Smoke-reuse internal heat type biomass carbonization furnace

A carbonization furnace and biomass technology, applied in the direction of carbonization furnace, biofuel, coke oven, etc., can solve the problems of biomass carbonization device cannot be moved, secondary pollution of tar flue gas, and inconvenient operation of adding amount, etc., to achieve secondary utilization Reduce, achieve secondary utilization, and adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

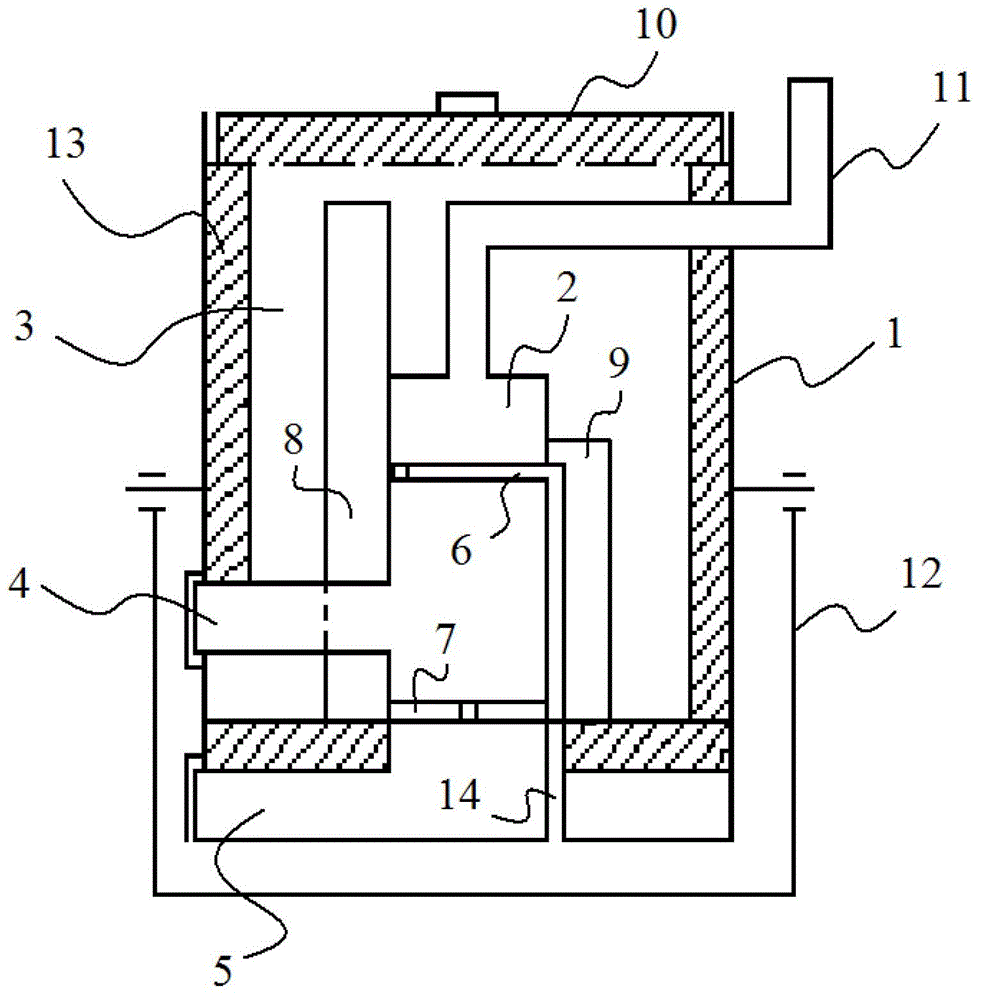

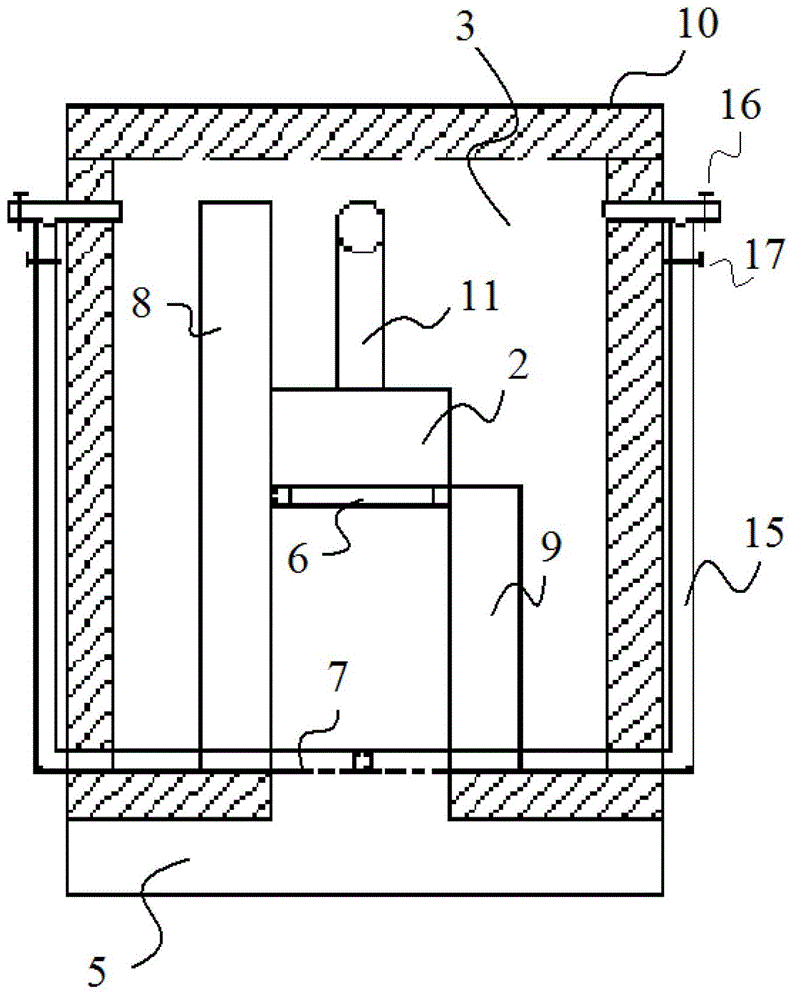

[0031] like Figure 1~Figure 2 As shown, the primary air inlet channel 5 includes a primary air inlet, a damper and ash receiving chamber, the primary air inlet is connected with the ash receiving chamber, and