Patents

Literature

77results about How to "Simple handling of equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In situ restoring agent for heavy metal polluted soil

ActiveCN1631561AGuarantee continuous developmentSimple handling of equipmentContaminated soil reclamationMicroorganismCoal

The invention concerns the repairing dose to repair the soil polluted by heavy metal, which belongs to the technique field of repairing soil polluted by heavy metal. The repairing dose mainly includes: Na unit soil, haibao stone, stick stone, coal powder and microorganism germ root. Every composition' rate by weight is: Na unit soil15--40%, haipao stone 10--50%, stick stone 10--30%, coal powder 5--30%, microorganism germ root 0--40%. The repairing dose in the invention has the advantages of low cost of material, simple working equipment, good effect and no second pollution.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

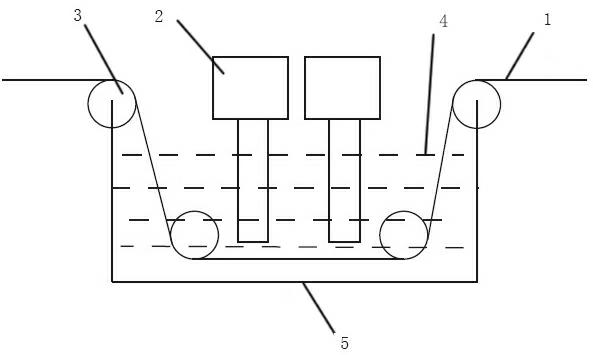

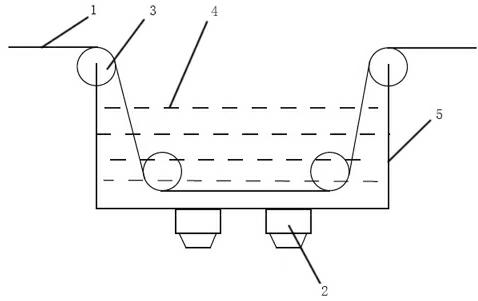

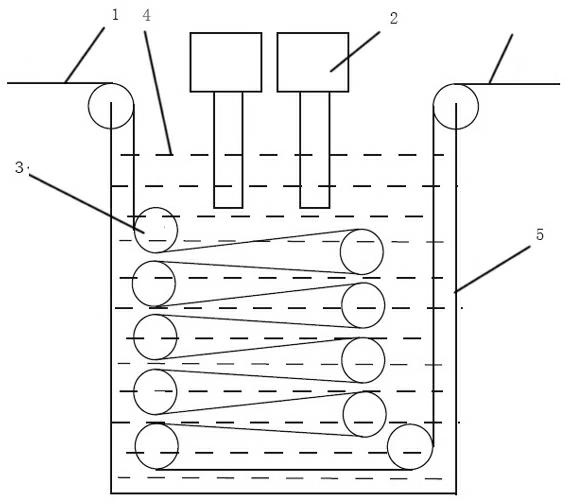

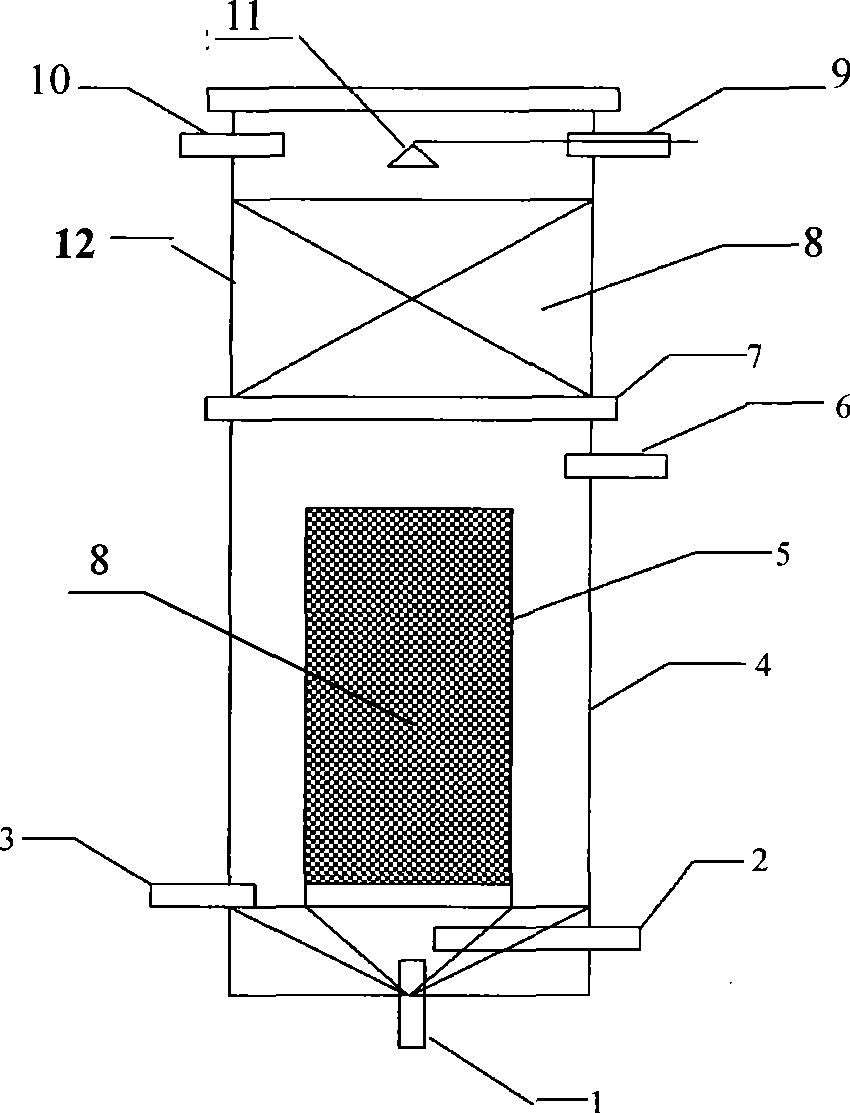

Carbon fiber surface treatment method based on ultrasonic strengthening

InactiveCN102628212AImprove surface morphologyImprove surface roughnessCarbon fibresUltrasonic/sonic fibre treatmentFiberPolymer science

The invention relates to a carbon fiber surface treatment method based on ultrasonic strengthening, comprising the following steps of: soaking carbon fibers into liquid medium in a surface treatment tank, carrying out ultrasonic radiation on the liquid medium by virtue of an ultrasonic generator or an ultrasonic array which is arranged above or below the surface treatment tank, and adjusting ultrasonic processing time according to ultrasonic intensity and frequency, so as to achieve the aim of carrying out the surface treatment on the carbon fibers. The carbon fiber surface treatment method disclosed by the invention has the beneficial effects that: surface morphology, surface roughness and the like of the carbon fibers are improved to improve mechanical properties of carbon fiber composite, and the oil stains produced in the production process of the carbon fiber composite are removed through ultrasonic cleaning at the same time that the carbon fiber is subjected to surface oxidation treatment; and compared with the other traditional methods, the carbon fiber surface treatment method disclosed by the invention has the characteristics of simple treatment equipment, simple and easy operation, no damage to environment, high treatment speed, high treatment efficiency, and easy implementation on assorted online production.

Owner:WUHAN UNIV OF TECH

Leaf vegetable organic fertilizer and preparation method thereof

InactiveCN103641630AImprove breathabilityImprove water storage capacityBio-organic fraction processingOrganic fertiliser preparationManihot esculentaOzone Sterilization

The invention relates to a leaf vegetable organic fertilizer and a preparation method thereof. The preparation method comprises the steps of grinding maize straws, wheat straws, soybean straws and sesame straws into straw particles according to a mass ratio of 3:3:2:2, pretreating the straw particles by adding water and ammonium hydroxide to obtain a mixture A; carrying out ultraviolet ray treatment on the taken duck manure and duck feathers, and then carrying out ozone treatment, thus obtaining a mixture B; adding aspergillus niger and saccharomycetes into a mixture of grinded manioc wastes, grinded kelp wastes and water, and fermenting to obtain a mixture C; mixing the mixtures A, B and C, shell powder, plant ash and sodium humate, and adding EM (Effective Microorganism) for fermentation to obtain a mixture D; and adding bone meal and charcoal dust into the mixture D, then carrying out ozone sterilization, drying, charging in a separating manner, and carrying out ultraviolet sterilization to obtain the leaf vegetable organic fertilizer. The prepared leaf vegetable organic fertilizer contains various nutritional ingredients needed by the growth of leaf vegetables, regulates soil, activates the activity of microorganisms in the soil, overcomes soil hardening, and improves the permeability of soil air.

Owner:RUZHOU JIULONG ANIMAL HUSBANDRY

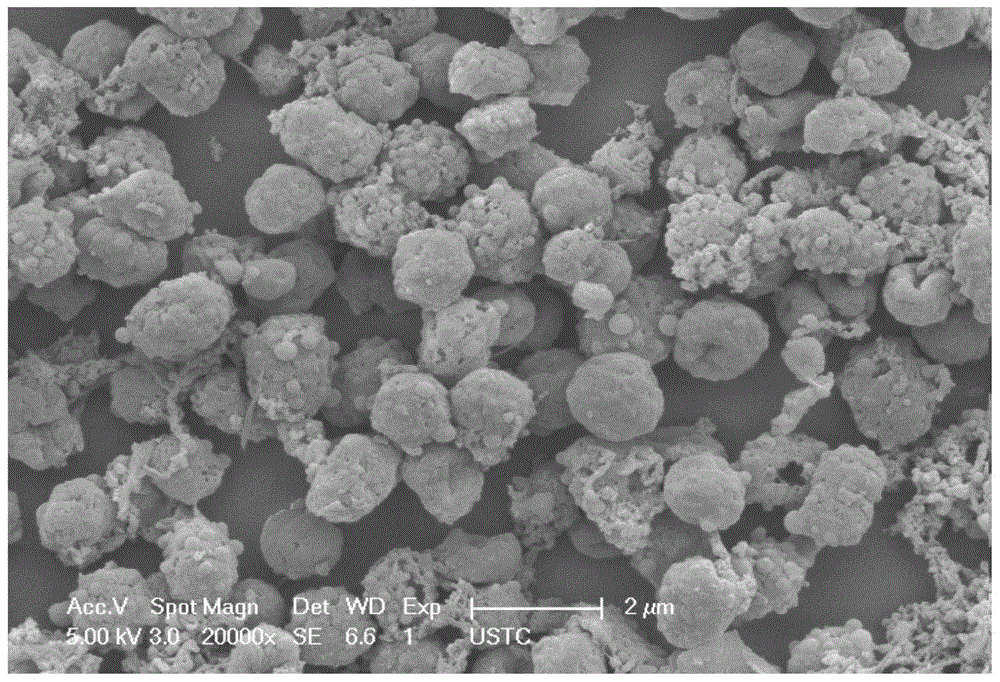

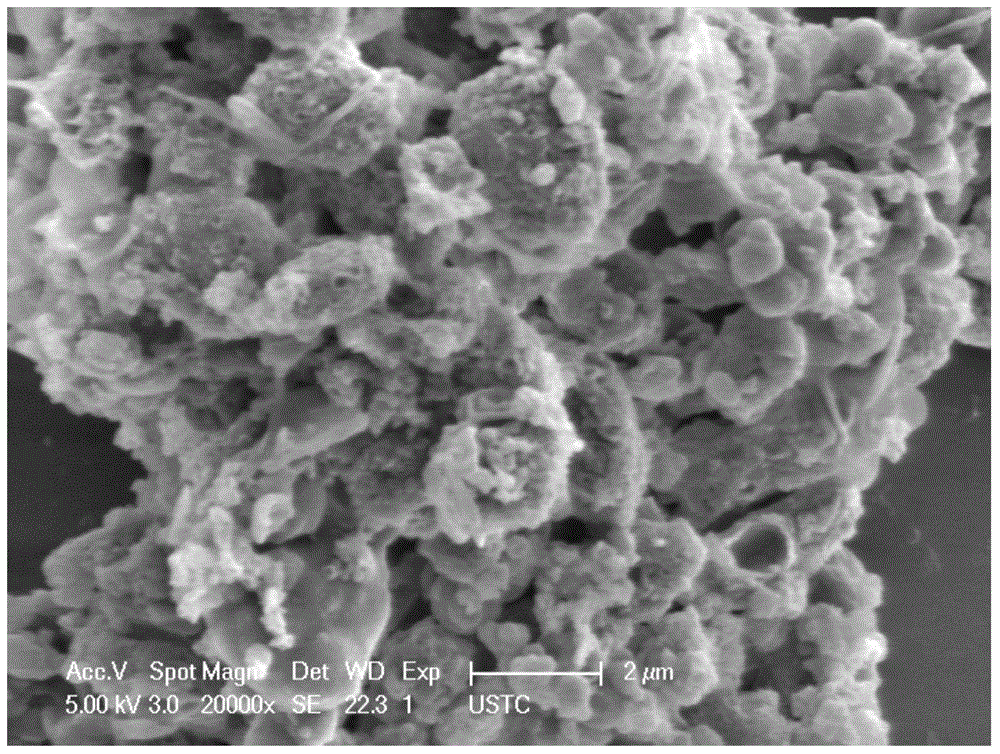

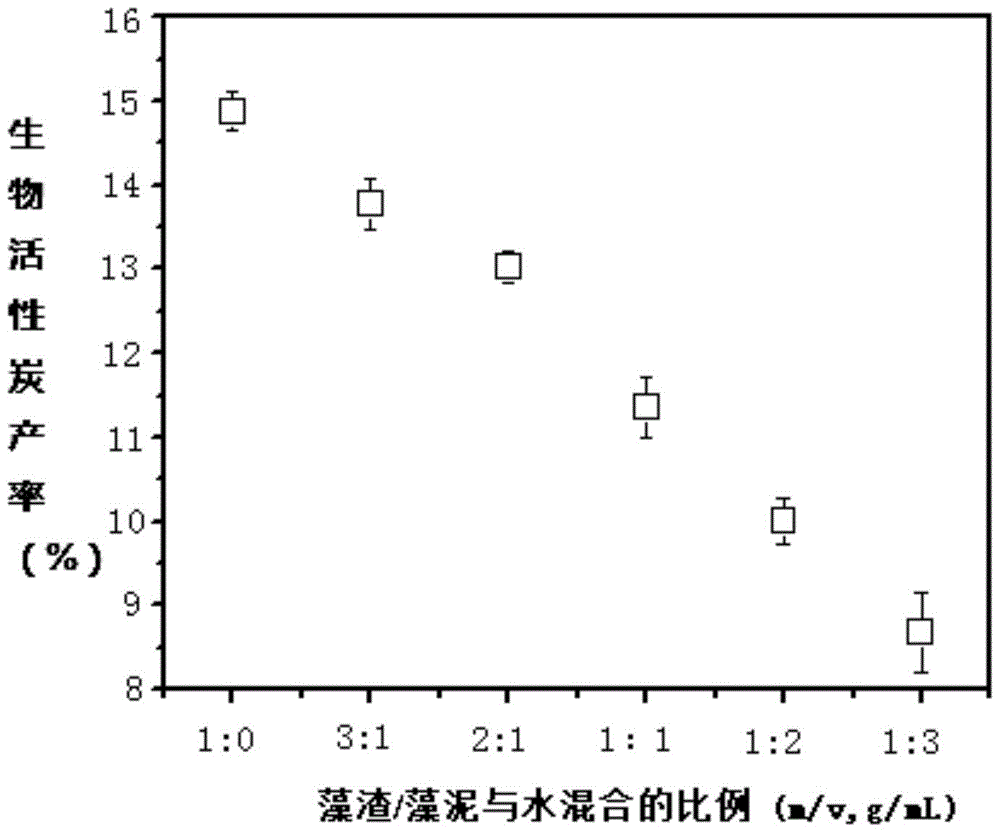

Method for preparing biological activated carbon by hydrothermal carbonization of algae residue/algae sludge

