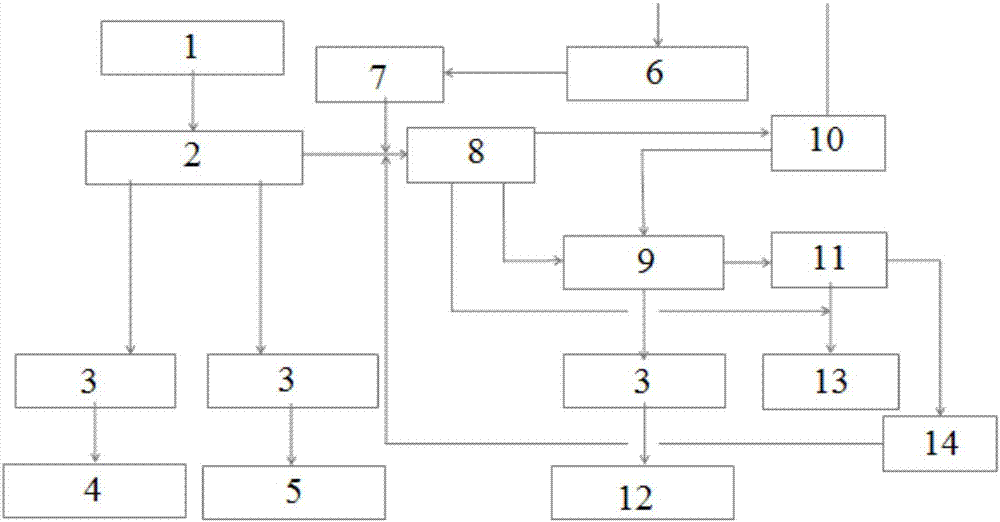

Patents

Literature

61results about How to "In-place processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

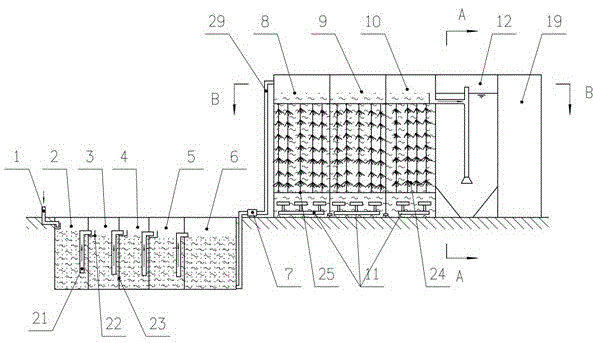

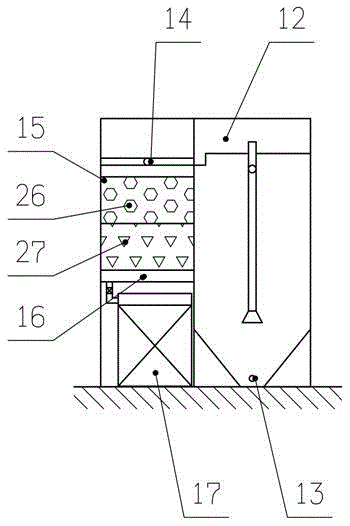

Integrated sewage treatment device with high efficiency and low consumption and treatment method

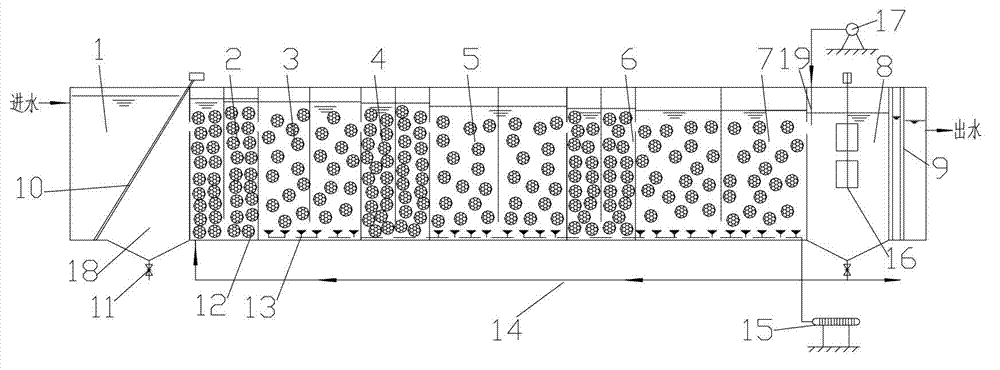

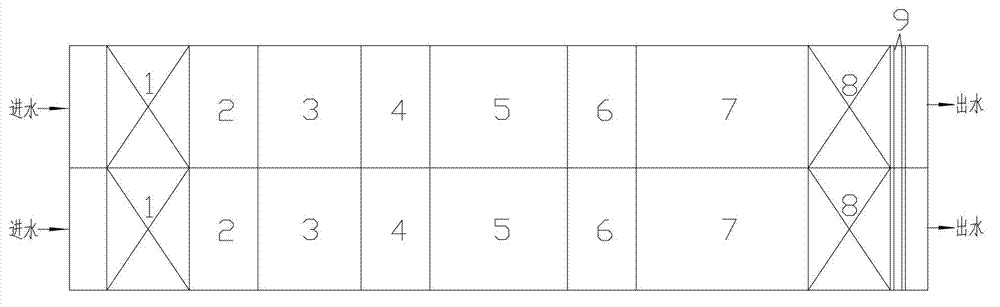

The invention relates to an integrated sewage treatment device with high efficiency and low consumption and a treatment method, and belongs to the field of sewage treatment. The integrated sewage treatment device comprises a pretreatment unit, a multi-oxidation-deoxidation environment coupling biological reaction pond unit and a deep treatment unit sequentially connected. The multi-oxidation-deoxidation environment coupling biological reaction pond unit adopts a three-stage anoxia-aerobiotic alternating reaction pond filled with a circular composite glass ball porous microbial carrier. The deep treatment unit comprises a filter cloth dynamic film biological reaction pond and first and second dynamic films. Sewage is treated through the devices sequentially. The device provided by the invention cannot only remove carbon containing organic matters, but also has good nitrogen and phosphorus removal capacity.

Owner:BEIJING UNIV OF TECH

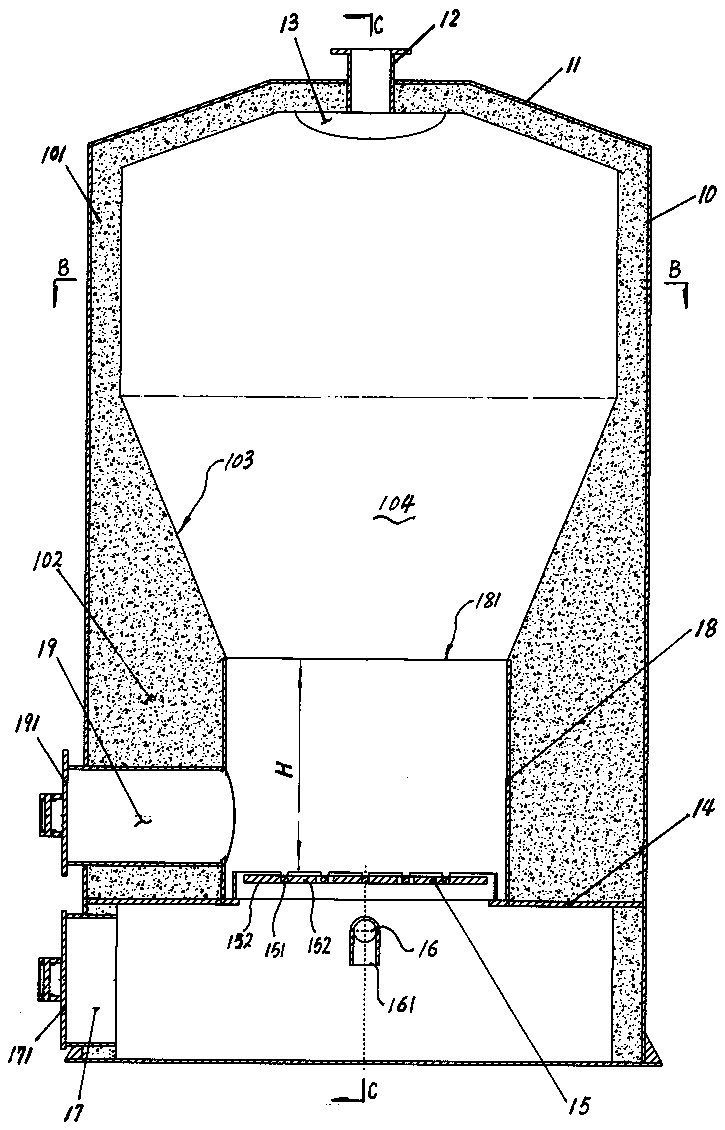

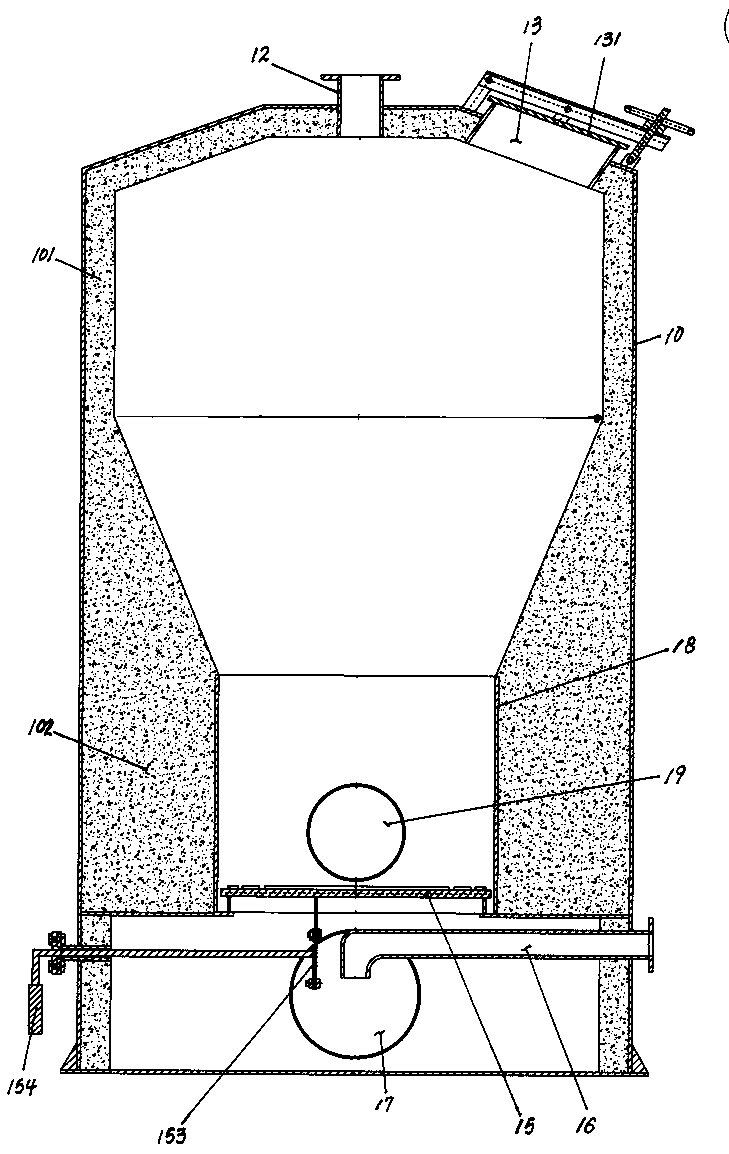

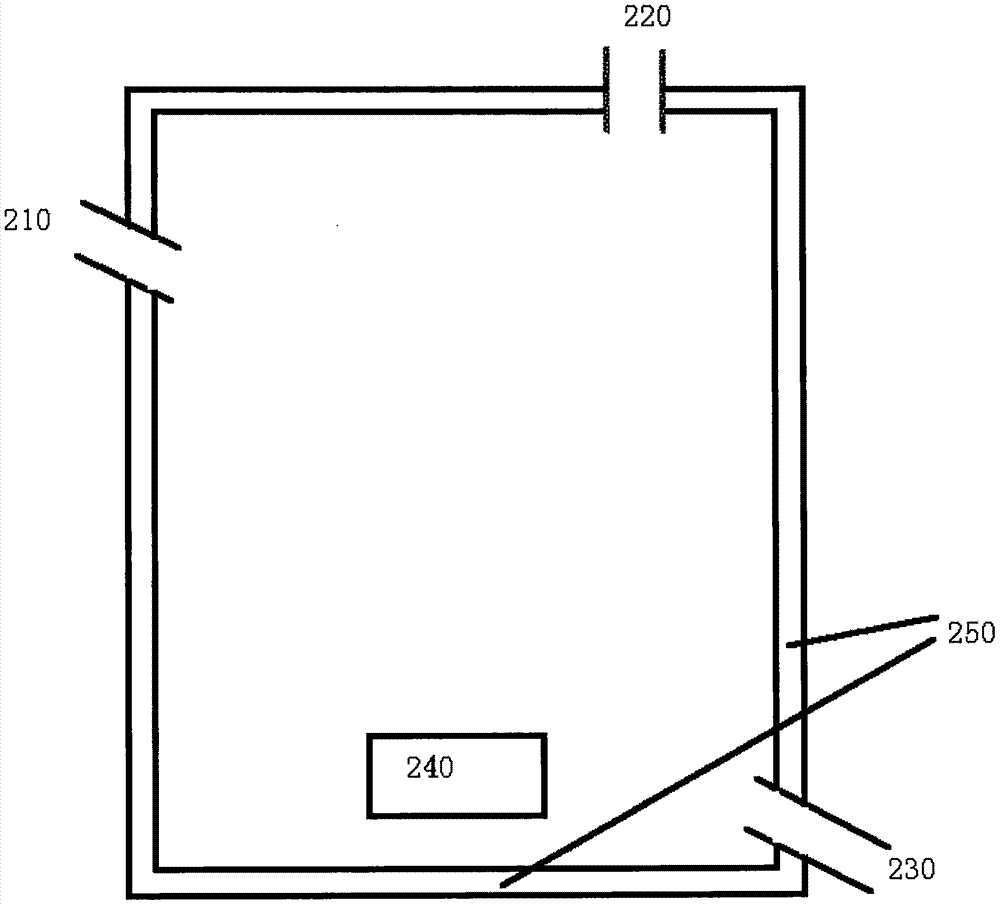

Fermentation device for sludge compost treatment and treatment method using same

InactiveCN102557772APromotes rapid ripeningImprove the microenvironmentClimate change adaptationSewage/sludge fertilisersSludge compostSewage treatment

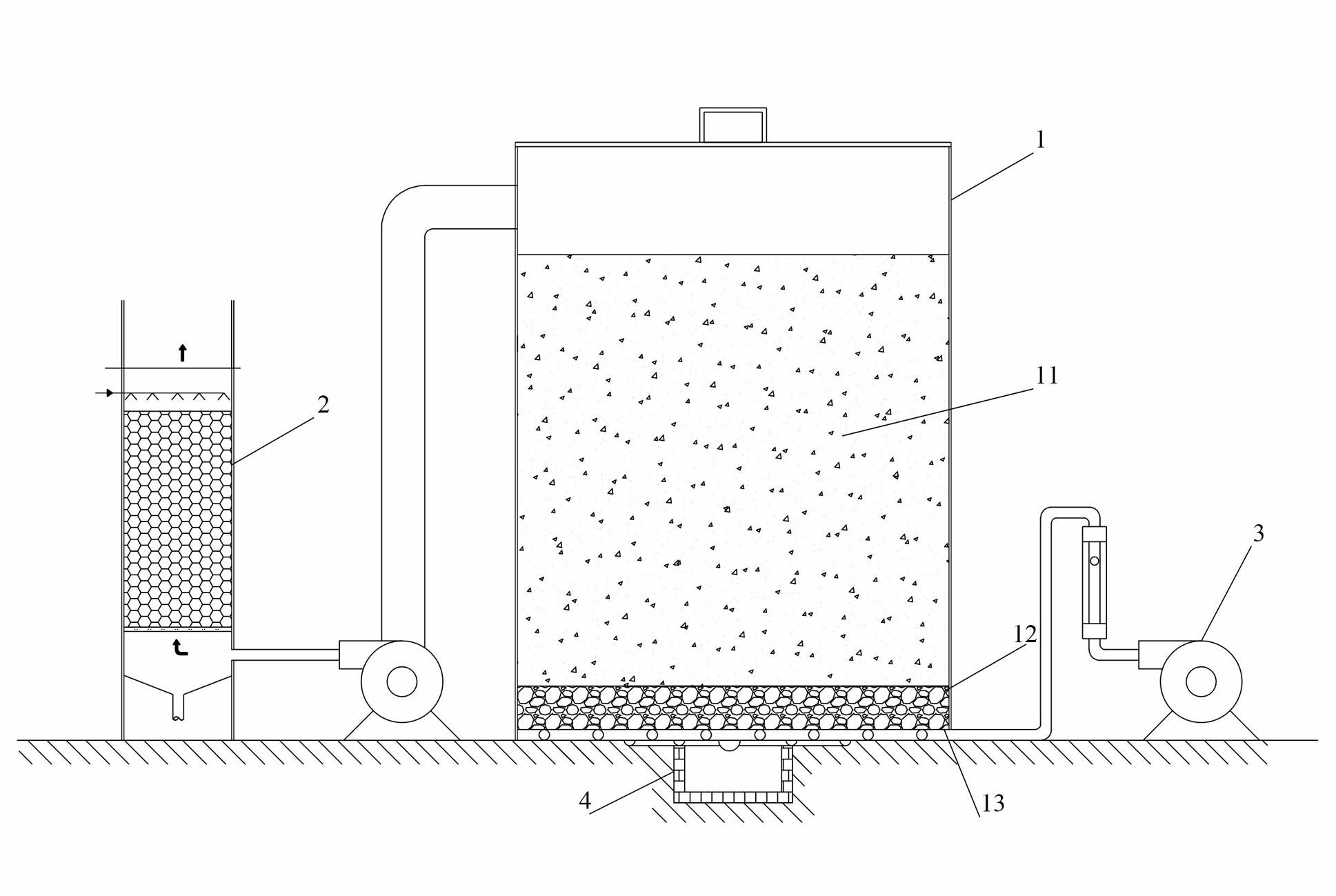

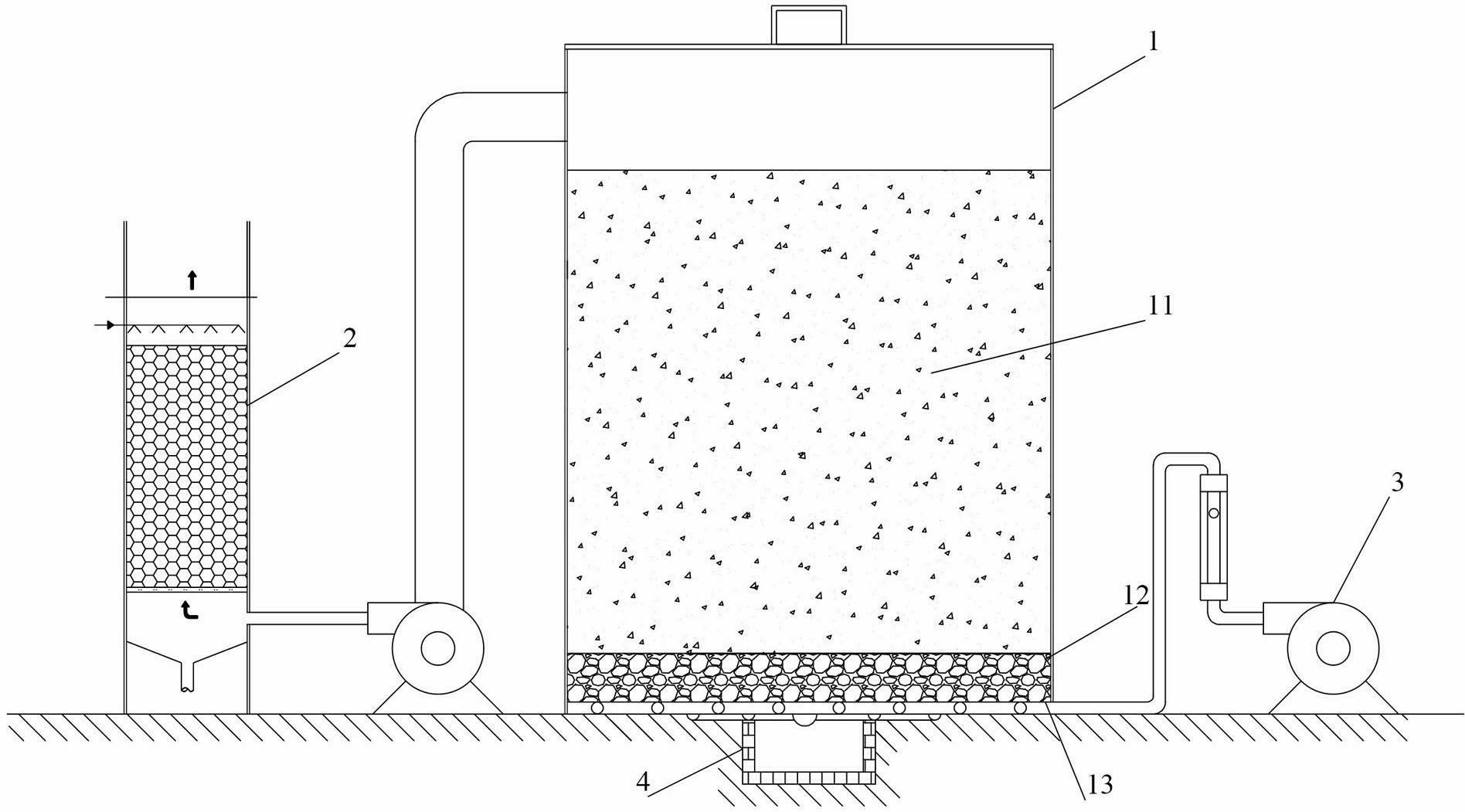

The invention discloses a fermentation device for sludge compost treatment and a treatment method using the same. The device comprises a fermentation cabin body, wherein the bottom of the fermentation cabin body is externally provided with a forced ventilation device; a filter layer is laid at the bottom of the inner cavity of the fermentation cabin body; a percolate collecting groove is arranged under the filter layer; and the top of the fermentation cabin body is connected with the bottom of a waste gas treatment system through a pipeline. The treatment method disclosed by the invention comprises the following steps of: firstly, adding an organic conditioner to regulate the water content and C / N of sludge so as to form sludge composting, and then simultaneously inoculating a composite bactericide suspension and a surfactant solution in the sludge composting; then placing the sludge composting in the fermentation device disclosed by the invention, and carrying out primary fermentation by adopting batch-type static forced ventilation treatment; and finally, carrying out secondary fermentation so as to complete compost treatment. The treatment method disclosed by the invention is high in resource utilization rate and treatment efficiency, is environment-friendly and safe, and is especially suitable for small-sized sewage treatment plants.

