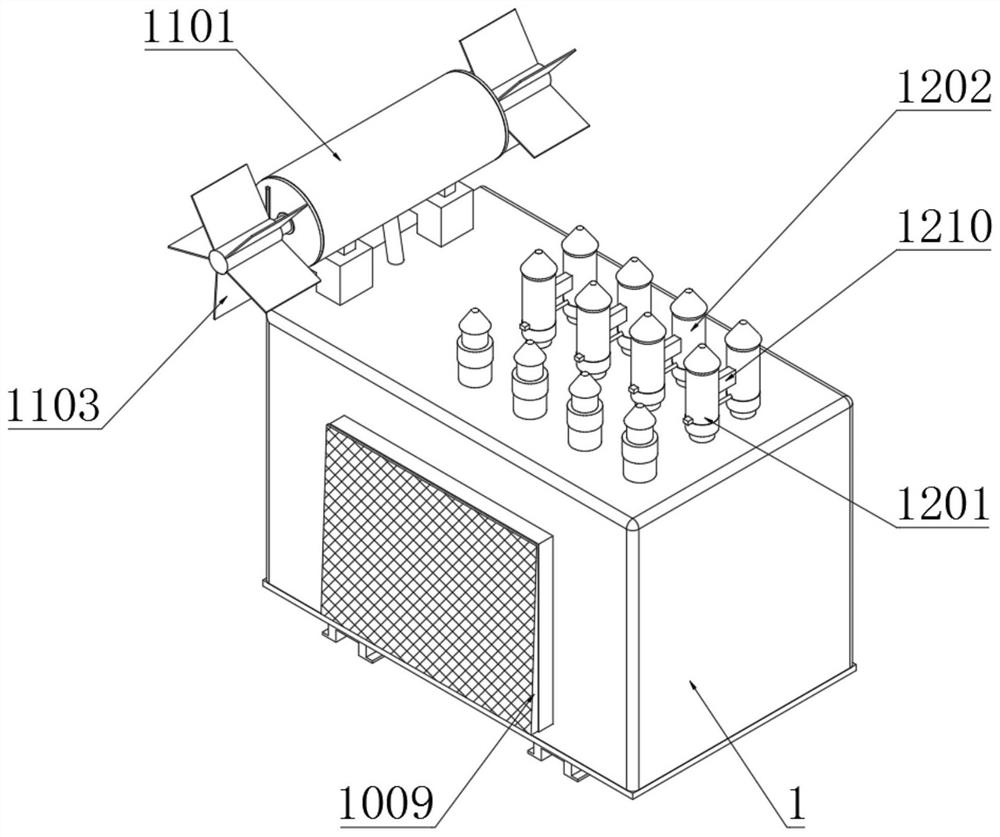

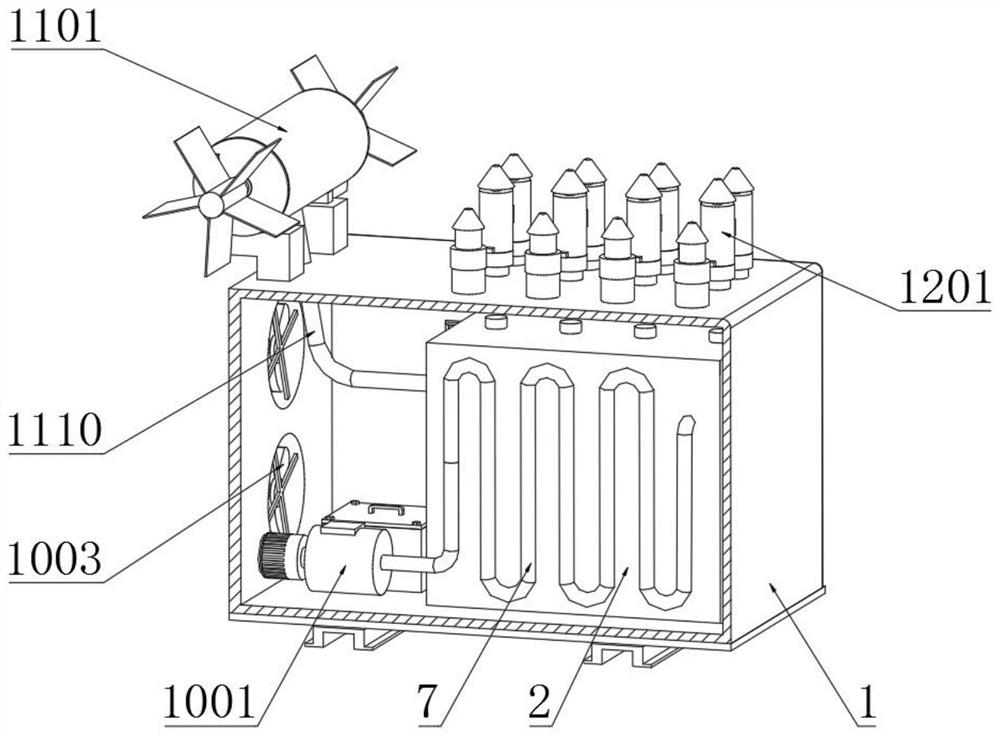

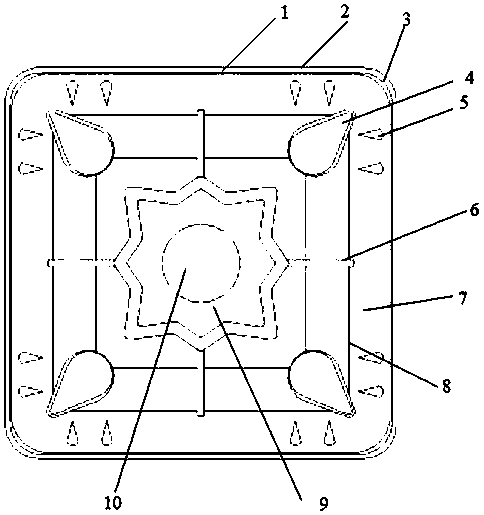

Rapid cooling method based on outdoor transformer

ActiveCN111816414AFlow thoroughlyExtended pathTransformers/inductances coolingTransformers/inductances casingsTransformerOil pump

The invention discloses a rapid cooling method based on an outdoor transformer. One end of a connecting pipe is fixedly connected with an oil pump; spoilers are fixedly mounted in the connecting pipeand a cooling oil pipe; one end of an oil pump is connected with the cooling oil pipe; cooling fans are symmetrically and fixedly installed at the end, away from an oil tank, of the middle of a transformer box body; a dust filtering plate is fixedly mounted on the surface of each cooling fan; and air holes are symmetrically formed in two side walls of the transformer box body. By using the spoilers, cooling oil spirally flows in the cooling oil pipe, the flowing path of the cooling oil is prolonged, and thus the cooling oil is cooled more thoroughly; through cooperative use of the cooling fansand the air holes, heat in the transformer is discharged outwards; the interior of the transformer is cooled from different angles through cooperation of the cooling fans and the cooling oil, therebyguaranteeing that the temperature in the transformer is not too high; and the cooling fans play a role in cooling the cooling oil pipe, and the cooling rate of the cooling oil is increased.