InactiveCN105668564AImprove performanceEfficient decomposition and removalBiological activated carbonSludge

The invention discloses a method for preparing biological activated carbon by hydrothermal carbonization of algae residue / algae sludge.The method includes the following steps: (1) mixing the algae residue / algae sludge with water prior to putting the mixture into a reaction kettle, performing heating reaction under the pressure less than 6 MPa and at the temperature of 160-220 DEG C for 2-20 hours, and naturally cooling to the room temperature; (2) subjecting a hydrothermal product obtained in the step (1) to filtration or centrifugal separation to obtain solid, and washing the solid; (3) drying the product obtained after washing in the step (2) at the temperature of 50-60 DEG C to obtain the biological activated carbon.Plenty of algae residue can be disposed highly efficiently as well as be utilized to turn waste into treasure; harm brought by the algae residue and algae toxins is reduced, and high efficiency and environmental friendliness are realized.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

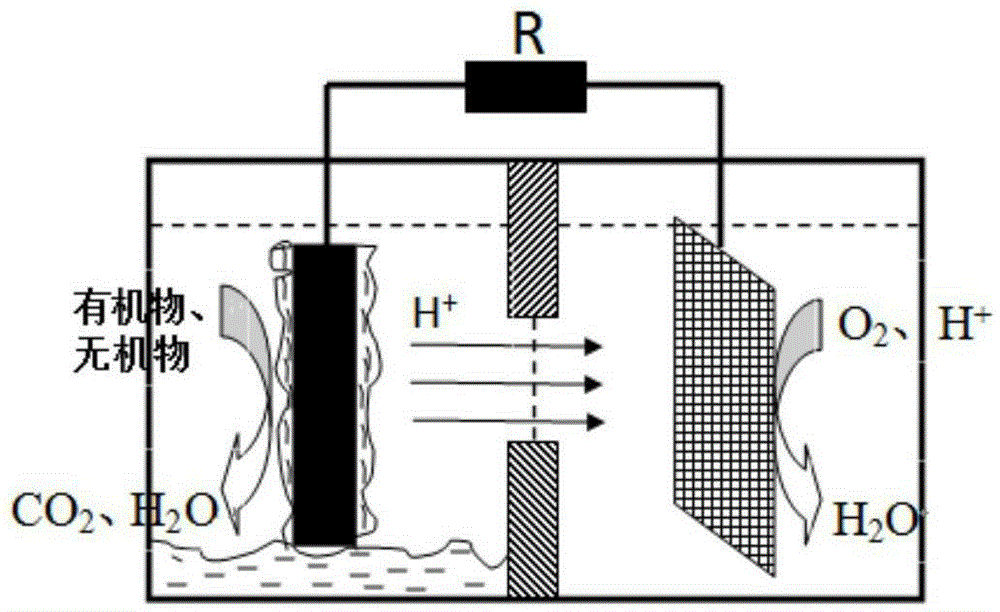

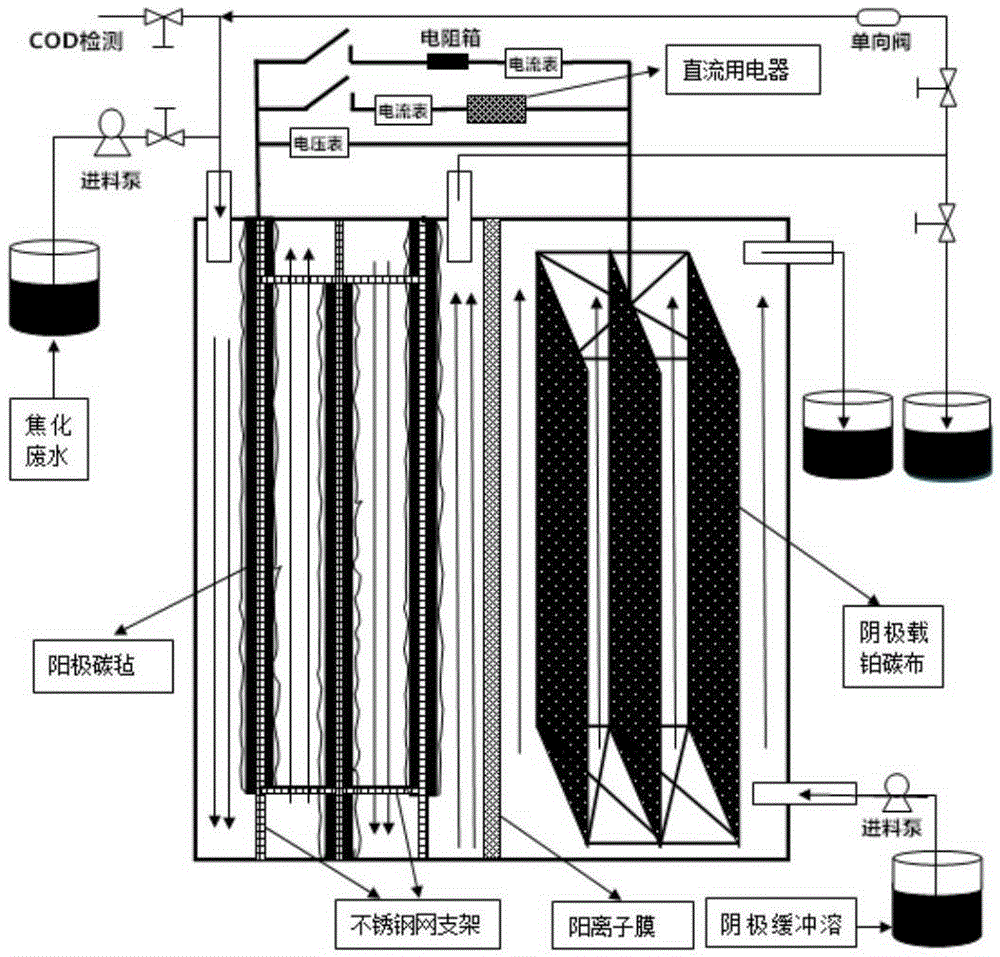

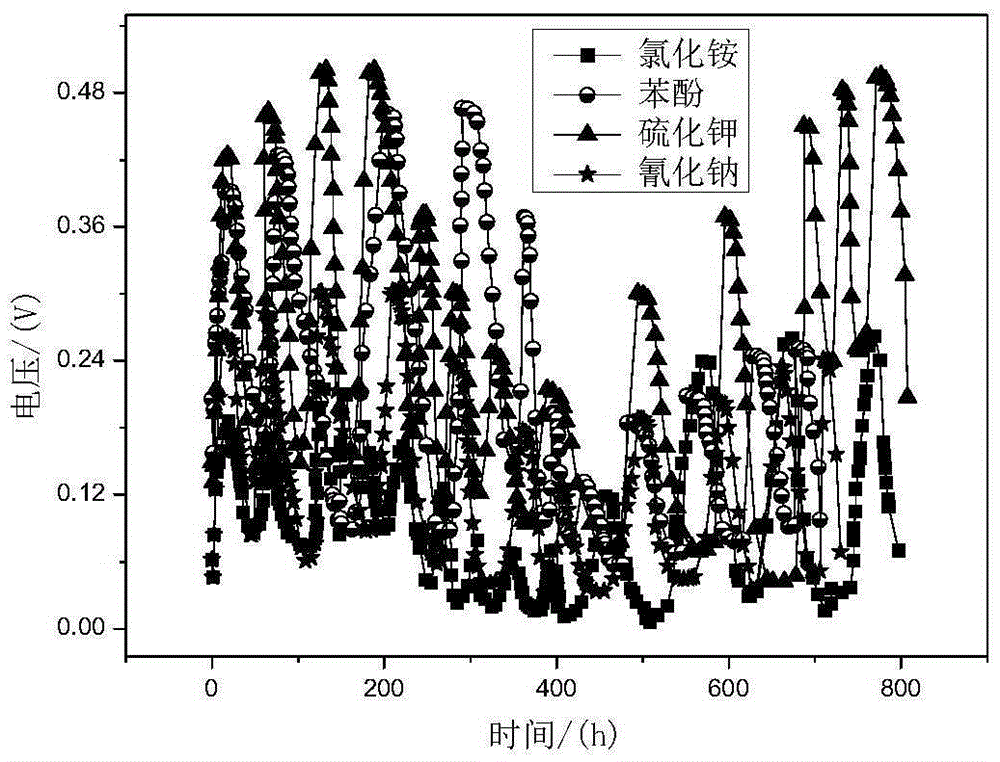

Method for coking wastewater degradation and synchronous power generation by taking coking active bacterium as biocatalyst

The invention relates to a method for coking wastewater degradation and synchronous power generation by taking coking active bacterium as a biocatalyst. The method is carried out according to the following steps of partitioning a carbon-based active coking microbial film positive electrode and a platinum-loaded carbon fabric negative electrode at two chambers by using a cation membrane or a proton membrane; degrading organic matters and inorganic matters which are high in toxicity and are difficult to be degraded in coking wastewater in an anode anaerobic environment by using the coking active bacterium; allowing oxidation reaction; transferring electrons released through reaction to a positive carbon felt by a medium or a pigment secreted from the bacterium; sequentially transmitting the electrons to a negative electrode through an external wire; and allowing an electron acceptor of the negative electrode to generate reduction reaction. By the process, the treatment of high-toxicity and degradation-resistant coking wastewater is achieved, chemical energy reserved in the process is also converted to electrical energy, a new method is provided for coking wastewater treatment, and meanwhile, a wide prospect is provided for green treatment of the coking wastewater in future.

Owner:TAIYUAN UNIV OF TECH

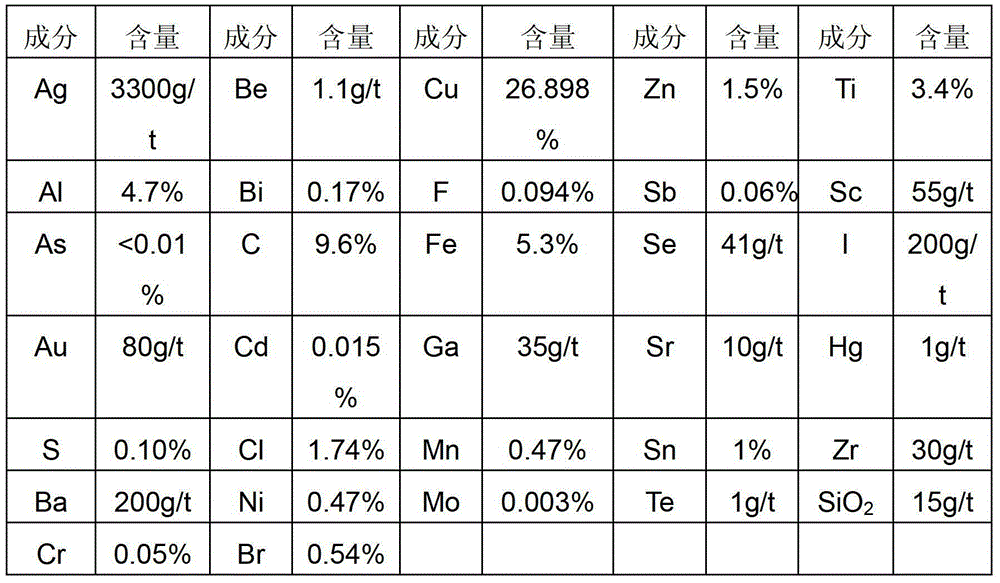

Method for processing waste circuit board

ActiveCN104028530AReduce harmHigh recovery rateSolid waste disposalProcess efficiency improvementEngineeringCopper

The invention relates to a method for processing a waste circuit board, which solves the problems of low metal recovery rate, low purity and complex equipment in prior art. The method comprises the following steps: heating the circuit board, carbonizing the plastic in the circuit board under vacuum environment or inert atmosphere; then performing ball milling in a bowl mill, sorting the material through ball milling, and separating metal and plastic, then adding alkali in metal for roasting, then performing water leaching for leaching metals such as tin, antimony and lead, electrorefining to obtain copper, and recovering precious metal by anode mud; the steps better solve the problems. The method provided in the invention is used for industrial production for processing the waste circuit board.

Owner:SINOPEC SHANGHAI ENG +1

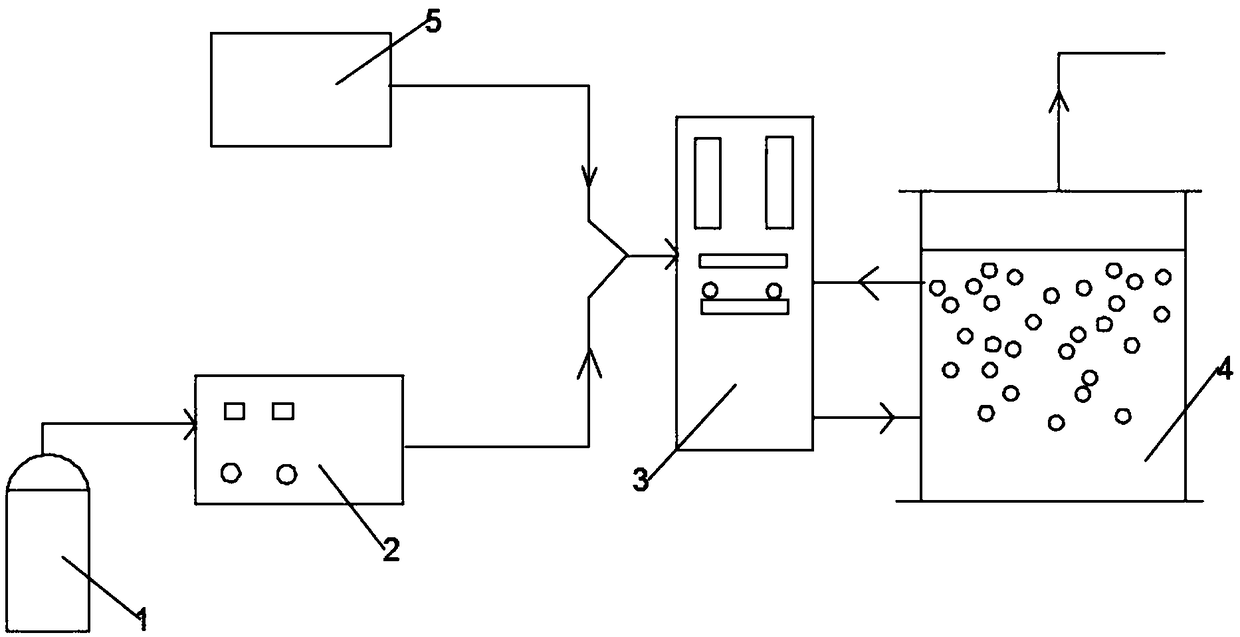

Biological treatment apparatus and method for wastewater containing volatile organic matter

InactiveCN101481171AEasy to transport and installSimple process daily operationDispersed particle separationSustainable biological treatmentWater dischargeAtmospheric air

The invention relates to a device and a method for the biological processing of waste water containing volatile organic substances. The main part of the device comprises a liquid-phase biological fluidized bed and a gas-phase biological dripping filtration bed which are coupled, a porous flow guiding cylinder is arranged in the liquid-phase biological fluidized bed, a compound magnetic polyurethane foam carrier is filled in the porous flow guiding cylinder, and the bottom of the porous flow guiding cylinder is provided with a micropore aeration system to provide sufficient oxygen for biological oxidizing reaction. A compound magnetic polyurethane foam carrier is filled in the gas-phase biological dripping filtration bed to further degrade the volatile organic chemical compound generated in the biochemical process to thoroughly degrade the volatile organic substances. The device has high sewage processing efficiency, ensures the water quality of processed water reaches the national first-grade waste water discharge standard, and eliminates the atmosphere pollution by the volatile organic compound in the biochemical process. The device of the invention has simple structure, small occupied land, low investment, high waste water processing efficiency and low energy consumption, and is suitable for the processing and the recovery of the waste water containing volatile organic substances.