Owner:HUNAN UNIV

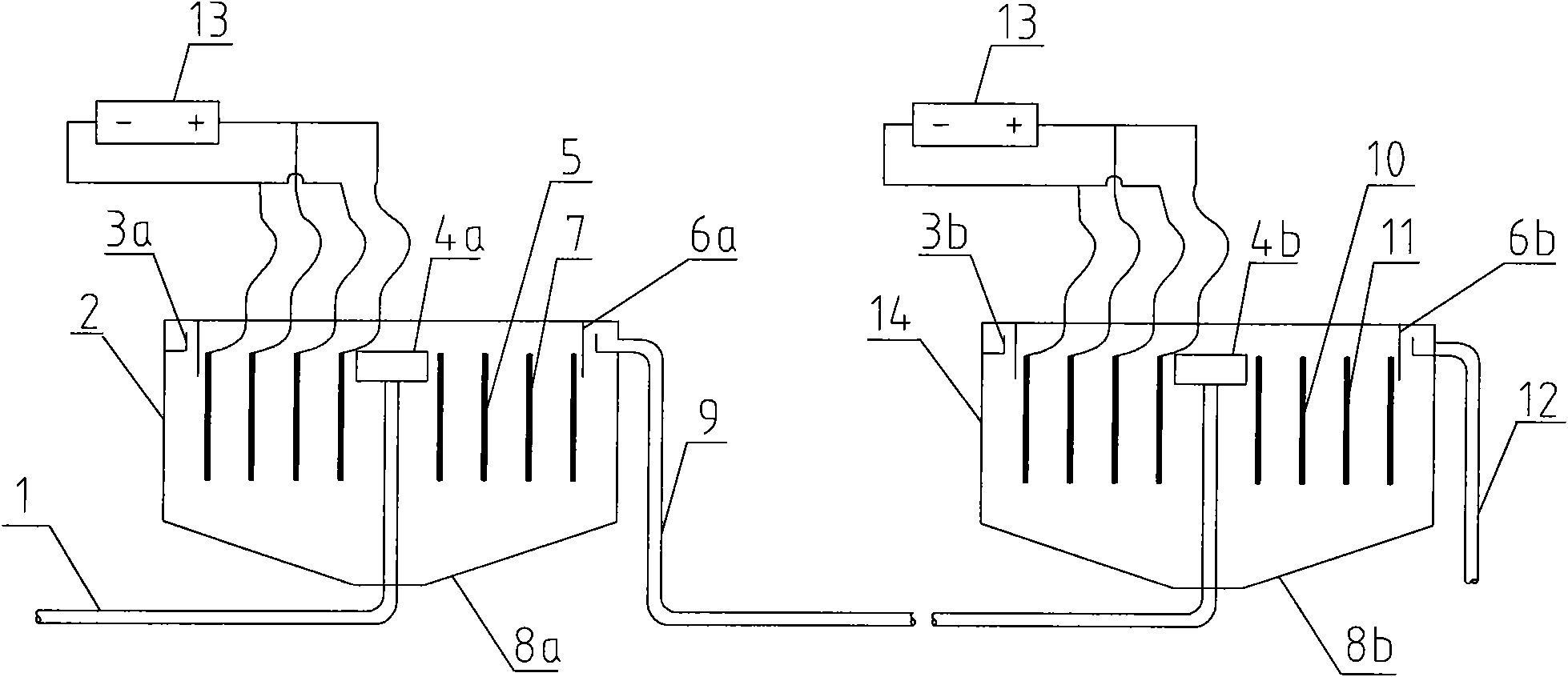

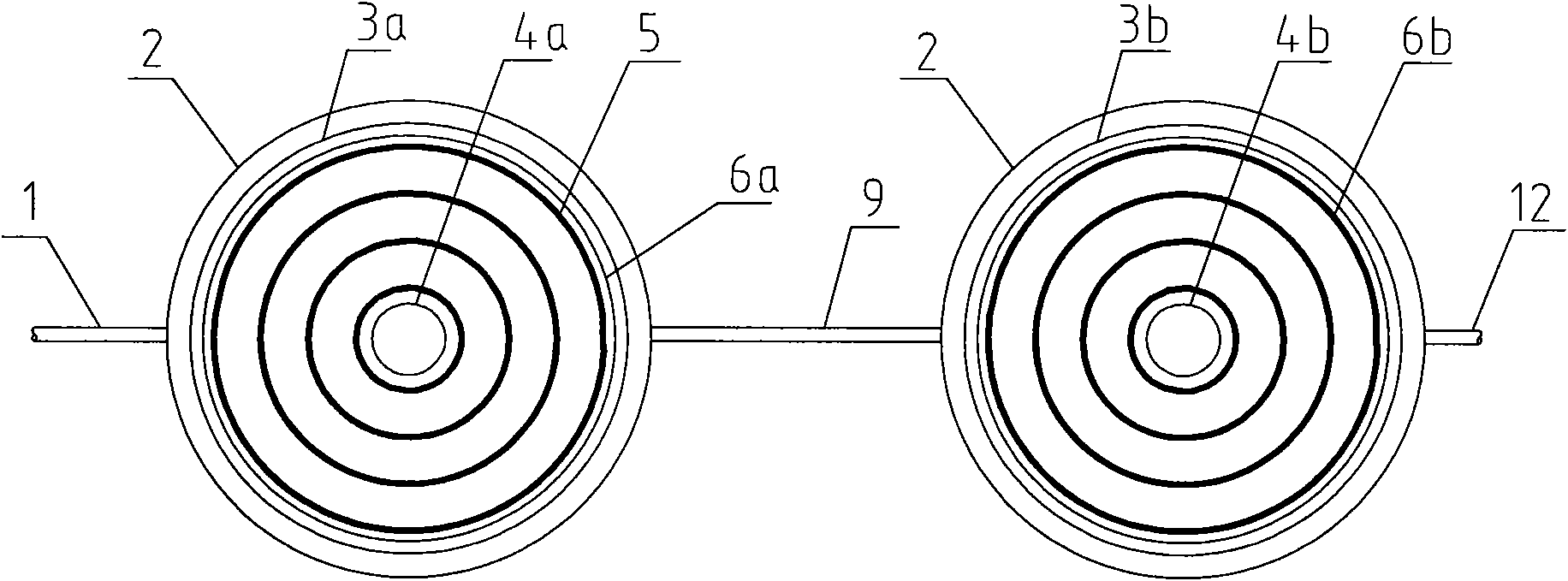

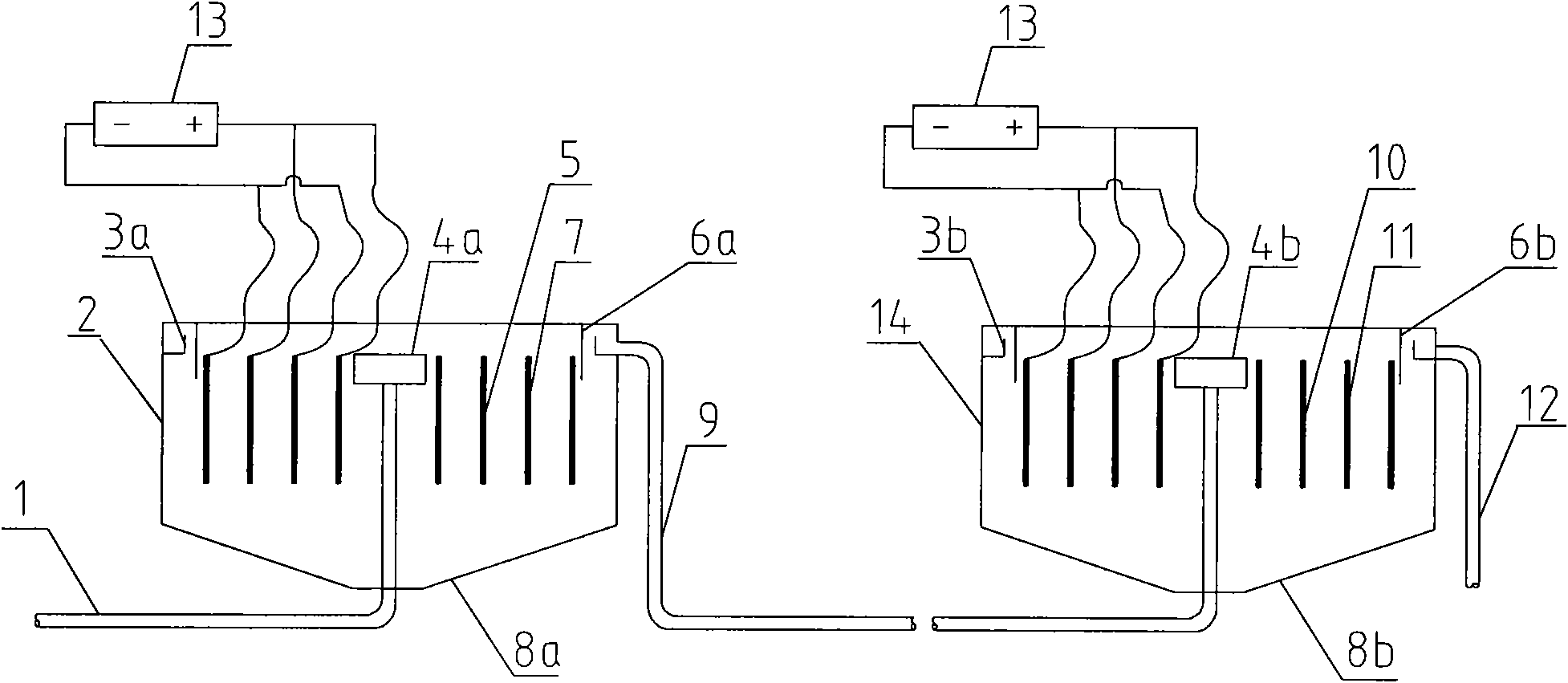

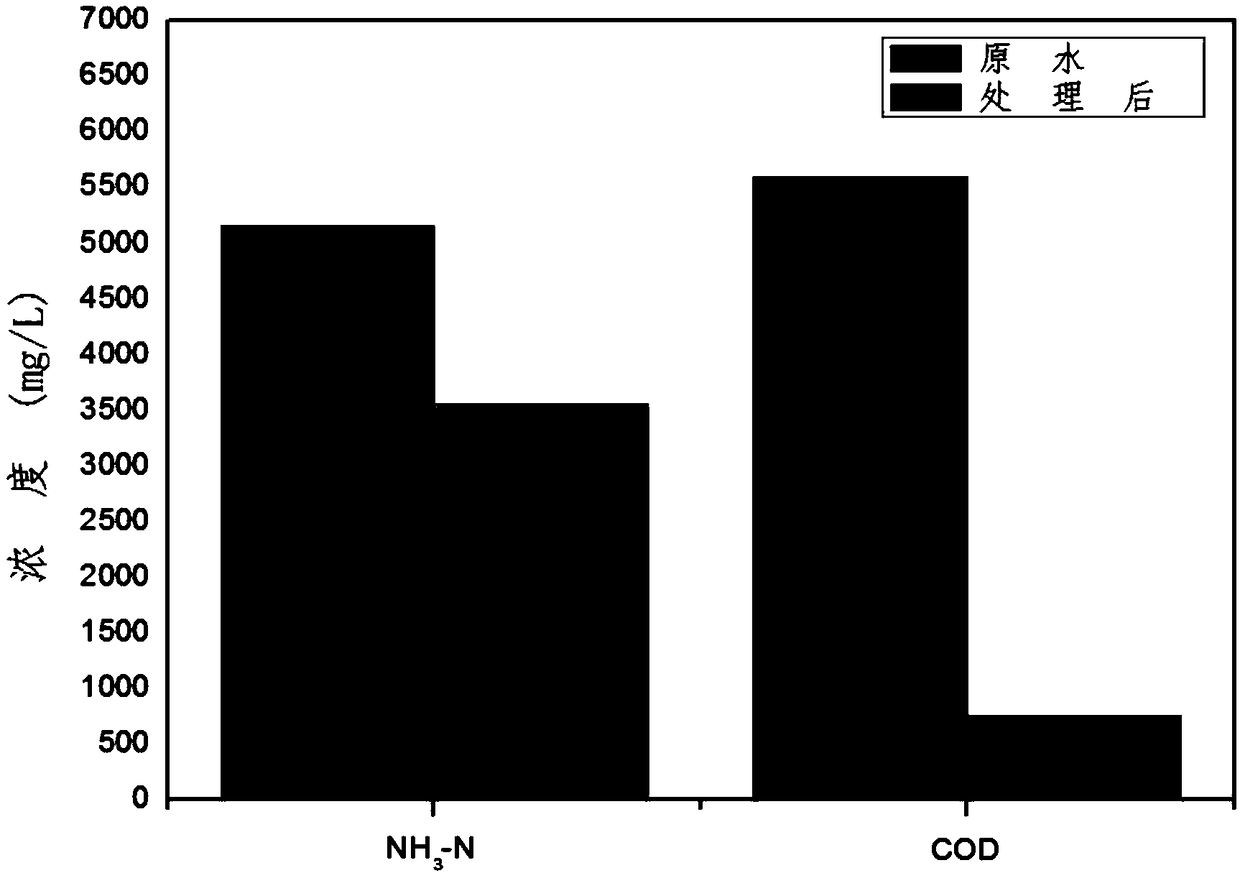

Method for processing effluent by two-stage electrolysis and device thereof

InactiveCN101781001AEfficient removalAvoid secondary pollutionWater/sewage treatmentElectrolysisMicro bubble

The invention discloses a method for processing effluent by two-stage electrolysis and a device thereof. The invention is characterized in that a first electrolytic tank and a second electrolytic tank are respectively arranged; in the first electrolytic tank, a positive electrode is made of titanium mesh plated with ruthenium and a negative electrode is made of stainless steel mesh; in the second electrolytic tank, a positive electrode is made of aluminum mesh and a negative electrode is made of stainless steel mesh; working power supply of the two electrolytic tanks is pulsed DC power supply; at first, electrolytic oxidation or reduction reaction is carried out on the effluent to be processed in the first electrolytic tank; then the effluent is injected into the second electrolytic tank for condensation processing suspended substance and colloid in the water; meanwhile, micro-bubbles generated at the positive electrode and the negative electrode in both the first electrolytic tank and the second electrolytic tank, capture and adhere impurity particles and organic matter in the water and bring them to the water surface. The invention separates the impurity particles and the organic matter in the water by means of electrolytic flotation, which greatly improves the efficiency of processing water pollutants by electrolysis.