Owner:江苏保庆电器设备有限公司

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

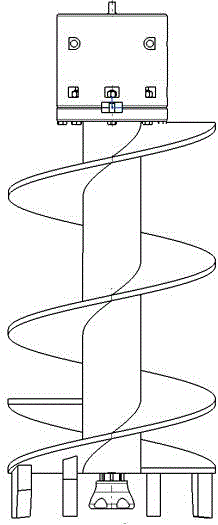

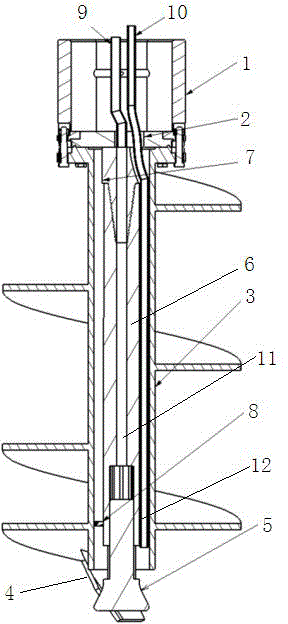

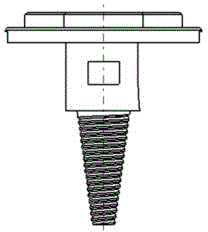

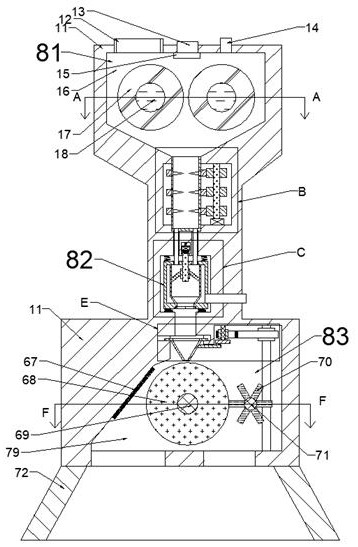

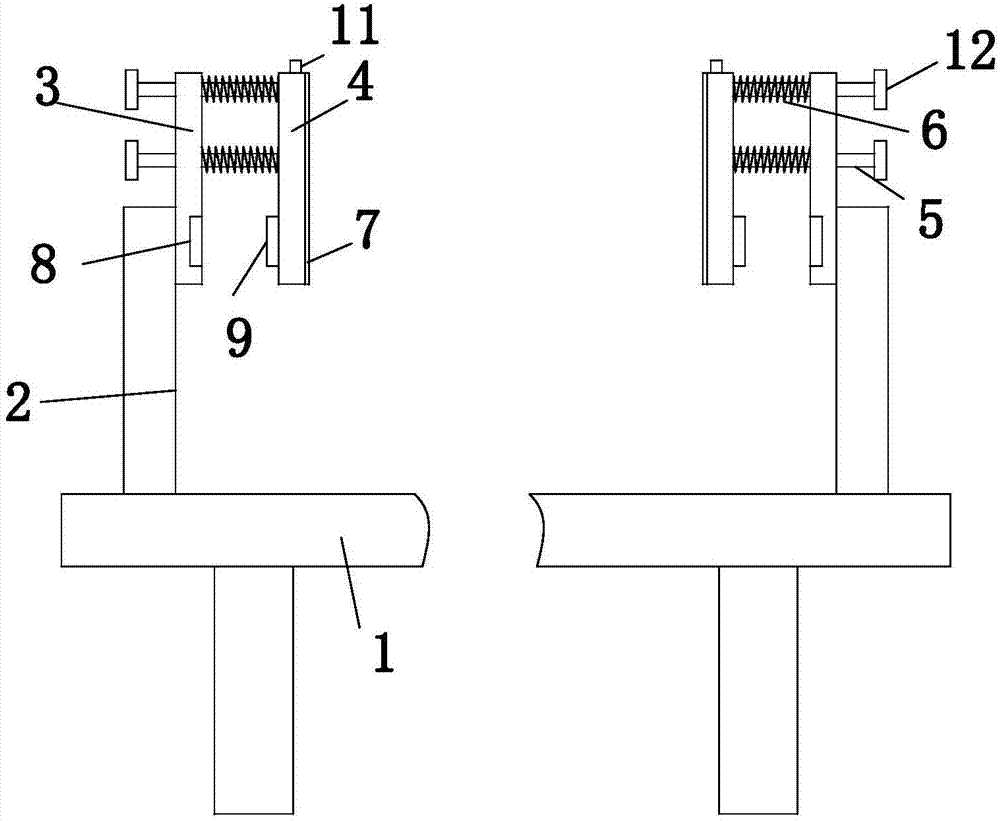

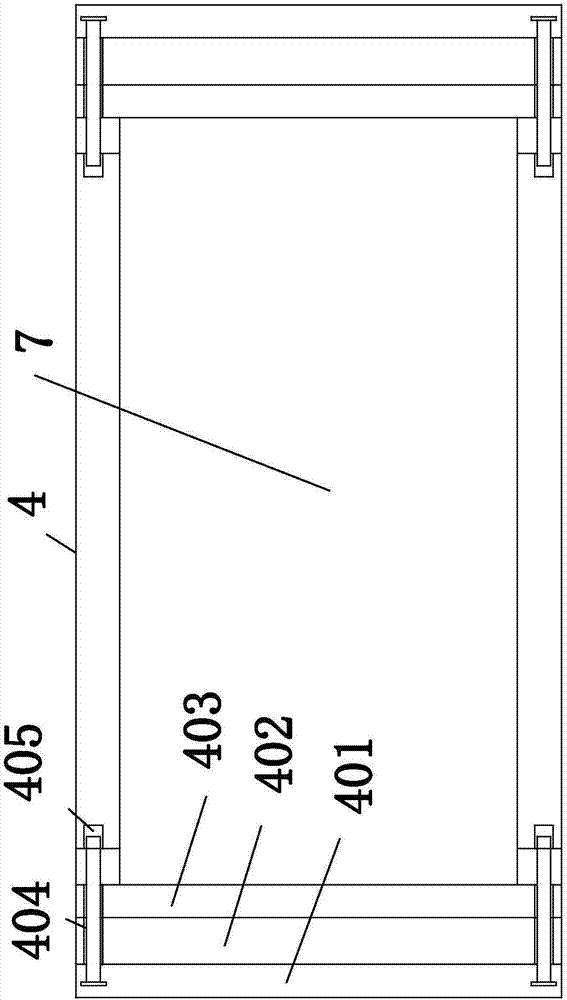

Long screw pile machine

ActiveCN104533284APlay a role in coolingImprove adaptabilityDrill bitsDrilling rodsEngineeringWater pipe