Owner:深圳市中拓天达环保科技有限公司

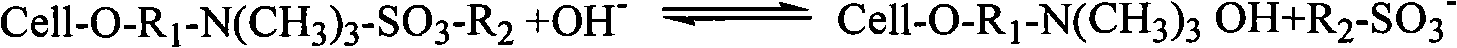

Method for processing negative ion surface active agent in wastewater

InactiveCN101628762AReduce consumptionReduce manufacturing costOther chemical processesWater contaminantsCelluloseProcess equipment

The invention discloses a method for processing negative ion surface active agent in wastewater, belonging to the field of chemical environmental protection and adopting the steps of wastewater acidification pretreatment, filtration, quaternary ammonium cationic cellulose composite adsorption column adsorption, and the like; and the process route of treatment is short, and the concentration of negative ion surface active agent in the treated water is greatly lower than the national wastewater discharge standard. The processing method of the invention has the advantages of simple process equipment, low energy consumption, high adsorption speed and large adsorption capacity, adsorbent can be used in the way of regeneration and circulation, the processing cost is low, and raw materials used for preparing the quaternary ammonium cationic cellulose has low production cost and wide range of acquisition, is non-toxic, can not cause secondary pollution to environment, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

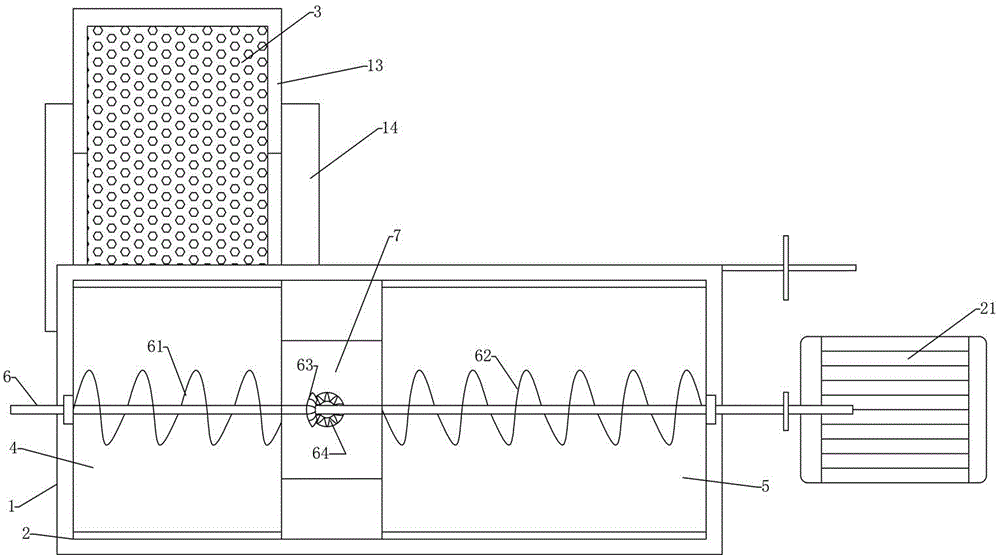

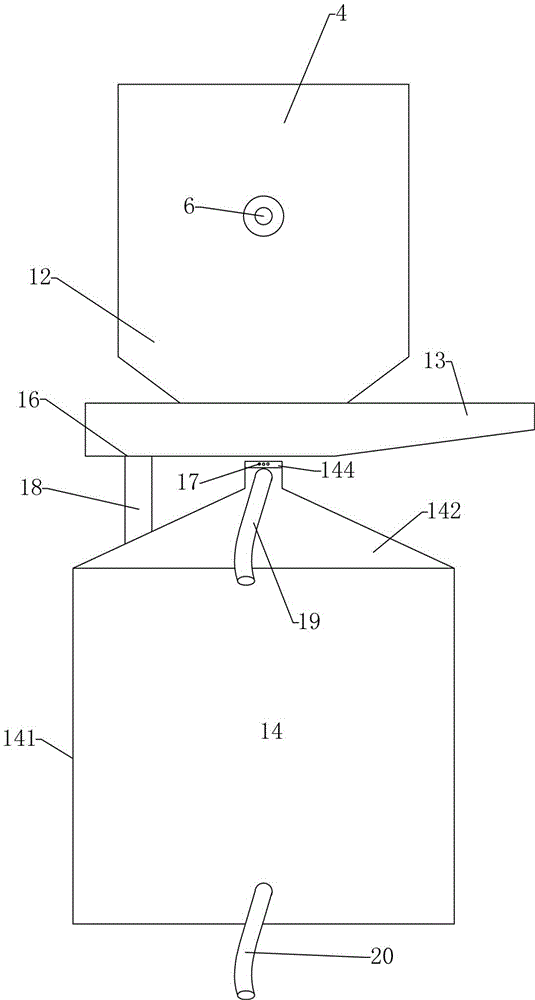

Kitchen waste integrated processing method and equipment thereof

InactiveCN105327931AIncrease nutritionAvoid excessive consumptionSolid waste disposalNutritionProcess engineering

The invention discloses a kitchen waste integrated processing method and equipment thereof. According to the method, kitchen waste is naturally filtered for the first time, and naturally filtered-out liquid is removed; the kitchen waste with high viscosity is squeezed and filtered through a screw for the second time, the liquid capable of being separated out through squeezing is separated out, and waste residues are obtained; the obtained waste residues and basal feed with adsorbability are mixed to form a mixture containing oil and water, and animal feed is obtained after drying and forming; and the naturally filtered-out liquid and the liquid separated out through squeezing are subjected to oil and water separation. The equipment comprises a machine frame, a pre-processing system and an oil and water separation system, wherein the pre-processing system and the oil and water separation system are arranged on the machine frame. The equipment is compact and ingenious in structure and small in size. When the kitchen waste is rapidly converted into the animal feed, high-degree dehydration before forming is not needed, proper oil and water in the residues are reserved, nutrition of the animal feed is improved, and excessive consumption of resources caused by high-degree dehydration is avoided. The processing equipment is simplified, the process steps are reduced, the process period is shortened, the cost is low, and the conversion efficiency is high.

Owner:刘 杨

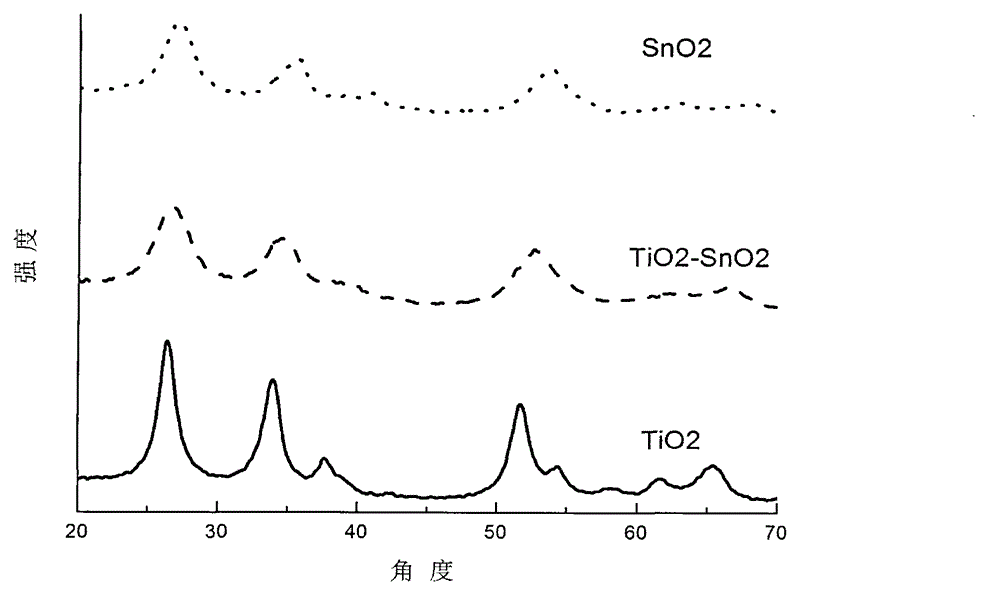

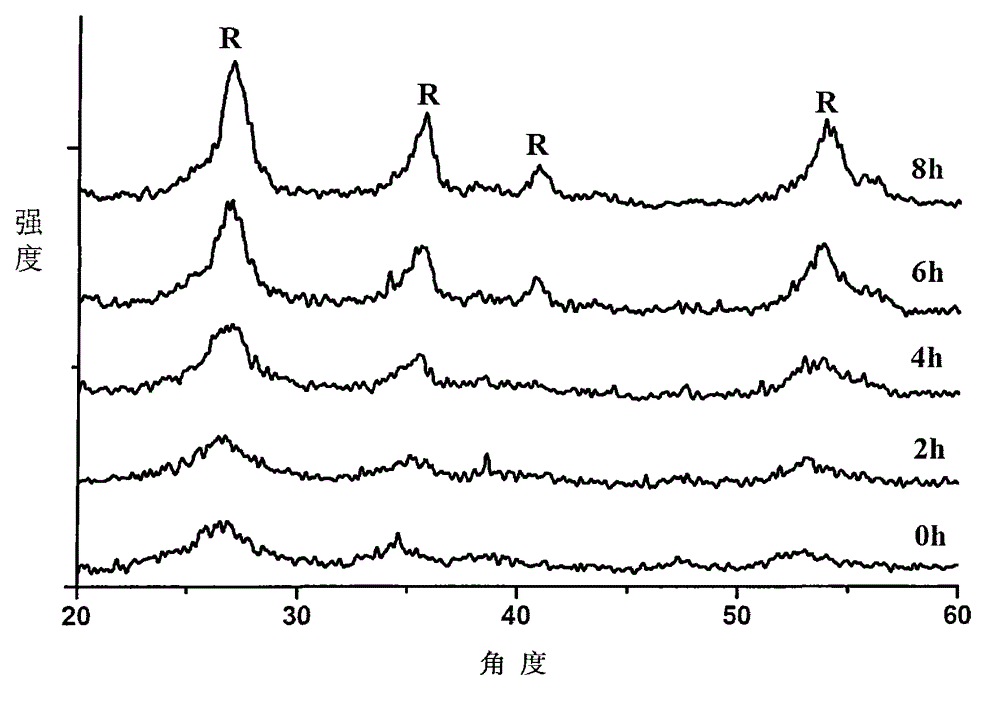

Synthesizing method of water-based nano conductive sol and transparent conductive thin film made of water-based nano conductive sol

InactiveCN102910672AWide variety of sourcesLow priceSolid/suspension decomposition chemical coatingTitanium oxides/hydroxidesTin dioxideWater based

The invention relates to a synthesizing method of tin dioxide / titanium dioxide solid solution nano sol composite and a film forming technique for preparing transparent conductive thin films on surfaces of different substrates on the basis of the sol. The synthesizing method includes the steps of firstly, precipitating tin-titanium hydroxide; secondly, dispersing precipitate with hydrogen peroxide; and thirdly, synthesizing final product. The synthesizing method is few in steps and simple in process. The synthesized tin-titanium oxide solid solution nano sol is water-based, defects in the prior art are overcome, environmental pollution is avoided, synthesizing of water-based sol at normal pressure and low temperature is achieved, and film forming is easy.

Owner:程明明 +2

Cooperative treatment method for refuse incineration fly ash and refuse leachate

InactiveCN106391652AImprove processing efficiencyStrong oxidation abilitySolid waste disposalWater contaminantsSolubilityDecomposition

The invention relates to a cooperative treatment method for refuse incineration fly ash and refuse leachate. According to the cooperative treatment method for the refuse incineration fly ash and the refuse leachate, a solvent which has quite high oxidation performance in the subcritical state or the critical state is used for simultaneous treatment of dioxin in the fly ash, the flay ash and heavy metal and organic pollutants in the refuse leachate. Under the alkaline hydrothermal condition, carbon, aluminum and silicon matter in the refuse incineration fly ash can easily synthesize a zeolite-like structure, so that a large amount of heavy metal in the fly ash is adsorbed into pores of the zeolite-like structure, and therefore the leaching toxicity of the heavy metal in the fly ash is lowered. Under the hydrothermal condition, along with continuous rising of the temperature and the pressure in a sealed reactor, the water solubility of the dioxin is greatly improved, the reactivity is improved beneficially, and oxidation and decomposition of the dioxin are accelerated.

