Novel wooden structural material with stable durability and preparation method of novel wooden structural material

A wood structure and durability technology, applied in the direction of wood compression, humidity control wood, manufacturing tools, etc., can solve the problems of difficult control of internal temperature, too fast internal temperature rise of wood, decline of wood strength, etc., so as to facilitate popularization and use, overcome Significant reduction in strength and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

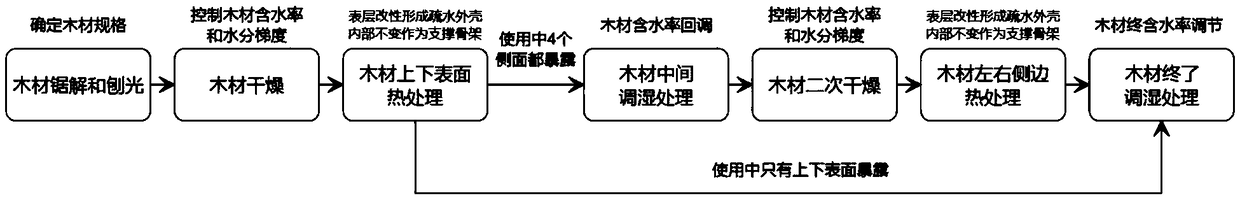

[0032] In order to further understand the content of the present invention, the method of the present invention will be described in detail in conjunction with the accompanying drawings.

[0033] Step 1, sawing and planing the wood. In terms of wood species and specifications, conifer planed boards with a thickness greater than 5cm are used. If the thickness is greater than 5cm, it is considered that the wood is used for load-bearing purposes, and there are certain requirements for the section size. In addition, technically higher thickness specifications also tend to create a sufficient temperature difference between the wood surface and core. The planed surface is conducive to the close combination of wood and heating plate, and improves the heat transfer effect.

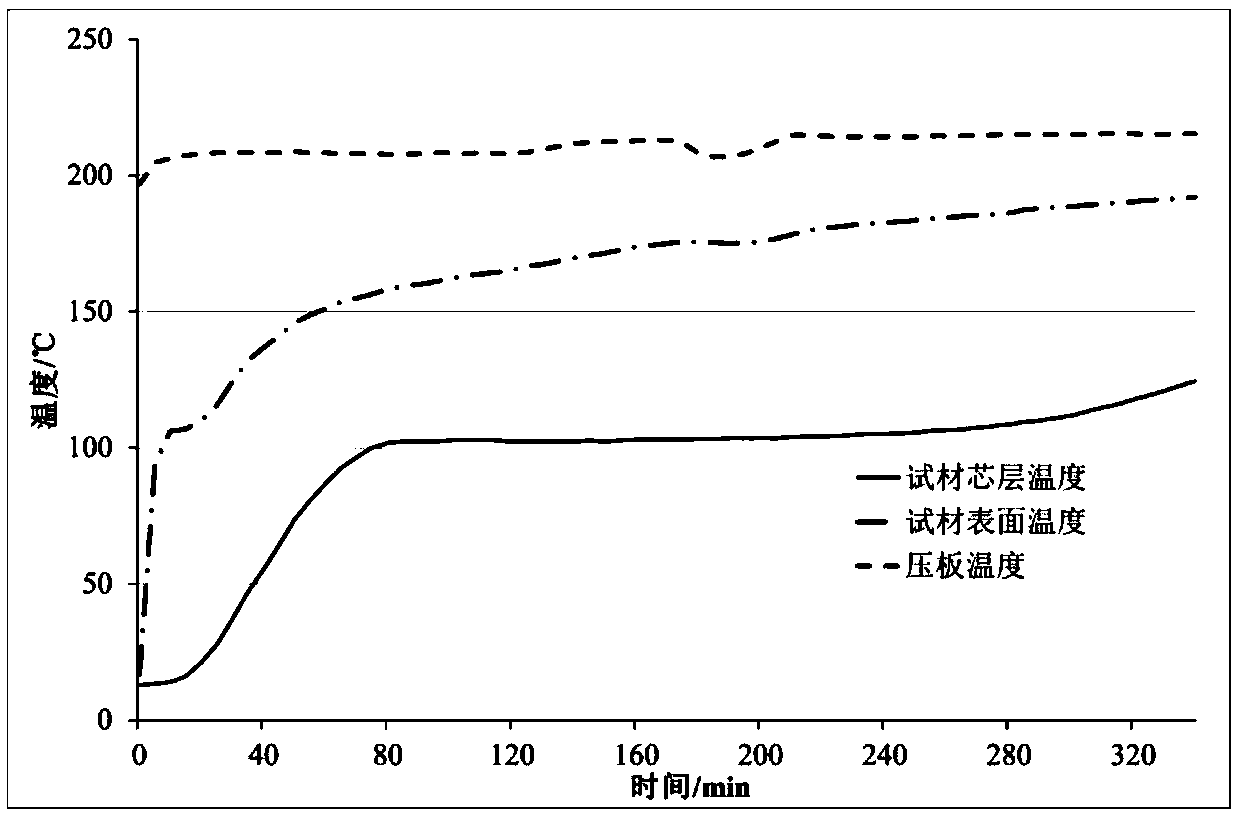

[0034] Step 2, wood pretreatment, drying the wood, and controlling the average moisture content in the range of 15% to 17%, increasing the air circulation speed in the drying kiln to moderately increase the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com