Mobile well flushing waste water processing system

A wastewater treatment system and technology of a treatment system, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as inconvenient operation and operation, low treatment efficiency, and long process , to achieve the effect of saving equipment investment and operating costs, reducing COD content, and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

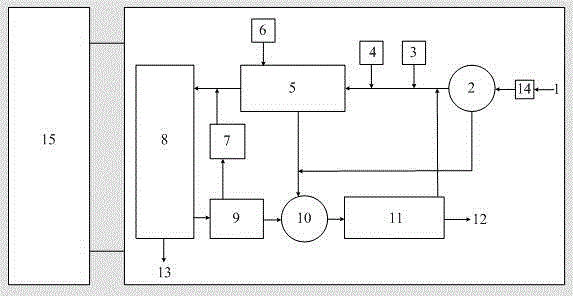

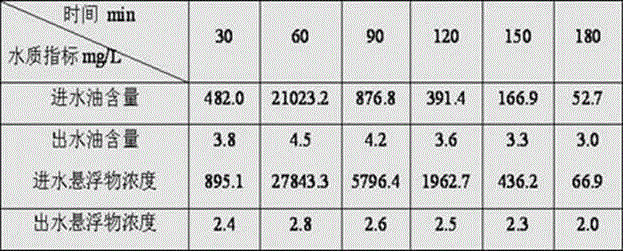

[0027] Such as figure 1 As shown, the mobile well-flushing wastewater treatment system of the present invention is used to treat the well-flushing wastewater of an oilfield. During the well washing process, the quality of the effluent water from the well washing wastewater changes with time. When the water is first spouted, the water quality is relatively clear. After the peak, the water quality gradually improved again. For the influent water in this treatment, the timing starts from the well flushing, and the water inlet of the grit chamber is sampled at intervals of 30 minutes. At the same time, the readings of the oil in water online analyzer are recorded until the well flushing ends after 3 hours. The treated effluent is introduced into the collection tank for recycling. Each influent sample was analyzed for suspended matter content, and each effluent sample was analyzed for oil content and suspended matter content. After all the influent samples were mixed, the COD co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com