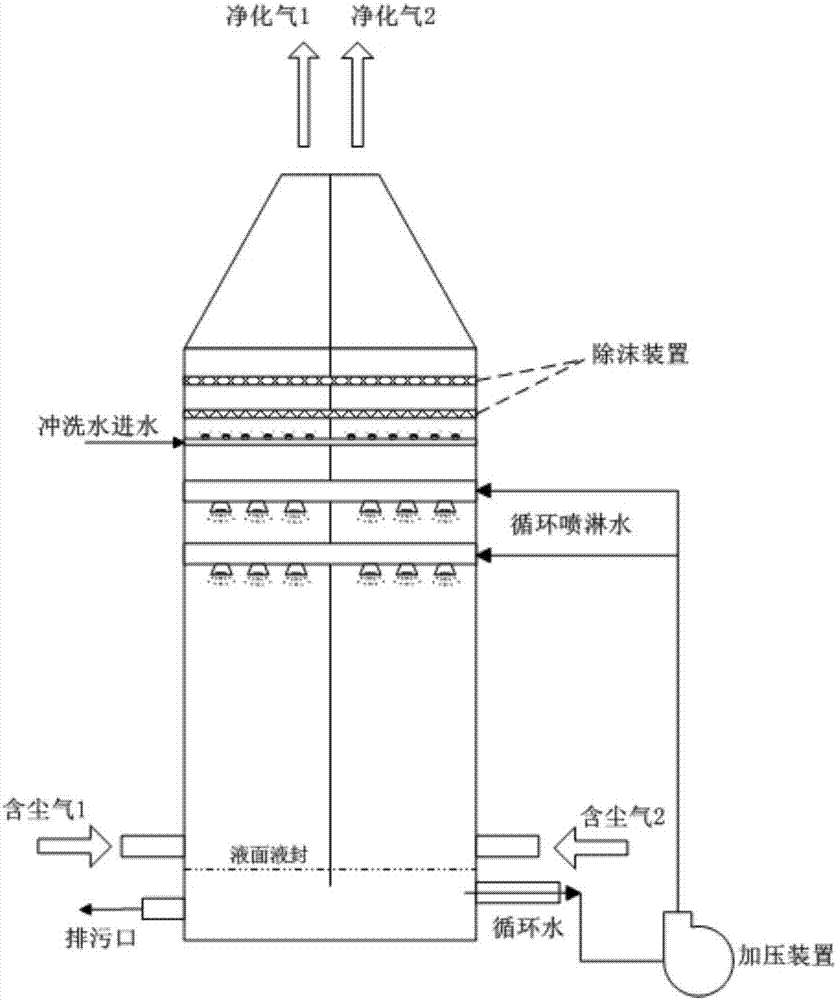

Double-shaft-furnace joint production system and method for treating two paths of gas with single bath towers

A technology of combined production and water washing tower, applied in the field of metallurgy, can solve the problem of low utilization rate of resources, and achieve the effect of simplifying gas processing equipment, improving energy utilization rate, and reducing equipment input cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