Owner:HEFEI UNIV OF TECH

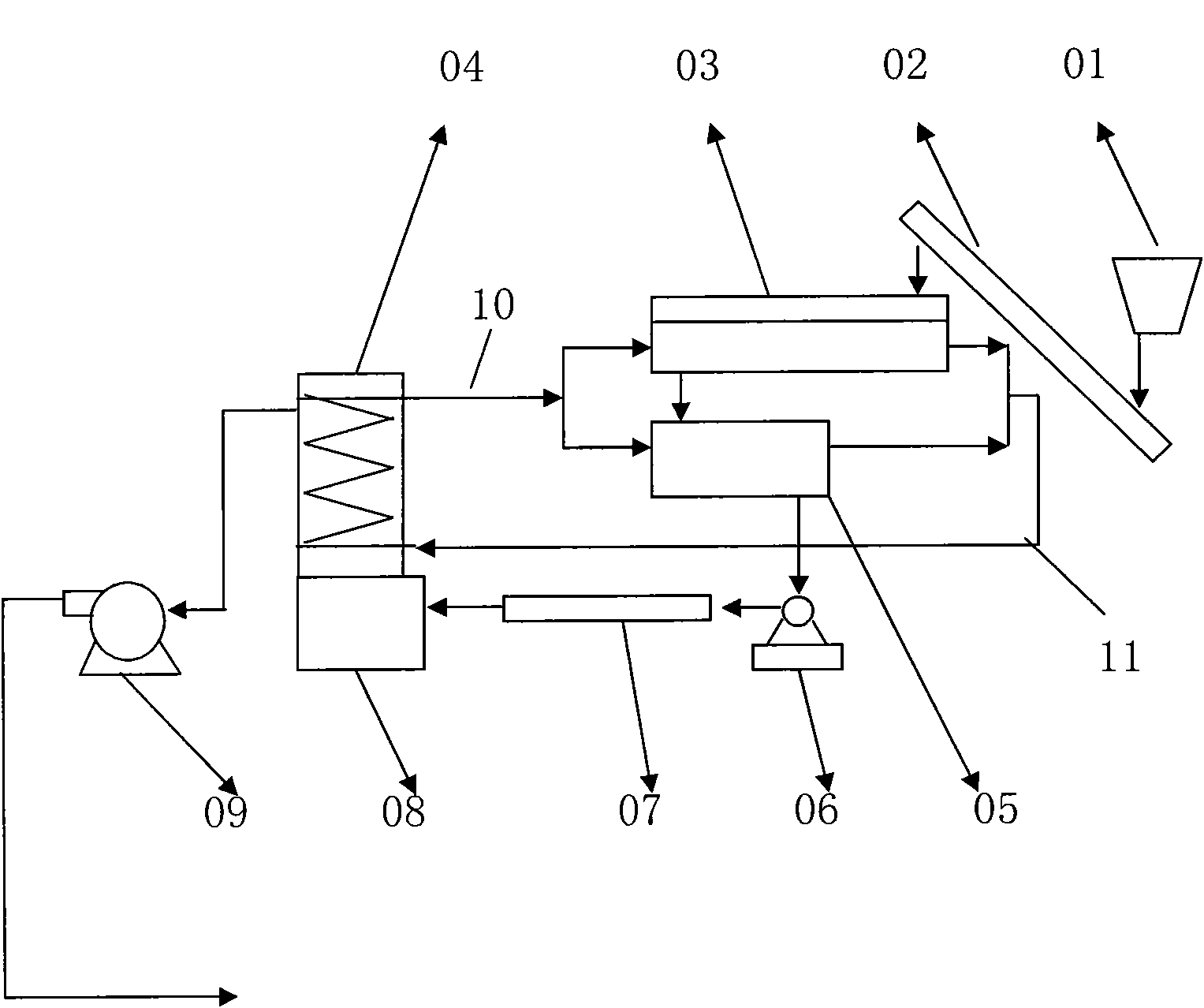

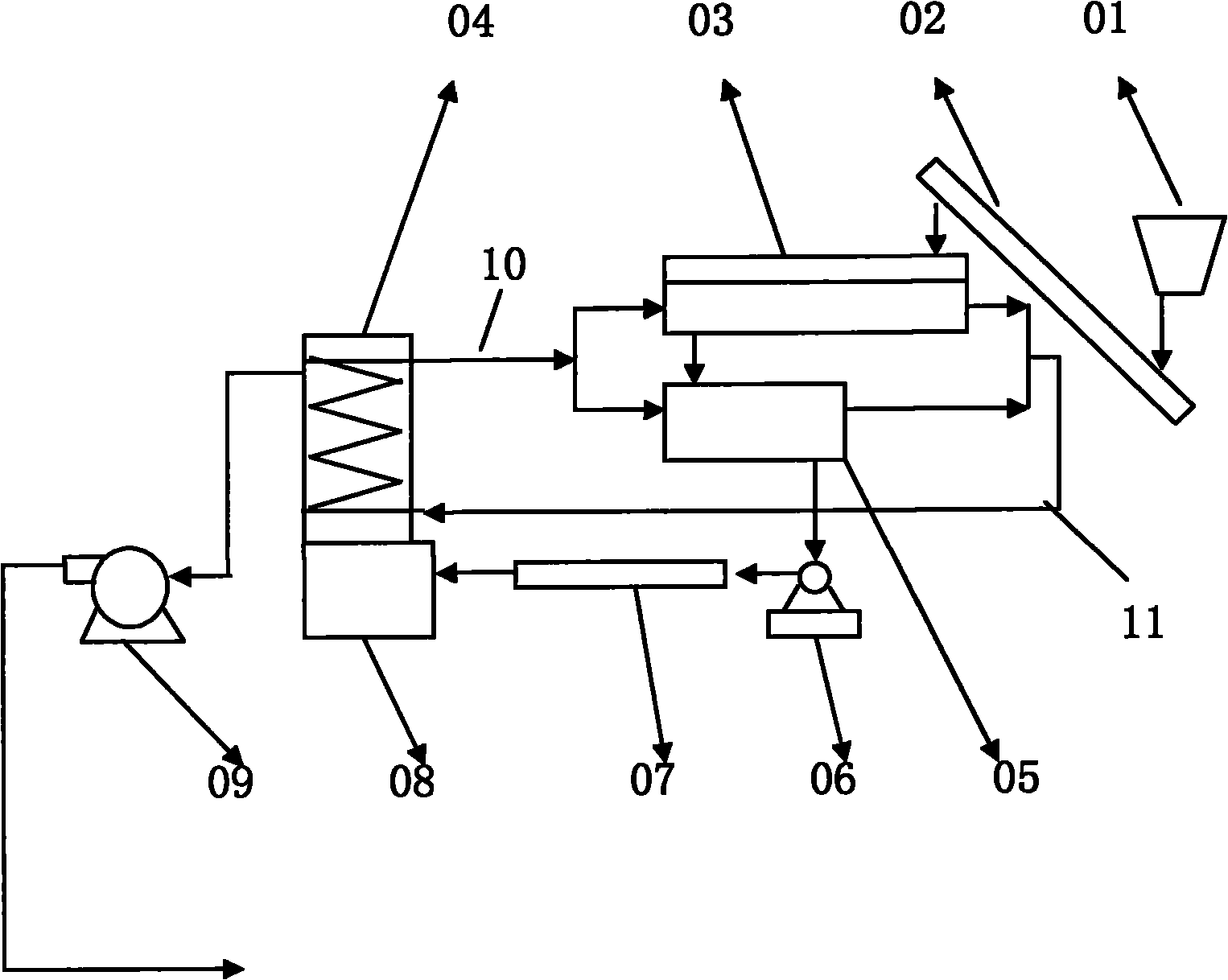

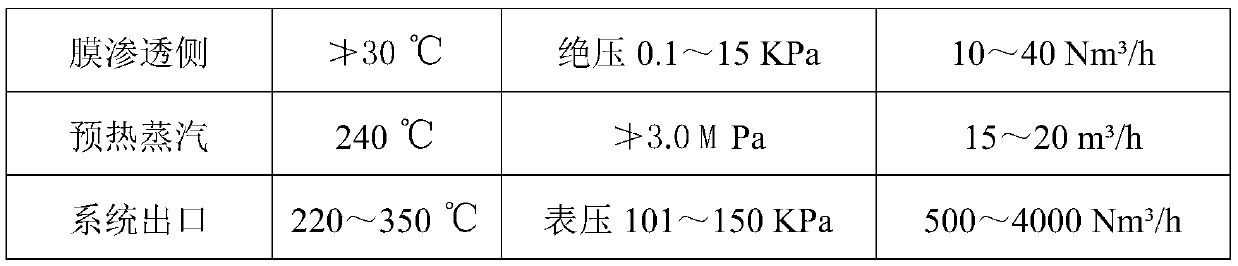

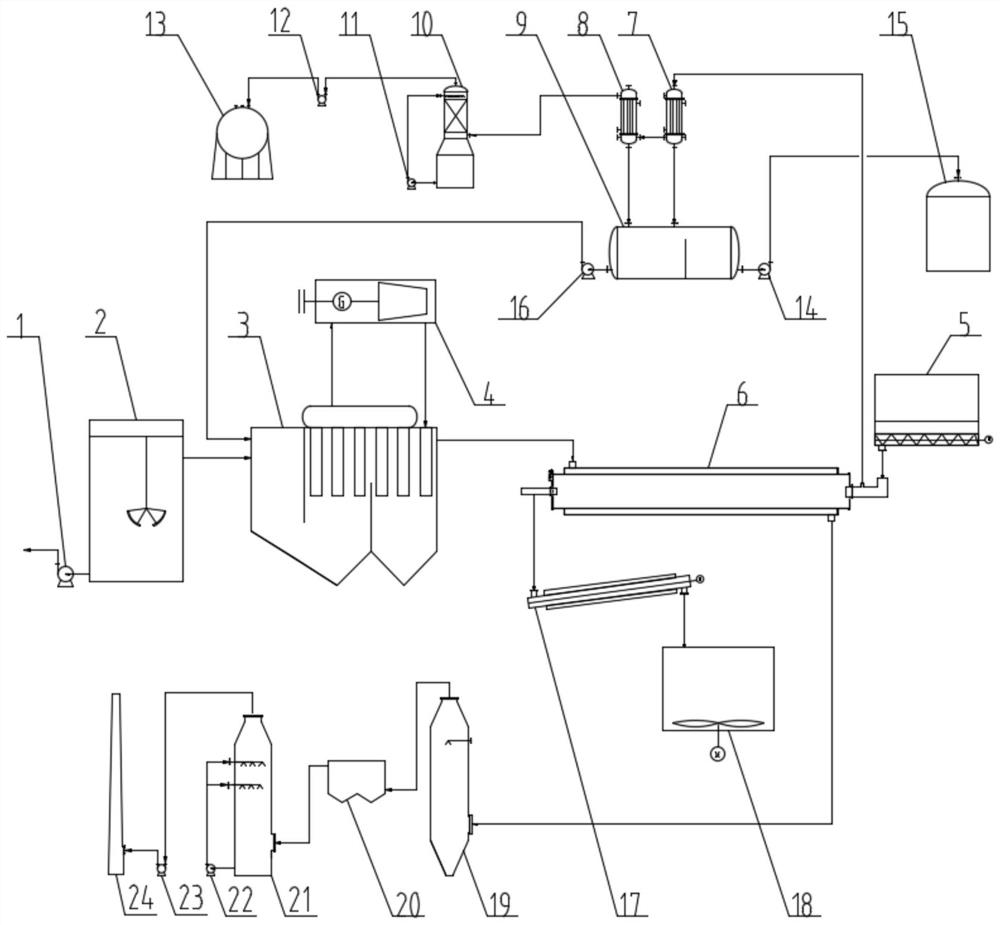

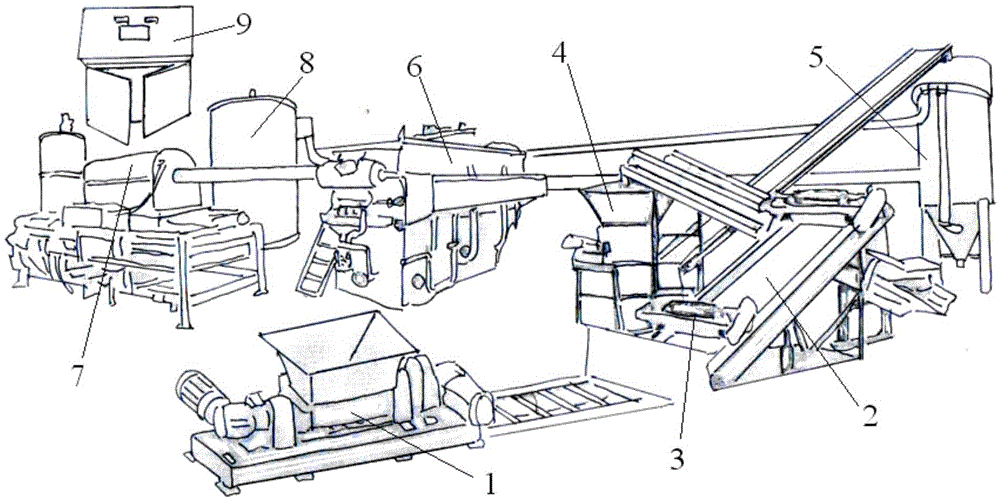

System for pyrolyzing and burning sludge at low temperature

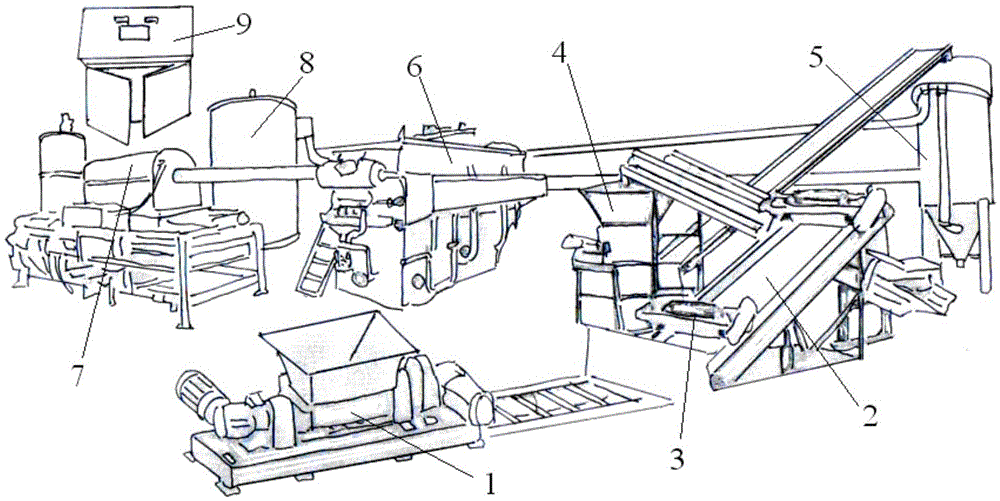

InactiveCN101871649AReduce volumeLow investment costIncinerator apparatusExtrusion mouldingScrew conveyor

The invention discloses a system for pyrolyzing and burning sludge at low temperature, which comprises a sludge hopper, a dryer, a spiral conveyer, a low-temperature pyrolysis reactor, an extrusion moulding machine, an incinerator and a draught fan, wherein the spiral conveyer is used for conveying the sludge output from the sludge hopper to a feed inlet of the dryer; the low-temperature pyrolysis reactor is connected with a discharge port below the dryer; the extrusion moulding machine is connected with the discharge port of the low-temperature pyrolysis reactor; the incinerator is connected with the extrusion moulding machine through a conveyer and is provided with a waste heat boiler; the draught fan is connected with the waste heat boiler; and the upper part of the waste heat boiler is respectively connected with the dryer and the low-temperature pyrolysis reactor through waste heat input pipelines. After the dewatered sludge is dried and pyrolyzed at low temperature, the amount of the sludge entering the incinerator is reduced, thereby reducing the volume of the incinerator, greatly lowering the energy consumption and reducing the investment cost; the cost of manufacture, installation, operation and maintenance of an incinerator system is greatly reduced; and because the equipment investment is reduced, the system is convenient for dispersive treatment of sludge and has wide adaptability.

Owner:GUANGDONG CHANT GRP

Micro-ecological activation system and micro-ecological activation bag prepared therefrom

PendingCN110002607AImprove self-cleaning abilityImprove the efficiency of processing biochemical systemsWater treatment compoundsBiological treatment apparatusFood chainSelf purification

The invention relates to a micro-ecological activation system for water treatment. The micro-ecological activation system comprises a porous adsorption and in-situ micro-ecological activation materialand an ultrafine porous adsorption and in-situ micro-ecological activation material; and the porous adsorption and in-situ micro-ecological activation material and the ultrafine porous adsorption andin-situ micro-ecological activation material contain nutrients and trace elements, needed by microorganisms. A bag made from a porous easy-adsorption material is filled with the above components to form a micro-ecological activation bag. The system and the bag are suitable for purifying various water environments. A biotechnology and a new material technology are organically combined, nutrients are provided to rapidly breed indigenous microorganisms in the water environment, including bacteria, actinomycetes and prokaryotes in order to form bio-flocs and a multilayer biofilm, and in-situ treatment of pollutants is realized by the denitrification of the microorganisms and the establishment of an efficient food chain in order to repair the ecosystem, restore the self-purification ability ofwater and form a microbial in-situ culture purification system.

Owner:上海泰缘生物科技股份有限公司

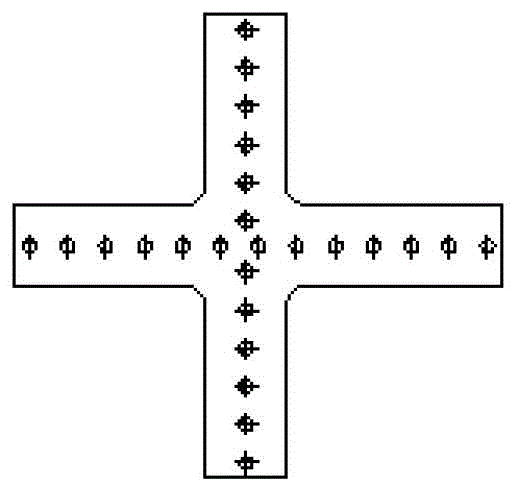

Smoke-reuse internal heat type biomass carbonization furnace

InactiveCN103333701AIn-place processingRealize secondary useBiofuelsRetortsInlet channelCombustion chamber

The invention discloses a smoke-reuse internal heat type biomass carbonization furnace. The carbonization furnace comprises a carbonization furnace body, and also comprises a combustion chamber arranged in the carbonization furnace, a primary air inlet channel connected with the bottom of the combustion chamber and a filler channel connected with the bottom of the combustion chamber, and a carbonization chamber is formed between the carbonization furnace body and the combustion chamber; and the top of the combustion chamber is connected with the outside of the carbonization furnace body, a cross smoke reuse pipeline is arranged at the lower portion of the combustion chamber, a cross secondary air inlet pipeline is arranged at the upper portion of the combustion chamber, and the outer wall of the combustion chamber is connected with heat conduction sheets. The smoke-reuse internal heat type biomass carbonization furnace has the advantages of simple operation, strong adaptability to a raw material, cheapness and easy obtaining of the raw material, realization of in-situ carbonization treatment of the biomass raw material, transportation and treatment cost reduction, small pollution to the environment, and good application prospect.

Owner:HUAZHONG AGRI UNIV

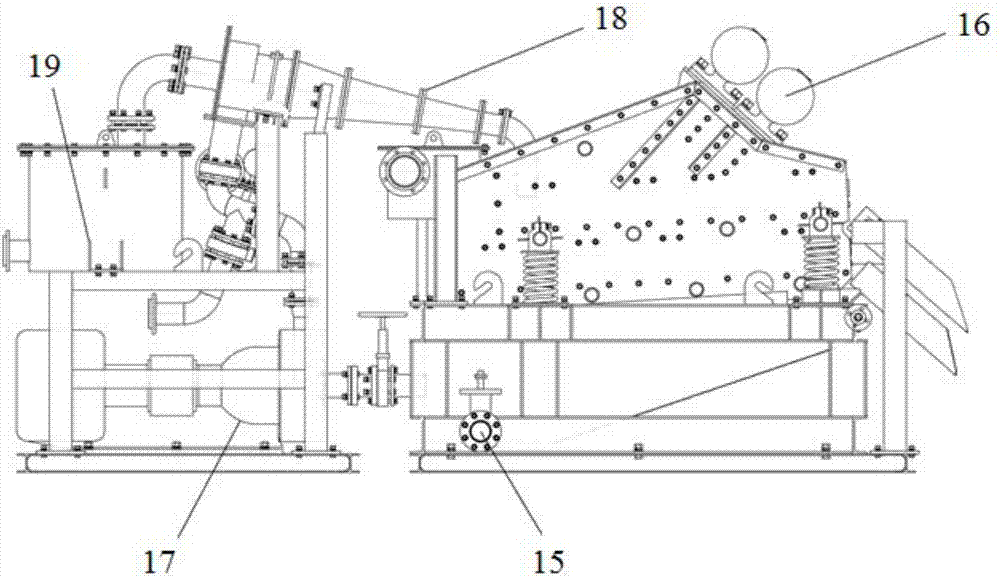

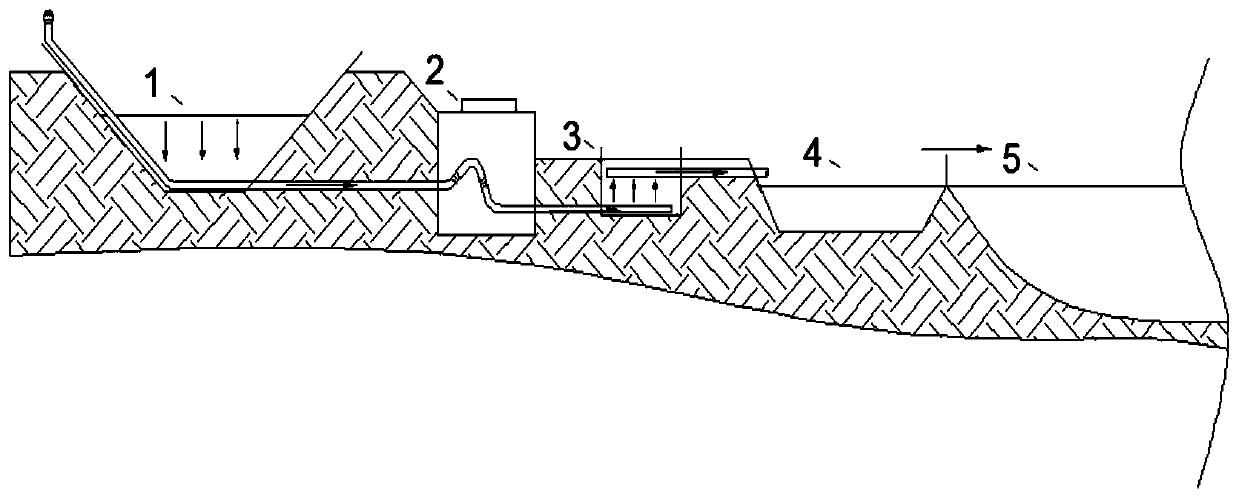

Movable contaminated bottom sediment on-site treatment integral device and treatment process thereof

InactiveCN107140802AGuaranteed stable operationSolve processing problemsSludge treatment by de-watering/drying/thickeningRunoff/storm water treatmentSlagSites treatment

The invention relates to a movable contaminated bottom sediment on-site treatment integral device and a treatment process thereof. The integral device comprises a movable assembly and an integral treatment assembly loaded on the movable assembly, wherein the integral treatment assembly comprises a slag-removing sand-removing integral unit, a pre-concentrating unit, a dosing conditioning unit and a deep concentrating and dewatering unit; a slag-removing outlet of the slag-removing and sand-removing integral unit is connected with a sundry collecting device; a sand-removing outlet is connected with a sand grain receiving device; a sewage outlet and a dosing hole of the dosing conditioning unit are connected with the inlet of the pre-concentrating unit together; a bottom sludge outlet of the pre-concentrating unit is connected with the inlet of the deep concentrating and dewatering unit; the bottom outlet of the deep concentrating and dewatering unit is connected with a mud cake receiving device. Compared with the prior art, the movable contaminated bottom sediment on-site treatment integral device and the treatment process thereof have the advantages that contaminated bottom sediment can be treated effectively, and resource utilization of sand grains in the bottom sediment is realized synchronously; meanwhile, the integral treatment assembly is loaded on ta container or a ship in a centralized way, so that the floor area is saved effectively, building cost is lowered, and operation is flexible.

