High-stability power battery electrolyte

A high-stability technology for power batteries, applied in the field of electrolytes for high-stability power batteries, can solve the problems of shortening the storage time of electrolytes and the inability to suppress the rise of chroma, so as to avoid white precipitates, irritating problems, and high temperature The effect of excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Electrolyte solution preparation steps: In a glove box filled with argon, mix ethylene carbonate, ethyl methyl carbonate and diethyl carbonate according to the mass ratio of EC:EMC:DEC=3:5:2, and then add to the mixed solution Slowly add lithium hexafluorophosphate with a concentration of 1.0mol / L, and finally add 2wt% vinylene carbonate (VC), 300ppm triphenyl phosphite (TPPi), 300ppm N,N'-dicyclohexylcarbodi imine (DCC), after stirring evenly, obtain the lithium ion battery electrolyte of embodiment 1.

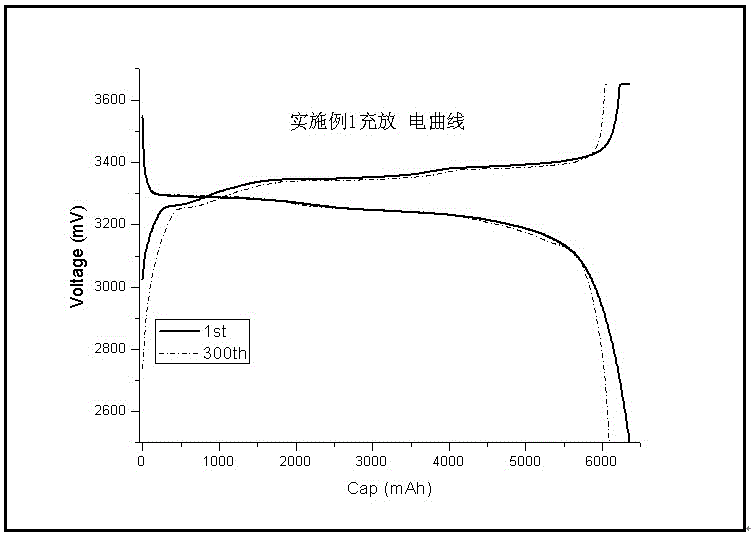

[0026] Lithium iron phosphate power battery 0.5C@60℃ cycle test:

[0027] Inject the lithium-ion battery electrolyte prepared in the above steps into the fully dried graphite / LiFePO 4 In the prismatic power battery, after the battery is left at 45°C, formed, clamped, re-sealed, and routinely divided, it is subjected to a 0.5C@60°C cycle test: at 60°C, the battery after capacity-divided is subjected to a constant current of 0.5C Charge to 3.65V at constant voltage, cu...