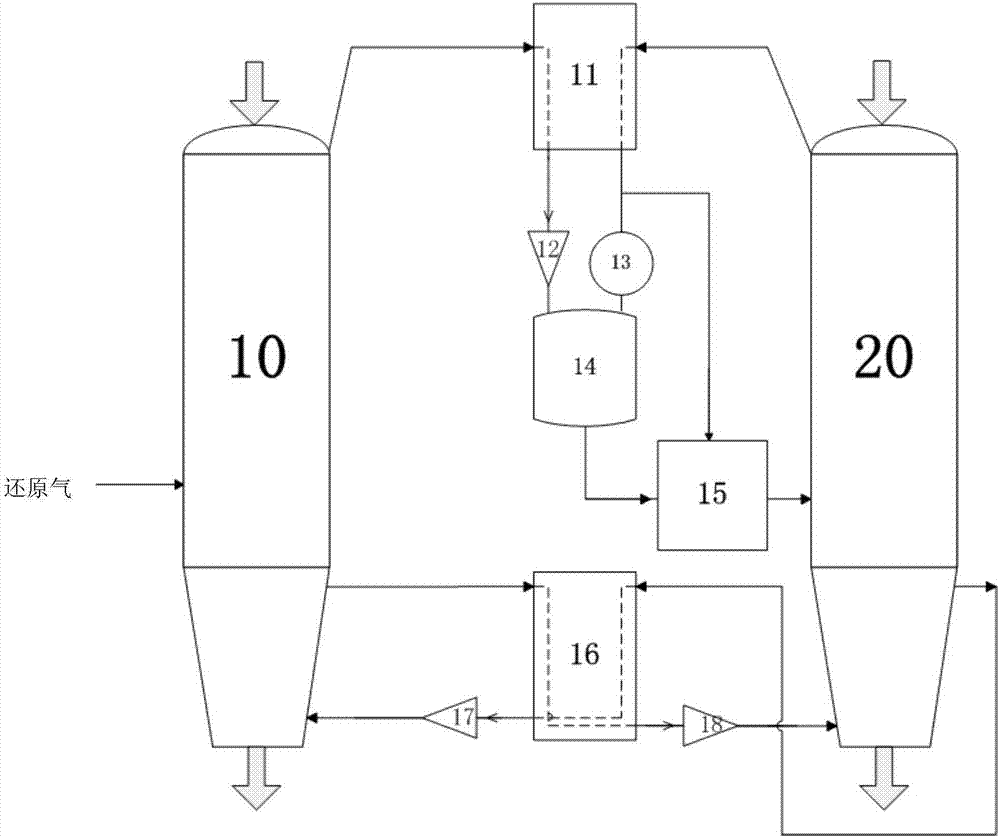

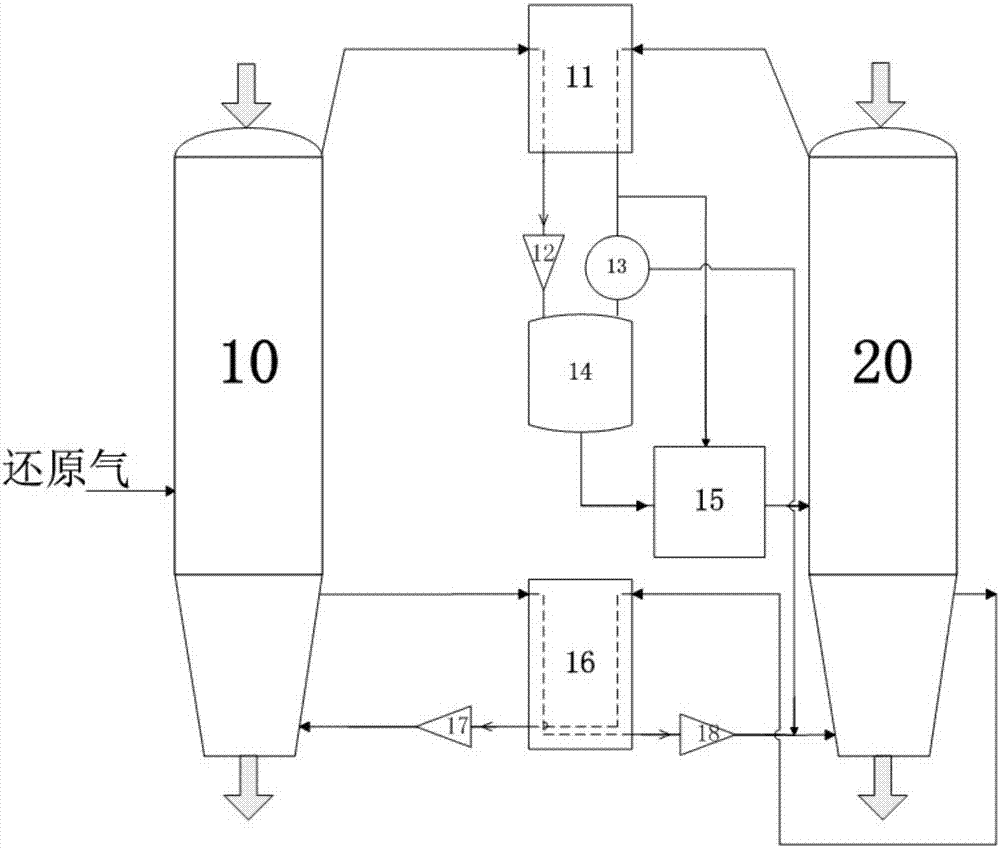

[0069] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and the reducing gas volume of the first shaft furnace is 1000Nm 3 / h, the composition ratio is H 2 With a volume ratio of 5 to CO, the effective reducing gas (H 2 +CO) volume ratio ≥ 0.90, the temperature is 1050° C., the pressure reaches 0.7 MPa, react in the first shaft furnace 10 to produce vanadium-titanium sponge iron and the first top gas. The pressure of the first top gas is 0.65MPa after it is passed into the top gas water washing tower 11, and the pressure is adjusted to 0.2MPa at the pressure reducing valve 12, and then this gas enters the mixing tank 14. After the second top gas is passed into the top gas washing tower 11, most of it passes through the CO 2 After removing the device 13, it enters the mixing tank 14, and the remaining small part is used as the fuel gas of the heating furnace 15. The gas volume in the mixing ta...

Embodiment 2

[0072] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and the gas volume of the reducing gas in the first shaft furnace is 1000Nm 3 / h, the composition ratio is H 2 With a volume ratio of 4 to CO, the effective reducing gas (H 2 +CO) volume ratio ≥ 0.90, the temperature is 1000°C, the pressure reaches 0.4MPa, react in the first shaft furnace 10 to produce vanadium-titanium sponge iron and the first top gas. The pressure of the first furnace top gas is 0.3MPa after being passed into the furnace top gas water washing tower 11, and the pressure after water washing is 0.25MPa, and directly enters the mixing tank 14 without decompression. After the second top gas is passed into the top gas washing tower 11, most of it passes through the CO 2 After removing the device 13, it enters the mixing tank 14, and the remaining small part is used as the fuel gas of the heating furnace 15. The gas volume i...

Embodiment 3

[0075] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and the reducing gas volume of the first shaft furnace is 1000Nm 3 / h, the composition ratio is H 2 With a volume ratio of 3 to CO, the effective reducing gas (H 2 +CO) volume ratio ≥ 0.85, the temperature is 1000° C., the pressure reaches 0.5 MPa, react in the first shaft furnace 10 to produce vanadium-titanium sponge iron and the first top gas. The pressure of the first top gas is 0.4MPa after it is passed into the top gas water washing tower 11, and the pressure is adjusted to 0.15MPa at the pressure reducing valve 12, and then the gas enters the mixing tank 14. After the second top gas is passed into the top gas washing tower 11, most of it passes through the CO 2 After removing the device 13, it enters the mixing tank 14, and the remaining small part is used as the fuel gas of the heating furnace 15. The gas volume in the mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com