Owner:中国电建集团装备研究院有限公司

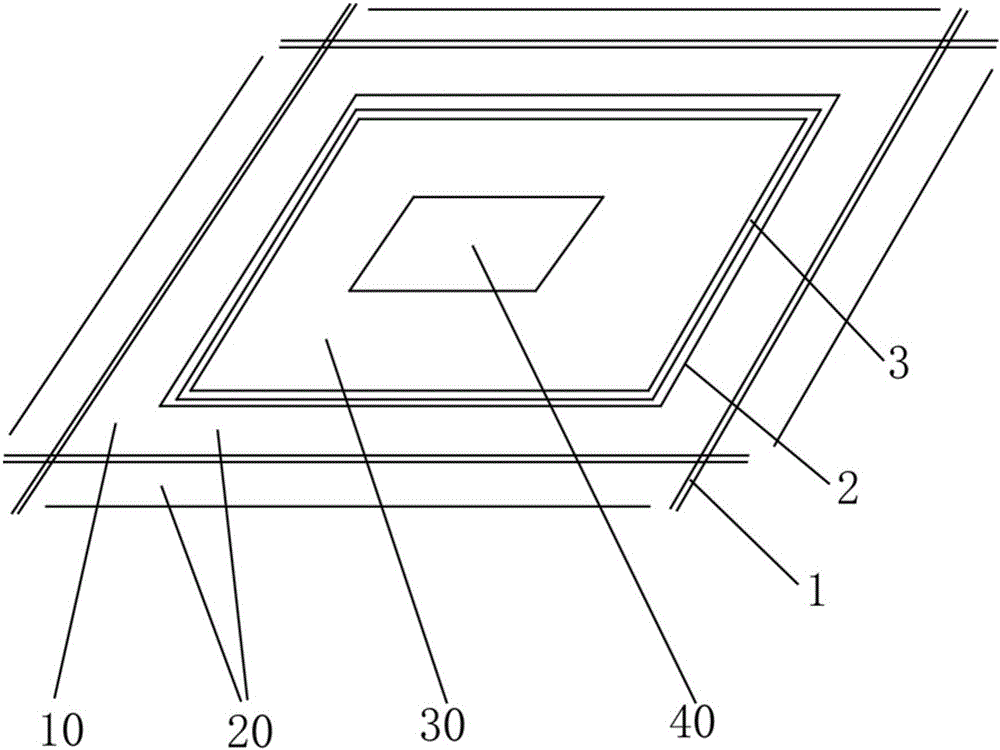

Sponge urban unit system

ActiveCN105735452AGreening and beautifying the cityEliminate heat island effectClimate change adaptationSewage drainingSewageUnit system

The invention relates to the technical field of urban planning design and urban water conservancy facilities, in particular to a sponge urban unit system.The system comprises a surrounding urban main road and an annular watercourse, wherein a planning region is defined by the surrounding urban main road, and a building region is arranged in the planning region; the annular watercourse is located in the planning region to be used for collecting rainwater in the planning region; an urban agricultural garden region is defined by the annular watercourse, an urban waste disposal region is arranged in the urban agricultural garden region, and sewage pipelines used for guiding sewage in the building region to the urban waste disposal region are laid in the planning region.In this way, urban rainwater is kept in cities, disposed locally and recycled, urban sewage and organic waste are digested and absorbed, urban afforestation and beautification can be achieved through the urban agricultural garden region, the agricultural product requirement of cities can be provided partially, ecological cities are realized, and environment pollution, water resource shortage, urban inland inundation, urban heat island effect and other city problems are solved.

Owner:PEKING UNIV

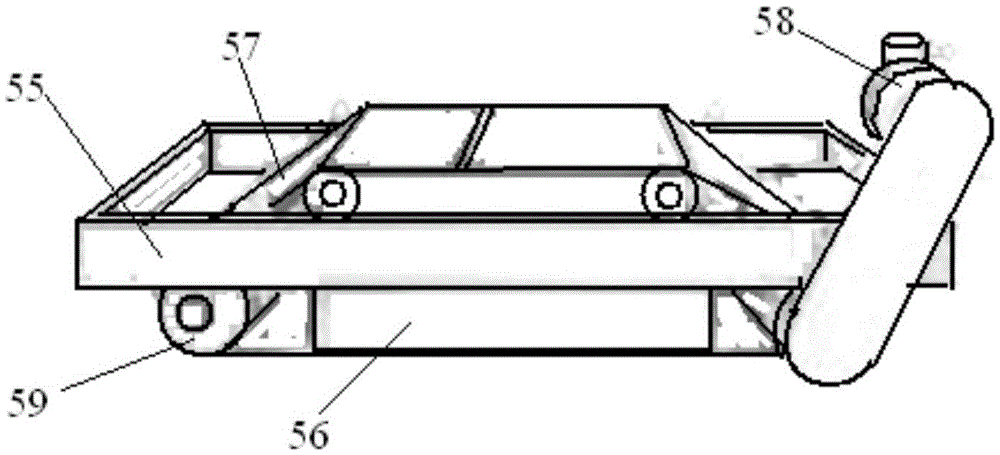

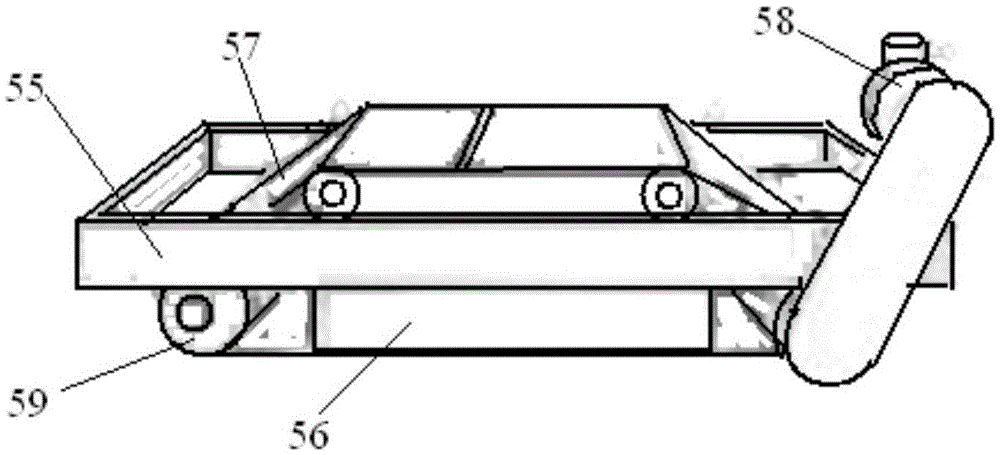

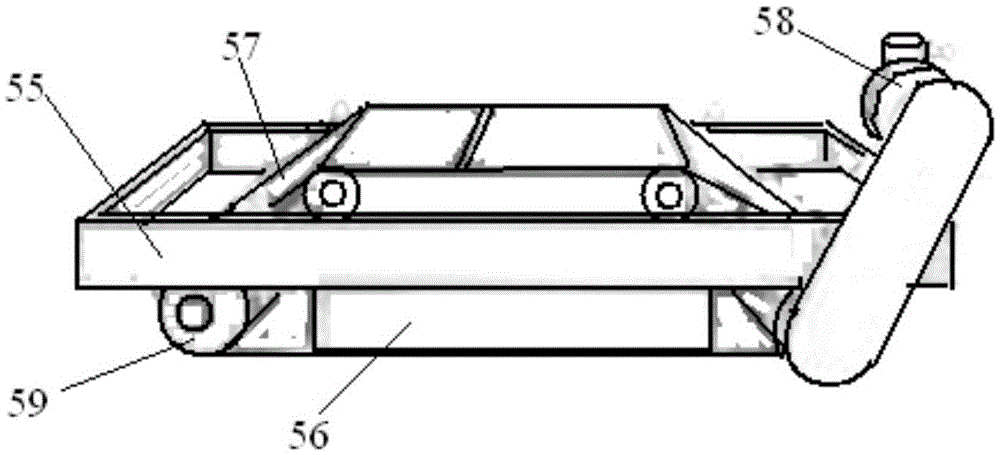

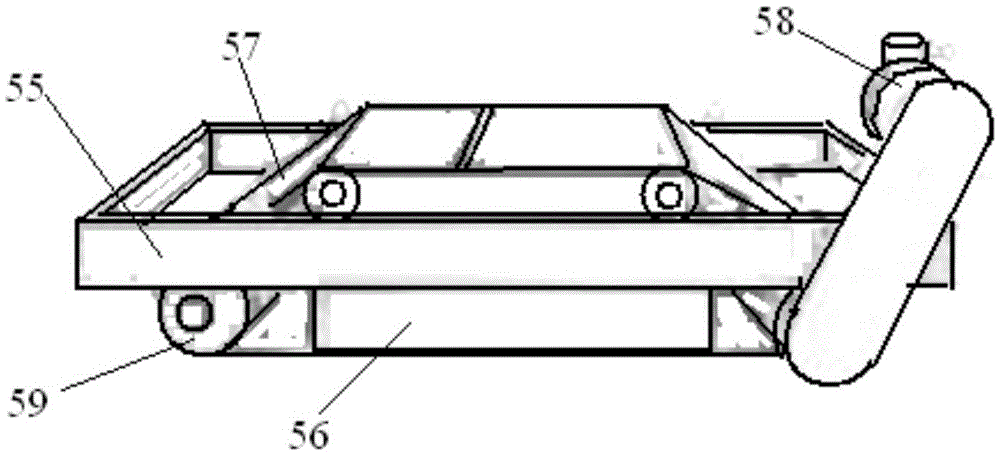

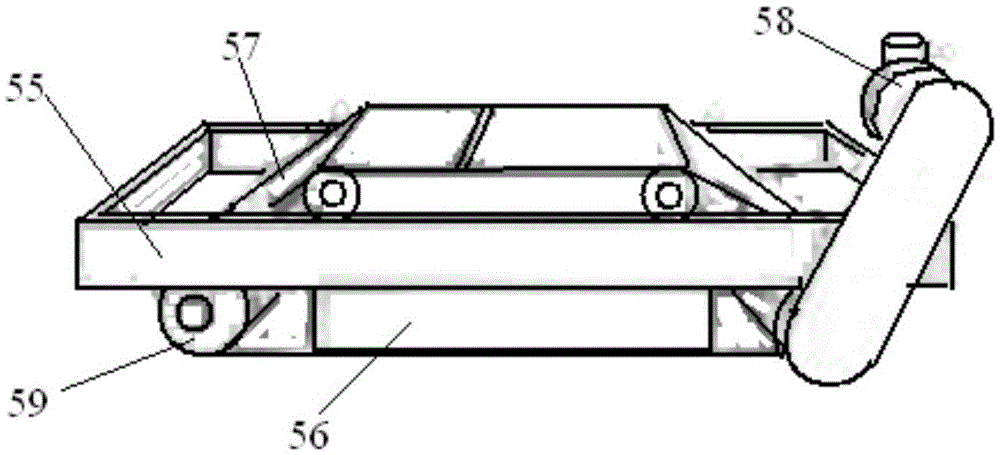

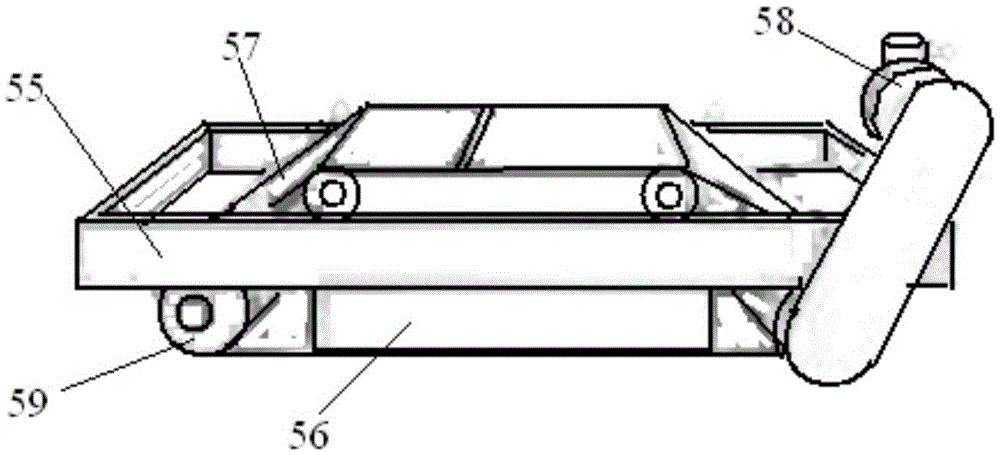

Iron removers of town domestic rubbish disposal system

InactiveCN105457749AReduce labor intensitySave manpower and material resourcesSolid waste disposalMagnetic separationMagnetic coreMaterial resources

The invention discloses iron removers of a town domestic rubbish disposal system. The iron removers are arranged on a belt conveyor (2). The iron removers (3) are permanent magnet self-discharging type iron removers and are each provided with a frame (55), a permanent magnet magnetic core (56) of a double-magnetic-pole structure, an iron abandoning belt (57), a speed reducing motor (58) and a roller (59). The two ends of the belt conveyor (2) are each provided with the corresponding iron remover. The technical scheme is adopted for advanced disposal of town domestic rubbish so that harmful gas in the rubbish can be decomposed, and meanwhile, harmful substances in the rubbish can also be diluted. Therefore, part of the substances is made to float and be cycled, the labor intensity in the disposal process is greatly relieved, and a large number of manpower and material resources are saved. The rubbish serves as production raw materials, and organic matter and inorganic matter in the rubbish are separated and reasonably used to produce organic fertilizer and building block materials. White pollutants are used for producing building thermal insulation materials, so that harmlessness and resource recovery of the rubbish are achieved.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

