Method for removing anion surfactant from waste water

A surfactant and anion technology, applied in the field of removing anionic surfactants in wastewater, can solve the problems of affecting the electrolytic removal rate, high energy consumption, and high operating costs, and achieve renewable and cyclic use of treatment costs, simple treatment equipment, and technology. short route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

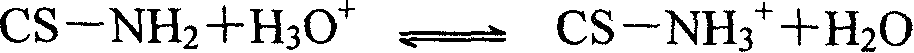

Method used

Image

Examples

Embodiment Construction

[0015] 1. Preparation of adsorbent: first dissolve chitosan with 0.1mol / L hydrochloric acid aqueous solution to form chitosan hydrochloride aqueous solution, and then soak absorbent cotton in this solution for 1-2 hours. Add 0.1 mol / L sodium hydroxide water dropwise to adjust the pH of the solution to slightly alkaline, allowing the dissolved chitosan to precipitate and adsorb on the cellulose. After washing with water and drying at 50°C, the cellulose-immobilized chitosan adsorbent is prepared.

[0016] 2. Wastewater pretreatment: Add 0.1mol / L hydrochloric acid aqueous solution to the wastewater containing anionic surfactants to adjust the pH of the wastewater to 5±0.5, let it stand for 4 hours, and filter to remove insoluble substances.

[0017] 3. Fixed bed adsorption (downflow type): two polyvinyl chloride pipes with a diameter of 0.32 meters and a length of 3 meters are connected in series, and 200 g of cellulose-immobilized chitosan adsorbent is put into each pipe to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com