The invention discloses a long screw pile machine. The machine is characterized in that a central through hole is formed in a screw bit, a down-hole hammer stretching out of a drill is arranged in the central through hole of the screw bit and is connected with a tapered threaded rod on a flange through a tapered threaded hole in the upper end of a handle to achieve location. A limit plate is arranged between the down-hole hammer handle and the screw bit through hole. An air through pipe and a water through pipe are arranged on the flange, an inlet of the air through pipe is communicated with an air guide pipe in a screw drill rod and a screw bit joint, an outlet of the air through pipe is communicated with an air inlet pipe in the down-hole hammer handle, an inlet of the water through pipe is communicated with a water guide pipe in the screw drill rod and the screw drill joint, an outlet of the water through pipe is connected with a water injection pipe, an outlet of the water injection pipe is formed in a lower port of the screw drill central through hole, and the air guide pipe and the water guide pipe in the screw drill rod and the screw drill joint are communicated with an air pipe and a water pipe on a power head. The machine has the advantages of being novel in structure, simple to operate, high in work efficiency, long in service life, wide in application range and the like.

Owner:WEIHAI HYDRAULIC & GEOTECHN ENG

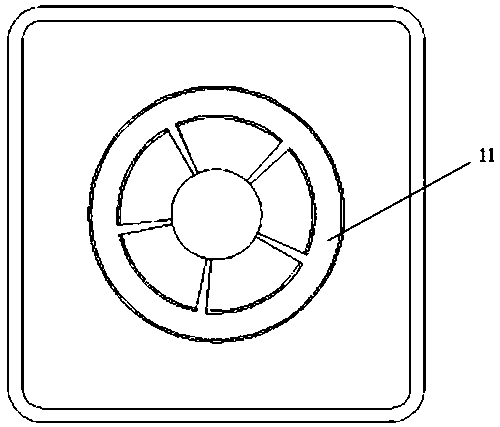

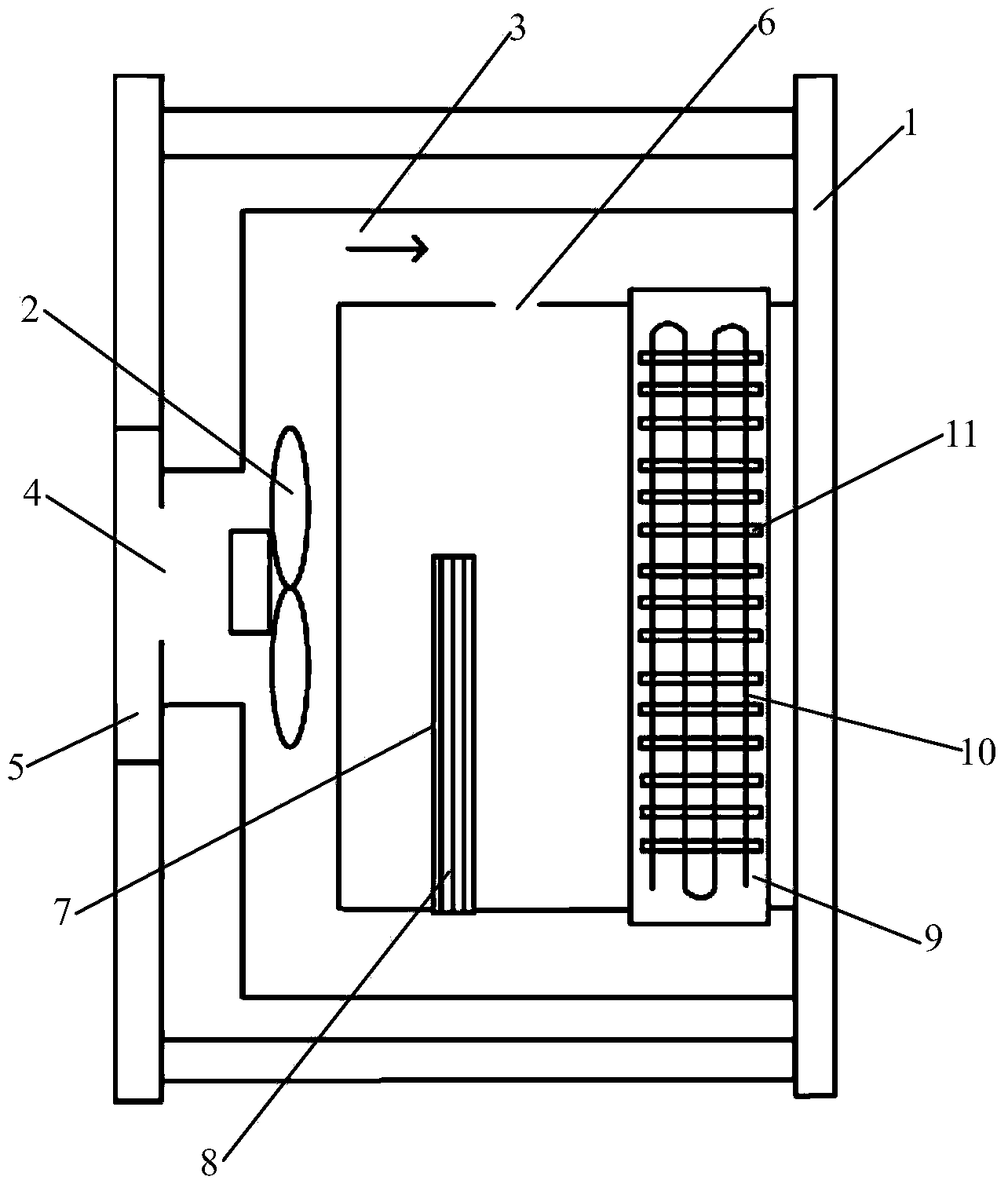

Efficient cooling device for computer case

InactiveCN104020829AEnsure normal flowPlay a role in coolingDigital data processing detailsCooling effectChiller

The invention belongs to the technical field of computer cooling, and particularly relates to an efficient cooling device for a computer case. The efficient cooling device for the computer case comprises a case body and a fan, wherein the fan is located in the case body. The efficient cooling device for the computer case is characterized by further comprising an air guiding cavity, a heat dissipation opening is formed in the case body, a heat dissipation cover is arranged on the heat dissipation opening, the air guiding cavity is formed in the case body and close to the inner wall of the case body, the fan is located in the air guiding cavity, the position of the fan corresponds to that of the heat dissipation opening, an air guiding opening is formed in the air guiding cavity, a heat sink is arranged outside the air guiding cavity and close to a main board, and a cooler is arranged on one side, opposite to the fan, of the case body. The efficient cooling device for the computer case has the advantages that the cooler is fixed though the air guiding cavity, the air guiding cavity and the cooler are matched for enclosing the main board, the cooling effect and the heat dissipation effect are more obvious, the working efficiency of a computer is high, and the computer is not prone to dead halt or burnout.

