Industrial wastewater treatment equipment and method

A technology for industrial wastewater and treatment equipment, which is applied in multi-stage water treatment, water/sewage treatment, adsorbed water/sewage treatment, etc. It can solve the problems of large-scale wastewater treatment, large energy consumption, and low freshwater recovery rate. To achieve the effect of reducing the salt penetration rate, increasing the salt rejection rate and increasing the treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

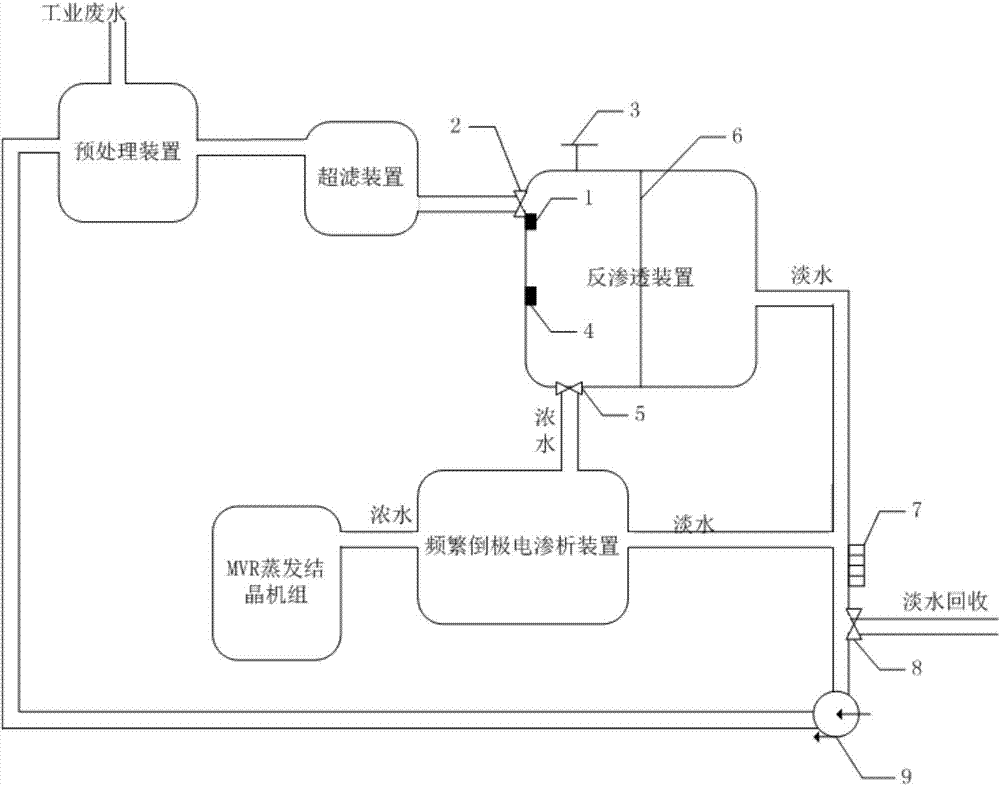

[0024] Specific Embodiment 1: Combining figure 1 Describe this embodiment, the structural diagram of a kind of industrial wastewater treatment equipment of this embodiment is as follows figure 1 As shown, it includes: pretreatment device, ultrafiltration device, reverse osmosis device, frequent electrode reversal electrodialysis device, MVR evaporation crystallization unit and water pump 9;

[0025] The reverse osmosis device includes a housing, a first liquid level sensor 1, a first valve 2, a booster valve 3, a second liquid level sensor 4, a second valve 5 and a semi-permeable membrane 6, and the semi-permeable membrane 6 is vertically Installed directly in the middle of the shell, the inside of the shell is divided into left and right parts, the left part is defined as the concentrated water side, and the right part is defined as the fresh water side, the first liquid level sensor 1, the first valve 2, the booster valve 3, Both the second liquid level sensor 4 and the sec...

specific Embodiment approach 2

[0027] Specific embodiment 2: This embodiment is further limited on the basis of specific embodiment 1. The industrial wastewater treatment equipment also includes a water quality monitor 7, and the water quality monitor 7 is located in the reverse osmosis device and the frequent electrode reversal electrodialysis device At the fresh water outlet, the water quality monitoring instrument 7, the water quality monitoring instrument 7 can monitor whether the fresh water obtained after the wastewater treatment meets the recovery standard, if not, then close the fresh water valve 8, continue the circulation process until the water quality reaches the standard, and then open Fresh water valve 8, recycles fresh water.

specific Embodiment approach 3

[0028] Specific embodiment 3: a kind of wastewater treatment method of industrial wastewater treatment equipment, is characterized in that, comprises the following steps:

[0029] Step 1: Wastewater flows into the pretreatment device for filtration to remove undissolved impurities in the wastewater;

[0030] Step 2: Perform ultrafiltration on the pretreated wastewater to retain colloid-sized particles in the water. The operating pressure is 0.11-0.6Mpa and the temperature is 20°C;

[0031] Step 3: Set the pressure to 0.5Mpa, the temperature to 20°C, and inject the waste water into the reverse osmosis device. When the water level is below the position of the first liquid level sensor 1, the first valve 2 will be automatically closed, and the pressure of the reverse osmosis device will be controlled by the booster valve 3. The concentrated water side is pressurized, so that the water molecules on the concentrated water side move further to the fresh water side, and the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com