Method for preparing straw biochar by hydrothermal carbonization

A hydrothermal carbonization and straw biotechnology, which is applied in the preparation/purification of carbon, can solve the problems of ineffective resource utilization of agricultural and forestry wastes, low degree of resource utilization of agricultural and forestry wastes, and small scale of comprehensive utilization enterprises. Improve comprehensive utilization and economic benefits, improve soil and fertilizer efficiency, and save pretreatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

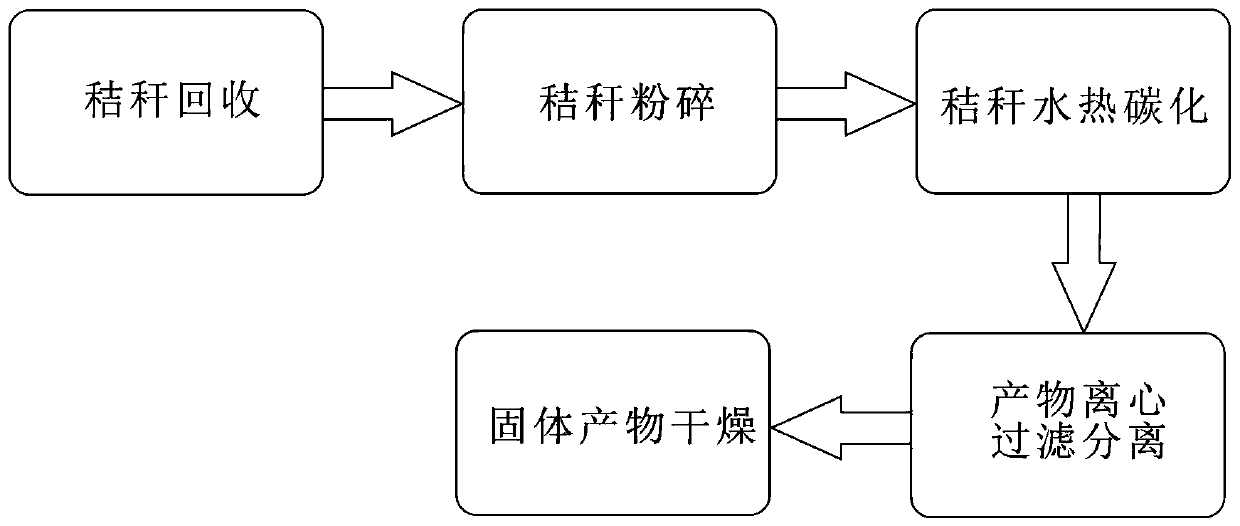

[0043] like figure 1 As shown, the preparation of straw biochar by hydrothermal carbonization is prepared according to the following steps:

[0044] Step 1. Recycling of tangerine stalks: after harvesting, recycle the remaining stalks.

[0045] Step 2, crushing of straw: crushing the straw to obtain small particles and small blocks of raw materials (less than 3 cm in length), which are stored for later use.

[0046] Step 3. Hydrothermal carbonization of straw: mix the straw with water, introduce it into a hydrothermal carbonization reaction tank, ensure that the hydrothermal carbonization reaction tank is airtight, and heat for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 200-270°C and the pressure is 5-30bar , the reaction time is 1.5-3h, and the ratio of straw raw material to water to solid to liquid is 10:2.

[0047] Step 4, filtration and separation of solid and liquid phase products: after the hydrothermal carbonization process ends, sto...

Embodiment 2

[0055] With reference to embodiment 1, different from embodiment 1 is:

[0056] Dry corn stalks after reaction conditions: temperature 270°C, pressure 10bar, time 2hr

[0057] Corn stalks before reaction: 8.01% ash, 75% moisture, calorific value 2670Kcal / kg

[0058] Corn carbon after reaction: ash content 7.15%; water content 38%, calorific value 5534kcal / kg

[0059] After the reaction, the ash content is reduced by about 1%, the water content is reduced by about 50%, and the calorific value is about doubled.

Embodiment 3

[0061] With reference to embodiment 1, different from embodiment 1 is:

[0062] Wet wheat straw after reaction conditions: temperature 250°C, pressure 20bar, time 2hr

[0063] Wheat stalk before reaction: 8.45% of ash, 82% of water content, 2574Kcal / kg of calorific value

[0064] Wheat carbon after reaction: ash content 7.61%; water content 40%, calorific value 5074kcal / kg

[0065] After the reaction, the ash content is reduced by about 1%, the water content is reduced by about 50%, and the calorific value is about doubled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com