Owner:TIANJIN ZEJUN TECH

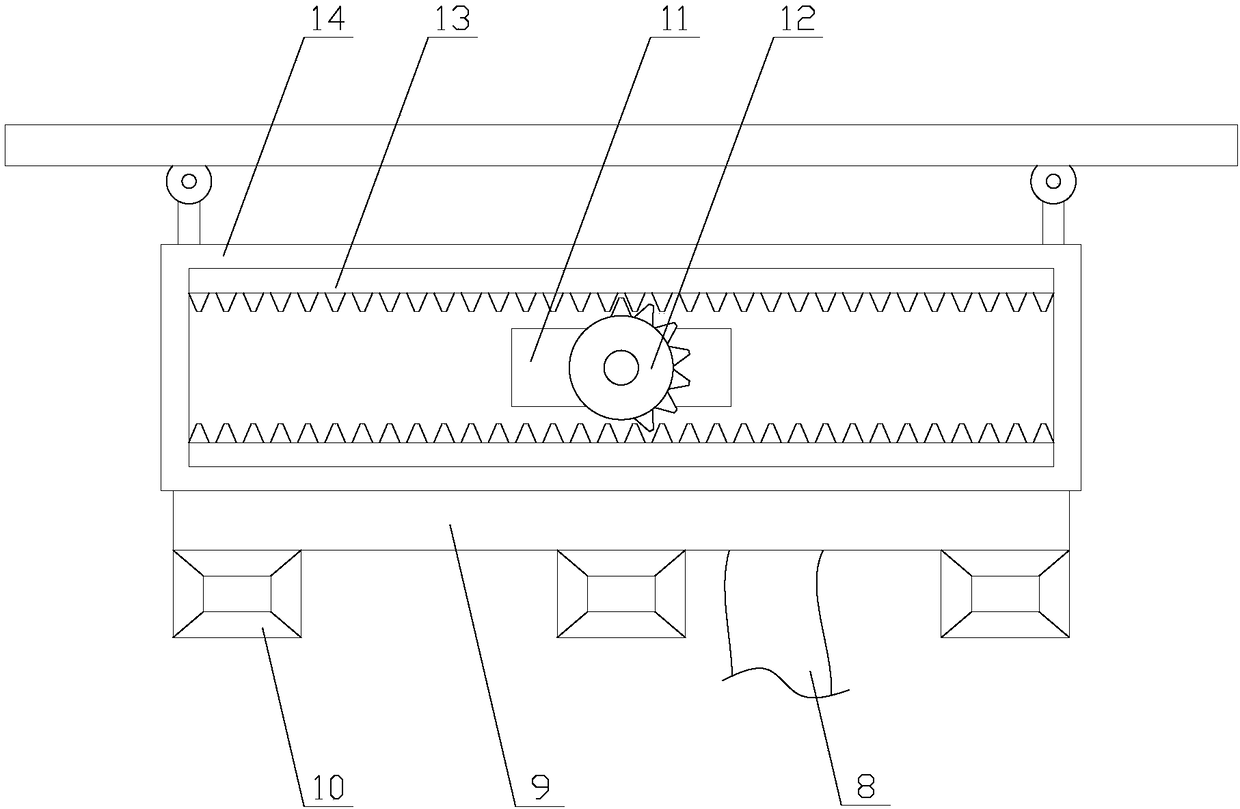

Lithium battery crushing and recycling machine with electrolyte recycling function

InactiveCN112828013AAchieve recyclingPlay a role in coolingSolid waste disposalWaste accumulators reclaimingElectrolytic agentElectrostatic separation

The invention discloses a lithium battery crushing and recycling machine with an electrolyte recycling function, which comprises a main body; the main body is internally provided with a crushing mechanism; the crushing mechanism comprises a primary crushing cavity arranged in the main body, and the primary crushing cavity is internally provided with two crushing wheels in bilateral symmetry. According to the lithium battery crushing and recycling machine with the electrolyte recycling function provided by the invention,dry ice is added in the crushing process, the cooling and flame-retardant effects are achieved, so that a lithium battery can be crushed without discharging firstly, the operation efficiency is greatly improved, the crushing cavity after crushing is completed is flushed through an organic solvent spray head arranged on the upper side of the crushing cavity, craps remaining on the inner wall of the crushing cavity and organic electrolyte flow into a centrifugal separation cavity along with an organic solvent, the organic electrolyte and the solid scraps are separated through the centrifugal separation cavity, the separated solid scraps are divided into a metal part and a plastic part through an electrostatic separation mechanism, and complete recycling of the lithium battery is achieved.

