Fallen leaf on-site processing device

A processing device and technology for fallen leaves, which are applied to road cleaning, construction, cleaning methods, etc., can solve the problems of low efficiency in processing fallen leaves, high transportation costs, and large volume of collected fallen leaves, and achieve the effect of reducing transportation costs and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

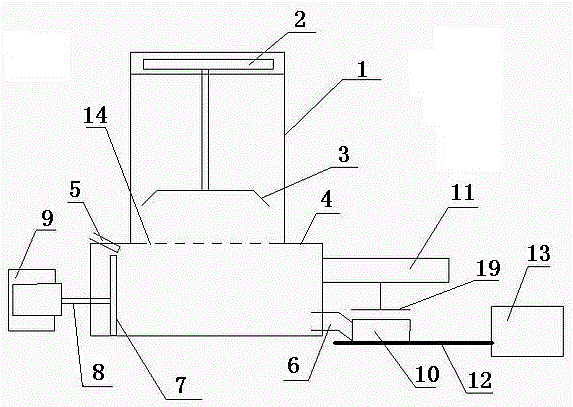

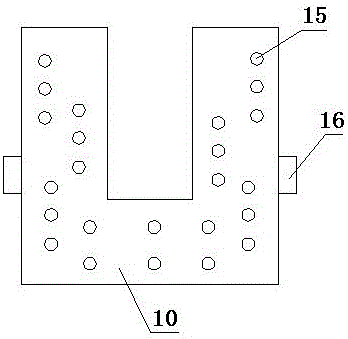

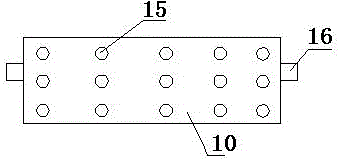

[0017] like figure 1 The on-site processing device for fallen leaves shown includes a storage tube 1, a pulverizer, a receiving box 4, a propulsion device, an electric compression device, a microwave drying device 13, a linear reciprocating mechanism 12 and a tray 10; the in-situ processing device for fallen leaves is connected to External power supply, the bottom of the storage tube 1 has a through hole 14, a pulverizer is arranged in the storage tube 1, the pulverizer is an electric pulverizer, a material receiving box 4 is arranged below the storage tube 1, and a water spray pipe is arranged above the material receiving box 4 5. The water spray pipe 5 is connected to the water tank, and a propulsion device is arranged on one side of the material receiving box 4. The propulsion device is a hydraulic propulsion device, including a hydraulic propeller 9, a transmission rod 8 and a push plate 7; the front end of the hydraulic propeller 9 is provided with a transmission rod 8, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com