Radially combined multistage ozone air floatation device

A technology of ozone flotation and ozone, applied in flotation water/sewage treatment, oxidized water/sewage treatment, special treatment targets, etc., can solve problems such as adhesion, save energy consumption, improve treatment efficiency, and save land occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

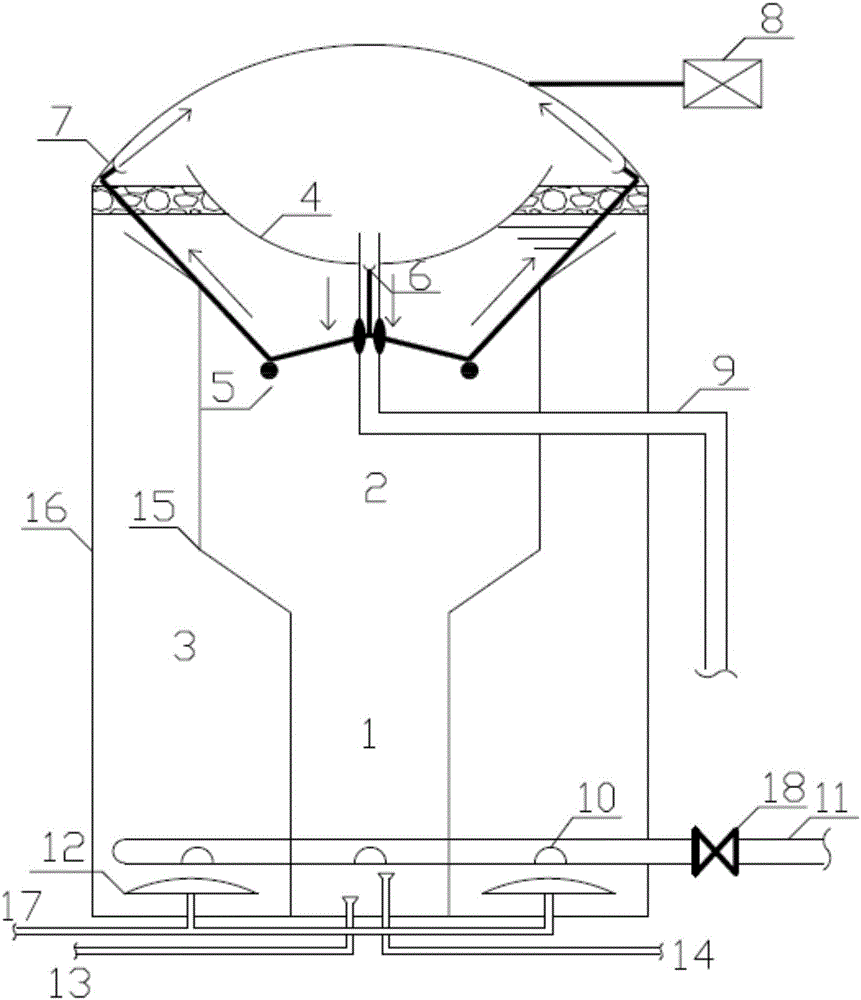

[0016] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0017] Such as figure 1 As shown, a radially combined multi-stage ozone flotation device, the bottom surface of the inner cylindrical body 15 and the outer cylindrical body 16 are concentric circles, and the bottoms of the inner cylindrical body 15 and the outer cylindrical body 16 are provided with an annular water collecting pipe 11, The water collecting holes 10 opened on the annular water collecting pipe 11 are all distributed in the inner cylindrical body 15 and the outer cylindrical body 16 .

[0018] The inner cylinder 15 is a contact zone 1 and a separation zone 2 in sequence from the bottom to the top. The top of the inner cylinder 15 is open, and the top of the outer cylinder 16 is closed. Between the inner cylinder 15 and the outer cylinder 16 It is the ozone oxidation zone 3, and the bottom of the ozone oxidation zone 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com