Owner:北京首创北科环境科技研究院有限公司

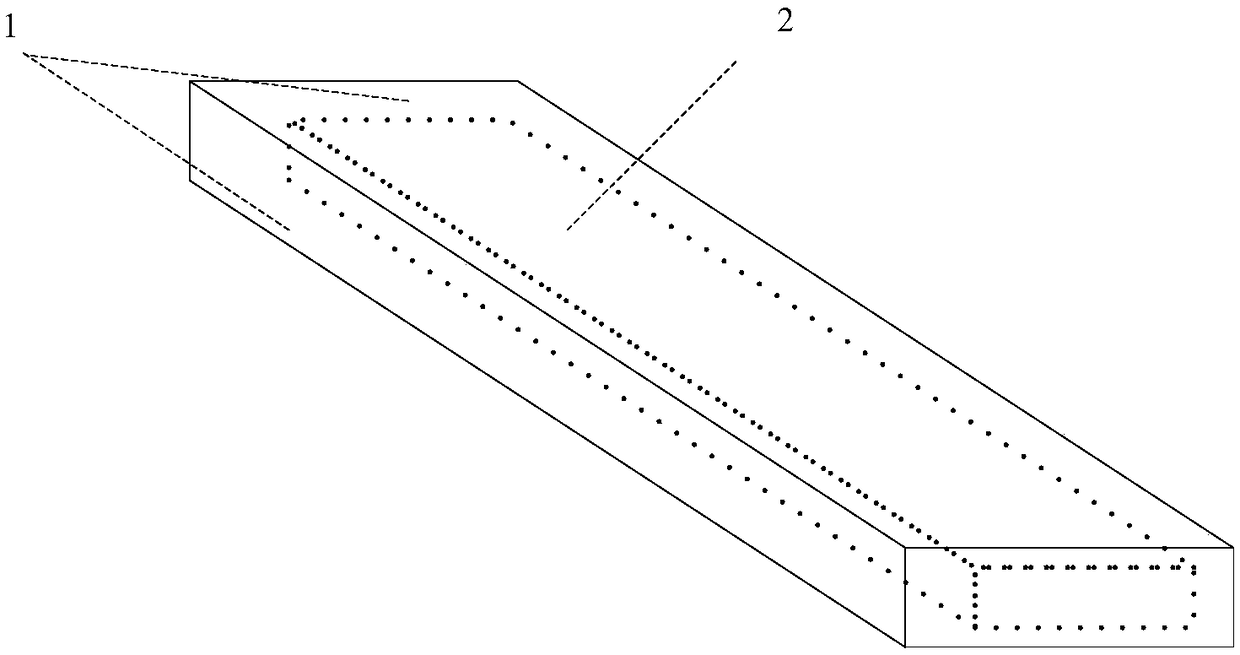

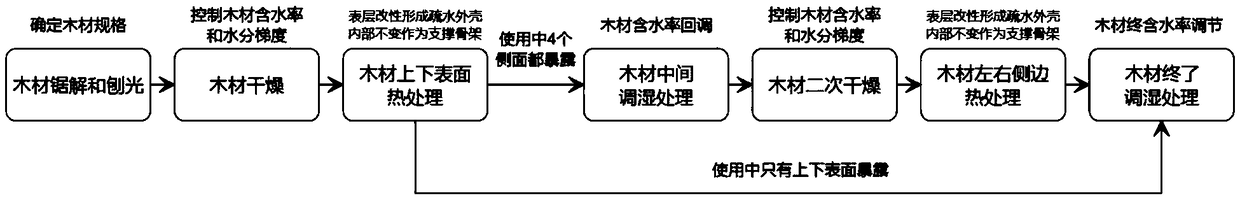

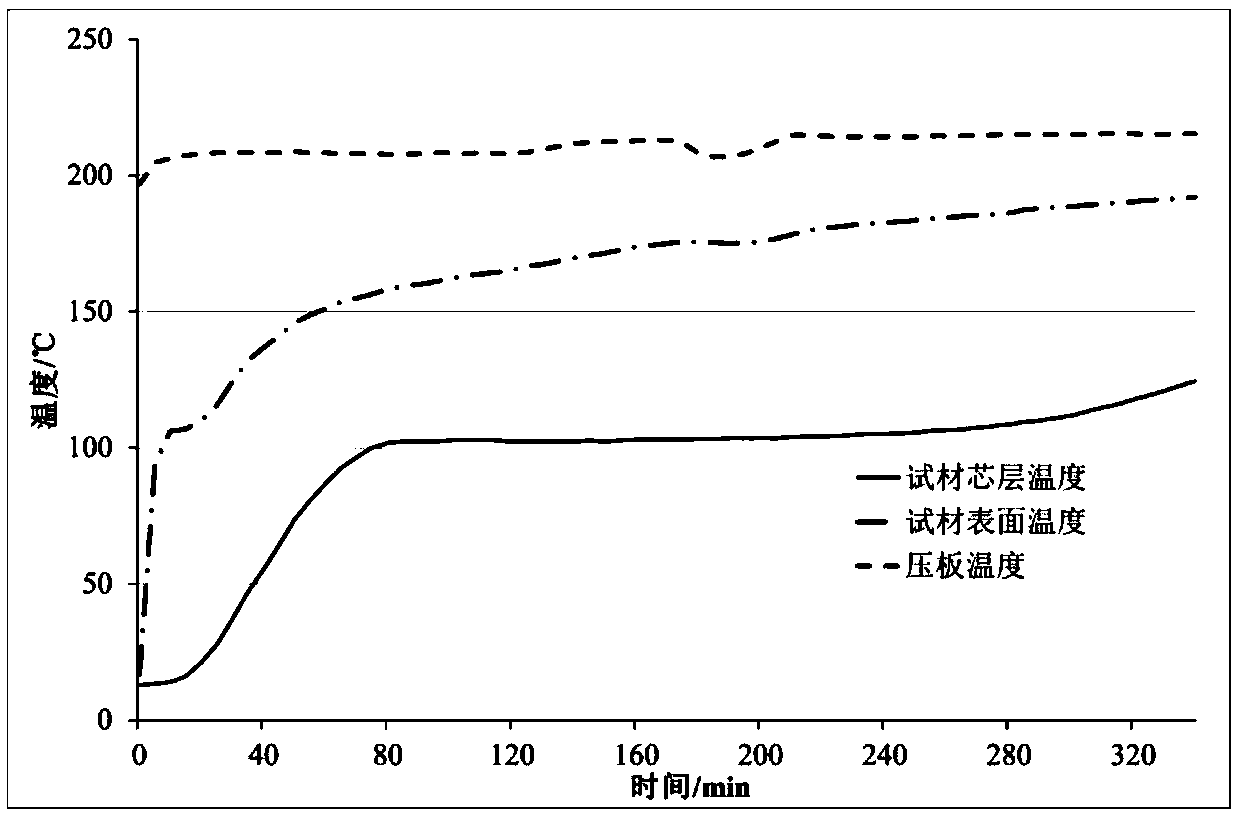

Novel wooden structural material with stable durability and preparation method of novel wooden structural material

ActiveCN108638277AOvercome the disadvantage of significant decrease in strengthImprove stabilityPlywood pressesWood compressionSurface layerUltimate tensile strength

The invention discloses a novel wooden structural material with stable durability and a preparation method of the novel wooden structural material and belongs to the technical field of wood protectionand modification. The novel wooden structural material with the stable durability comprises a protective outer shell formed through surface layer heat modification and a core layer. The core layer isa supporting skeleton with a temperature stagnant zone formed through process controlling in the preparing process. The preparation method of the novel wooden structural material with the stable durability comprises the steps that firstly, a wood is sawed and planed, then, the wood is dried, the moisture content of the wood is controlled, by means of a process method, a moisture gradient is formed between the wood surface layer and the core layer, a plate type hot press is used for carrying out heating treatment on the wood surface, the temperature of the core layer is controlled in the heating process, and finally, wet-conditioning treatment is carried out on the wood. The novel wooden structural material with the stable durability and the preparation method of the novel wooden structural material have the main beneficial effects that by means of scientific control over the initial moisture content level and the internal moisture content gradient of the wood and by adjusting the temperature rising rate of the wood surface layer and the core layer, the temperature stagnation area not formed through a conventional process is formed on the core layer, and the mechanical strength ofthe novel wooden structural material is not affected while the size stability of the wood is improved.

Owner:NANJING FORESTRY UNIV

Method for improving volume of production of corn straw biogas with sodium hydroxide wet-type solid state treatment at normal temperature

InactiveCN101368190AEliminate energy consumptionSimple handling of equipmentWaste based fuelFermentationDry weightPre treatment

The invention relates to a method for improving the yield of corn stalk biogas through sodium hydroxide wet type solid normal temperature treatment, which belongs to the field of biomass energy. The liquid chemical pretreatment and the solid chemical pretreatment of corn stalks have the problems of higher use amount of NaOH, high cost and the like. The method is that sodium hydroxide with the amount of 2 percent of the dry weight of the corn stalks, water with the amount of 7.5 times of the weight of the corn stalks and crashed corn stalks are fully mixed evenly, are sealed for preservation for 3 days after reaching the water saturation state, then are discharged and added with pig manure digestive liquid to undergo the anaerobic digestion and produce biogas. The invention has the advantages that the cost is saved, the pretreatment time is reduced, the gas yield is improved and the like.

Owner:赤峰元易生物质科技有限责任公司

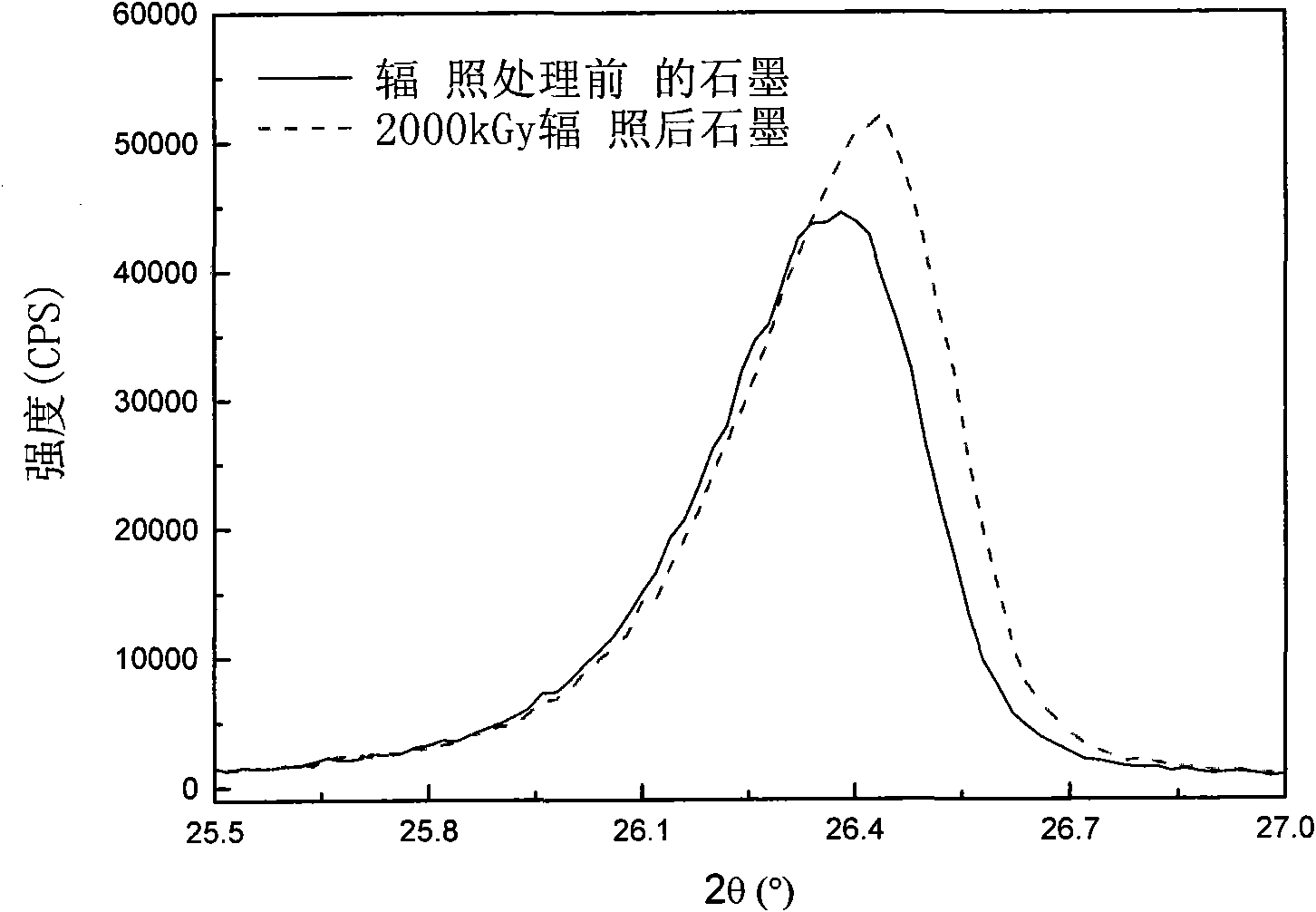

Method for improving degree of graphitization of graphite material

he invention relates to a method for improving degree of graphitization of graphite material, T comprising: the graphite material is placed inside a gamma ray radiation source chamber of Co and processed by gamma ray radiation under the conditions that the gamma ray radiation dose rate is 0.6*10Gy / h-6*10Gy / h, and the irradiation dose is 1*10Gy-6*10Gy. The method for improving the degree of graphitization of the graphite material utilizes the characteristics of high energy and strong penetrating power of gamma ray particles to initiate active points inside the graphite material, and leads the active points to react with medium around the material; meanwhile, the energy provided by the gamma ray is utilized to generate carbon free radicals at the defect part inside the graphite material, and stabler chemical bond can be formed among the carbon free radicals, thus the structure at the defect part inside the graphite material is rearranged to form stabler structure, the distance between graphite wafers becomes smaller and smaller, the microcrystal size in enlarged, and the degree of graphitization is improved.