Owner:深圳市金豪锋贸易有限公司

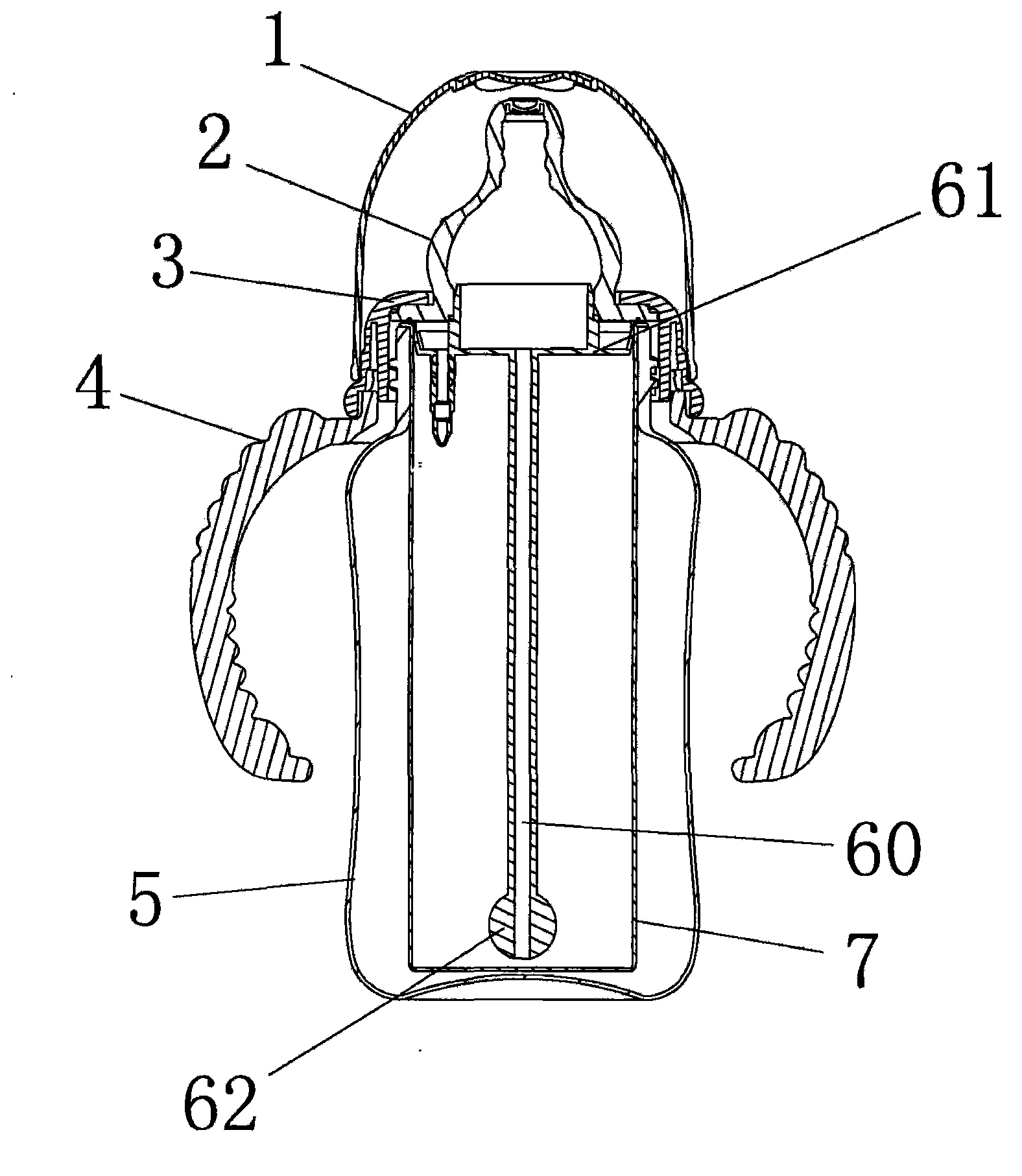

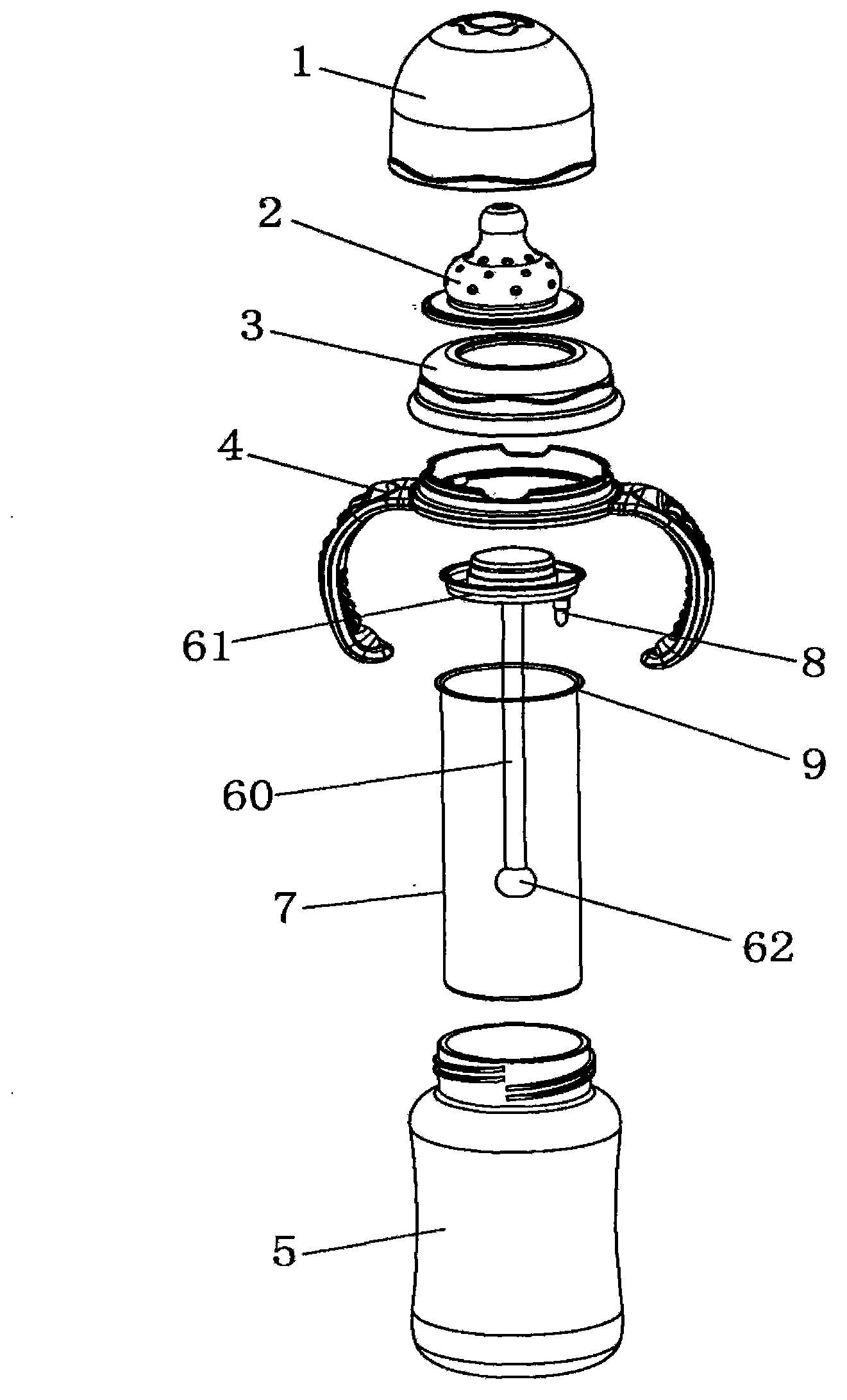

Double-layer milk bottle

The invention discloses a double-layer milk bottle which comprises an outer bottle, a nipple, a middle cover and an inner bottle, wherein the lower end of the inner bottle stretches into the outer bottle; the open end of the inner bottle turns outwards to form a turnup edge; after assembly, the turnup edge is clamped between the bottle mouth of the outer bottle and the middle cover; the volume of the outer bottle is much larger than that of the inner bottle, so that the outer bottle is suitable for feeding bigger babies with milk or water; and the inner bottle with smaller volume is suitable for feeding smaller babies with water, milk, medicine and the like. A heat insulating cavity is formed between the outer bottle and the inner bottle, so that the heat insulation function can be achieved; and appropriate amount of hot water or cold water can be added into the outer bottle, then the inner bottle is placed in, and then heating, heat preservation or cooling down functions can be achieved for a liquid in the inner bottle.