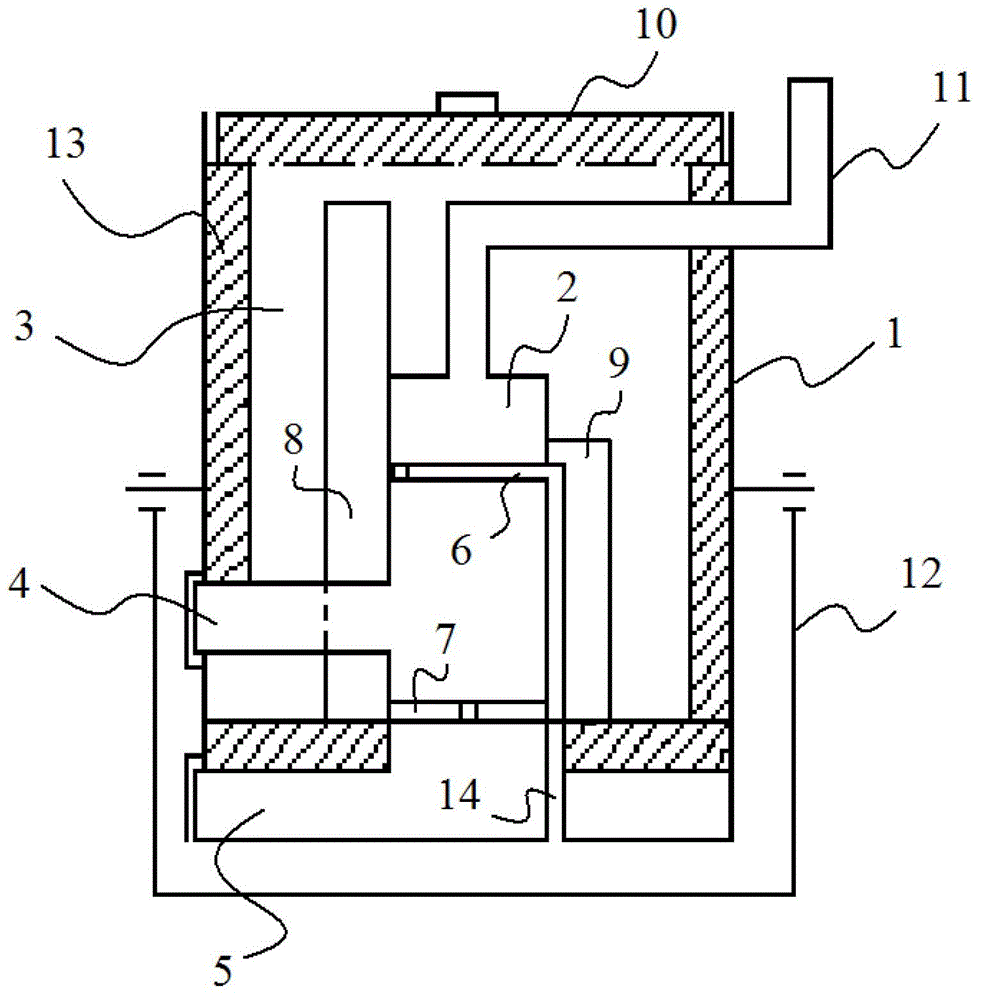

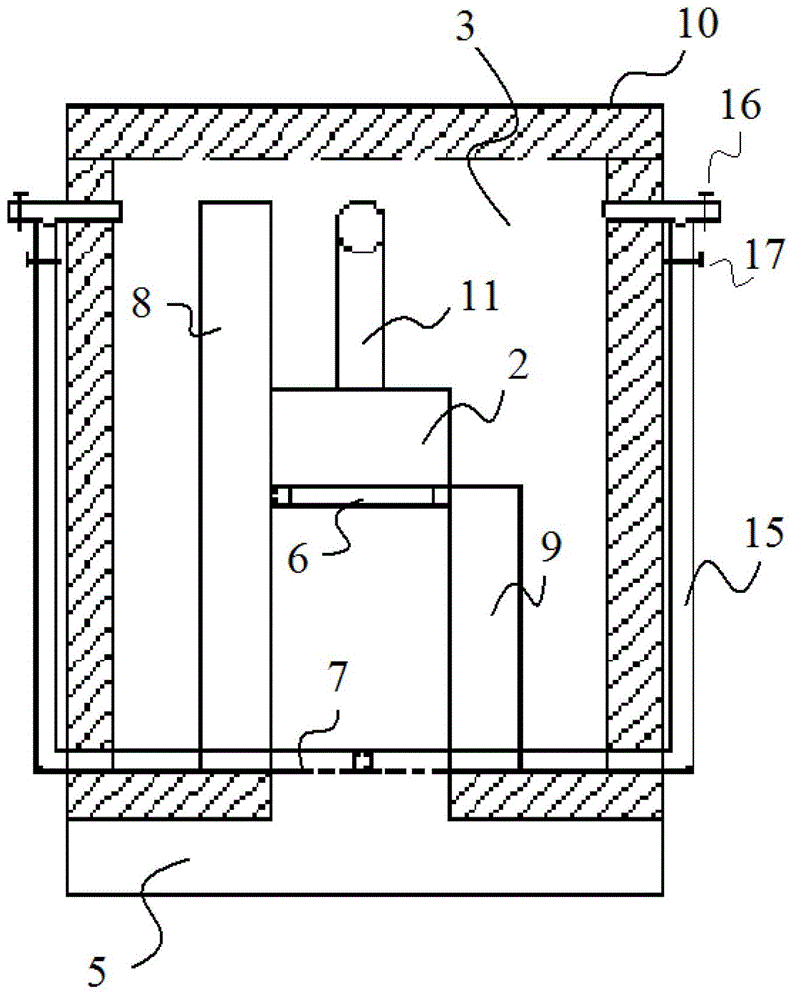

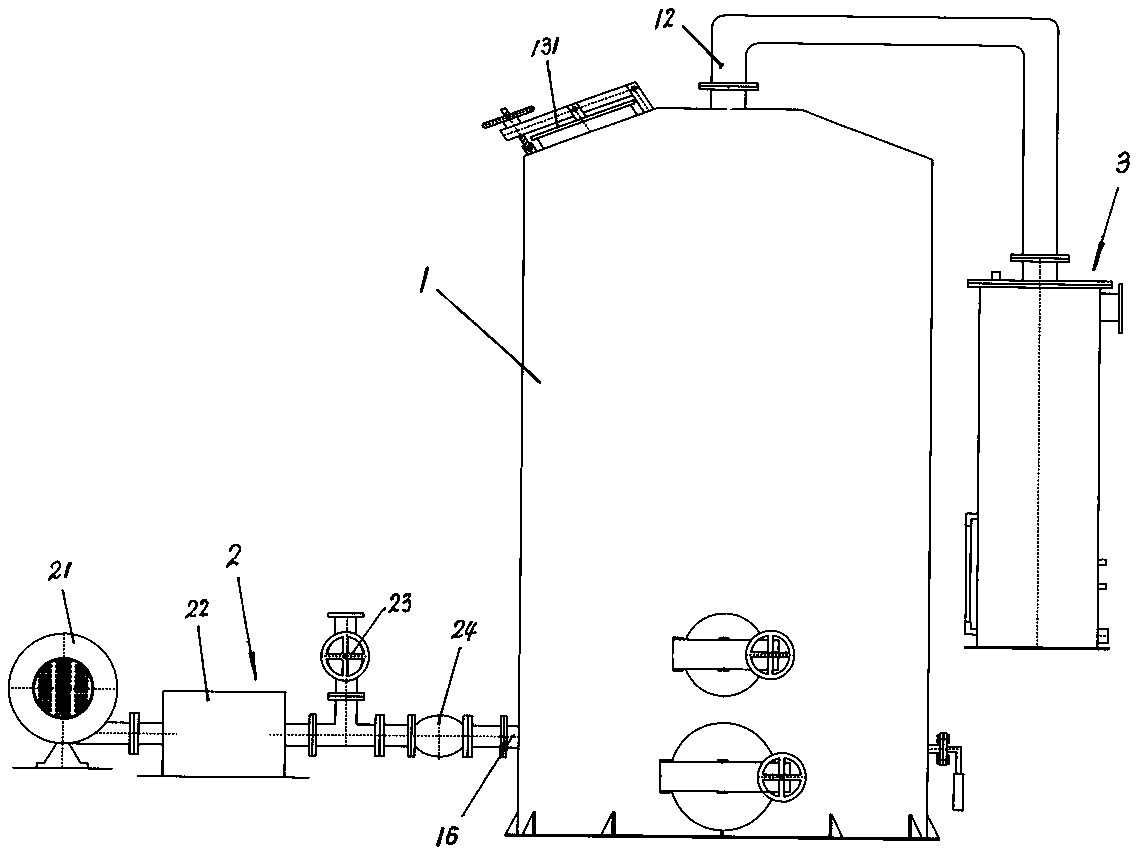

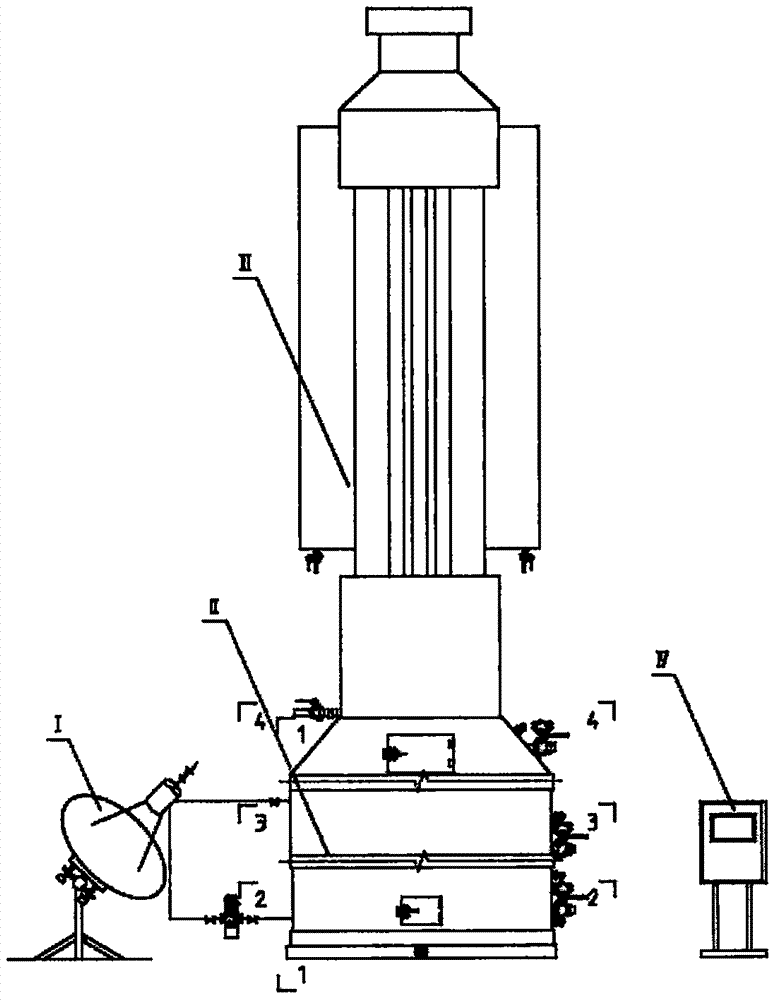

Low-temperature pyrolysis gasification method and pyrolysis gasification device for domestic garbage

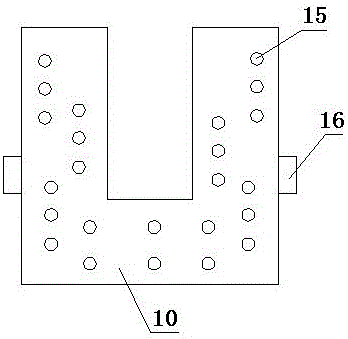

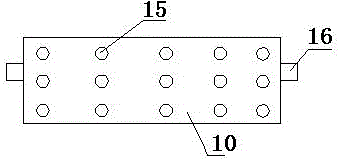

PendingCN108546557AIn-place processingAvoid pollutionSpecial form destructive distillationFlame arresterThroat

The invention relates to a low-temperature pyrolysis gasification method for domestic garbage and a low-temperature pyrolysis gasification device for domestic garbage. The low-temperature pyrolysis gasification device for domestic garbage comprises a low-temperature pyrolysis gasification furnace (1), an air magnetization air supply device (2), and a water seal flame arrester (3), wherein the low-temperature pyrolysis gasification furnace (1) mainly comprises a furnace body (10), an air outlet pipe (12), a feed port (13), an annular partition plate (14), an oscillating fire grate (15), an ashcleaning port (17), a throat pipe (18), an ignition port (19), and an air inlet pipe (16). In the domestic garbage from which unburnable large bricks and stones are sorted out, the low-temperature pyrolysis gasification furnace (1) is used and the air volume input into the furnace is controlled by adjusting the air magnetization air supply device (2); the temperature of an oxidization zone of an inner cavity of the throat pipe (18) is controlled between 450 DEG C and 550 DEG C, and the low-temperature pyrolysis gasification of domestic garbage is performed at the air outlet temperature of theupper part of the furnace body of between 100 DEG C and 250 DEG C. The low-temperature pyrolysis gasification device for domestic garbage is particularly suitable for the treatment of domestic garbagein rural towns, hospitals and the like, the operation is simple and convenient and the pyrolysis gasification effect is good.

Owner:孙吉林

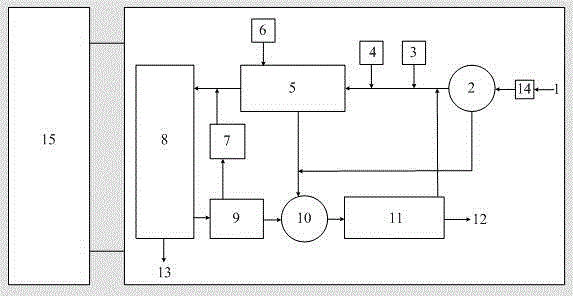

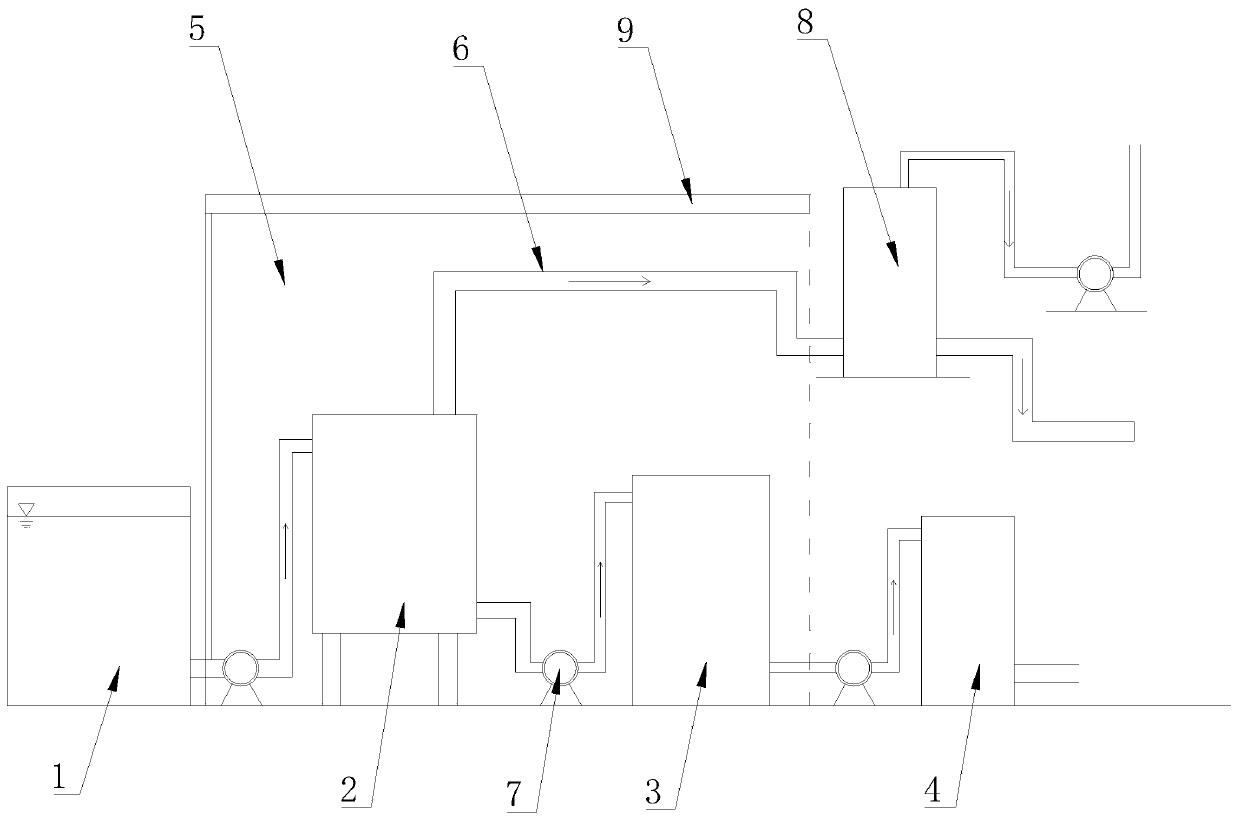

Systematic treatment method and device for restaurant wastewater

InactiveCN105481207ACompact structureSmall footprintTreatment using aerobic processesWater/sewage treatment by irradiationChemistryThree level

The invention relates to a systematic treatment method and device for restaurant wastewater, and belongs to the technical field of environmental engineering. The method comprises the steps that solid-liquid separation treatment is preliminarily performed on the restaurant wastewater to separate out solid residue precipitates; oil-water separation treatment is performed to lower the oil content of the restaurant wastewater to below 15 mg / L; the restaurant wastewater obtained through oil-water separation treatment is treated through hydrolysis and contact oxidation by adopting a three-level biological contact oxidation method; mud-water separation is performed after contact oxidation treatment is finished; the restaurant wastewater is treated through a bio-filter bed taking quartz sand and pelelith as media; deep phosphorus removal is performed on a water body by taking limestone as a framework and taking an aluminum preparation as packing; ultraviolet sterilization treatment is performed. Accordingly, the advantages of being reliable in technology, little in investment, easy to maintain, convenient to operate and manage, free of secondary pollution and the like are achieved.

Owner:DALI FLYING FISH ENVIRONMENTAL PROTECTION TECH CO LTD

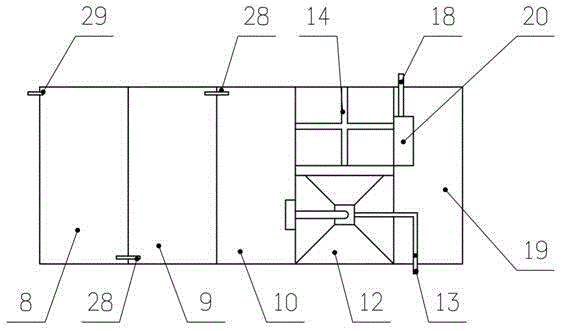

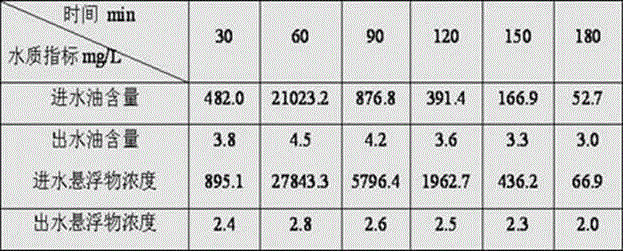

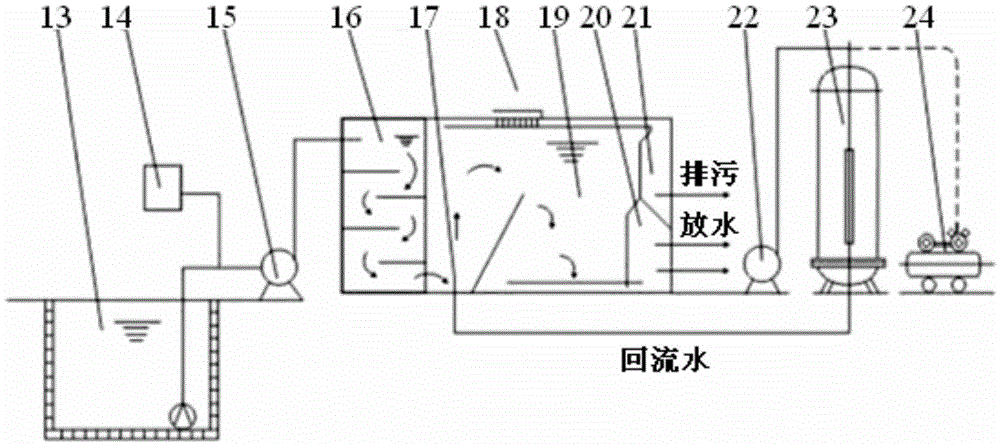

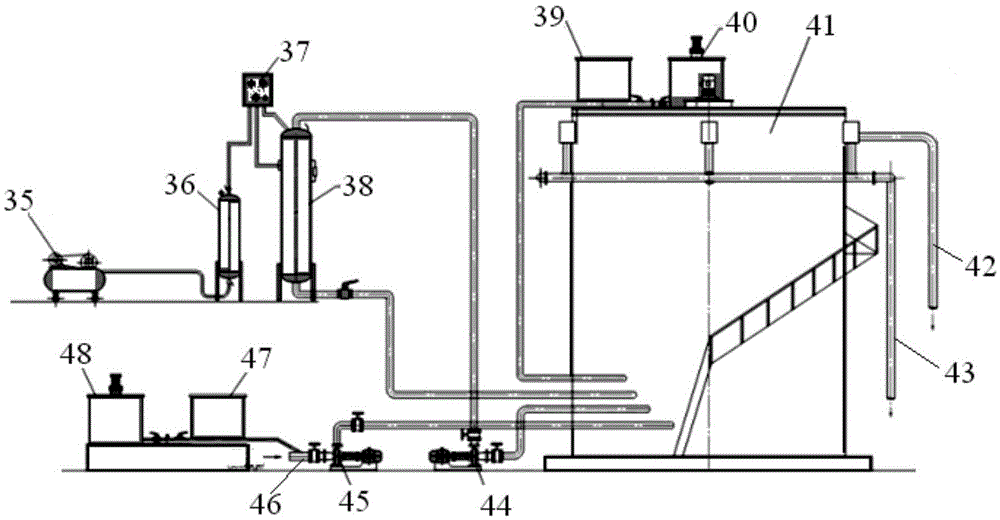

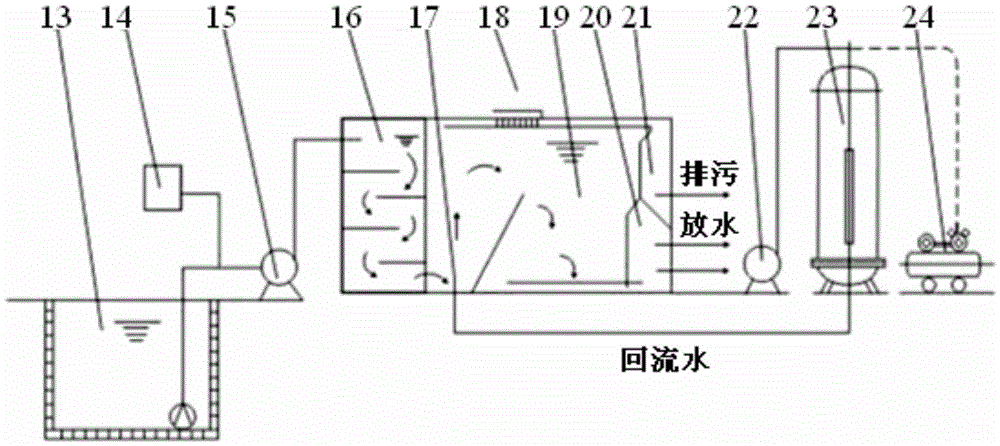

Mobile well flushing waste water processing system

ActiveCN104609635AFacilitate solid-liquid separationSimple handling of equipmentMultistage water/sewage treatmentFilling materialsWater quality

The invention discloses a mobile well flushing waste water processing system. According to the mobile well flushing waste water processing system, sand settling-high efficiency floating-magnetic separation combined process is adopted to process well flushing waste water, and mud cake obtained via magnetic separation is subjected to overlapping type dewatering. The mobile well flushing waste water processing system is high in processing efficiency; multistage filtering or multistage air floatation equipment is not needed; using of a large amount of backwashing water and changing of filling materials are avoided; and continuous processing can be realized. No filtering equipment is used; removing effect of oil and suspended materials is excellent; real-time monitoring on oil content of water can be realized; automatic adjusting on adding amount of flocculating agents is realized; and the floating process is high in efficiency and is reliable. Water processed by using the mobile well flushing waste water processing system is capable of reaching water quality indexes of oil field injection water quality standards and discharged water quality standards; and sludge size is reduced by processing mud cake, which is obtained via magnetic separation, using a sludge water extractor.