Owner:TIANJIN POLYTECHNIC UNIV

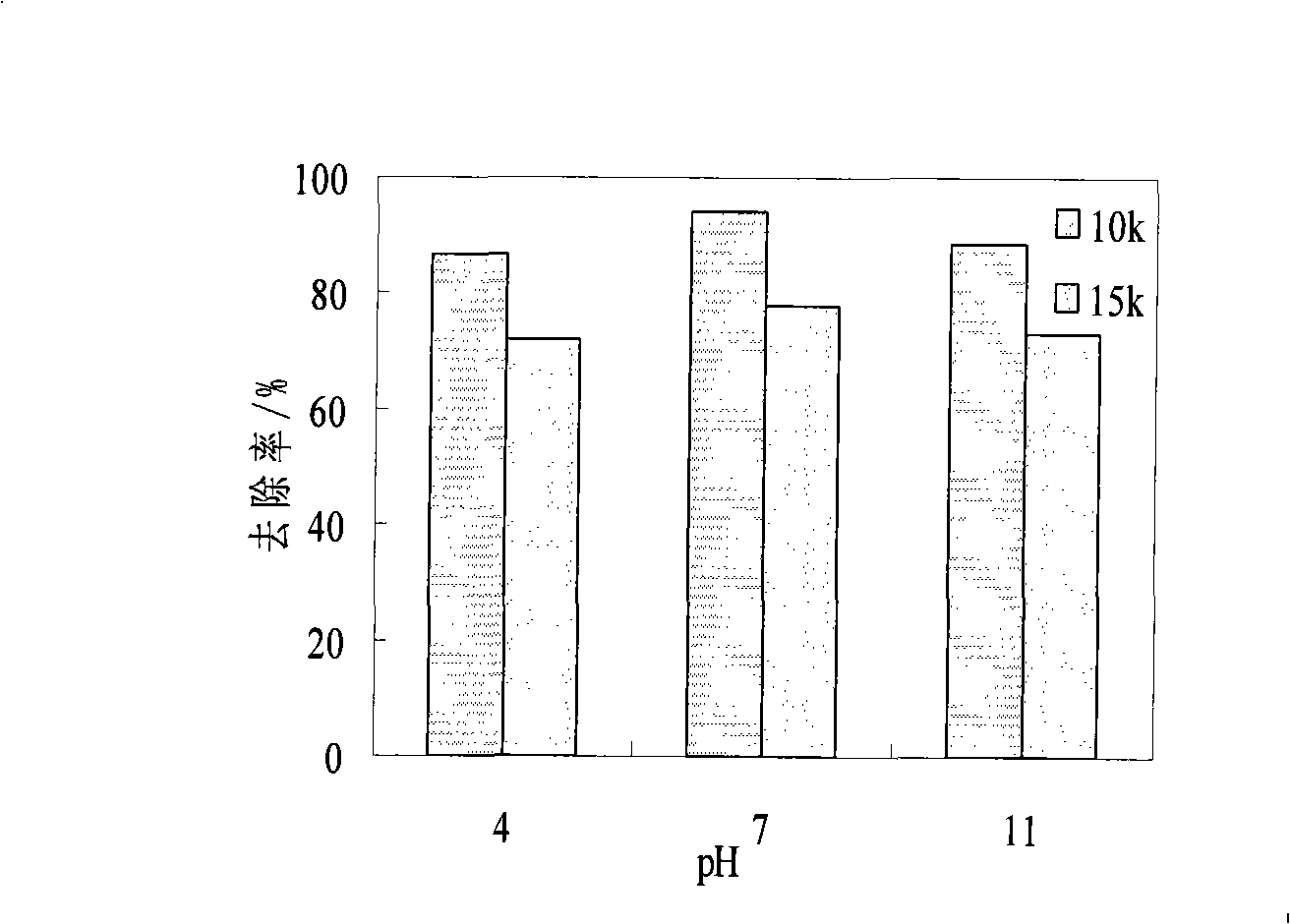

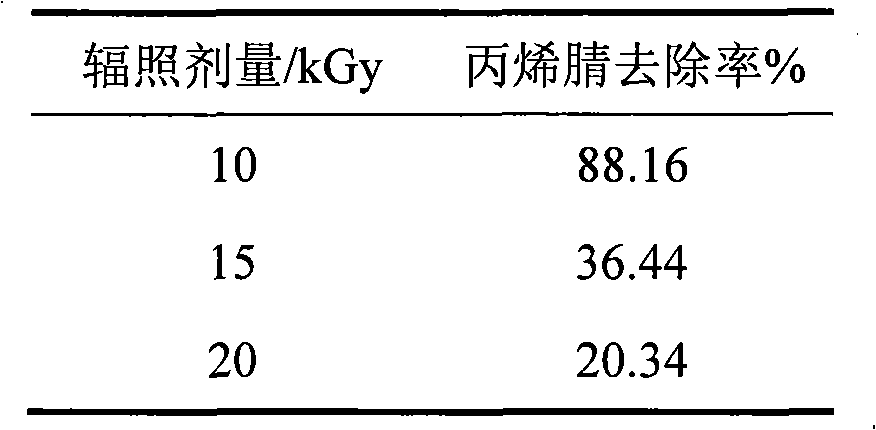

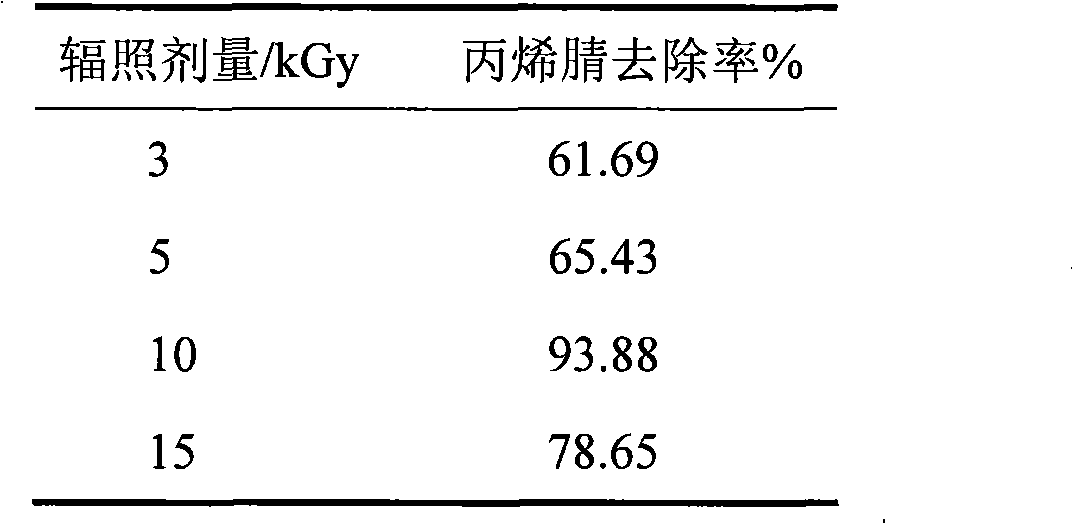

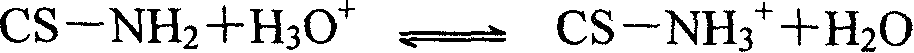

Irradiation treatment method for vinyl cyanide wastewater

InactiveCN101402476AEfficient removalLow costWater/sewage treatment by irradiationNature of treatment waterHigh concentrationCyanide

The invention discloses an irradiation processing method for acrylonitrile waste water, which belongs to the field of nuclear technology application and environmental protection. The method mainly makes use of the principle that ionizing radiation can induce acrylonitrile to have a polyreaction, enables the acrylonitrile in the waste water to have the polyreaction through the ionizing radiation; and then acrylonitrile polymer deposit is separated from the water phase through a filtration method so as to realize the aim of removing the acrylonitrile from the waste water. The method can effectively remove the biologically toxic acrylonitrile pollutant in the high-concentration acrylonitrile waste water. The method is a waste water processing technology with high efficiency, economy and environmental friendliness.

Owner:TSINGHUA UNIV

Method for removing anion surfactant from waste water

InactiveCN101121550AReduce consumptionReduce processing costsWater/sewage treatment by sorptionCelluloseAlkaline water

The present invention discloses a method to wipe off the activator on the surface of the negative ion in the wastewater. The present invention is characterized in that: the wastewater is treated by the technical of acidification, filter, and polysaccharide adsorption of the fibrin solid shell; the acidification to filter to polysaccharide adsorption of the fibrin solid shell. The technical of the polysaccharide adsorption of the fibrin solid shell is to dissolve the shell polysaccharide in the acid water solution first and then to adjust the solution to the alkalescence by the alkali, finally, the shell polysaccharide is separated out on the fibrin to become an adsorption material. The content of the shell polysaccharide in the adsorption material is 1-6 percent. The polysaccharide adsorption of the fibrin solid shell is put into the PolyvinylChloride tube to make a composite adsorption pole. The treatment process for the wastewater is that: the acid water solution is added into the wastewater first, and then the pH value of the wastewater is adjusted to 5 plus or minor 0.5, and the wastewater is deposited and filtered. And then the wastewater flows through the composite adsorption pole of the polysaccharide adsorption of the fibrin solid shell to be treated. The polysaccharide adsorption of the fibrin solid shell after being used is washed by the alkaline water solution and then to be recycled. The present invention has the advantages of short treating process, simple treating device, low energy consumption, fast adsorption speed, recyclable and reusable composite adsorption and low treating cost and so on.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

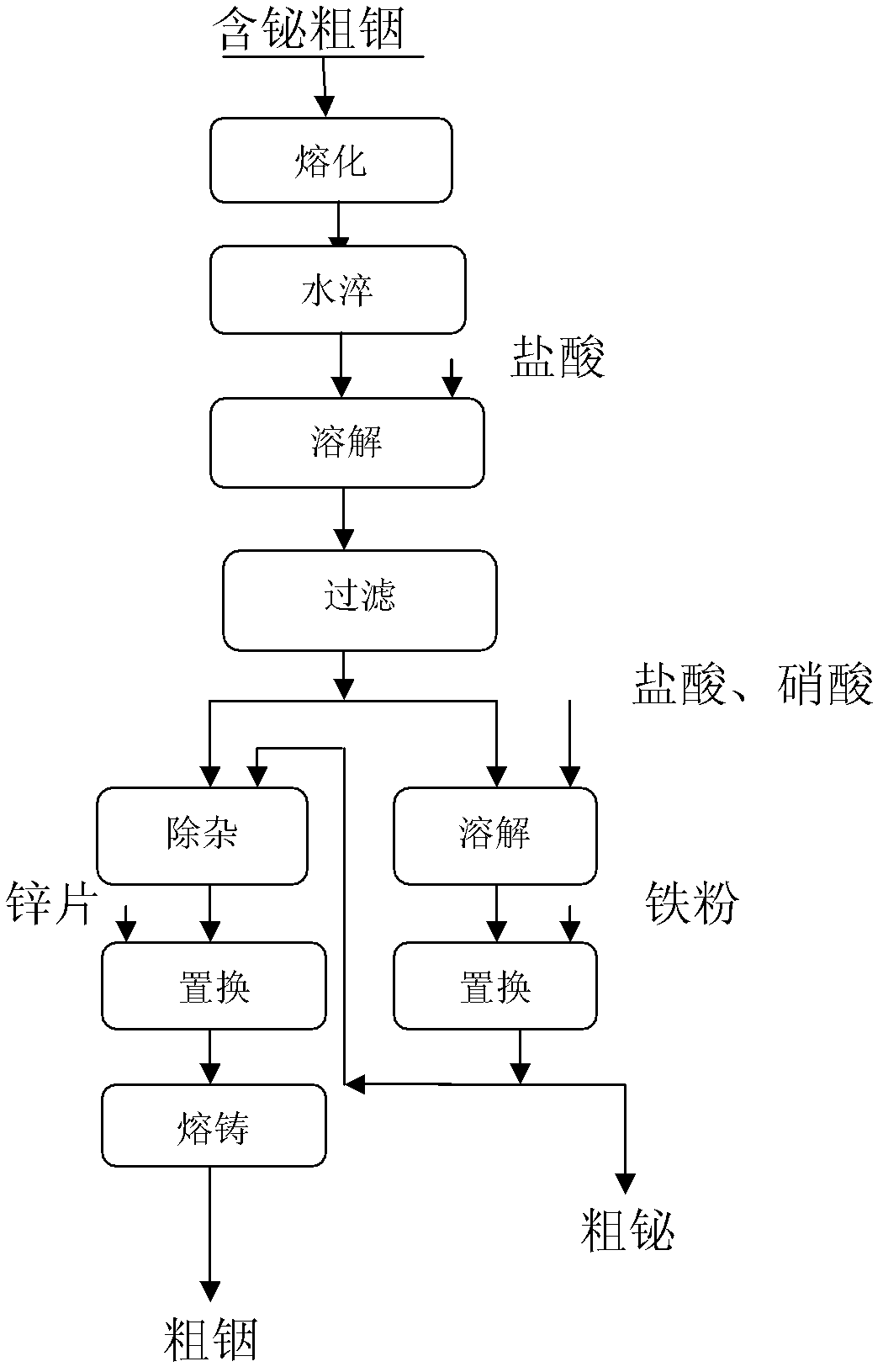

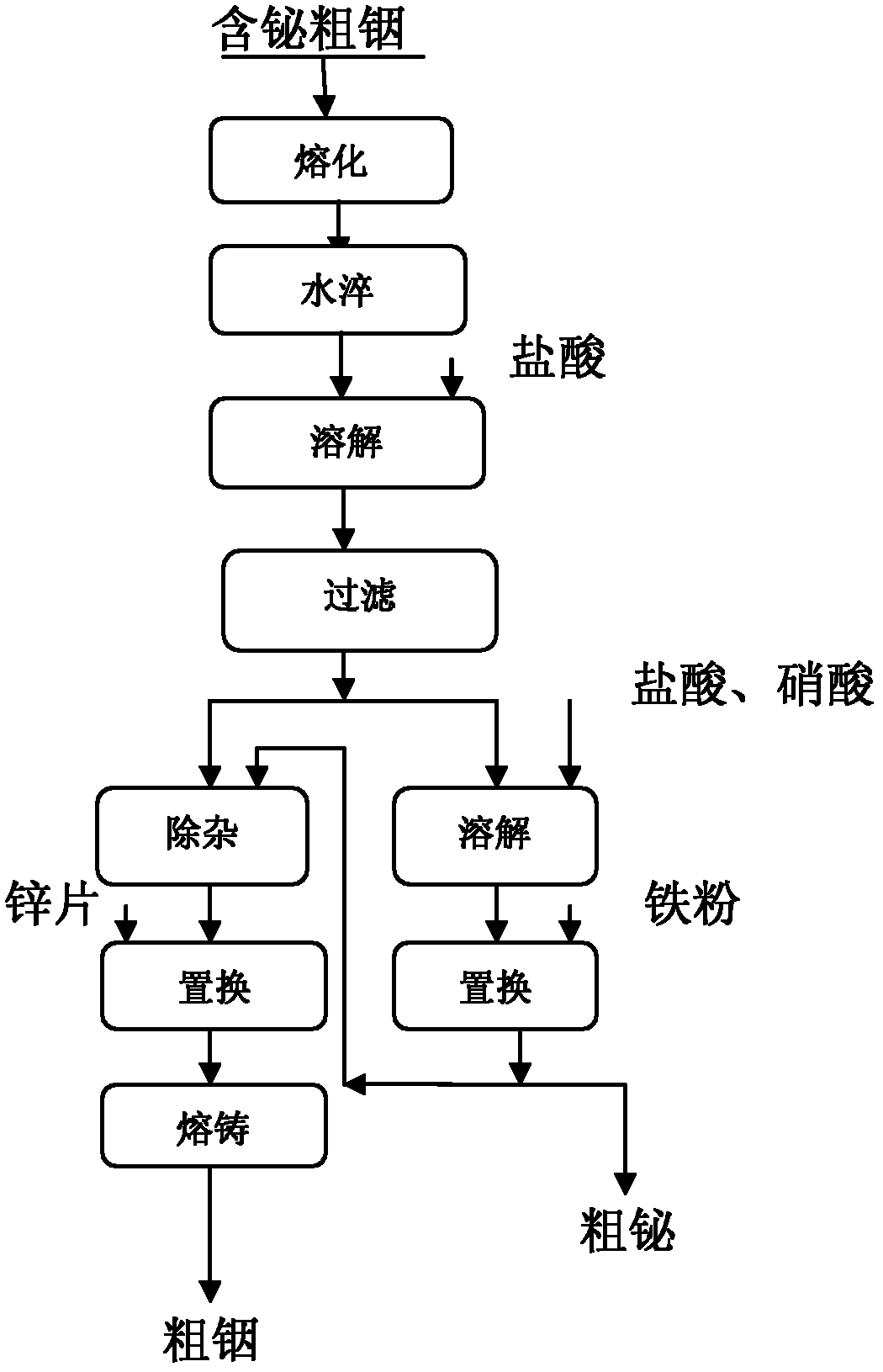

Method for preparing indium and bismuth from coarse bismuth-containing indium

The invention discloses a method for extracting indium and bismuth from coarse bismuth-containing indium. The method comprises the steps of indium preparation and bismuth preparation, wherein the technological process of the indium preparation comprises melting, water quenching, dissolving, filtering, hydrolysis impurity removal, replacement and casting, and the technological process of the bismuth preparation comprises dissolving, replacement and casting. The method has the advantages that the step-by-step dissolution is adopted, the coarse indium and coarse bismuth contain fewer impurities,and the purity can reach higher than 99 percent; the cost is lower, and the direct recovery rate of indium and bismuth is high and reaches higher than 95 percent; the application range is wide, the method can be used for treating the coarse indium with the bismuth content higher than 2 percent, and the method is particularly suitable for small-scale production; and the technological process is short, treatment equipment is simple, the investment is low, and the economic benefit is considerable.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

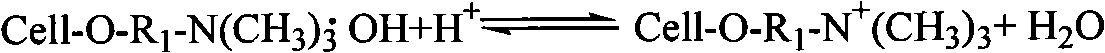

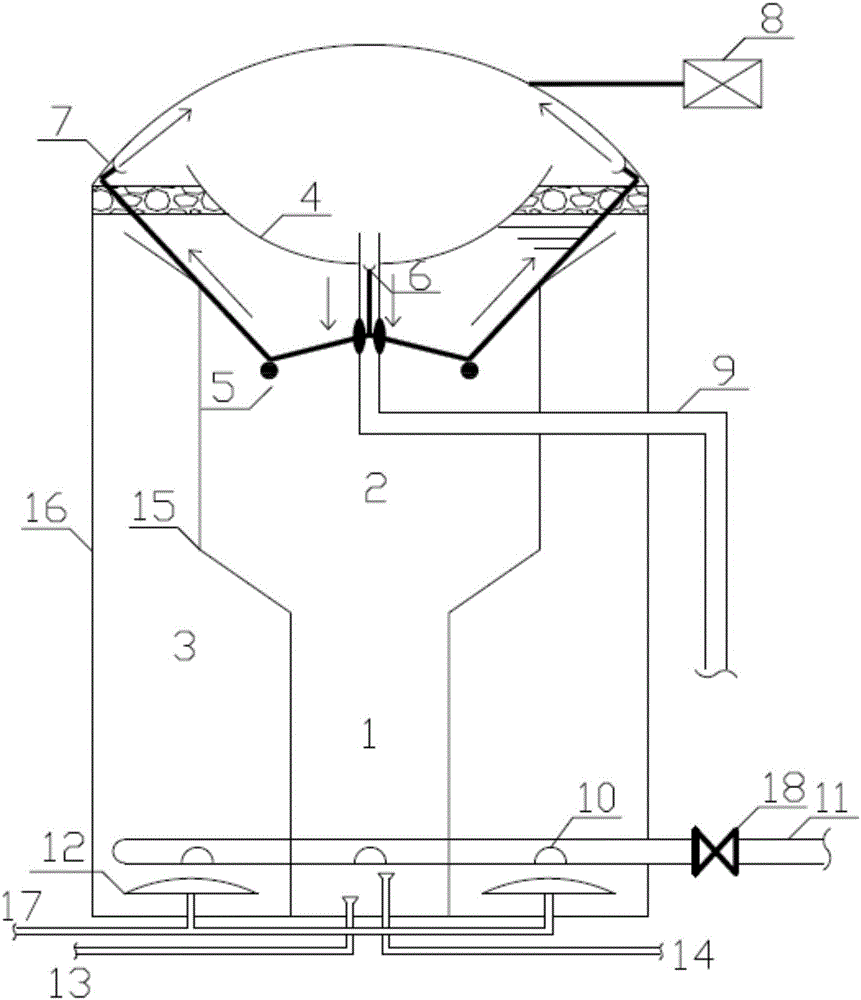

Radially combined multistage ozone air floatation device

ActiveCN106277151ASmall footprintSimple handling of equipmentSpecific water treatment objectivesWater/sewage treatment apparatusPipingSlag

The invention relates to a radially combined multistage ozone air floatation device. The radially combined multistage ozone air floatation device comprises an inner barrel cylinder and an outer barrel cylinder which share the bottom surface, wherein an annular water collecting pipe is arranged at the bottom of the inner barrel cylinder and the outer barrel cylinder, water collecting holes formed in the annular water collecting pipe are distributed in the inner barrel cylinder and the outer barrel cylinder respectively, the inner barrel cylinder is sequentially a contact zone and a separation zone from the bottom to the top, the top of the inner barrel cylinder is open, the top of the outer barrel cylinder is closed, a slag scraping device is arranged in front of the top of the inner barrel cylinder and the outer barrel cylinder, an ozone oxidation zone is arranged between the inner barrel cylinder and the outer barrel cylinder, and an aeration disc is arranged at the bottom of the ozone oxidation zone. The radially combined multistage ozone air floatation device has the advantages that an ozone air floatation unit and an ozone oxidation unit are radially combined, treatment device is optimized, floor area of equipment is reduced, and low energy consumption deslagging is completed by virtue of rise and fall of liquid level; and by virtue of combination of a deslagging device and an overflow deslagging way, scum is thoroughly eliminated, and treatment efficiency of the multistage ozone air floatation device is improved.

