Rapid cooling method based on outdoor transformer

A transformer and fast technology, applied in the field of transformers, can solve the problems of inability to achieve rapid cooling of transformers, reduce the service life of transformers, and residual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

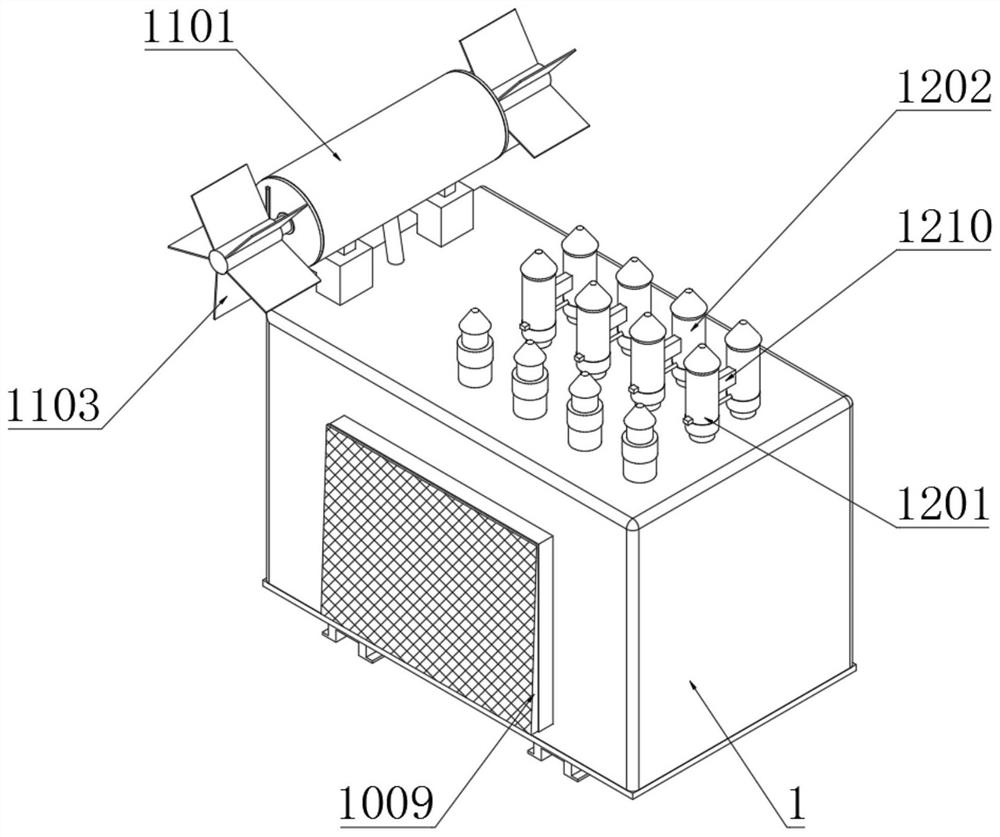

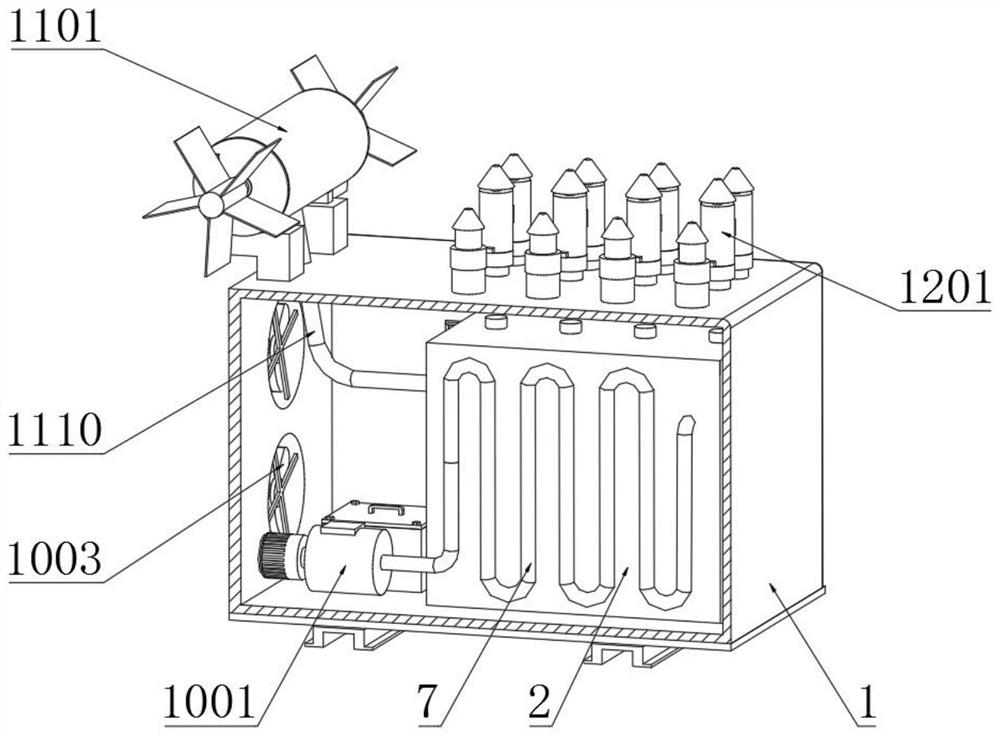

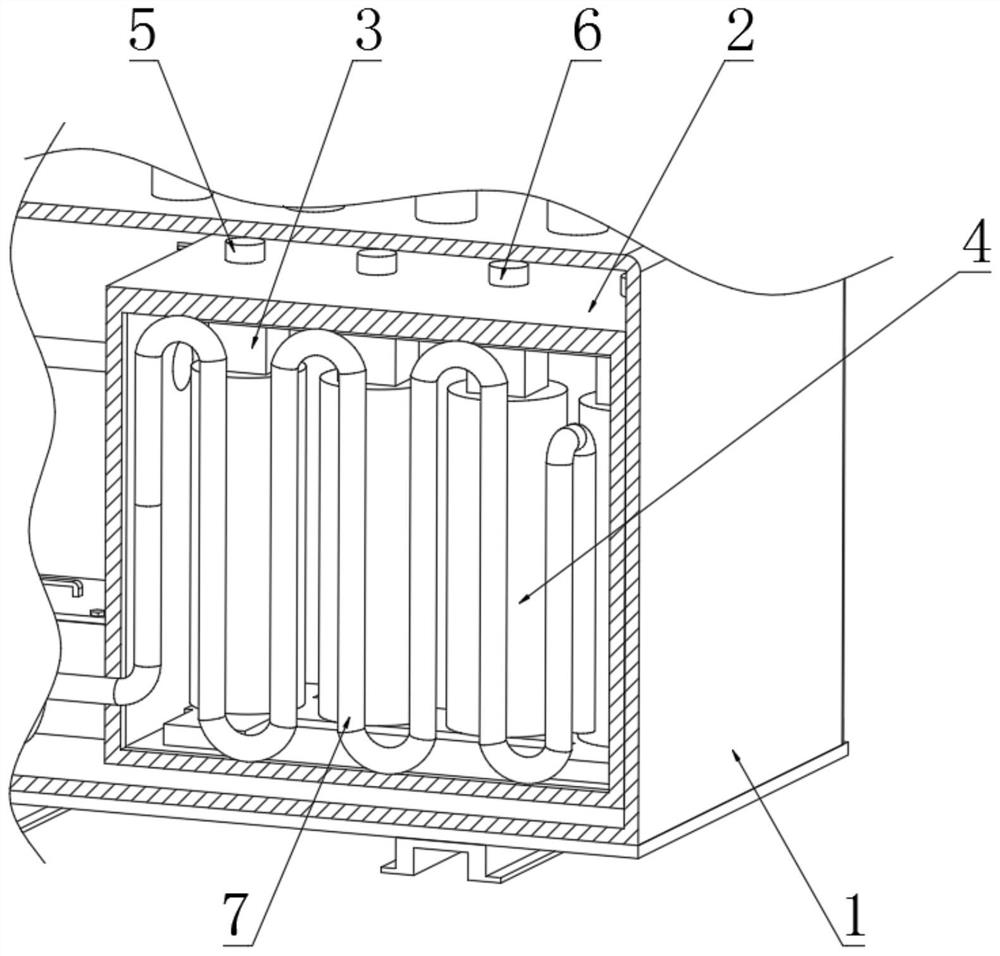

[0040] Example: as Figure 1-9As shown, the present invention provides a technical solution, a rapid cooling method based on an outdoor transformer, comprising a transformer box 1, an oil tank 2 is fixedly installed inside the transformer box 1, and an iron core is fixedly installed inside the oil tank 2 at equal distances 3. A coil 4 is wound on the surface of the iron core 3, a power inlet 5 is fixedly installed at one end of the top of the fuel tank 2, and a contact terminal 6 is symmetrically and fixedly installed on the top of the fuel tank 2 at one side of the power inlet 5. Both sides of the fuel tank 2 A cooling oil pipe 7 is fixedly installed on the walls at equal distances, one end of the cooling oil pipe 7 is fixedly installed with a cooling oil purification mechanism 8, one end of the cooling oil purification mechanism 8 is fixedly connected with a connecting pipe 9, and the side wall of the transformer box 1 is installed with a rapid cooling mechanism 10. An anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com