Nimodipime nanometer suspension freeze-dried composition, its preparing method and use

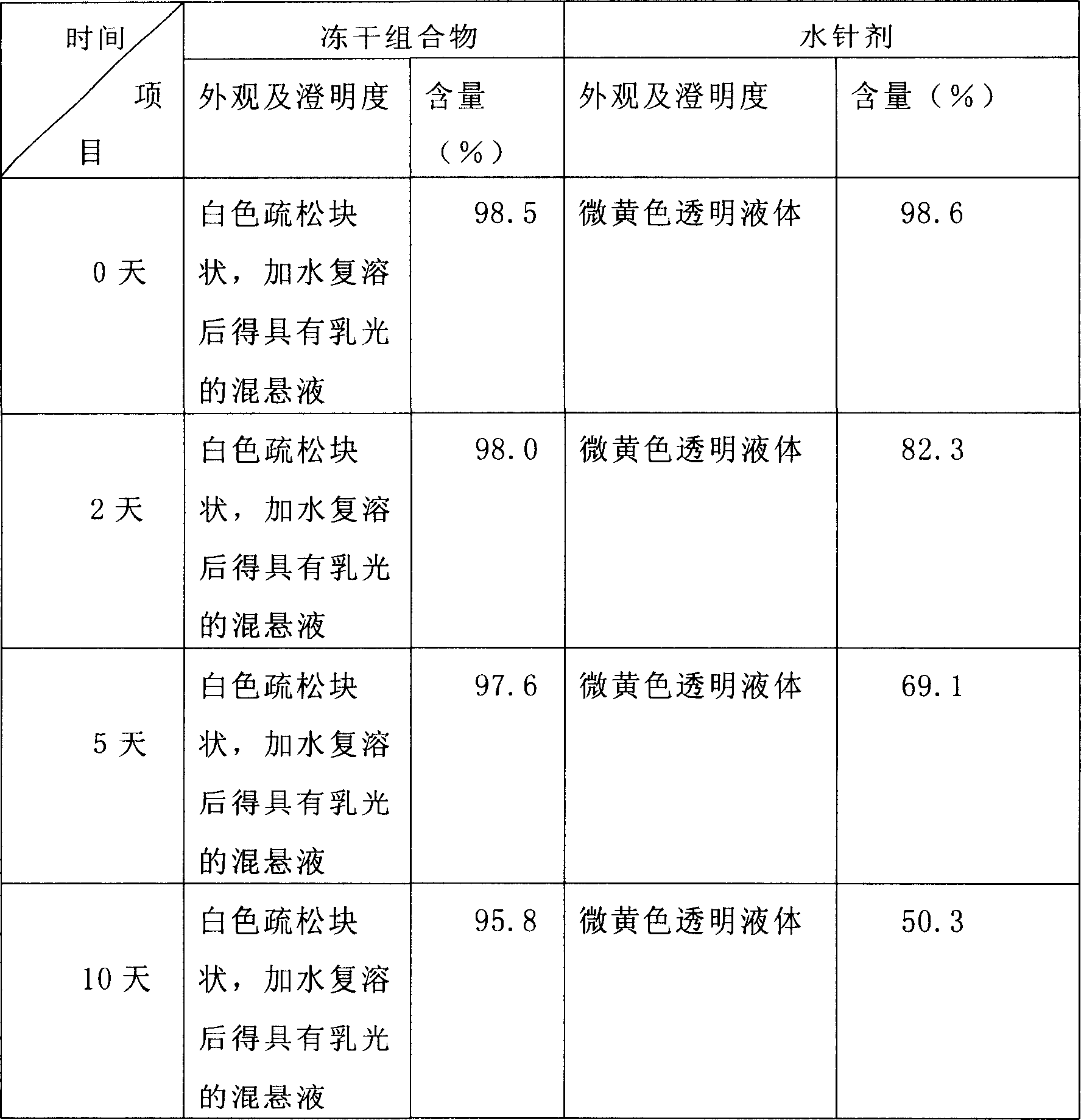

A nimodipine nano-suspension technology, which is applied in the direction of freeze-drying delivery, drug combination, cardiovascular system diseases, etc., can solve the problems of toxic and side effects, difficulty in accurate dosage, and less dissolution, so as to facilitate transportation and storage, Avoid irritation and reduce toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Direct dispersion method and high-pressure homogeneous method are combined to prepare nimodipine nano-suspension

[0021] Weigh 250 mg of sodium deoxycholate and 188 500 mg of poloxamer, add it into 50 ml of water, stir it magnetically to dissolve it completely, then add 500 mg of nimodipine pulverized by airflow, stir magnetically for 10 min; stir under high shear for 1 min; The suspension was subjected to high-pressure homogenization under the conditions of 150 bar for 2 cycles, 500 bar for 2 cycles, and 1500 bar for 15 cycles to finally obtain a milky white suspension with a measured particle size of 200 nm.

Embodiment 2

[0022] Embodiment 2: microprecipitation method and high-pressure homogenization method are combined to prepare nimodipine nanosuspension

[0023] Add 500mg of poloxamer 188 into 48ml of water, stir magnetically to dissolve it completely; put 1ml of propylene glycol in a water bath at 50°C, then add 250mg of soybean lecithin and 100mg of nimodipine, after completely dissolving, use a syringe to Add dropwise into 48ml of aqueous solution, stir magnetically for 20 minutes; carry out high-pressure homogenization on the initial suspension, the conditions are 150bar cycle 2 times, 700bar cycle 10 times, and finally obtain a milky white suspension with a measured particle size of 350nm.

Embodiment 3

[0024] Embodiment 3: Direct dispersion method and ultrasonic method are combined to prepare nimodipine nanosuspension

[0025] Pipette 25ml of 1% Tween 80 solution and add it to 25ml of water, then add 500mg of poloxamer 188, stir it with magnetic force to make it evenly mixed, then add 125mg of nimodipine, stir it with magnetic force for 10min; stir with high shear for 1min; The suspension is subjected to probe ultrasonication under the condition of 70Khz intensity for 15min. In order to prevent excessive heating, it can be stopped every 5min. Finally, a milky white suspension was obtained, and the measured particle size was 520nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com