Owner:陕西建科源环境工程有限公司

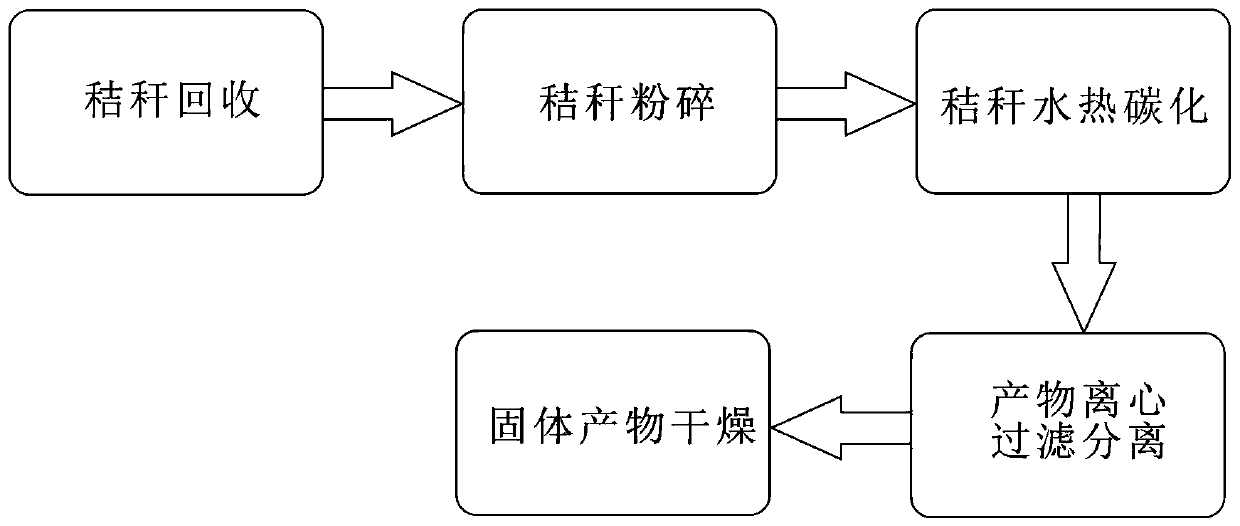

Method for preparing straw biochar by hydrothermal carbonization

InactiveCN110407191AIncrease profitImprove efficiencyCarbon preparation/purificationEconomic benefitsHydrothermal carbonization

The invention discloses a method for preparing straw biochar by hydrothermal carbonization. The method comprises the following steps that S1, straw is crushed and mixed with water, wherein the solid-liquid ratio of the straw to the water is (10:5)-(20:1); S2, the mixture is introduced into a hydrothermal carbonization reaction tank for a hydrothermal carbonization reaction; S3, a product of the hydrothermal carbonization reaction is cooled, filtered, separated and dried to obtain the straw biochar. The method has the advantages that a new straw recycling mode is provided, the process is simple, the potential of carbon fixation and emission reduction is increased, and the comprehensive utilization rate and economic benefit of the straw are increased.

Owner:厦门丰同科技有限公司

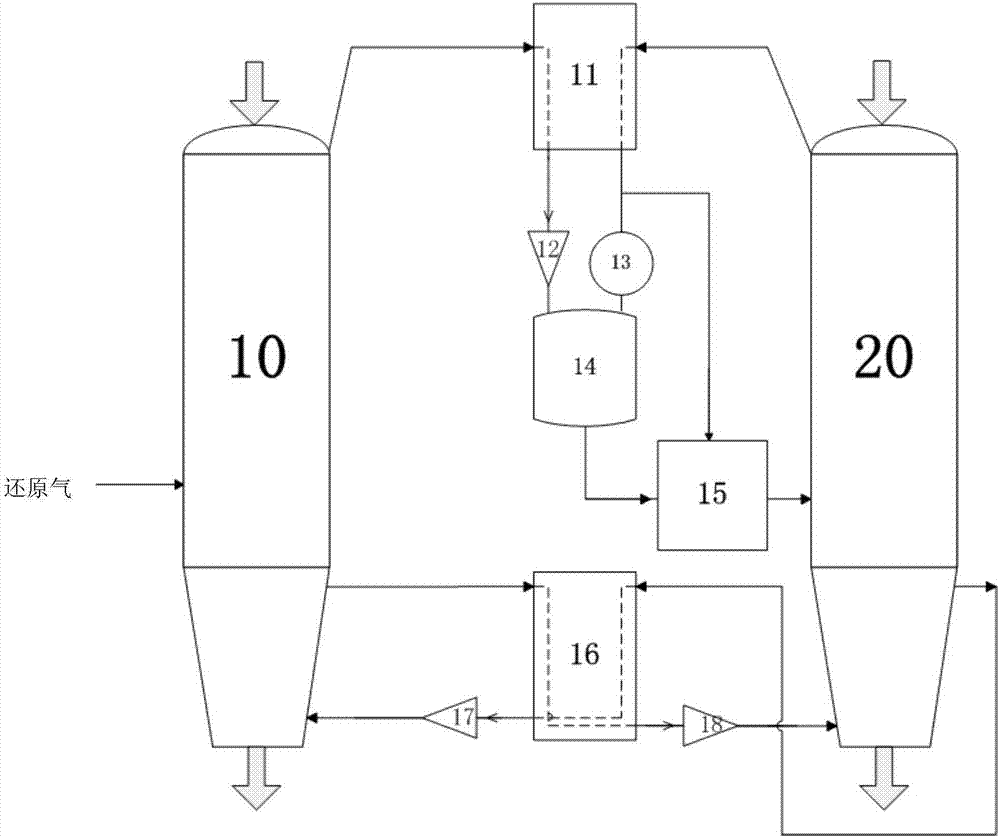

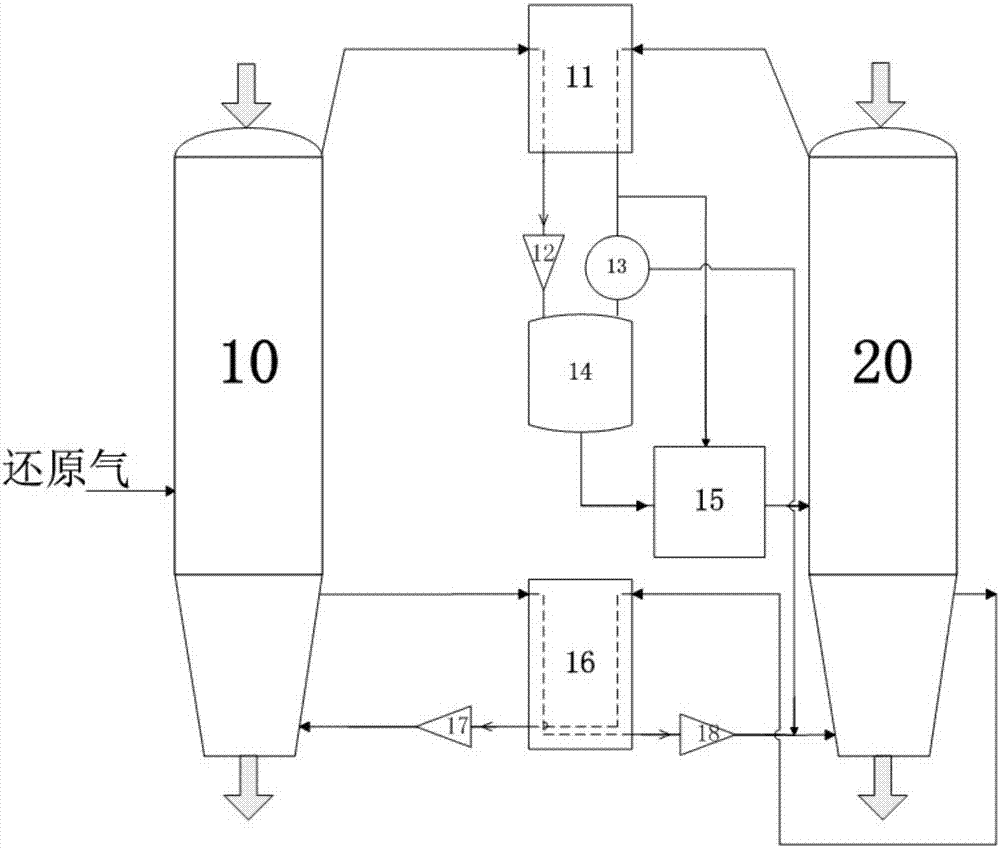

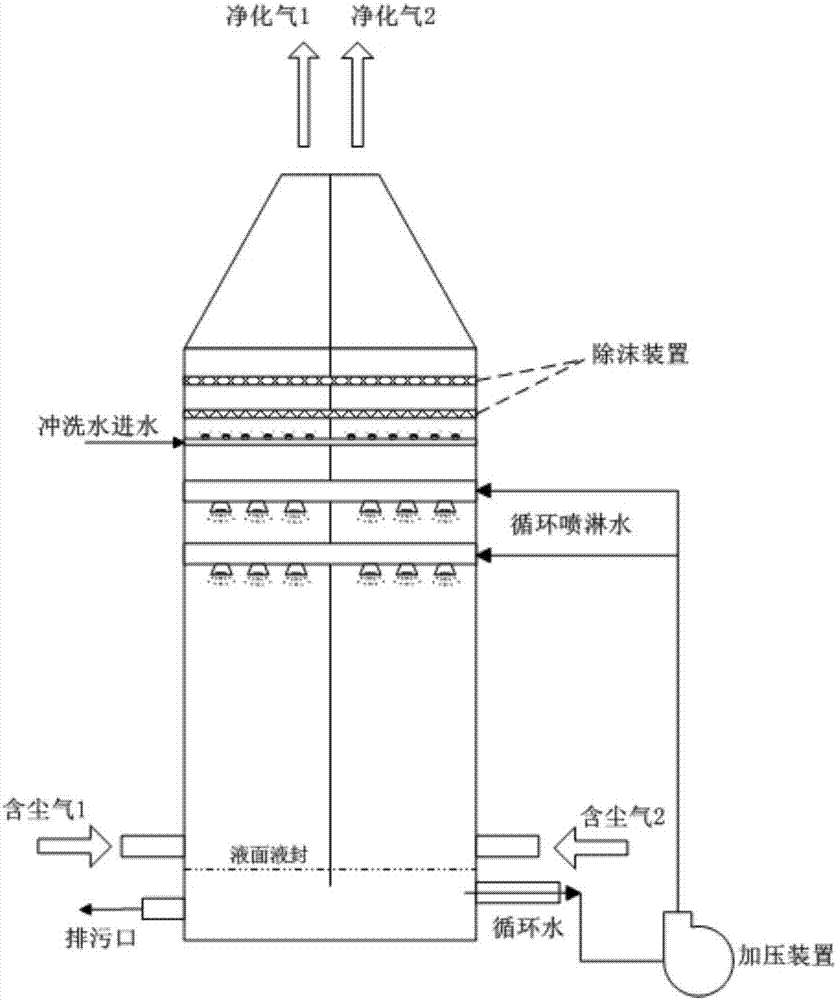

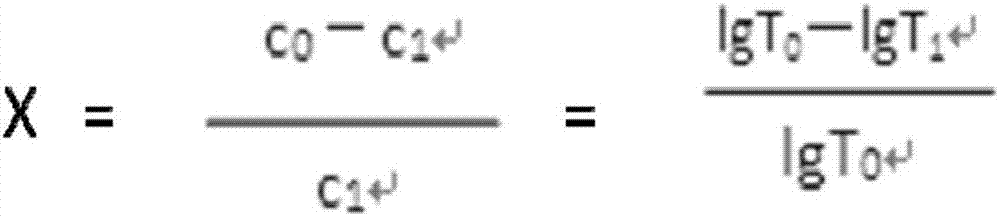

Double-shaft-furnace joint production system and method for treating two paths of gas with single bath towers

PendingCN107513597AImplement Gradients usingIncrease profitShaft furnaceGas emission reductionTitaniumEngineering

The invention discloses a double-shaft-furnace joint production system for treating two paths of gas with single bath towers. The system comprises a first shaft furnace, the top gas bath tower, a first pressure reducing device, a CO2 remover, a mixing tank, a heating furnace, a second shaft furnace, the cooling gas bath tower, a second pressure reducing device, a pressure boosting device and connecting pipelines between all the parts. Meanwhile, the invention discloses a method for joint production of iron-containing products with the system. According to the double-shaft-furnace joint production system, the sefstromite shaft furnace and the iron ore concentrate shaft furnace are coupled, the pressure difference of the two shaft furnaces and the H2 / CO ratio difference of two reducing gas ingredients are fully utilized in the production process, pressure and ingredient gradient utilization is realized, the utilization rate of resources and energy is increased, and vanadium-and-titanium-enriched sponge iron and sponge iron products are produced; and in addition, the same bath tower device is adopted according to the design of the two shaft furnaces, matched equipment investment is reduced while top gas and cooling gas are treated, and system equipment is effectively simplified.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Refining method for glycol

ActiveCN107973699AImprove UV transmittanceEasy to manufactureOrganic compound preparationHydroxy compound preparationHydrogenAlloy

The invention provides a refining method for glycol. The method comprises a step of subjecting a compound hydrogenation catalyst, hydrogen, coconut shell charcoal and a crude glycol product to a contact reaction, wherein a mass ratio of the coconut shell charcoal to the compound hydrogenation catalyst is 1: 10 to 20: 1; the total mass of the coconut shell charcoal to the compound hydrogenation catalyst is 1 to 10 wt% of the mass of the crude glycol product; and the compound hydrogenation catalyst comprises continuous-phase carbon and dispersion-phase Raney alloy particles, the dispersion-phaseRaney alloy particles are uniformly or nonuniformly dispersed in the continuous-phase carbon, and the continuous-phase carbon is prepared by carbonizing carbonizable organic matters or mixtures thereof. The method provided by the invention is high in glycol product treatment efficiency, simple in treatment equipment and low in investment.