Owner:李红彪

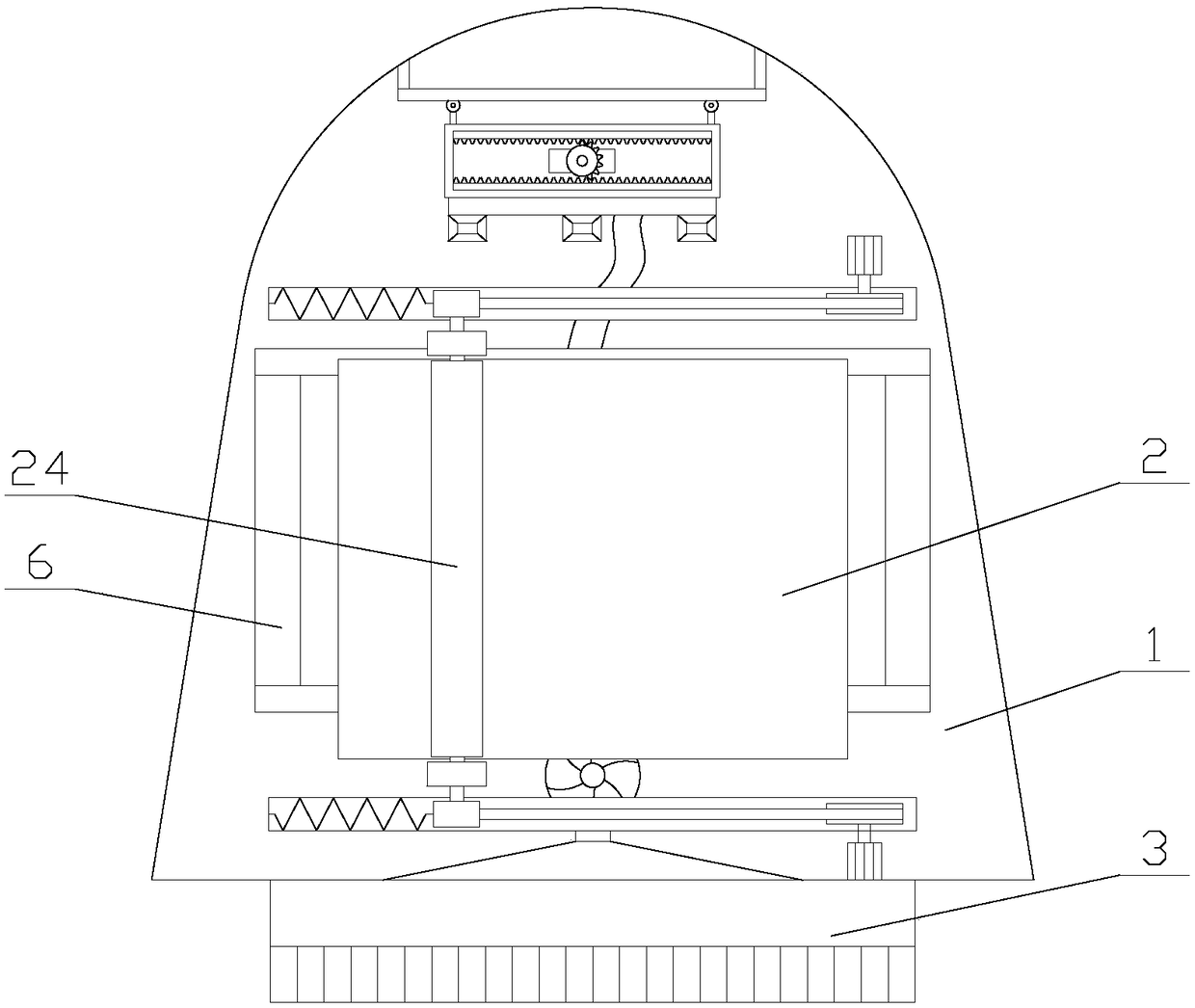

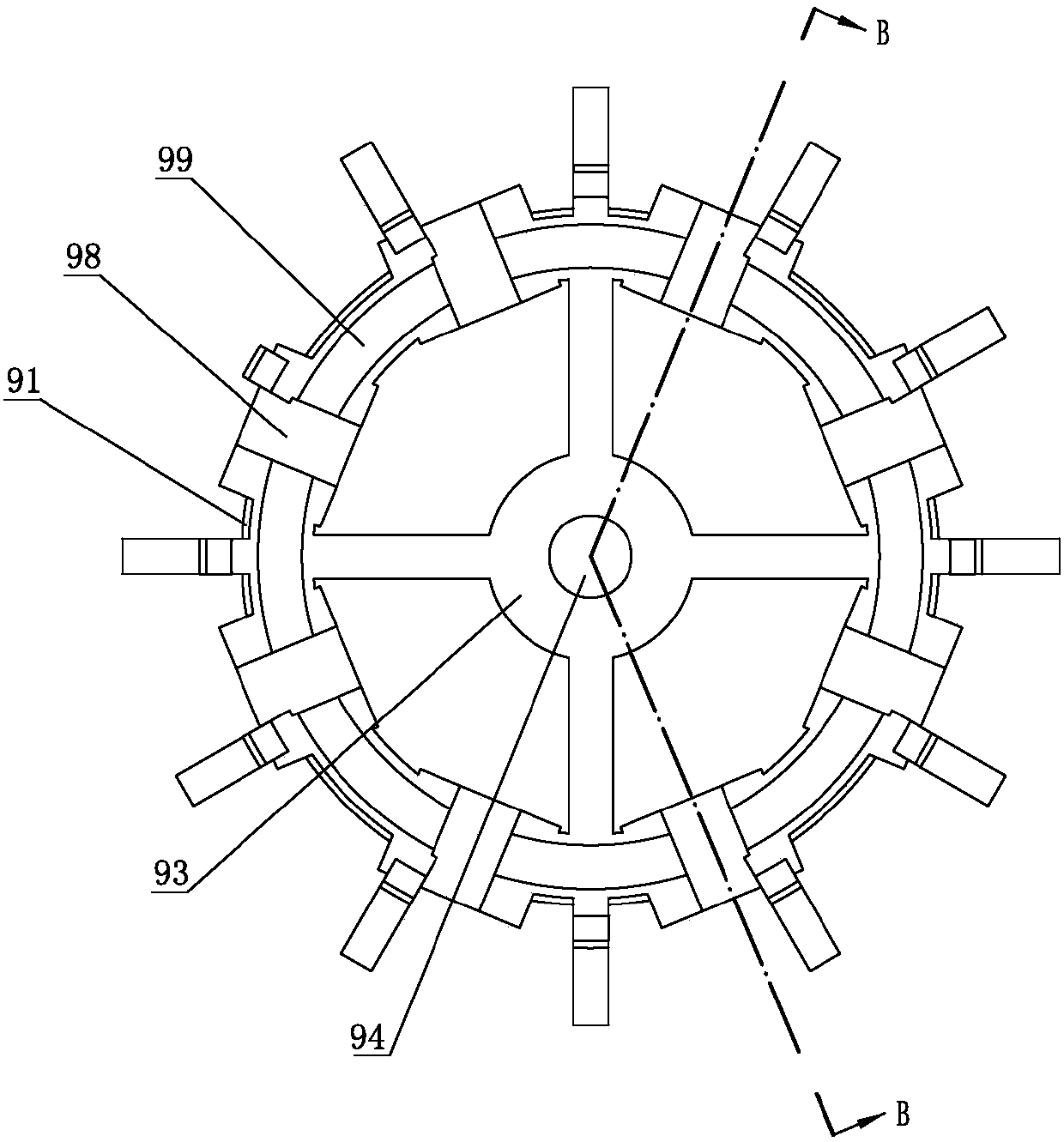

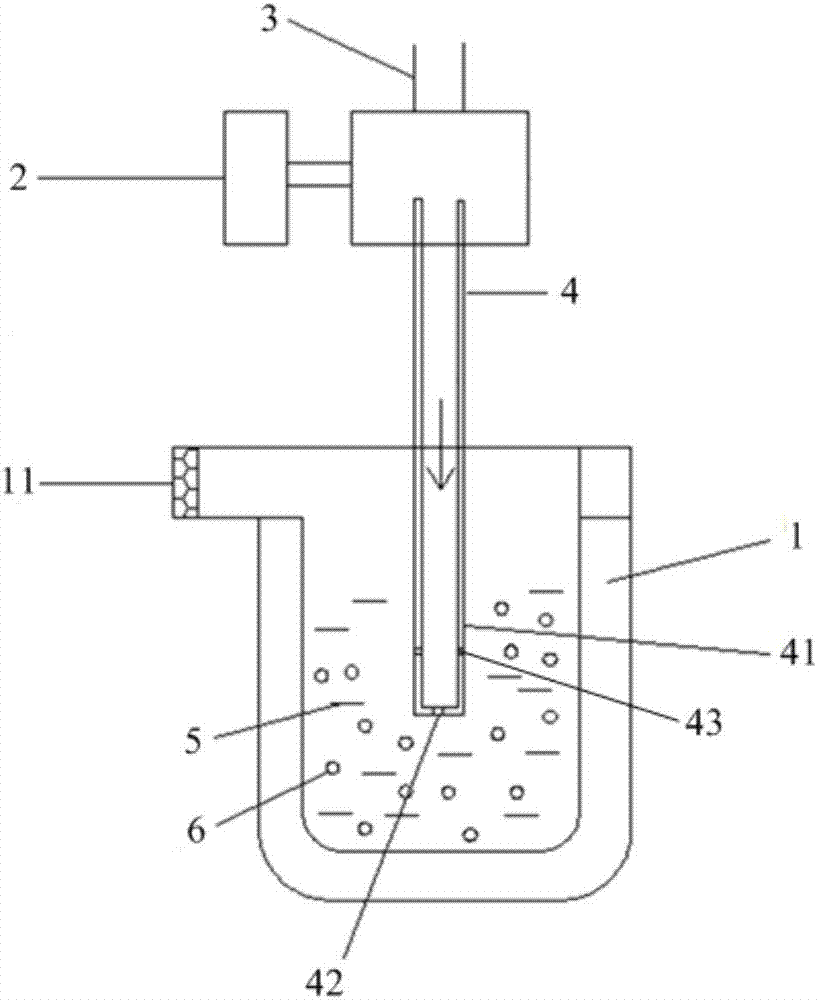

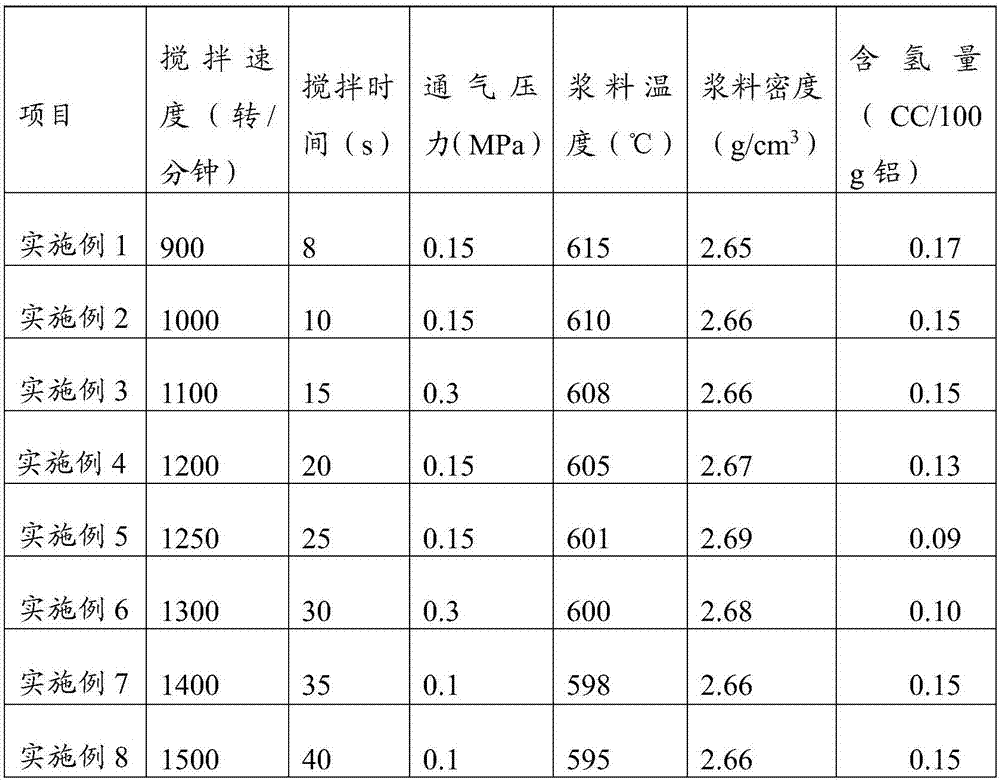

Light alloy semisolid slurry preparation technique and device

The invention discloses a light alloy semisolid slurry preparation technique. In the technique process, treatment gas is pumped into slurry while stirring is conducted, preparation and refining of the semisolid slurry are achieved by controlling distribution of ventilation holes, stirring parameters and ventilation parameters, wherein the rotation speed of stirring equipment is controlled to be no less than 800 rpm, the hole diameter of the ventilation holes is no greater than 2 mm, and thus slurry hydrogen and oxide inclusions can be effectively removed. The invention further discloses a device suitable for the preparation technique. The device can achieve the effects that in the continuous slurry making and die casting processes, the production efficiency is high, industrial production demands are met, the prepared slurry is good in quality, die-cast products are compact and free of pore defect, T6 heat treatment can be conducted for improving the mechanical property, and the high stress requirement is met.

