Ammonium chloride cooling patch and preparation method thereof

A technology of ammonium chloride and cooling patches, which is applied in the direction of anti-inflammatory agents, pharmaceutical formulas, chlorine active ingredients, etc., can solve the problems of poor cooling effect of cooling patches, and achieve the effect of maintaining comfort, convenient operation, and obvious cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned ammonium chloride cooling patch, concrete steps are as follows:

[0035] Step 1, weighing according to mass percentage: 3% to 6% of polyvinyl alcohol with a degree of polymerization of 1350 to 2050, 10% to 15% of methacrylic acid, 10% to 15% of pressure sensitive adhesive, and 10% to 15% of glycerin 3% to 6% of polylactic acid with a degree of polymerization of 500 to 800, 0.3% to 1% of pregelatinized starch, 9% to 18% of ammonium chloride, and the balance is water. The sum of the mass percentages of the above components is 100%. ;

[0036] Step 2, dissolve the mixture of polyvinyl alcohol, pregelatinized starch and polylactic acid in water and heat it at 70°C to 80°C until it becomes clear, then add methacrylic acid, pressure sensitive adhesive and glycerin after cooling, and stir well After pouring into the mold, cold molding at -15°C to -12°C, adding ammonium chloride after thawing, and cold molding again to obtain a gel;

...

Embodiment 1

[0039] Step 1, weighing according to mass percentage: 0.9 g of polyvinyl alcohol with a polymerization degree of 1950, 3.6 g of methacrylic acid, 3.0 g of pressure-sensitive adhesive, 3.6 g of glycerin, 0.9 g of polylactic acid with a polymerization degree of 600, pregelatinized Starch 0.15g, ammonium chloride 3.6g, water 14.25g;

[0040] Step 2. Dissolve the mixture of polyvinyl alcohol, pregelatinized starch and polylactic acid in water and heat it at 70°C until it becomes clear. After cooling, add methacrylic acid, pressure-sensitive adhesive and glycerin. Stir evenly and pour into In the mold, cold molding is performed at -12°C, and after thawing, ammonium chloride is added, and cold molding is performed again to obtain a gel;

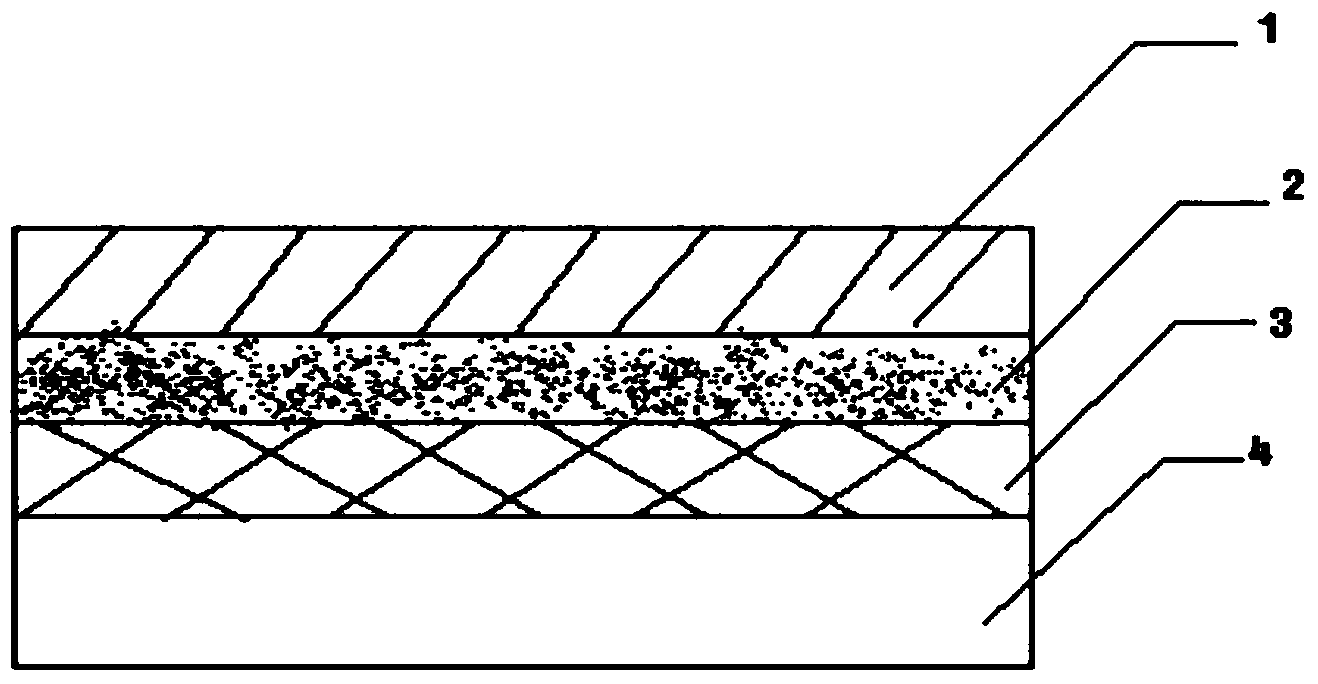

[0041] Step 3, use non-woven fabric as the backing layer, one side of the backing layer is printed with a pattern, and a gel with a thickness of 0.5mm is coated on the side of the backing layer without a pattern as a gel layer, and then the gel lay...

Embodiment 2

[0043] Step 1, weighing according to mass percentage: 1.6g of polyvinyl alcohol with a degree of polymerization of 2050, 4.0g of methacrylic acid, 4.8g of pressure-sensitive adhesive, 6.0g of glycerin, 1.6g of polylactic acid with a degree of polymerization of 500, pregelatinized Starch 0.12g, ammonium chloride 3.6g, water 18.28g;

[0044] Step 2. Dissolve the mixture of polyvinyl alcohol, pregelatinized starch and polylactic acid in water and heat it at 80°C until it becomes clear. After cooling, add methacrylic acid, pressure-sensitive adhesive and glycerin. Stir evenly and pour into In the mold, cold molding is performed at -13°C, after thawing, ammonium chloride is added, and cold molding is performed again to obtain a gel;

[0045]Step 3, use non-woven fabric as the backing layer, one side of the backing layer is printed with a pattern, and a gel layer with a thickness of 0.62mm is coated on the side of the backing layer without a pattern as a gel layer, and then the gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com