Owner:CHINA PETROLEUM & CHEM CORP +1

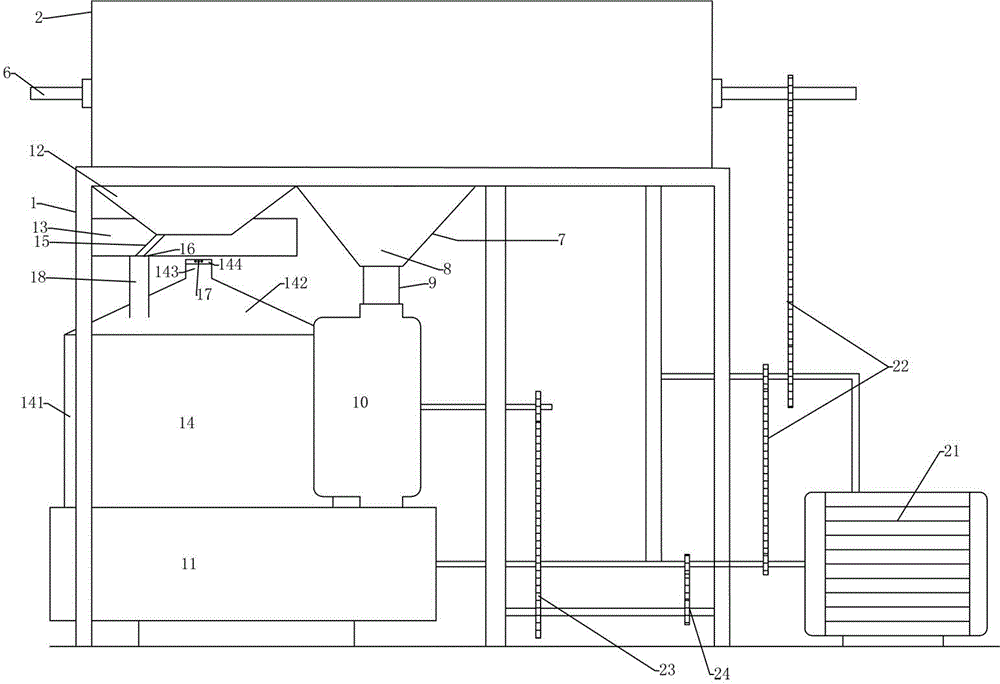

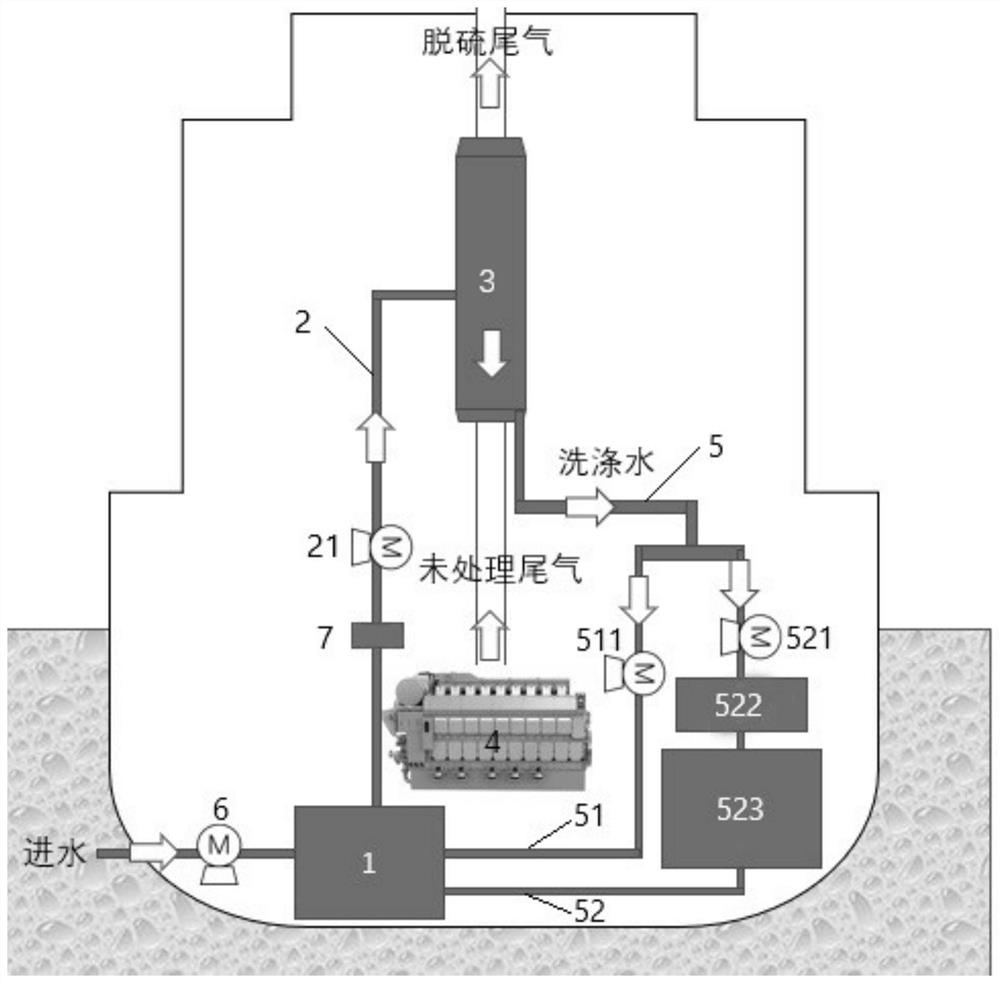

Advanced treatment and recycling device for ship tail gas desulfurization washing wastewater

PendingCN112919707AEfficient degradationCompletely degradedWater/sewage treatment by irradiationWater treatment compoundsWater circulationPollutant

The invention discloses an advanced treatment and recycling device for ship tail gas desulfurization washing wastewater. The device comprises a washing water storage tank, a washing water circulation pipeline, a filter and a wastewater treatment device, wherein the washing water storage tank is connected with a washing tower; one end of the washing water circulation pipeline is connected with the bottom outlet of the washing tower, and the other end is divided into a first circulation pipeline and a second circulation pipeline; the wastewater treatment device comprises an ultrasonic assembly, a photocatalysis assembly and an ultrafiltration assembly; the first circulation pipeline is connected with the washing water storage tank to form a first circulation system; and the second circulation pipeline is sequentially communicated with the filter, the wastewater treater and the washing water storage tank to form a second circulation system. According to the device, washing wastewater is treated by adopting a filtering and ultrasonic coupling multi-phase photocatalytic oxidation reaction technology, so that pollutants in the wastewater can be efficiently and thoroughly removed, and the cyclic utilization rate of washing water is also improved; and meanwhile, no chemicals are introduced for treating the washing wastewater, so that the negative influence on the ecological environment is small.

Owner:SHANGHAI MARITIME UNIVERSITY

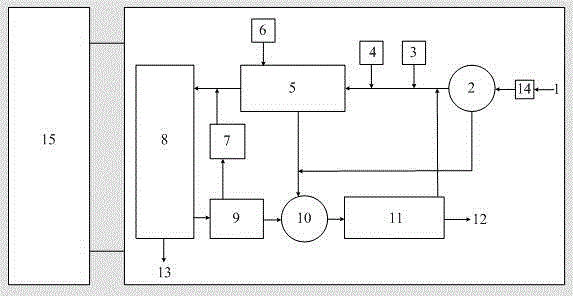

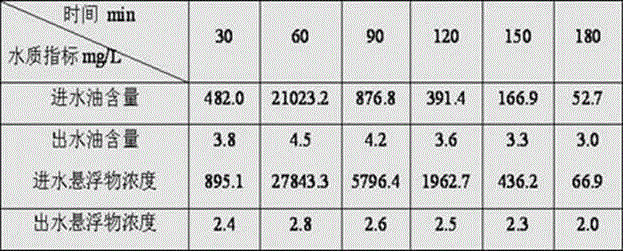

Mobile well flushing waste water processing system

ActiveCN104609635AFacilitate solid-liquid separationSimple handling of equipmentMultistage water/sewage treatmentFilling materialsWater quality

The invention discloses a mobile well flushing waste water processing system. According to the mobile well flushing waste water processing system, sand settling-high efficiency floating-magnetic separation combined process is adopted to process well flushing waste water, and mud cake obtained via magnetic separation is subjected to overlapping type dewatering. The mobile well flushing waste water processing system is high in processing efficiency; multistage filtering or multistage air floatation equipment is not needed; using of a large amount of backwashing water and changing of filling materials are avoided; and continuous processing can be realized. No filtering equipment is used; removing effect of oil and suspended materials is excellent; real-time monitoring on oil content of water can be realized; automatic adjusting on adding amount of flocculating agents is realized; and the floating process is high in efficiency and is reliable. Water processed by using the mobile well flushing waste water processing system is capable of reaching water quality indexes of oil field injection water quality standards and discharged water quality standards; and sludge size is reduced by processing mud cake, which is obtained via magnetic separation, using a sludge water extractor.

Owner:CHINA PETROLEUM & CHEM CORP +1

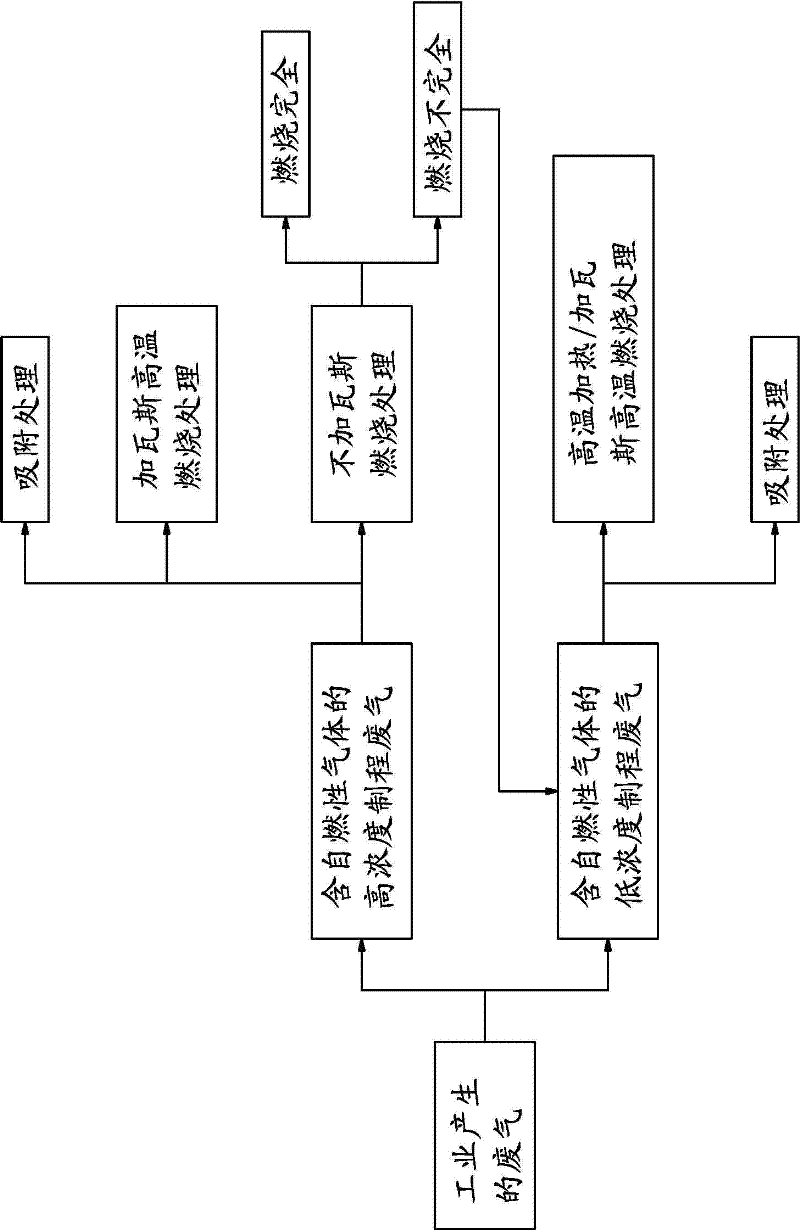

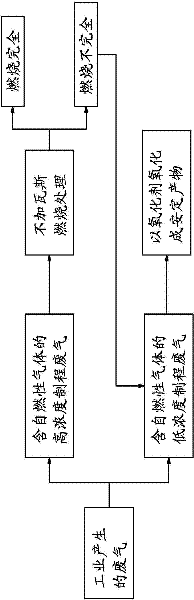

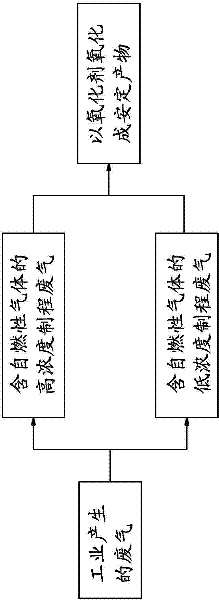

Method for treating waste gas containing spontaneously-combustive gas

InactiveCN102631831AAvoid energy consumptionSimple handling of equipmentDispersed particle separationCombustionRedox

The invention discloses a method for treating waste gas containing spontaneously-combustive gas. A stability product can be generated by enabling an oxidant and spontaneously-combustive gas to have an oxidization-reduction reaction, so as to solve the problems in the prior art that the energy consumption is high and the cost of treating equipment is high by taking high-temperature heating oxidization or high-temperature combustion oxidization as a treating manner. The method for treating waste gas containing the spontaneously-combustive gas disclosed by the invention can provide a novel waste gas treating method of an industry of science and technology.