Owner:CHINA PETROLEUM & CHEM CORP +1

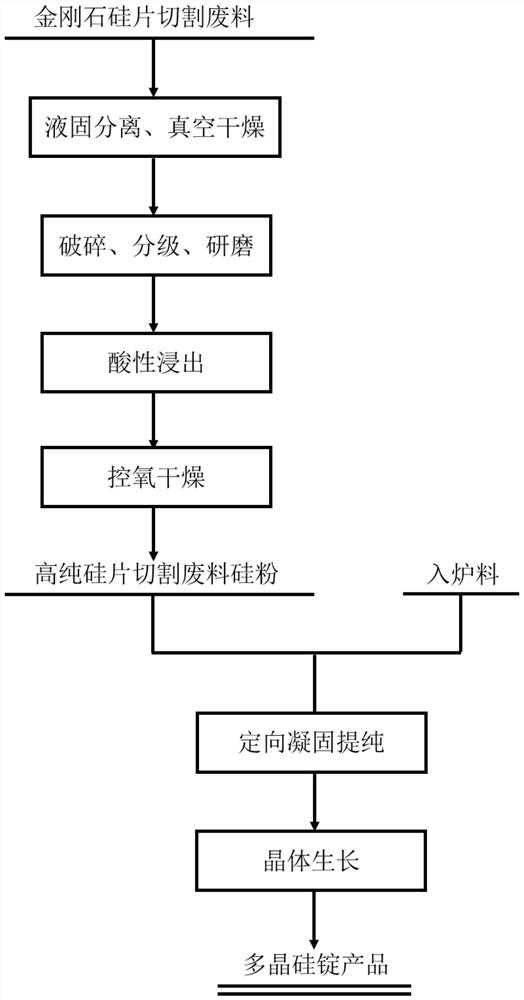

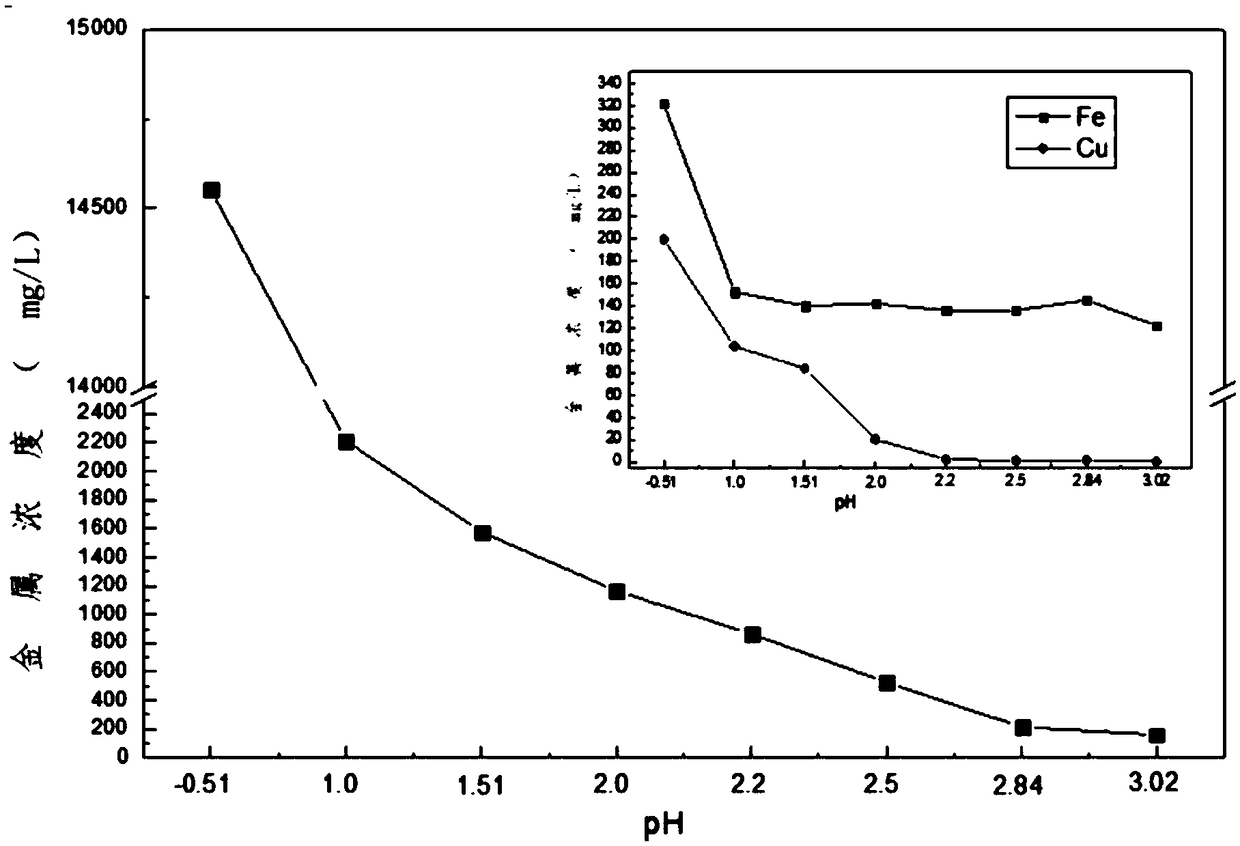

Method for high-valued recycling of wastes of diamond wire silicon wafer cutting

PendingCN111777070ASimple equipment requirementsShort processPolycrystalline material growthSilicon compoundsSilica fumeWire cutting

The invention relates to a method for high-valued recycling of wastes of diamond wire silicon wafer cutting, and belongs to the technical field of silicon secondary resource recycling. In order to realize high-valued recycling of diamond wire cutting wastes, an acid wet leaching pretreatment is adopted; a large number of metal impurities on the surfaces of silicon micro-particles and the oxidizedlayer of silicon dioxide can be quickly dissolved and removed, high-purity silicon powder purified by a wet method is mixed with ingot casting raw materials by a polycrystalline silicon ingot castingmethod, and ingot casting and crystal growth are carried out to obtain a polycrystalline silicon ingot for a polycrystalline silicon solar cell. The method has the advantages of simple equipment requirements, short flow, low cost, easy operation, and suitability for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

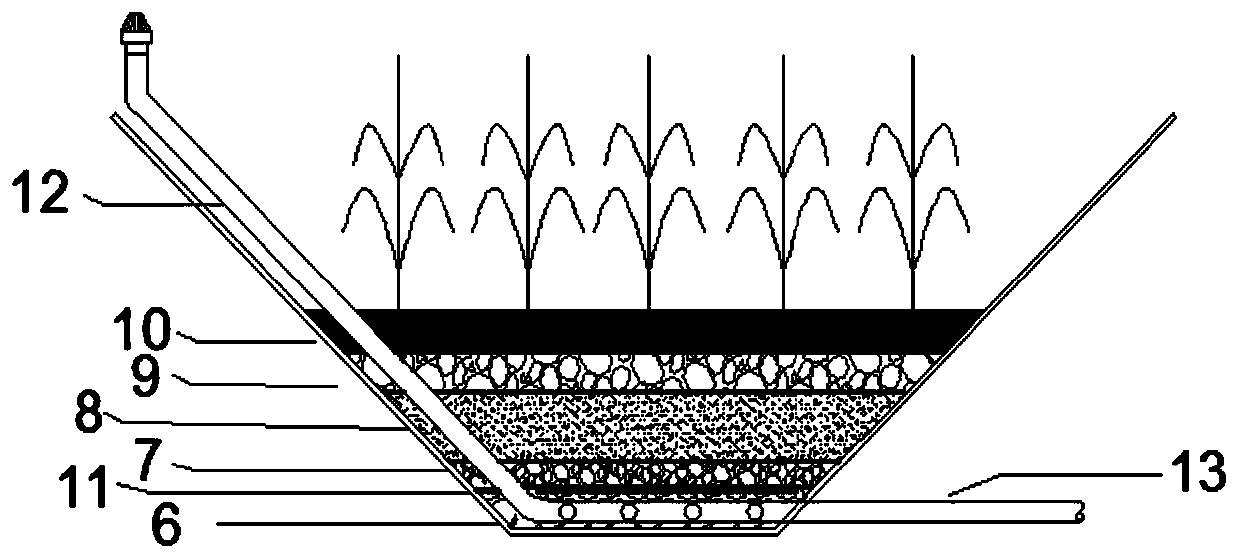

Integral shoreland zone system for on-site treatment of river and lake sludge and application of integral shoreland zone system

ActiveCN110171917AReduce construction investment costsImprove water qualitySewerage structuresWater contaminantsPipingSites treatment

The invention discloses an integral shoreland zone system for on-site treatment of river and lake sludge and application of the integral shoreland zone system and belongs to the technical field of sludge treatment. The integral shoreland zone system consists of three subsystems, namely a sludge ecological treatment subsystem, a siphon water discharge subsystem and a sludge percolate deep treatmentsubsystem, wherein the sludge ecological treatment subsystem comprises plants, fillers, aeration tubes and water collection tubes from top to bottom; air through tubes are connected with the water collection tubes; a siphon tube in the siphon water discharge subsystem takes the shape of a telescopic hump; and the sludge percolate deep treatment subsystem comprises a first-stage ecological treatment unit up-flow wetland and a second-stage ecological treatment unit surface-flow wetland. Due to transpiration and absorption functions of the plants, filtration and adsorption functions of the fillers and degradation functions of microorganisms, dewatering and harmless treatment of sludge, deep treatment of sludge percolate and purification of a part of river / lake water can be effectively achieved.

Owner:JIANGNAN UNIV

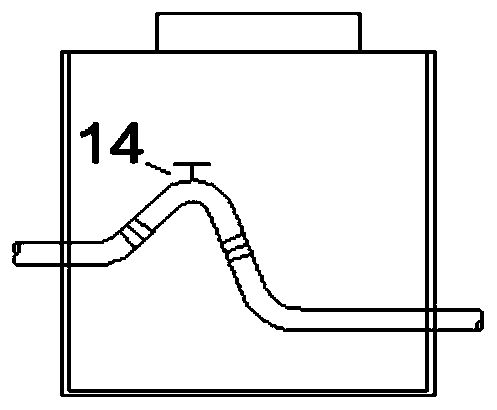

Integrated sewage treatment technology and system for tin-removing wastewater

PendingCN108911421AAchieve recyclingIn-place processingWater/sewage treatment by irradiationWater treatment compoundsLiquid wasteSites treatment

The invention provides a tin-removing wastewater treatment technology. The tin-removing wastewater treatment technology sequentially comprises the following steps: recycling metal components by adopting neutralizing-precipitating; removing organic pollutants by utilizing UV / Fenton advanced oxidation processes; and then, performing biochemical denitrification process in a denitrification filter. The tin-removing wastewater treatment technology is capable of effectively removing metal ions, including tin ions, copper ions and the like, as well as organic compounds from tin-removing wastewater; moreover, biochemical denitrification process is also performed on the wastewater, so that discharged wastewater meets relevant environmental protection standards. The invention further provides a tin-removing wastewater treatment system which is capable of synchronously recycling metals from tin-removing wastewater and ensuring that the treated wastewater meets environmental emission standards. The system is integrated wastewater treatment equipment which is capable of performing on-site treatment and small in floor area; and the system is composed of two parts, including an integrated tin metal and UV cooperative oxidation treatment station which can be designed as a vehicle-mounted system, and an on-site biochemical sewage treatment station. The integrated tin-removing wastewater treatment system is economical, highly efficient and suitable for wide application in industrial production.

Owner:SHENZHEN TOMORI ENVIRONMENTAL TECH

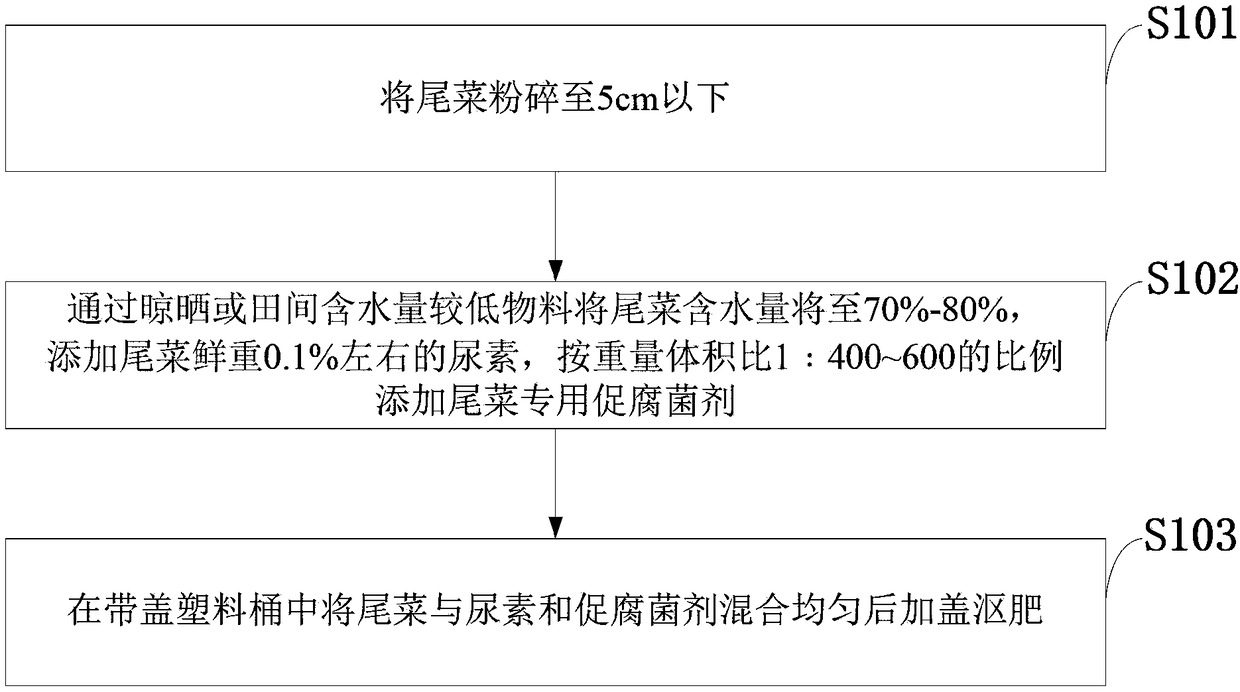

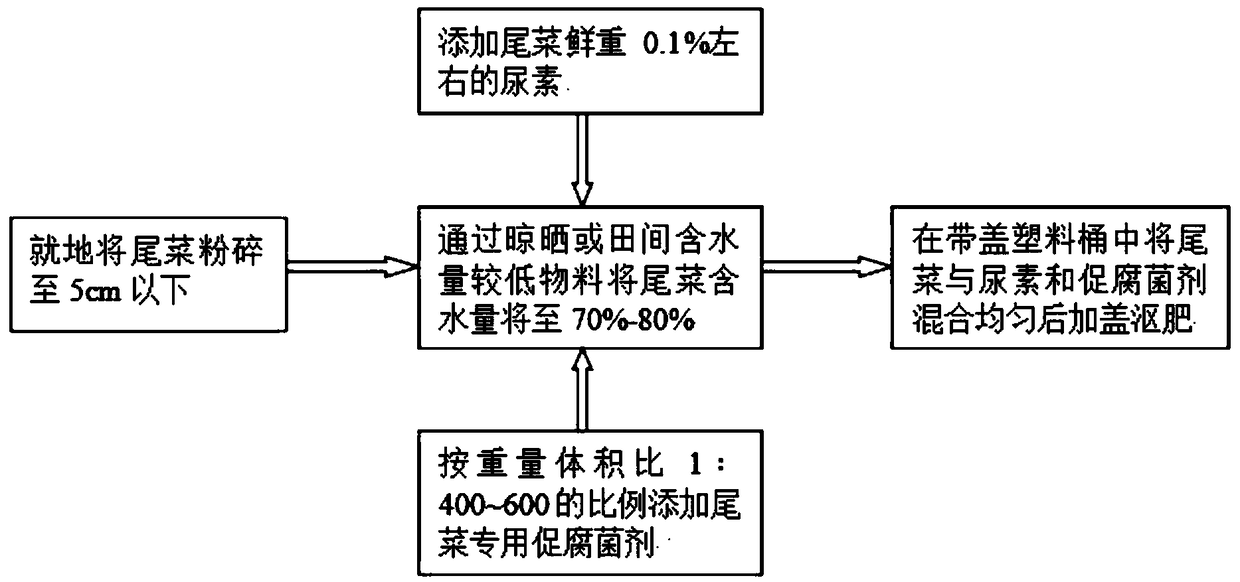

Fertilizer utilization method for rotten vegetable leaves

InactiveCN109485478AIn-place processingLow costBio-organic fraction processingBioloigcal waste fertilisersMoisturePollution

The invention belongs to the technical field of treatment of rotten vegetable leaf wastes and discloses a fertilizer utilization method for rotten vegetable leaves. The fertilizer utilization method comprises the following steps: crushing the rotten vegetable leaves until the size is less than 5cm; airing or utilizing field materials with relatively low moisture content to reduce the moisture content of the rotten vegetable leaves to be 70 to 80 percent; adding urea which accounts for about 0.1 percent of the fresh weight of the rotten vegetable leaves; and adding a special composting-promoting bacterium agent for the rotten vegetable leaves according to the weight-to-volume ratio of 1 to (400 to 600). The rotten vegetable leaves, the urea and the composting-promoting bacterium agent are uniformly mixed in a plastic bucket with a cover and then are composted by covering the cover. According to the fertilizer utilization method disclosed by the invention, the rotten vegetable leaves with a relatively high fibration degree are crushed in situ through applying a movable small-size pulverizer; the moisture content of the rotten vegetable leaves is adjusted and the special composting-promoting bacterium agent and the urea are added, so that the composting efficiency and effect of the rotten vegetable leaves are improved; and the plastic bucket with the cover is used as a compostingcontainer, so that environment pollution caused by composting is avoided and the flexibility of a composting field is also improved.

Owner:CHONGQING AGRI TECH EXTENSION STATION

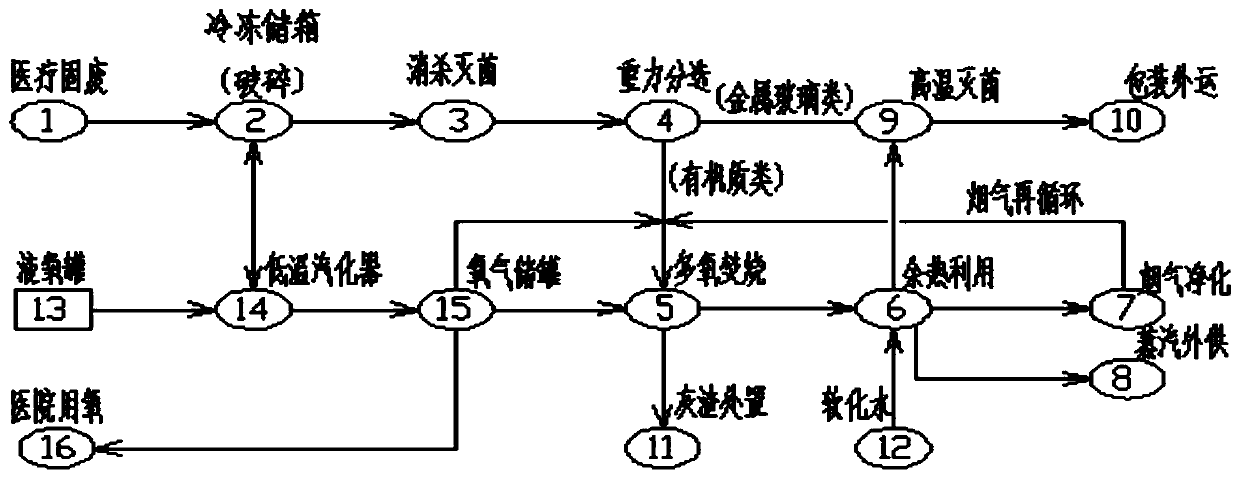

High-temperature pyrolysis and oxygen-rich incineration treatment process and system for medical waste

PendingCN111288456ARealize serialized designRealize containerized productionIndirect carbon-dioxide mitigationIncinerator apparatusMedical treatmentOxygen gas

The invention provides a high-temperature pyrolysis and oxygen-rich incineration treatment process and system for medical waste. According to the process, the medical waste is crushed after being frozen, and then is screened; during screening, inorganic matter-like substances in the medical waste are separated, and are discharged after being sterilized; reversal combustion gasification and oxygen-rich incineration is performed on remaining organic matter; waste heat utilization is firstly performed on produced gasified gas, and low-pressure steam generated by waste heat utilization is used formedical institutions, and produced low-temperature flue gas is used for performing backflow regulation on the oxygen-rich concentration of reversal combustion gasification and oxygen-rich incineration; ash and slag disposal is performed on solid products of reversal combustion gasification and oxygen-rich incineration; and oxygen during reversal combustion gasification and oxygen-rich incineration is supplied by surplus oxygen in a liquid oxygen production link. The process system provided by the invention has the characteristic of distributed miniaturization, is quickly started and stopped,is ready to start and use, can stop at any time, and reasonably utilizes surplus cold energy in gasification of liquid oxygen of a hospital, reasonably utilizes energy, meets the oxygen demand for oxygen-rich incineration, and is a distributed comprehensive utilization system for waste of comprehensive medical institutions.

Owner:西安联创分布式可再生能源研究院有限公司

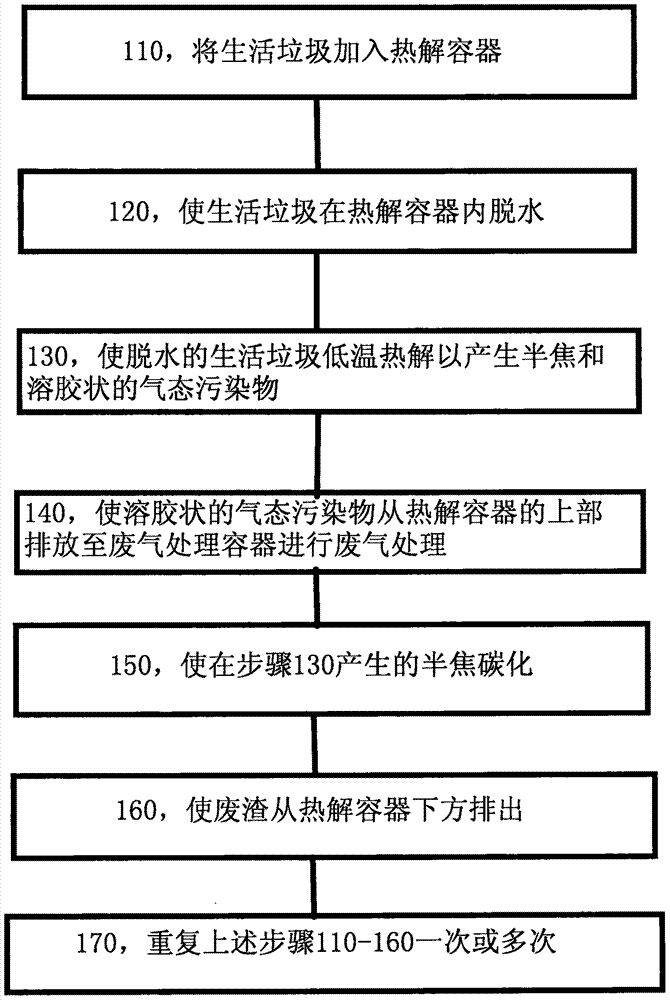

Domestic garbage low-temperature treatment method

InactiveCN107282589ASuppress generationIn-place processingSolid waste disposalTransportation and packagingExternal energyThermodynamics

The invention relates to a domestic garbage low-temperature pyrolysis treatment method. Low-temperature pyrolysis is used, and heat which is stored in heat storage materials and generated in the garbage pyrolysis process is adopted and used for continuing to treat new garbage, so that the purpose of continuous garbage pyrolysis is achieved without the need for continuous adding of external energy. In addition, secondary pollutants generated by pyrolysis are treated by combining electrical tar precipitator technology and corona plasma air purification technology, and direct smokeless peculiar-smell-free discharge of domestic garbage pyrolysis is achieved.

