Latent curing epoxy resin binder diamond grinding tool and preparation method thereof

A technology of epoxy binder and epoxy resin, which is applied in the direction of metal processing equipment, grinding/polishing equipment, abrasives, etc., and can solve the problems of heat resistance, short service life, difficult adjustment of resin liquid viscosity, and difficult adjustment of curing speed, etc. problems, achieve good wear resistance, improve self-sharpness, and product compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

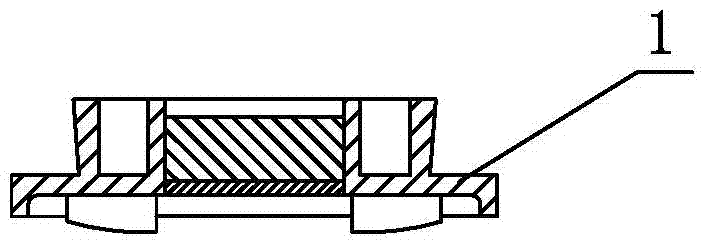

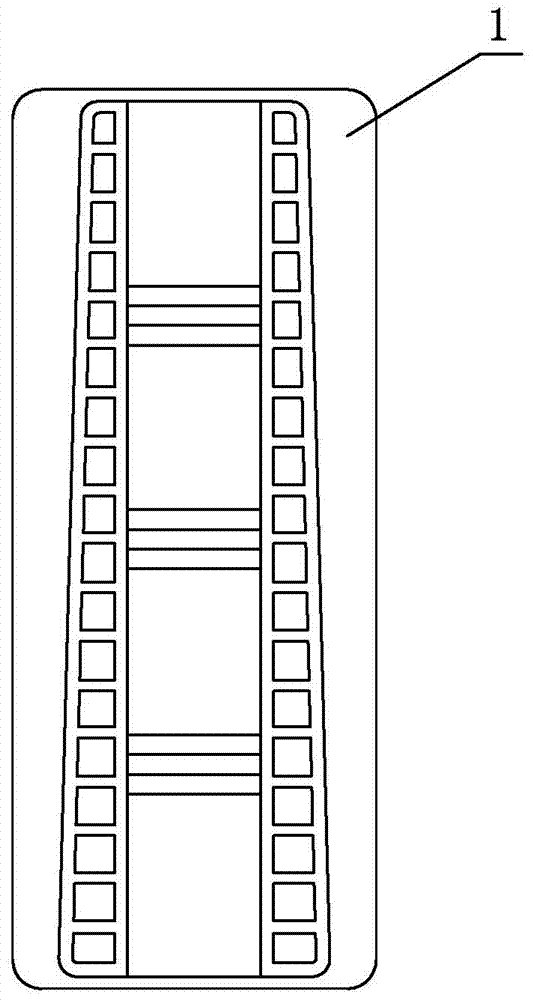

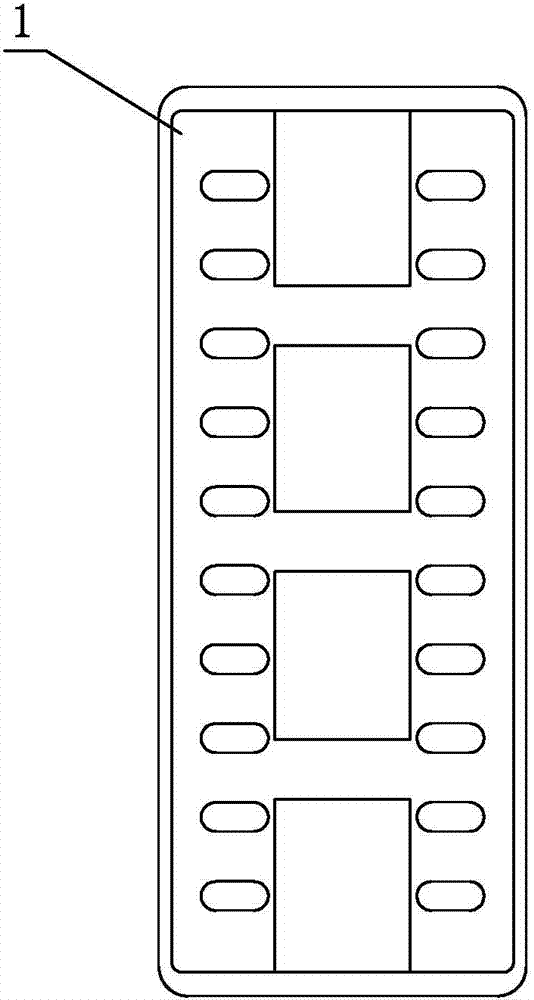

[0026] The diamond abrasive tool of the latent curing epoxy resin bond, its working layer is mainly made of epoxy resin bond, diamond abrasive, curing agent, accelerator, water-soluble porogen and filler; wherein, epoxy resin 17 Parts, 4 parts of 230# diamond for diamond abrasive, 14 parts of methyl tetrahydrophthalic anhydride for curing agent, 2 parts of DMP-30 for accelerator, 15 parts of sodium chloride for water-soluble porogen, and 16 parts of zinc oxide, 2 parts PTFE powder and 30 parts aluminum oxide.

[0027] Its preparation method comprises steps as follows:

[0028] (1) Prepare latent curing type epoxy binder: Epoxy resin (epoxy value 51), methyltetrahydrophthalic anhydride and DMP-30 are mechanically mixed to obtain latent curing type epoxy binder;

[0029] (2) Mixing: After mixing zinc oxide, polytetrafluoroethylene powder, aluminum oxide, and sodium chloride evenly, add 30-85 parts of latent curing epoxy binder prepared in the diamond abrasive and step (1) and p...

no. 2 example

[0033] The diamond abrasive tool of this latent curing type epoxy resin bond is different from the first embodiment in that: 17 parts of epoxy resin, 8 parts of 3000# diamond are selected for the diamond abrasive, and 14 parts of methyltetrahydrophthalic anhydride are selected for use as the curing agent , choose 2 parts of DMP-30 as accelerator, 30 parts of sodium chloride as water-soluble porogen, 9 parts of cerium oxide and 20 parts of alumina as filler.

[0034] The preparation method and other undescribed parts are the same as those in the first embodiment, and will not be analyzed and described here.

no. 3 example

[0036] The diamond abrasive tool of this latent curing type epoxy resin bond is different from the first embodiment in that: 17 parts of epoxy resin, 4 parts of 230# diamond are used for diamond abrasive, and 14 parts of methyltetrahydrophthalic anhydride are selected for use as curing agent , choose 2 parts of 2-ethyl-4-methylimidazole as accelerator, choose 15 parts of sodium chloride as water-soluble porogen, choose 16 parts of zinc oxide, 2 parts of polytetrafluoroethylene powder and 30 parts of aluminum oxide as filler.

[0037] The preparation method and other undescribed parts are the same as those in the first embodiment, and will not be analyzed and described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com