Owner:ZHUHAI RUNXINGTAI ELECTRICAL

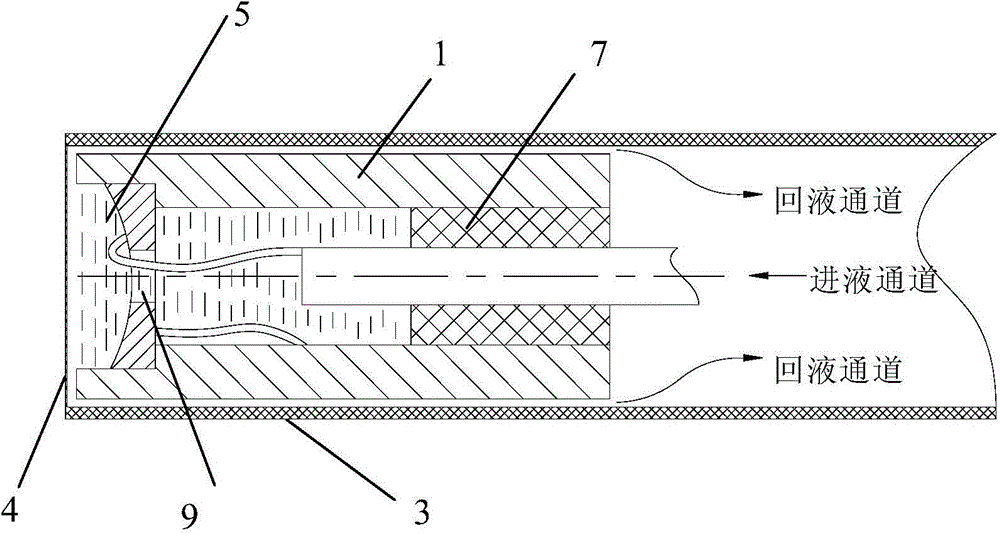

Focusing ultrasonic treatment head and ultrasonic treatment equipment

The invention provides a focusing ultrasonic treatment head. The focusing ultrasonic treatment head comprises a shell and an ultrasonic transducer, wherein one end of the shell is open; the ultrasonic transducer can be arranged in the opening; the position of the ultrasonic transducer in the opening is set in such a manner that the focal lengths of ultrasonic waves emitted by the ultrasonic transducer are 3-5 millimeters. The focusing ultrasonic treatment head is simple in structure, and is mainly suitable for treating cervicitis.

Owner:RONGHAI SUPERSONIC MEDICINE EN

Noise eliminating device for reducing exhaust noise of internal combustion engine

InactiveCN108979816ATo achieve the effect of noise reductionAchieve a buffering effectExhaust apparatusSilencing apparatusComing outExternal combustion engine

The invention discloses a noise eliminating device for reducing the exhaust noise of an internal combustion engine. The noise eliminating device comprises a shell, wherein the shell comprises an innershell and an outer shell, a cavity is formed between the inner shell and the outer shell, an air inlet pipe is arranged on the left side of the shell, the air inlet pipe extends into the inner cavityof the shell, a first baffle is arranged in the inner cavity of the shell, a buffer groove is formed in the middle of the left side of the first baffle plate, the buffer groove and the air inlet pipeare located on the same horizontal plane, and noise eliminating pipes are arranged on the periphery of the buffer groove. Through the arrangement of the buffer groove, the airflow can play a role inbuffering when coming out of the air inlet pipe, and the air flow can circularly flow on the left side of the first baffle to reduce the noise; sound absorbing cotton is arranged on the inner surfaceof the buffer groove, so that when the air flow is transmitted to the buffer groove, the effect of absorbing noise is achieved; the noise eliminating pipes are arranged, so that air flow is transmitted to the right side of the first baffle from the left side of the first baffle; and first noise eliminating holes are formed, so that the energy of the air flow in the noise eliminating pipes is prevented from being attenuated, and the effect of noise eliminating is achieved.

Owner:全椒县全动机械有限公司

Multifunctional carpet

The invention belongs to the field of household articles, and particularly relates to a piece of multifunctional carpet, which comprises a carpet surface, base carpet and a sponge layer, wherein the sponge layer is fixedly connected with the base carpet. The multifunctional carpet is characterized by also comprising a massage layer, wherein the massage layer is arranged between the carpet surface and the sponge layer, in addition, the massage layer is respectively bonded with the carpet surface and the sponge layer through a bonding layer, bulges are arranged on the massage layer, the sponge layer is arranged between the massage layer and the base carpet, and the carpet surface is a suede surface blended by stretch yarns and yarns. The multifunctional carpet has the beneficial effects that the multifunctional carpet can be used in summer and can also be used in winter, the health care function is realized, and the multifunctional carpet is suitable for being popularized.

Owner:天津立秋工艺品有限公司

Rolled steel side edge cleaning equipment for producing elevator guide rail bracket

InactiveCN107322442AExtended service lifeImprove rust removal effectGrinding wheel securing apparatusGrinding machinesArchitectural engineeringUltimate tensile strength

The invention discloses a coil steel side cleaning device for producing elevator guide rail brackets, which includes a frame, hydraulic lifting rods are arranged on the front and rear sides of the frame, and a sanding mechanism is arranged on each hydraulic lifting rod. The sanding mechanism includes a fixed plate and a friction plate arranged on the hydraulic lifting rod, a guide post is provided between the friction plate and the fixed plate, a compression spring is set on the guide post, and sandpaper is provided on the surface of the friction plate; the fixed There is also an electromagnet on the plate, and an iron block corresponding to the electromagnet is arranged on the friction plate; the electromagnet is connected with a controller, and the controller is connected with the hydraulic lifting rod. Rangefinder on top of the board. The invention has the characteristics of being able to improve the rust removal effect on the side of the steel coil and reduce the labor intensity of workers.

Owner:湖州南浔电梯配件配送中心有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com