Owner:湖南中元世联环保科技有限责任公司

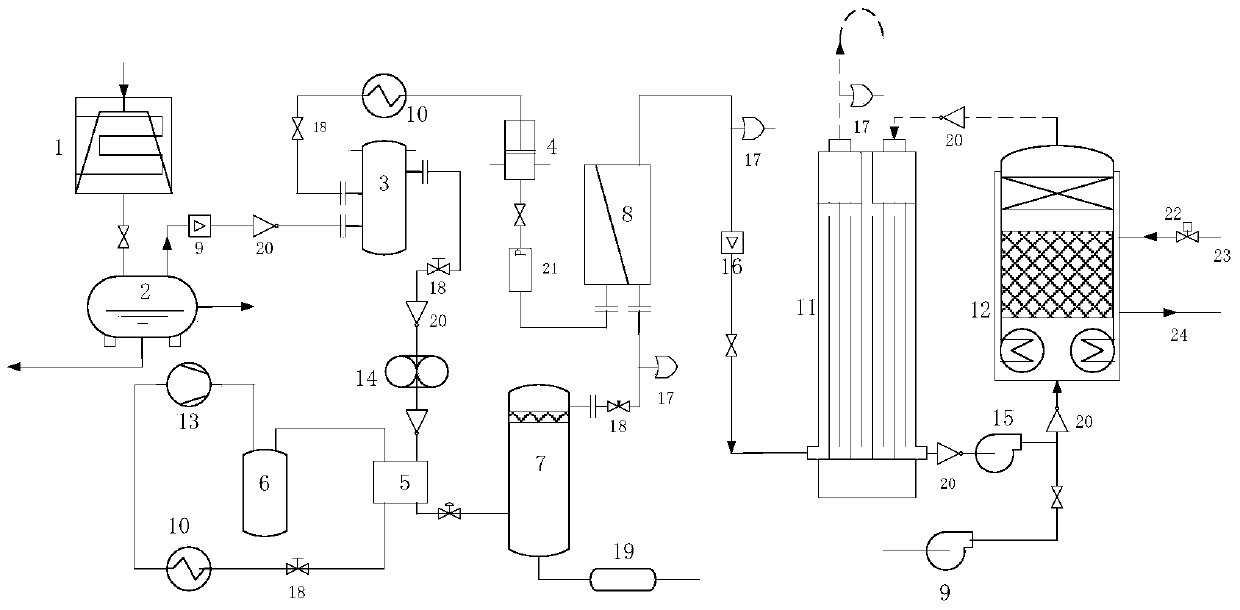

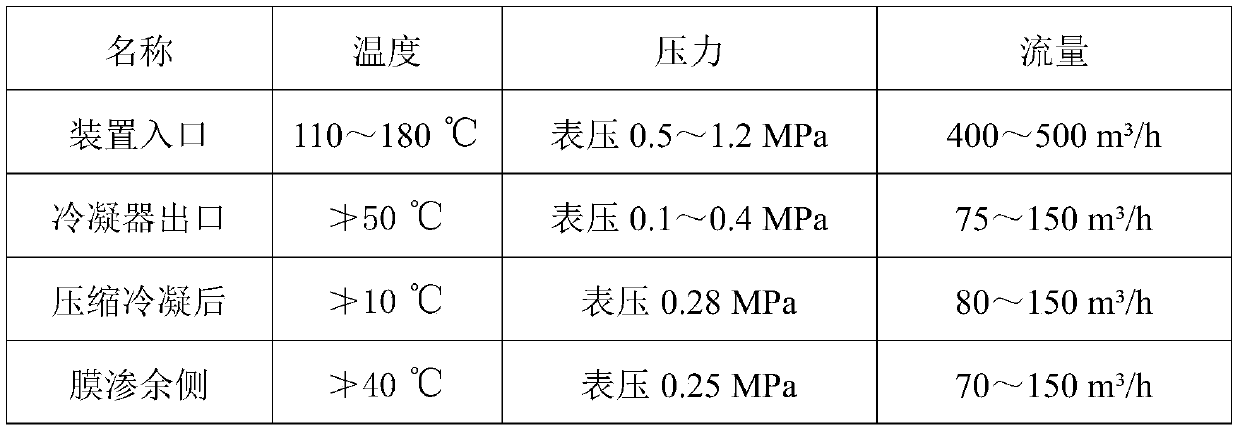

A steam purging tail gas treatment process and complete set of equipment

ActiveCN107297085BOvercome the disadvantages of not being able to meet the application requirements of refining and chemical enterprisesOvercome the drawbacks of application requirementsDispersed particle separationVapor condensationCatalytic oxidationPetrochemical

Owner:CHINA PETROLEUM & CHEM CORP +1

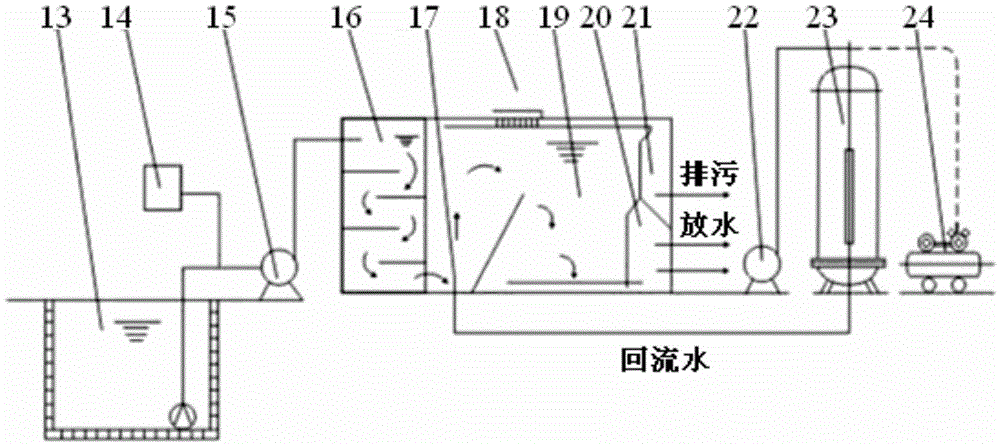

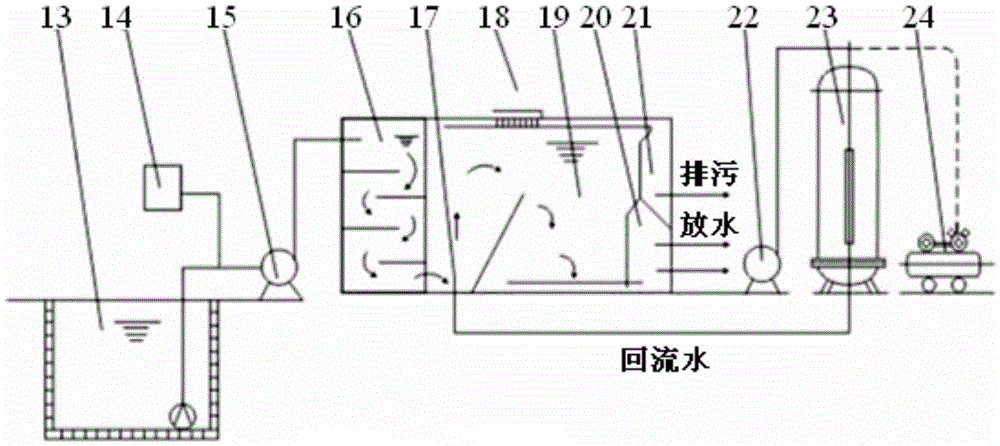

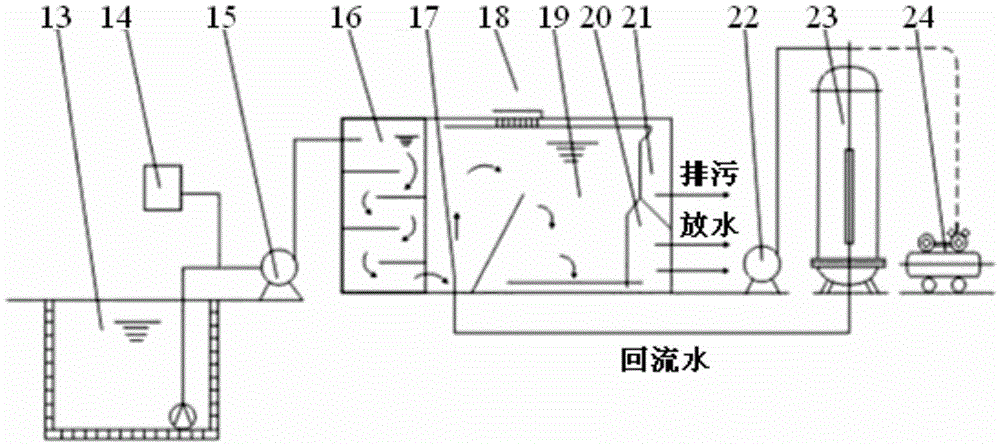

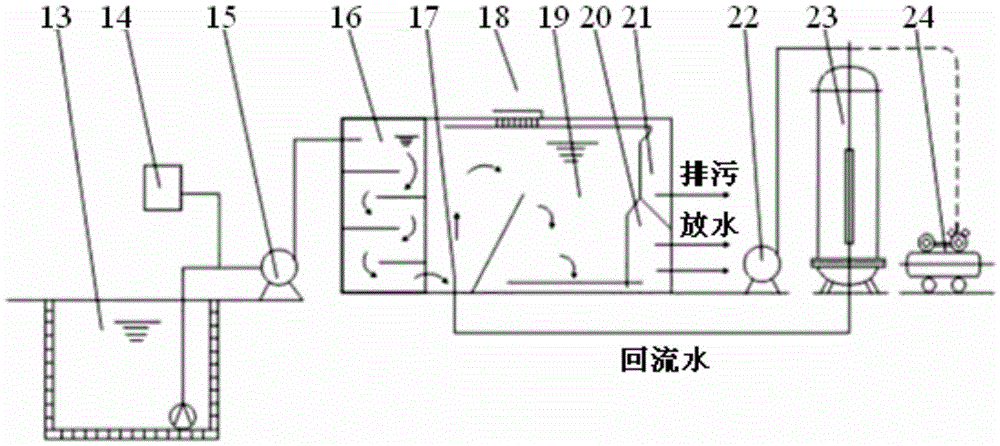

Dissolved gas floatation machine of urban household garbage treatment system

InactiveCN105461000AHarmlessRealize resourcesTreatment involving filtrationMultistage water/sewage treatmentHazardous substanceMaterial resources

The invention discloses a dissolved gas floatation machine of an urban household garbage treatment system. The dissolved gas floatation machine is provided with a gas floatation pool (19), a dissolved gas water pump (22), a pressure dissolved gas tank (23) and an air compressor (24); and the dissolved gas floatation machine (6) is provided with an adjusting pool (13). By adopting the technical scheme, the urban household garbage is further treated; harmful gases in the garbage can be decomposed, and harmful substances in the garbage also can be released; partial substances are floated and circulated, so that the labor intensity in the treatment process is greatly alleviated, and a great amount of manpower and material resources are saved; the garbage is used as a production raw material, and organic matters and inorganic matters in the garbage are separated and reasonably utilized to produce organic fertilizers and construction building block materials; and white pollutants are used for producing construction heat-preservation materials, so that the harmless utilization and recycling of the garbage are realized.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Four-shaft crusher of urban household garbage disposal system

InactiveCN105457723AReduce labor intensitySave manpower and material resourcesSolid waste disposalGrain treatmentsThermal insulationPollutant

The invention discloses a four-shaft crusher of an urban household garbage disposal system. The four-shaft crusher comprises four cutter shafts including the two main shearing cutter shafts and the two auxiliary shearing cutter shafts. The two main shearing cutter shafts are adjacent to each other. A main shearing cutter on each main shearing cutter shaft forms a main shearing blade. The two auxiliary shearing cutter shafts are arranged on the two sides of the two main shearing cutter shafts. Auxiliary shearing cutters on the two auxiliary shearing cutter shafts and the main shearing cutters form auxiliary shearing blades respectively. A crusher screen is arranged on the four-shaft crusher. By the adoption of the technical scheme, deep treatment is conducted on urban household garbage; harmful gas in the garbage can be decomposed, and meanwhile hazardous substances in the garbage can also be diluted; manpower and material resources are greatly saved; the garbage serves as production raw materials, organic matter and inorganic matter in the garbage are separated and utilized reasonably for producing organic fertilizer and building block materials; white pollutants are used for producing building thermal insulation materials, and harmlessness and resource recovery of the garbage are achieved.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Household garbage and organic hazardous waste collaborative treatment system and method

PendingCN111853792ASolve the problem of cross-region transferResolve in-placeSolid waste disposalEmission preventionCracking reactionBoiler (power generation)

The invention discloses a household garbage and organic hazardous waste collaborative treatment system and method. The collaborative treatment system includes a boiler system, a household garbage addition system used to add household garbage to the boiler system to incinerate, a steam turbine power generation system carrying out power generation by utilizing steam generated by the boiler system, and an organic hazardous waste cracking system using smoke of the boiler system as a heat source. According to the collaborative treatment system and method, on the basis of household garbage incineration for power generation, the smoke generated by incineration of the household garbage provides the heat source for an organic hazardous waste cracking reaction, the problem of organic hazardous wastetrans-regional transfer is solved, the on-site treatment of the organic hazardous waste is achieved, obtained products including combustible gas, carbon residue, and cracking oil in the cracking process can provide a fuel source in the initial stage of driving and an open flame source during the period of operation for the boiler system, and good economic benefits, environmental benefits, and social benefits can be achieved.

Owner:湖南叶林环保科技有限公司

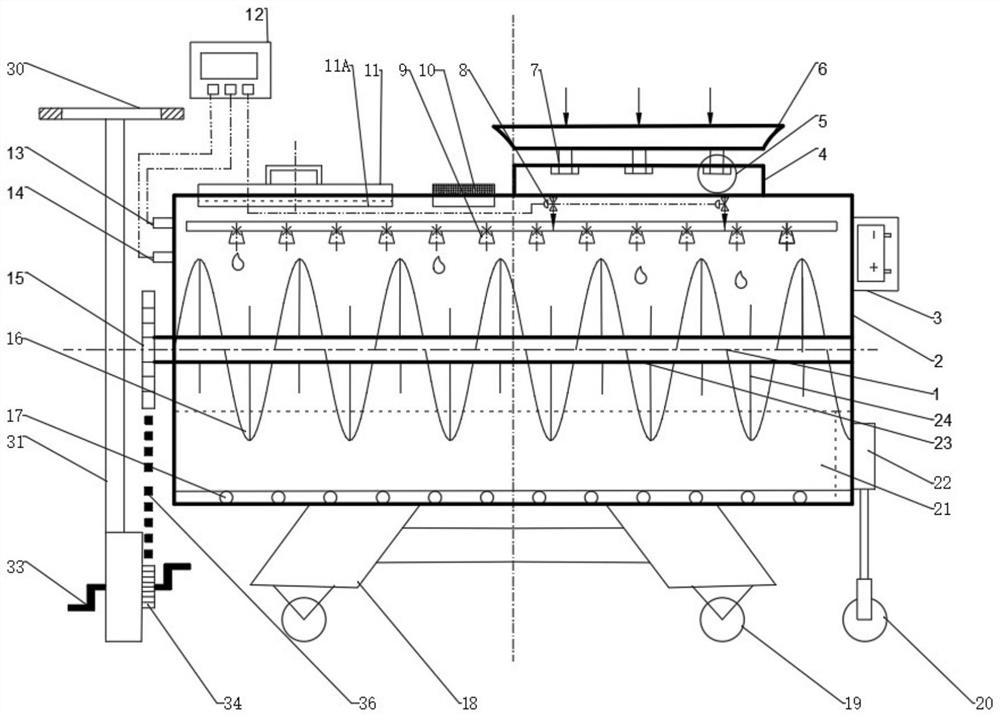

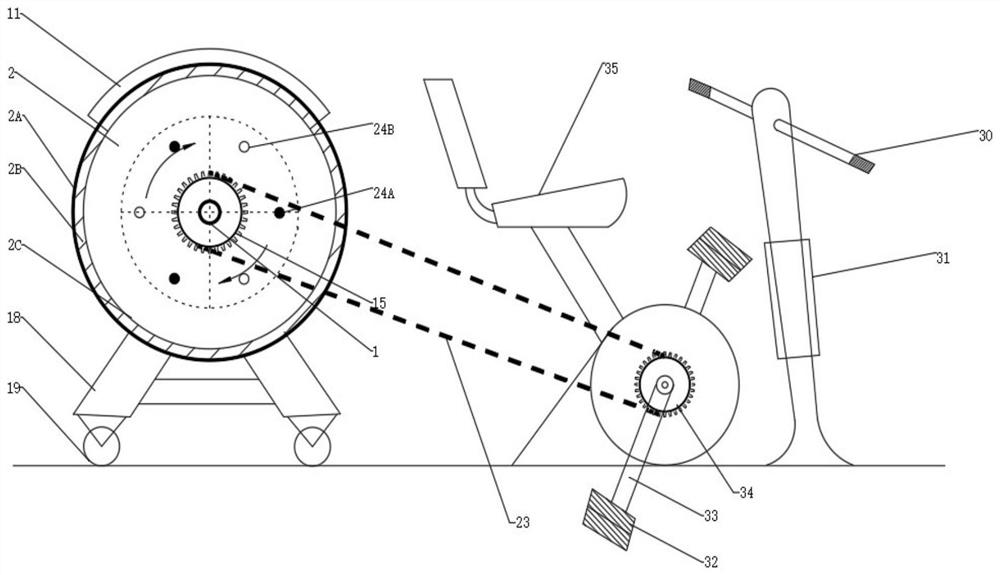

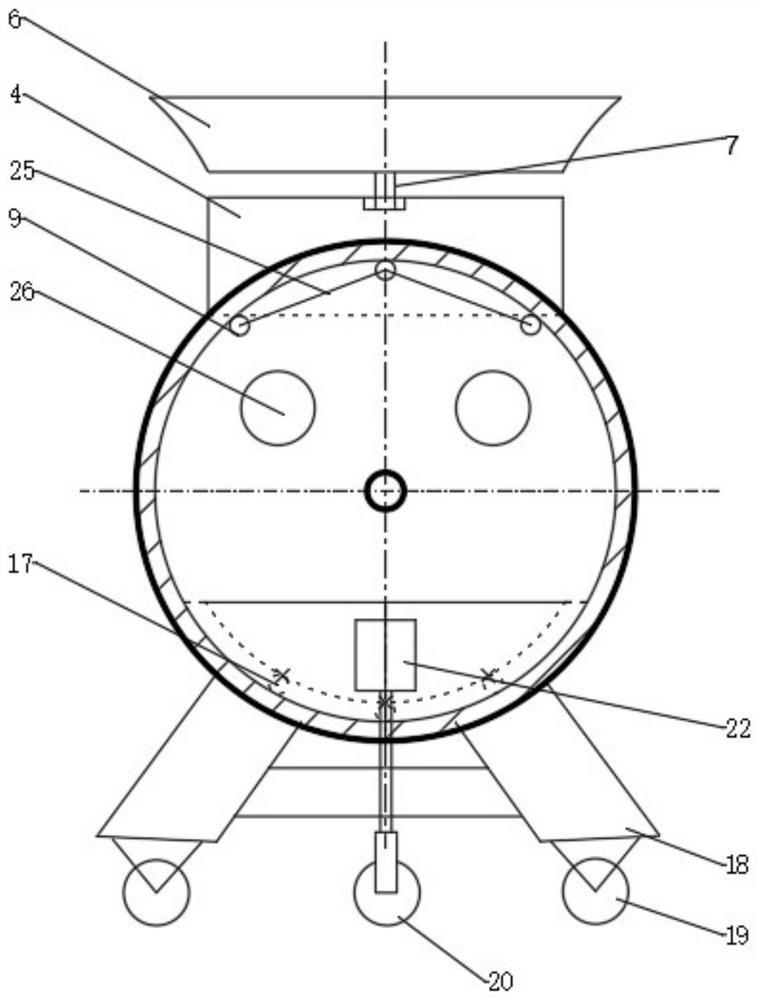

Composting reactor

PendingCN112209758AIn-place processingFacilitate reuse in placeBio-organic fraction processingOrganic fertiliser preparationProcess engineeringAgitator

The invention discloses a composting reactor. The composting reactor comprises a roller device, a feeding device, a discharging device, a driving device, a stirring device and an automatic flow storage and humidification device, the device is mainly applied to parks, fallen leaves, grass clippings and the like in the parks are collected and directly added into the reactor to be subjected to on-site composting treatment, residents use the foot-operated fitness equipment to exercise, and generated power is used for driving the stirring shaft in the composting reactor to rotate. The stirrer is ofa novel screw rod type and comprises the stirring rods and the screw rods, the stirring rods comprise the long stirring rod and the short stirring rod, and the screw rods are sequentially and spirally arranged at the top end of the long stirring rod, so that materials are fully mixed in the axial direction and the radial direction. Meanwhile, the automatic flow storage and humidification device is arranged at the top of the reactor, the temperature and humidity change condition of the reactor body can be monitored in real time, and collected rainwater is used for humidifying the reactor body.