the whole is made into the shape of a drawer, and the primary air inlet is controlled by controlling the opening of the ash receiving drawer. The size of the air volume, after the carbonization process, pull out the drawer and pour out the burned ashes.

[0032] The packing channel 4 is composed of a packing port and a packing port door, and the packing port is a square structure, such as figure 1 As shown, in the carbonization process, a small amount of biomass is added into the combustion chamber through the filling port to provide heat for the carbonization of biomass fuel in the carbonization chamber.

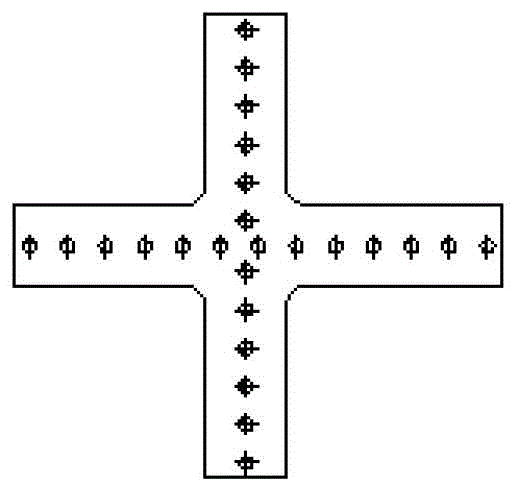

[0033] The heat conduction sheet can be composed of 4 first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com