Owner:KUN SHAN UNIVERSITY

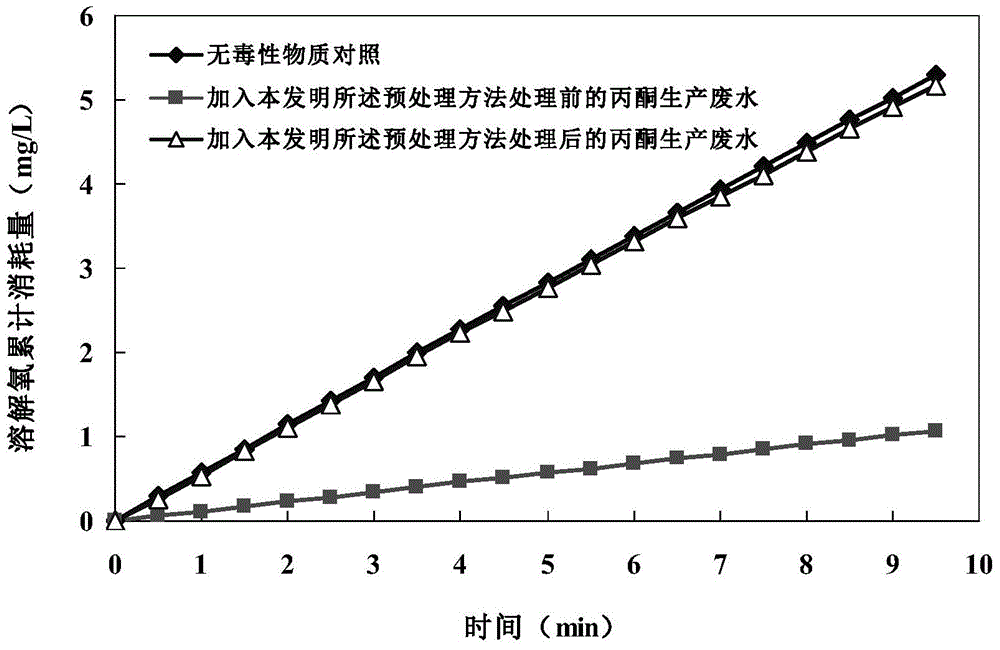

Method for treating wastewater generated in acetone production process

InactiveCN104355501ALow toxicityLow oxygen consumption rateTreatment using aerobic processesWater treatment compoundsChemical oxygen demandSludge

The invention discloses a method for treating wastewater generated in an acetone production process, which comprises the following steps: (1) wastewater pretreatment: (2) aerobic biological treatment: adding a nitrogen source nutrient substance, a phosphorus source nutrient substance and a trace nutrient substance into the pretreated wastewater, and carrying out aerobic biological treatment; and (3) suspended organic matter removal: sending the wastewater subjected to aerobic biological treatment into a precipitation tank or floatation tank to perform sludge-water separation, wherein no acetone is detected in the effluent water, and the COD (chemical oxygen demand) content is lowered to 100 mg / L below. The method disclosed by the invention has the advantages of high treatment load, stable operation and low treatment cost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

System for treating high-concentration VOCs gas and workflow thereof

InactiveCN109126421AImprove processing efficiencySimple handling of equipmentGas treatmentDispersed particle separationHigh concentrationOzone generator

The invention discloses a system for treating high-concentration VOCs gas and a work flow thereof. The system comprises an ozone generator, a microbubble generator and a reactor, wherein the inlet ofthe ozone generator is communicated with the outlet of an oxygen bottle; the outlet of the oxygen bottle is communicated with the microbubble generator; the water / gas outlet of the microbubble generator is communicated with the bottom of the reactor and adopts a sealed structure; a tail gas emission pipe is arranged at the top of the reactor. The system takes water as an absorbing / reaction medium,produces ozone / VOCs gas mixed gas microbubble through the microbubble generator, performs rapid absorbing and rapid oxidation in the water medium to remove VOCs gas, can efficiently purify the high-concentration VOCs gas, and does not produce secondary pollutant during treatment; the system provides a novel available technology for high-concentration VOCs gas treatment.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

System for treating desulfurization wastewater of coal-fired power plant by magnetic coagulation

InactiveCN112591952AGood removal effectImprove settlement characteristicsWater contaminantsWater/sewage treatment by magnetic/electric fieldsThermodynamicsSludge

The invention relates to a system for treating desulfurization wastewater of a coal-fired power plant by magnetic coagulation. The system consists of a dosing tank, a stirring device, a stirring speeddistribution box, a water inlet controller, a rotary decanter, a submersible sewage pump and a rotary drum type magnetic mud sorting device. The treatment course comprises the following specific steps: the desulfurization wastewater enters a reactor from the bottom through a water inlet controller; a PAC coagulant and magnetic powder are added from the dosing tank, stirring is conducted for 1 minat a speed of 50 r / min, a PAM coagulant aid is added, stirring is conducted for 2 min at a speed of 250 r / min, stirring is conducted for 6 min at a speed of 50 r / min, standing is conducted for 30 minafter stirring is finished, supernatant in the reactor is guided out through the rotary decanter, desulfurization wastewater is injected, the above operations are repeated, the water outlet controller is turned on when bottom flocs reach the maximum storage capacity, the bottom flocculate is conveyed into a magnetic mud separator for separation, the separated magnetic powder can be repeatedly utilized, and the sludge is subjected to solidification treatment.

Owner:中能化江苏地质矿产设计研究院有限公司

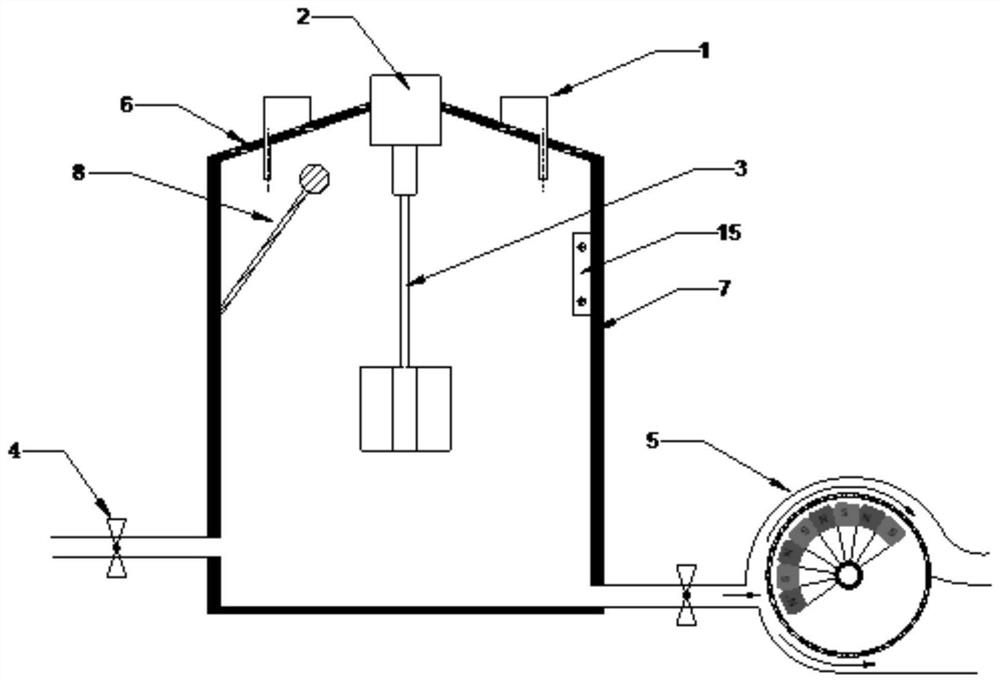

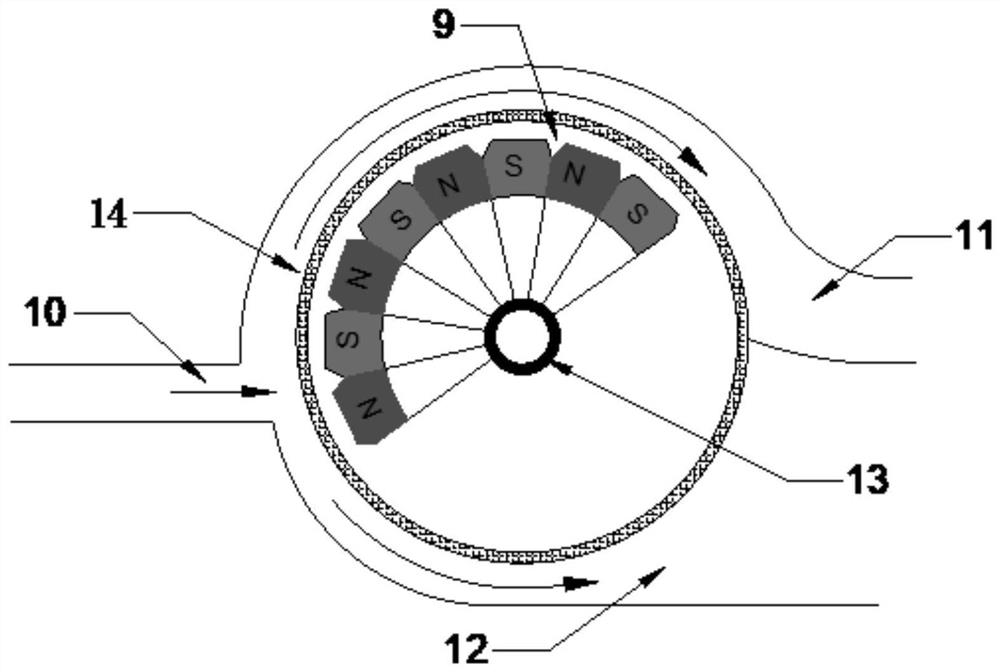

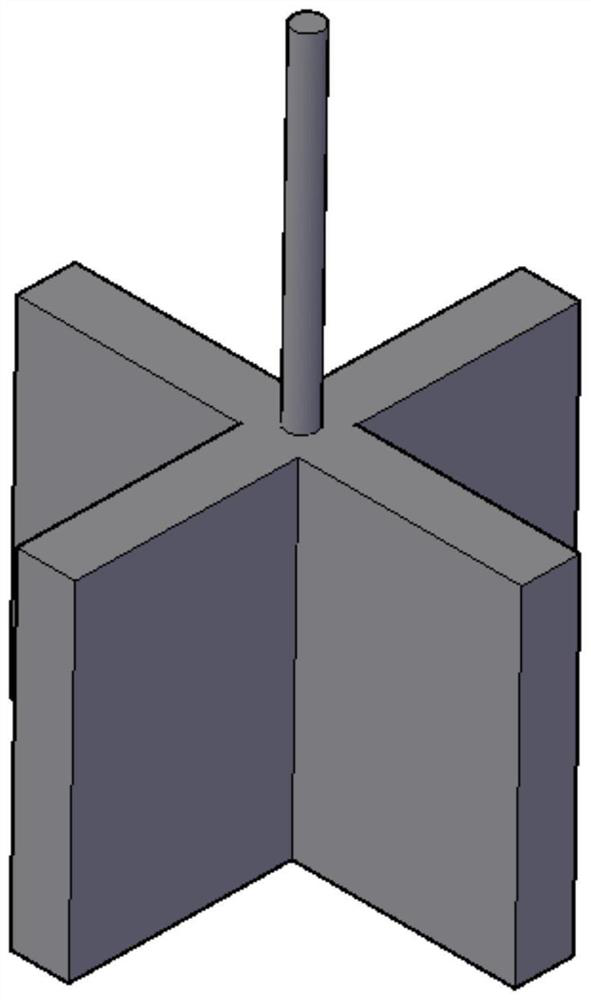

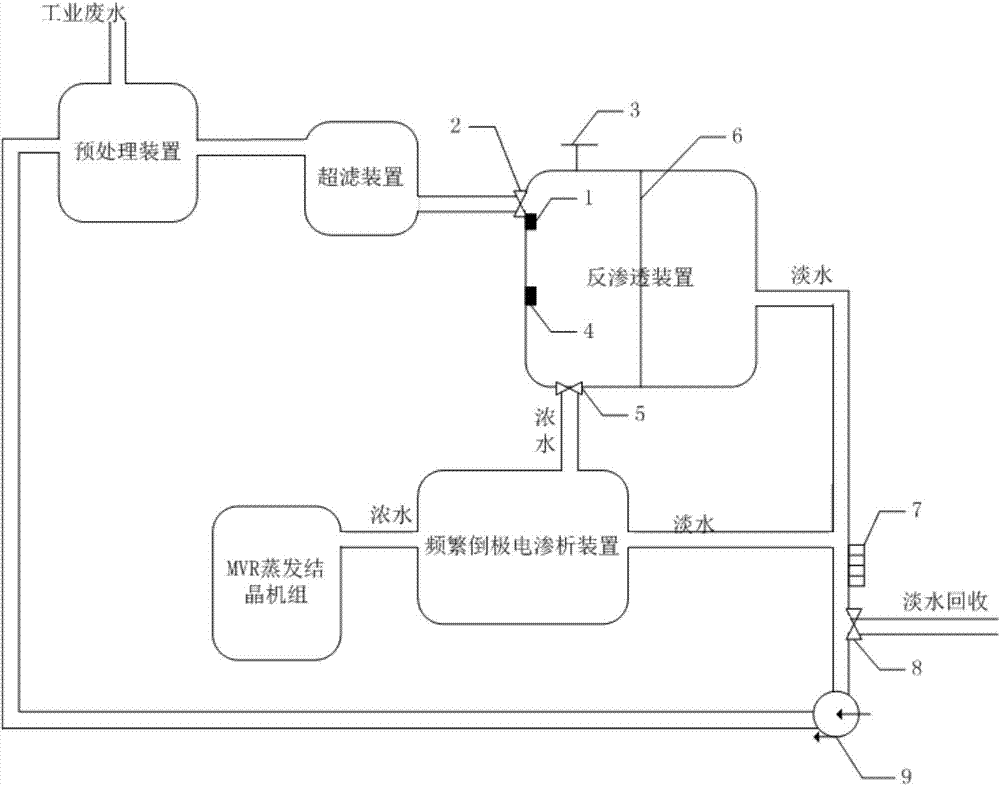

Industrial wastewater treatment equipment and method

InactiveCN106977037AReduce evaporationReduce consumptionTreatment involving filtrationMultistage water/sewage treatmentHigh energyUltrafiltration

The invention relates to the field of industrial wastewater treatment, in particular to an industrial wastewater treatment equipment and method, aiming to solve the problems of large-scale wastewater treatment with high equipment investment, high energy consumption, low equipment efficiency and low fresh water recovery rate at present. The industrial wastewater treatment equipment comprises a pretreatment device, an ultrafiltration device, a reverse osmosis device, a first liquid-level sensor, a first valve, a pressure charging valve, a second liquid-level sensor, a second valve, a semipermeable membrane based frequently electrode polarity changing electrodialysis device, an MVR evaporative crystallization unit and a water pump. The wastewater is subjected to pretreatment, ultrafiltration, reverse osmosis, frequently electrode polarity changing electrodialysis, the primarily treated wastewater is then returned to the equipment through the water pump for realizing circular process; thus, wastewater treatment efficiency and fresh water recovery rate are both increased. The industrial wastewater treatment equipment and method is applicable to wastewater treatment systems for large factories.

Owner:HARBIN BOILER

Method for preparing poultry and pig manure as well as discarded animals and plants into feed through sulfuric acid sterilization and organism fermentation

The invention discloses a method for preparing poultry and pig manure as well as discarded animals and plants into feed through sulfuric acid sterilization and organism fermentation, which is characterized in that poultry and pig manures as well as discarded animals and plants, which are not seriously rotten and spoiled, are used as raw materials and sterilized with sulfuric acid, neutralized with ammonium bicarbonate and fermented with feed yeast to be prepared into the safe high-efficiency feed, therefore, recycling of the wastes are realized with greatly increased value, meanwhile, the problem of environmental pollution by the poultry and pig manure as well as the discarded animals and plants is solved, and the obtained feed products are safe and high-efficiency and can guarantee animal meat quality. The invention has simple processing equipment, convenient operation, low cost, is suitable for both factorized production and culturist use.

Owner:衡山卓越能源科技有限责任公司

Method for extracting lycium barbarum polysaccharide

The invention discloses a method for extracting lycium barbarum polysaccharide. The method for extracting the lycium barbarum polysaccharide comprises the following steps: A, weighing a certain weightof lycium barbarum, performing vacuum freeze drying, crushing and passing through a sieve of 60 to 80 meshes; B, taking the sieved dried lycium barbarum powder, adding 700 to 900 ml of water into per100 g of lycium barbarum according to the material liquid ratio, and stirring uniformly; C, adding cellulase and papain, putting into ultrasonic extraction equipment and extracting enzymolysis liquid; D, filtering the enzymolysis liquid to obtain filtrate, adding absolute ethanol into the filtrate according to the ratio of 1:4, precipitating and standing at 4 DEG C for 24 hours, centrifuging for15 minutes at the centrifugal rotating speed of 5000 rpm, collecting the precipitate, performing freeze drying, crushing and passing through a 80-mesh sieve to obtain soluble polysaccharide. Enzymolysis is assisted by high-frequency ultrasonic treatment, so that the obtaining time of the lycium barbarum polysaccharide is greatly shortened, the polysaccharide extraction rate is relatively high on the premise of guaranteeing the purity of the lycium barbarum polysaccharide, treatment equipment is simple, a toxic organic solvent is not used, and industrialization is facilitated.

Owner:邱媛媛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com