Owner:清华苏州环境创新研究院

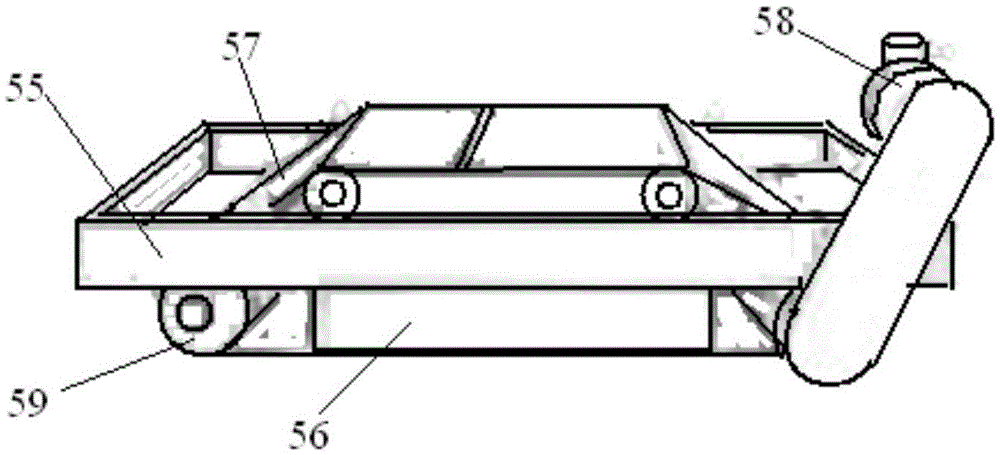

Bag opening and emptying machine of municipal solid waste treatment system

InactiveCN105537241AHarmlessRealize resourcesSolid waste disposalBags openingGroove widthHazardous substance

The invention discloses a bag opening and emptying machine of a municipal solid waste treatment system. The bag opening and emptying machine is characterized in that a vibration screening device (60) is provided with an adjustable screening structure (61); screening plates (62) of the adjustable screening structure (61) are arranged in the same direction; the cross sections of the screening plates (62) are V-shaped, and leaking grooves (63) are formed; and the adjustable screening structure (61) is provided with a screening plate distance adjustment structure for adjusting the groove widths of the leaking groves (63). With the adoption of the technical scheme, advanced treatment is carried out on municipal solid waste; harmful gas in the municipal solid waste can be decomposed, and hazardous materials in the municipal solid waste can be diluted; parts of matters can float and be recycled, so that the labor intensity in a treatment process is reduced greatly, and a lot of manpower and material resources are saved; the municipal solid waste acts as a raw material for production, organic matters in the municipal solid waste are separated from inorganic matters, and the organic matters and the inorganic matters are used reasonably for producing organic fertilizers and building block materials; and white pollutants are used for producing building thermal insulation materials, and waste harmlessness and recycling are realized.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

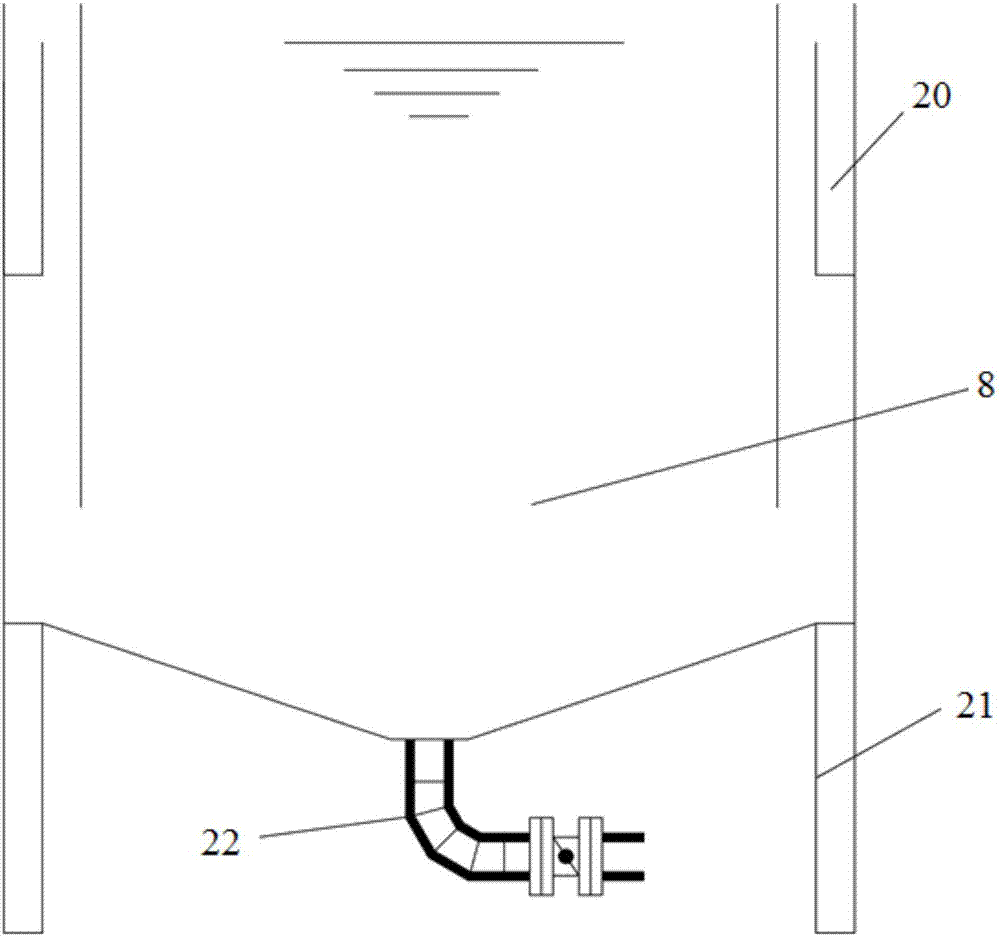

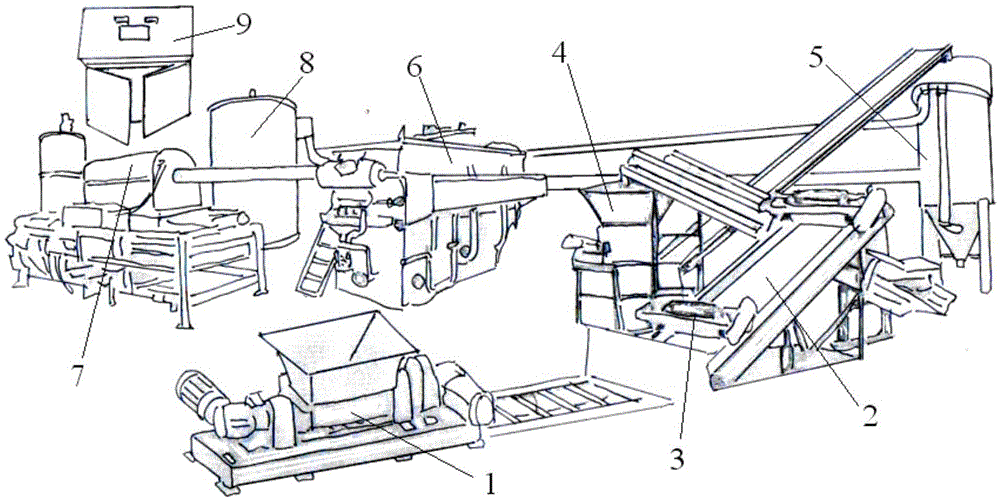

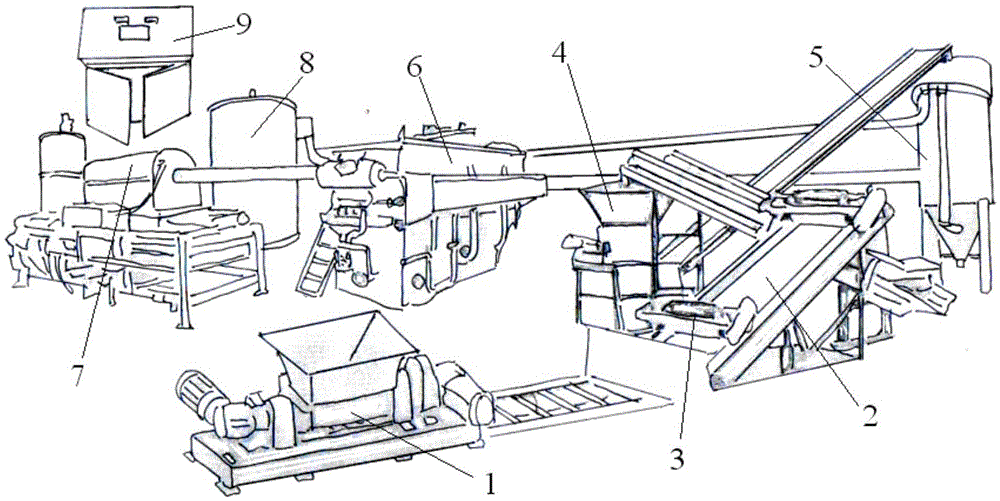

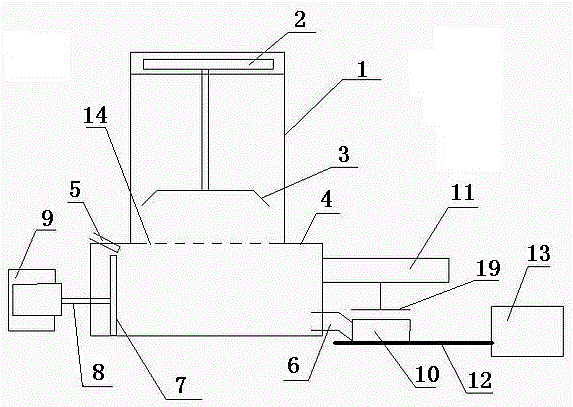

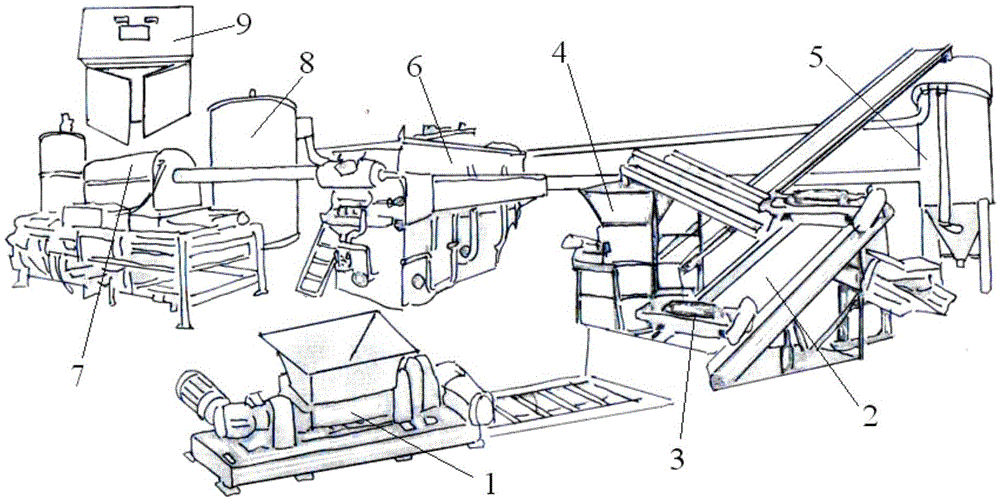

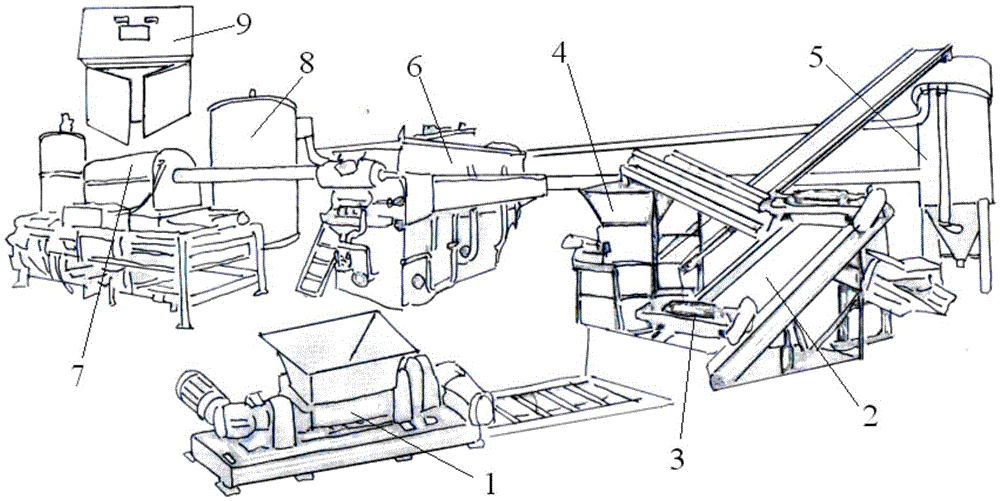

Urban household garbage disposal system

InactiveCN105457981AHarmlessRealize resourcesSolid waste disposalThermal insulationHazardous substance

The invention discloses an urban household garbage disposal system. The urban household garbage disposal system is provided with a bag breaking machine (1), a belt conveyor (2), a four-shaft crusher (4), a vertical spiral gas flotation machine (5), a dissolved air flotation machine (6), a solid-liquid separator (7), sewage purification equipment (8) and a garbage disposal station house (10). By the adoption of the technical scheme, deep treatment is conducted on urban household garbage; harmful gas in the garbage can be decomposed, and meanwhile hazardous substances in the garbage can also be diluted; part of the substances are made to float and circulate, the labor intensity in the disposal process is greatly relieved, and manpower and material resources are greatly saved; the garbage serves as production raw materials, organic matter and inorganic matter in the garbage are separated and utilized reasonably for producing organic fertilizer and building block materials; white pollutants are used for producing building thermal insulation materials, and harmlessness and resource recovery of the garbage are achieved.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Pear wine and preparation method thereof

The invention discloses pear wine which is prepared from the following raw material components in parts by weight: 60-75 parts of snowflake pears, 50-55 parts of glutinous sorghum, 22-28 parts of barley, 16-20 parts of corn, 12-16kg of peas, 5-7 parts of Chinese yeast, 52-56 parts of bergamot pears, 6-8 parts of active dry yeast and 2-4 parts of white granulated sugar. The technical means have thebeneficial effects that: according to the pear wine, the raw materials are reasonably proportioned, thus ensuring nutrient ingredients to be rich, and meeting needs, on nutrient substances of pear wine, of people better. Moreover, the processes can be grasped better in a pear wine preparation process, so that the processes are guaranteed well; and the prepared pear wine is good in taste, is aromatic and fresh in smell, is rich in nutrient, is good in quality, and avoids deterioration.

Owner:贵州果源浆酒业有限公司

Fallen leaf on-site processing device

The invention discloses a fallen leaf on-site processing device. The fallen leaf on-site processing device comprises a storage cylinder, a pulverizer, a material collecting box, a propelling unit, an electric compressing device, a microwave drying device, a linear reciprocating mechanism and a tray. The fallen leaf on-site processing device is connected with an external power source. The bottom of the storage cylinder is provided with a through hole. The pulverizer is installed in the storage cylinder. The material collecting box is installed below the storage cylinder. A water spray pipe is installed above the material collecting box. The water spray pipe is connected with a water tank. One side of the material collecting box is provided with the propelling unit. A discharging pipe is installed below the other side of the material collecting box. The tray is arranged at the outlet of the discharging pipe. The electric compressing device is installed above the tray. The linear reciprocating mechanism is installed below the tray. The other end of the linear reciprocating mechanism is provided with the microwave drying device. The fallen leaf on-site processing device is capable of realizing the on-site processing of the fallen leaves, reducing the transporting cost of the fallen leaves, improving the working efficiency, and making a contribution to the fallen leaf treatment and city environment protection.

Owner:HANGZHOU LANDSCAPE ENG

Urban household garbage disposal system

InactiveCN105457980AReduce labor intensitySave manpower and material resourcesSolid waste disposalMaterial resourcesSewage

The invention discloses an urban household garbage disposal system. The urban household garbage disposal system is provided with a bag breaking machine (1), a belt conveyor (2), a four-shaft crusher (4), a vertical spiral gas flotation machine (5), a dissolved air flotation machine (6), a solid-liquid separator (7), sewage purification equipment (8) and a garbage disposal station house (10). By the adoption of the technical scheme, deep treatment is conducted on urban household garbage; harmful gas in the garbage can be decomposed, and meanwhile hazardous substances in the garbage can also be diluted; part of the substances are made to float and circulate, the labor intensity in the disposal process is greatly relieved, and manpower and material resources are greatly saved; the garbage serves as production raw materials, organic matter and inorganic matter in the garbage are separated and utilized reasonably for producing organic fertilizer and building block materials; white pollutants are used for producing building thermal insulation materials, and harmlessness and resource recovery of the garbage are achieved.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Movable sludge reduction treatment device and process thereof

PendingCN110127982AIn-place processingReduce shipping costsSludge treatment by de-watering/drying/thickeningSites treatmentStorage tank

The invention discloses a movable sludge reduction treatment device and a process thereof. The device comprises a raw sludge tank which is connected with a steam explosion machine; the steam explosionmachine is respectively connected with a water vapor absorption mechanism and a sludge storage tank group; the sludge storage tank group is connected with a fermentation tank; wherein the raw mud pool and the steam explosion machine, the steam explosion machine and the mud storage tank group, and the mud storage tank group and the fermentation tank are respectively connected through conveying mechanisms; and the steam explosion machine and the sludge storage tank group are arranged in the movable box body. According to the technical scheme, the steam explosion machine and the sludge storage tank group are arranged in the movable box body; the structure has the advantages that on-site treatment of sludge can be realized, and the transportation cost of the sludge is reduced; due to the facts that the occupied area of the device is small, and the steam explosion machine and the sludge storage tank set can be moved in a vehicle-mounted mode, the device is suitable for the situation that at present, land resources are insufficient, and production cost can be reduced.

Owner:江苏安识环境科技有限公司

Disposal system for urban domestic waste

InactiveCN105618457AReduce labor intensitySave manpower and material resourcesSludge treatment by de-watering/drying/thickeningSolid waste disposalMaterial resourcesSewage

The invention discloses a disposal system for urban domestic waste. The disposal system is provided a bale breaking machine (1), a belt conveyor (2), a four-shaft crusher (4), a vertical spiral air floatation machine (5), a dissolved air flotation machine (6), a solid-liquid separation machine (7), sewage purification equipment (8) and a waste disposal station room (10). According to the technical scheme, the urban domestic waste undergoes advanced treatment; harmful gas in the waste can be resolved, and harmful substances in the waste can be diluted; partial substances float and circulate, the labor intensity in the disposal process is lowered greatly, and a lot of manpower and material resources are saved; the waste serves as raw production material, and organic matter and inorganic matter in the waste are separated and reasonably utilized for producing organic fertilizers and building block material; white pollutants are used for producing thermal insulation material for buildings, and harmless treating and recycling of the waste can be realized.

Owner:ANHUI JIHONG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com