Embodiment 2~9

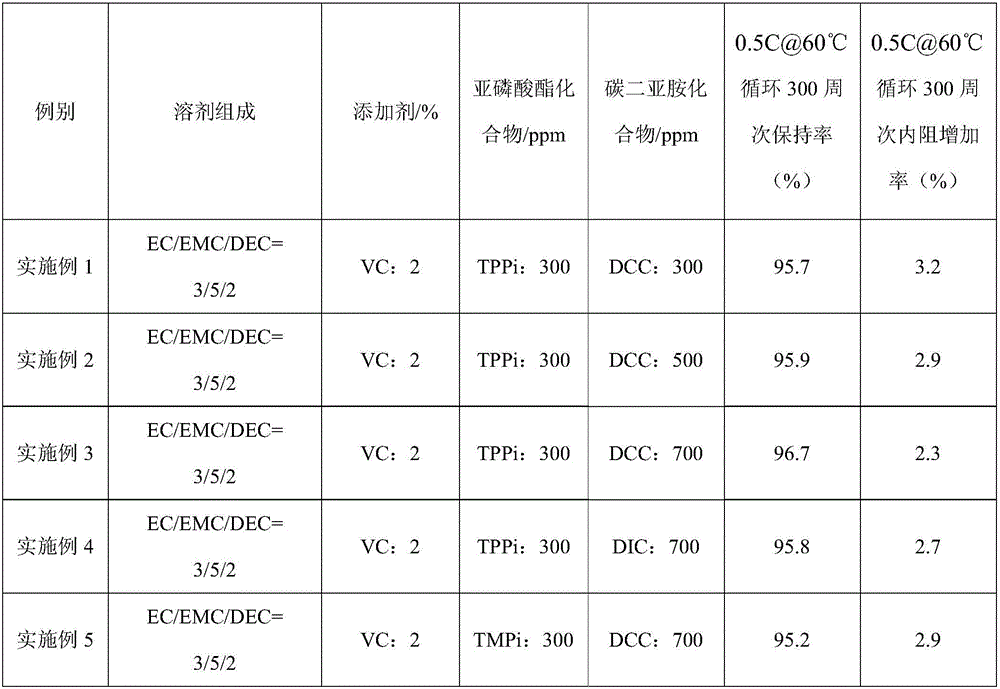

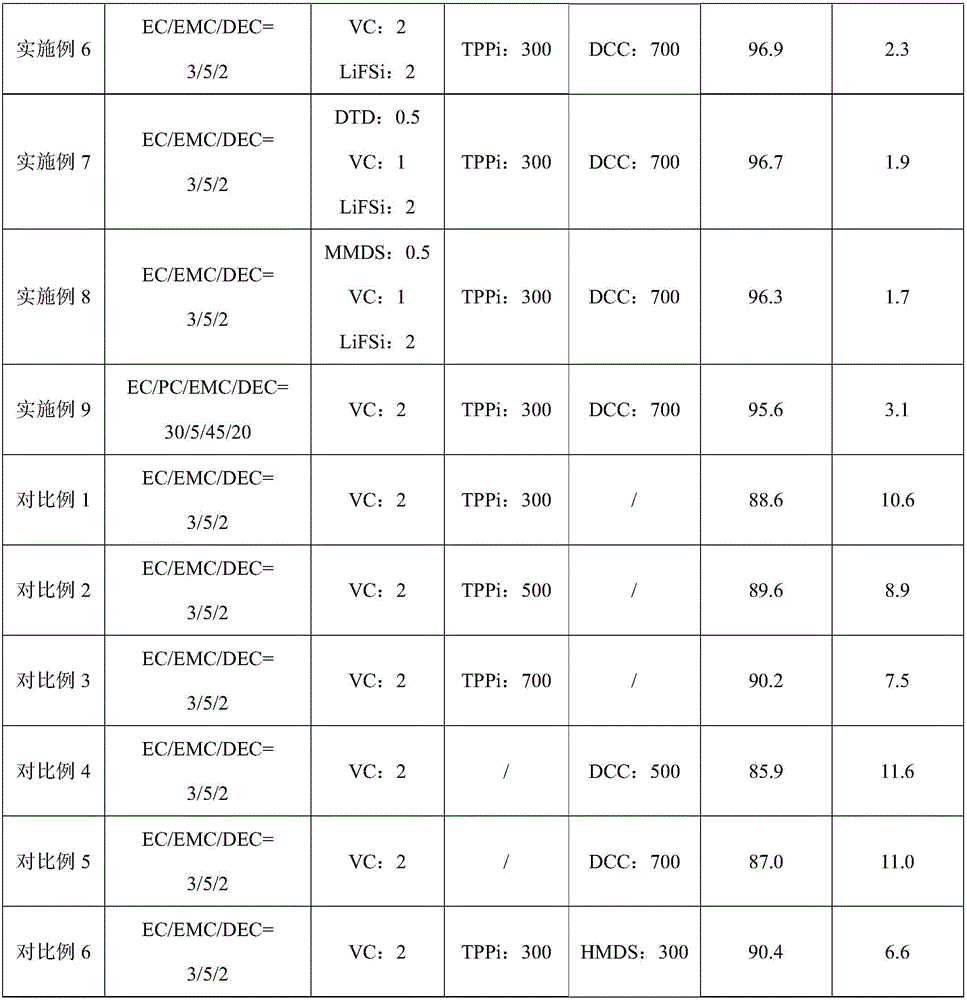

[0028] Embodiment 2~9 and comparative example 1~6

[0029] Examples 2-9 and Comparative Examples 1-6 are the same as Example 1 except that the composition and content of the electrolyte solvent, additives and stabilizer are added as shown in Table 1.

[0030]

[0031]

[0032] In the above Table 1, the abbreviated names of each chemical substance are as follows:

[0033] EC (ethylene carbonate), PC (propylene carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), VC (vinylene carbonate), LiFSi (lithium difluorosulfonyl imide), DTD (vinyl sulfate), MMDS (methylene disulfonate), TPPi (triphenyl phosphite), TMPi (trimethyl phosphite), DCC (N,N'-dicyclohexylcarbodiimide) , DIC (N,N'-diisopropylcarbodiimide), HMDS (hexamethyldisilazane).

[0034] Electrolyte storage chromaticity, acidity test:

[0035] Put the lithium-ion battery electrolyte prepared in the above steps into an imported sealed aluminum bottle in the glove box, and the aluminum bottle is vacuum-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com